Equipment

Cobra’s King F7 and F7+ drivers, fairways and hybrids: What you need to know

Cobra’s new King drivers — the King F7, F7+ and the new King LTD Black — may just change how drivers are sold. The secret is their grips, and the built-in technology could change the way golfers approach their tee shots.

Aside from the grips, Cobra’s King F7 clubs for 2017 use new technologies and materials throughout the line, while the King LTD Black drivers and fairway woods will blow you away with their stealthy looks. The King LTD Black drivers and fairways will be available on Nov. 18, while the King F7 and King F7+ lines will hit stores on Jan. 13, 2017.

Pricing is as follows (click the links for photos and more discussion): King F7 ($349), King F7+ ($399), King F7 fairway woods ($239), King F7 hybrids ($199), King LTD Black driver ($449), King LTD Black fairway wood ($299).

Here’s what you need to know about Cobra’s new line.

Cobra Connect

When you look back at this article in five years, you may remember it as the first time you ever heard about a tracking device built into an off-the-rack driver. And in five years, a lot more drivers may have similar technologies in their grips… or not. But for now, Cobra’s new technology allows golfers to track their performance on the course, share it with friends on social media, and compete against other golfers with the same technology in their club.

Here’s how it works.

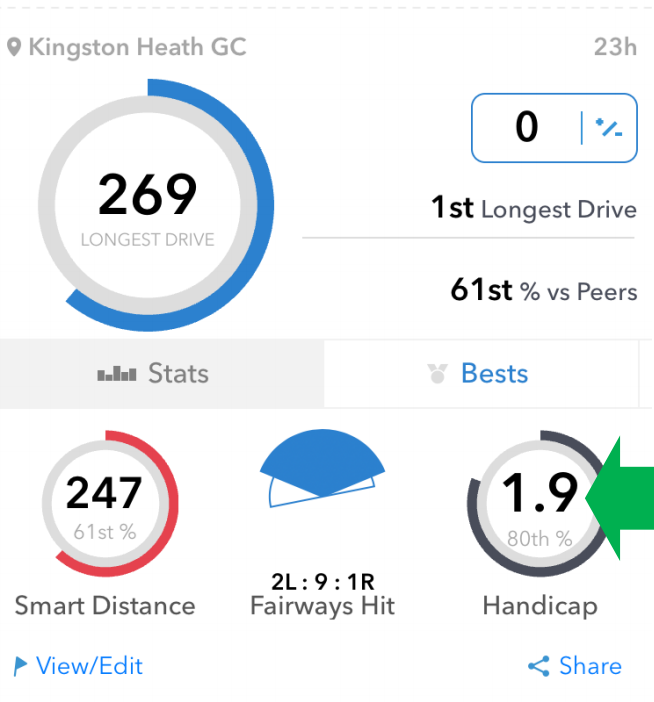

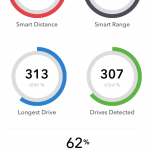

Cobra Connect, which is made by Arccos, is housed in the grip of the club, and is fully automatic once you download the free Arccos driver app. Cobra Connect then sends signals back and forth from your phone to the grip, picking up the location of where you hit your tee shot and where you hit your second shot, thus determining distance and if you hit the fairway.

To pick up the location of your second shot, the app uses a proprietary shot detection algorithm and sensors on your smartphone, which allows driving distance and accuracy to be recorded in real time. Remember this all-important step, however; you need to have your phone turned on and in your front pocket for it to work.

Cobra Connect users also have access to driving trends, performance tracking, global competitions and live game-improvement tips. Say you miss three fairways in a row to the right. You may have Rickie Fowler show up on your app with advice for curing a push or a slice.

Through the system, there’s a neat game called “King of the Hole,” where the longest drive on that particular hole keeps the crown. That means if Rickie Fowler plays golf in your area and hits a drive in the fairway and you play on the same course, you can effectively take the crown from him.

The app also doubles as an on-course GPS.

For an idea of what the user experience is like, check out the gallery below. Cobra Connect will come stock in the King F7 and F7+ in an Lamkin REL grip, and in a Lamkin UTx non-cord grip in the King LTD Black. Other grips are available through custom.

King LTD goes stealthy

Cobra’s King LTD driver, launched in 2015, was wildly popular among GolfWRX Members. It employed what Cobra called a “Zero CG,” a design that led to more distance through a high-launching, low-spinning trajectory. It’s currently in the bag of Rickie Fowler, and performed extremely well in our 2016 Gear Trials: Best Drivers Club Test. So why not keep the same technology, but offer a better-looking alternative? Thus, the King LTD Black.

The original King LTD had a glossy crown, and Fowler’s familiar Oklahoma State color scheme — orange and