Equipment

Mizuno brings the MP family closer together with its new MP-18 irons

With its MP-18 iron family, Mizuno has narrowed the differences between its four new iron models to make mixing sets not only easier, but completely seamless.

Check out our WITB Page, and you’ll notice that most PGA Tour players are using combination iron sets. That means they’re playing muscleback short irons and cavity-back longer irons with thicker toplines and more forgiveness. This combo-set trend makes perfect sense; it allows golfers to use an iron set that gives them maximum control in their short irons where they want maximum control, and more forgiveness and distance in their long irons where they want more distance and forgiveness. Duh!

The problem is that most iron sets attempt to cater to the needs of muscleback players with their muscleback irons, cavity-back players with their cavity-back irons, and game-improvement players with their game-improvement irons. By segmenting iron families, it leaves gaps in looks, feel, playability, and distance for golfers who want to make their own combination set.

Mizuno has gone to great lengths to address that problem with its MP-18 iron family, which is intended to be mixed and matched. The MP-18 family includes four irons types:

- MP-18 (Muscleback)

- MP-18 SC (Split Cavity)

- MP-18 MMC (Multi-Material Compound)

- MP-18 MMC Fli-Hi

While the SC, MMC, and MMC Fli-Hi irons are larger than the MP-18 muscleback irons, they maintain the same sole, head profile, and topline ratios in their shaping. That means they look almost identical at address; they’re just slightly larger. Their lofts and pricing are also essentially identical. Only a trained eye will be able to tell any difference at all.

In terms of materials, Mizuno went back to its roots with the MP-18. The irons are forged from 1025E Pure Select Mild Carbon, a switch from the 1025 Boron the company was using in some of its MP irons in recent years. Boron was used because it is stronger than Mizuno’s 1025E carbon steel, allowing engineers to thin out structures within the irons for added distance and forgiveness. “That’s just not MP,” as one Mizuno representative put it.

With this launch, Mizuno strived to give the MP-18 irons the look and feel of irons that “could have been made 100 years ago,” the company says. They’re for players who want the best-feeling, best-looking irons they can play, with simple color schemes and classic shapes, while still getting maximum performance. There’s still a place for cutting-edge designs and materials in Mizuno players irons — just ask Brooks Koepka, who used the JPX-900 Tour irons forged from Boron to win the 2017 U.S. Open — but it’s not in the MP-18 line.

To get the artistic shaping the company desired in the MP-18 line, Mizuno brought its computer-designed club heads to Japan where its expert craftsmen refined the shapes. The club-grinding experts worked to blend the transition of the hosels into the club faces in a way that reduced the look of offset. They also dialed in toe and heel shapes while adding camber to the sole. These prototype models were used as the starting point for each of the MP-18 irons to ensure consistency through the lineup.

Despite their throwback looks, the company relied on new school technologies to refine the sound and feel of the irons. Mizuno’s stated goal with the irons was to extend impact frequencies so they not only feel softer, but so that golfers get more feedback on the club. To that end, the irons were forged with a new “Grain-Flow Forged HD” process. The company’s H.I.T. (Harmonic Impact Technology) was also used to dial in acoustics for enhanced feedback.

Below, we break down each of the individual offerings in the MP-18 family. The irons will sell for $149.99 each and will be available September 15.

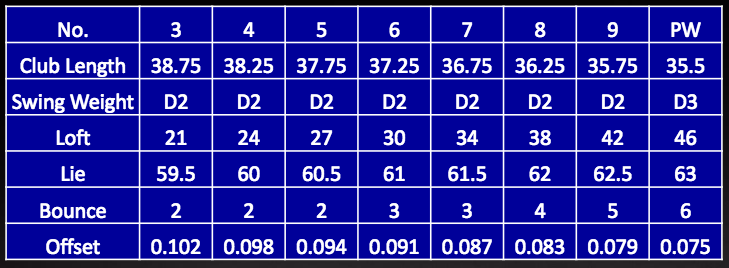

Mizuno MP-18

In relation to previous Mizuno MP muscleback irons, the MP-18 irons are significantly smaller than the MP-5 irons and slightly smaller than one of Mizuno’s smallest modern muscleback irons, the MP-4. Their toplines appear thinner than they measure due to a camber that makes them look slimmer in the address position. In comparing topline thicknesses, the MP-18’s are thinner than the MP-5, but they’re a bit thicker than the MP-4.

The MP-18 scoring irons (9 and PW) are smaller in size than previous models. All of the irons in the set also have lower heel heights. “That’s what this player wants,” a Mizuno representative said.

The MP-18 irons will come stock with True Temper Dynamic Gold S300 shafts and Golf Pride MCC White/Black grips. They are right-handed only offerings.

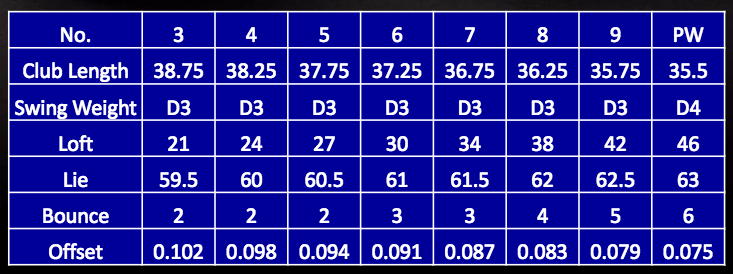

Full Specs

Mizuno MP-18 SC (Split Cavity)

The MP-18 Split Cavity irons feature what Mizuno calls a half-cavity design. Mass has been taken of the upper portion of the irons, focusing CG (center of gravity) lower in the club head for an easier launch and more forgiveness.

The MP-18 SC irons are only fractionally longer from heel-to-toe than the MP-18 muscleback irons. They’re also 0.5 millimeters taller and have soles that are 1.5 millimeters wider. With identical specs (aside from swing weight in the longer irons) and offset, these irons are designed to blend seamlessly into a combination set with the MP-18 muscleback irons regardless of where golfers decide to split their set.

The MP-18 SC irons come stock with KBS Tour shafts and are available for left- and right-handed golfers.

Full Specs

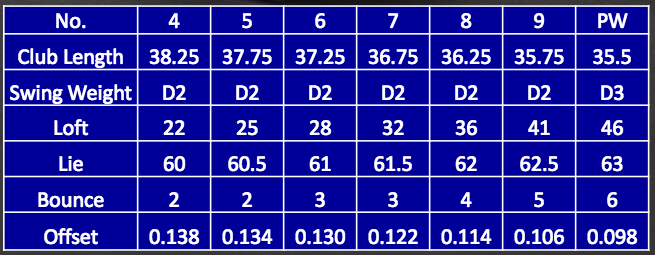

Mizuno MP-18 MMC (Multi-Material Construction)

The MP-18 MMC irons are Grain Flow Forged from 1025E, but they use a multi-material construction to move weight to the center of the club heads to enhance moment of inertia (MOI), a measure of forgiveness. The more centered CG is achieved by adding 20 grams of tungsten, a material more dense than steel, in the toe section of the irons. An 8-gram titanium insert, which is lighter than steel, was also placed behind the club face and toward the heel section of the club.

The titanium insert is used in each of the MMC iron designs. Tungsten was not used in the 8, 9, and PW club heads, however, as it was not needed to center CG due in those clubs.

The MP-18 MMC are designed with 0.8 millimeters less offset more than the MP-18 and SC irons, but they also have 2 degrees less loft per head. According to Mizuno, however, each degree of loft that is added when bending an iron weaker adds 0.4 millimeters of offset. That means if a golfer matches the lofts of the MP-18 MMC irons to the MP-18 or MP-18 SC irons, offset will be essentially identical.

The MP-18 MMC irons will come stock with a Nippon Modus 120 shaft, and they’re a right-handed only offering.

Full Specs

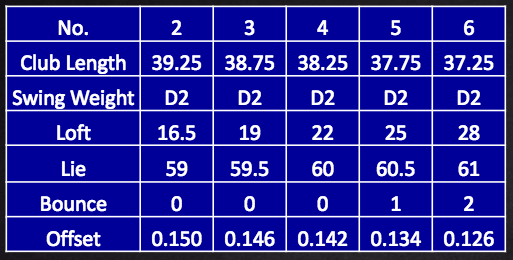

Mizuno MP-18 MMC Fli-Hi

Offered in long-irons only (2-6 iron), the Mizuno MMC Fli-HI irons have an X-30 steel body material with club faces made from Maraging 1770HT steel, a high-strength material that can be made thinner to help create faster ball speeds.

Mizuno made the toplines of its new Fli-Hi significantly thinner than its predecessor, the MP-H5 iron. The toplines are also cambered to look thinner than they measure, creating a look that will suit the eye of better players, according to Mizuno. Like the MP-MMC irons, the MMC Fli-Hi irons also have 20 grams of tungsten in their toes. The insert is forged into the inside of the cavity, however, and it sits behind the face. According to Mizuno, this design helps golfers hit higher shots with the irons and increases forgiveness.

The MP-18 MMC Fli-Hi irons will come stock with KBS C-Taper shafts, and are a right-handed only offering.

Full Specs

Discussion: See what GolfWRX members are saying about the MP-18 irons in our forums

- LIKE328

- LEGIT29

- WOW42

- LOL3

- IDHT6

- FLOP2

- OB2

- SHANK12

Equipment

Cobra launches new limited-edition Darkspeed ‘season opener’ driver

Cobra Golf has today introduced a new limited-edition Darkspeed season opener driver in celebration of golf’s first major.

The new Darkspeed season opener limited edition driver combines a unique colorway with azaleas on the sole and Augusta green highlights for a festive, spring feel.

The driver comes paired with a matching limited edition head cover and a Mitsubishi Tensei 1K Black shaft in choice of X, S, or R flex and 9- and 10.5-degree loft options.

The Cobra Darkspeed season opener driver is available in X and LS models and retails for $649. It is available now on cobragolf.com.

- LIKE3

- LEGIT2

- WOW2

- LOL1

- IDHT1

- FLOP1

- OB1

- SHANK6

Equipment

Coolest thing for sale in the GolfWRX Classifieds (3/29/24): Mint Miura MB 101 irons

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a set of Mint Miura MB 101 irons.

From the seller: (@Citixen): “MINT Miura MB 101 5-PW KBS $1700 + Shipping. Miura MB 101 irons 5-PW with KBS C-Taper Lite X Stiff shafts +0.5″, Standard Loft and Lie. Mint condition, includes magnetic head-covers.”

To check out the full listing in our BST forum, head through the link: Mint Miura MB 101 irons

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE4

- LEGIT0

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Chesson Hadley WITB 2024 (March)

- Chesson Hadley what’s in the bag accurate as of the Texas Children’s Houston Open. More photos from the event here.

Driver: Titleist TSR3 (10 degrees, D1 SureFit setting)

Shaft: Mitsubishi Diamana D+ 70 TX

3-wood: Titleist TSR2+ (14.5 degrees, A1 SureFit setting)

Shaft: Mitsubishi Diamana D+ 80 TX

Irons: Titleist T200 (3), Titleist 620 CB (4, 5), Titleist 620 MB (6-PW)

Shafts: Graphite Design Tour AD DI 105 X (3), True Temper Dynamic Gold Tour Issue X100 (4-PW)

Wedges: Titleist Vokey Design SM10 (52-12F, 56-14F), WedgeWorks (60-K)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: Odyssey White Hot OG 2-Ball

Grip: Odyssey

Grips: Golf Pride Tour Velvet

Ball: Titleist Pro V1x

Check out more in-hand photos Chesson Hadley’s clubs here.

- LIKE4

- LEGIT0

- WOW0

- LOL2

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole4 days ago

19th Hole4 days agoJohn Daly stuns fans into silence with brutal opening tee shot on PGA Tour Champions

-

19th Hole1 week ago

19th Hole1 week ago2-time major champ announces shock retirement from the sport at age of 33

-

19th Hole1 week ago

19th Hole1 week agoEdoardo Molinari reveals the latest PGA Tour golfer to turn down ‘good offer’ from LIV Golf

-

19th Hole2 weeks ago

19th Hole2 weeks agoScottie Scheffler had an interesting response when asked how he ‘quiets the noise’ following Players victory

-

Equipment2 weeks ago

Equipment2 weeks agoBest driver 2024: The best driver for you, as recommend by expert club fitters

-

19th Hole1 week ago

19th Hole1 week agoJon Rahm dealt fresh blow to hopes of qualifying for 2025 Ryder Cup

-

19th Hole4 days ago

19th Hole4 days agoCharlie Woods finds it tough going on American Junior Golf Association debut

-

19th Hole1 week ago

19th Hole1 week agoWhy Kevin Streelman sought USGA approval to use this equipment tool as he leads Valspar after round one

D

Aug 8, 2017 at 2:23 am

At least you feel special that you can do things that right-handers can’t.

Mr Poopoo

Aug 7, 2017 at 9:00 pm

There goes my next paycheck

D

Aug 7, 2017 at 4:20 pm

You would know all about being hopeless, you’re hopeless

BRI

Aug 7, 2017 at 2:13 pm

Article is littered with errors.

ShankLampard147

Aug 7, 2017 at 2:04 pm

No combo set if you’re left handed, which is a big fail. I wanted the sc18’s, but it feels like mizuno doesn’t want my money. No fli hi is a deal breaker for me. Add to that the blue wedges and I think they should just stop making left handed clubs altogether. Any self respecting lefty wouldn’t play Mizuno.

joro

Jul 11, 2018 at 11:47 am

What do most people need with a combo set. Is it skill or ego that they think it will make them a player with them in the Bag. I am a leftie and play with the Hot Metals in Leftie that more people need, they are strong, hit high and feel soft. And the Graphite shaft is a good one.

So Leftie, take a good look at then, them, then are grrrrrrrrreat.

Edit

Aug 7, 2017 at 11:38 am

Think you meant to say tungsten was not used in 8-paw heads of MMC. You wrote titanium.

Tommy

Aug 7, 2017 at 11:34 am

I’m surprised by the fat soles on the 18’s. How’s that “classic Mizuno”? I’ll wait to see them in hand but that really pops the bubble for me…

Tiemco

Aug 7, 2017 at 10:19 am

When you say the Fli-Hi iron’s are only offered in the long irons and then you put in parentheses 6-PW. I think you meant to write 2-6.

Lee Shaw

Aug 7, 2017 at 10:15 am

Surely these MP18’s can’t be any good they are not over $3000 for 8 irons!!

Dat

Aug 7, 2017 at 8:57 am

Sign me up! 3 Fli-Hi, 4-6 SC, 7-PW MB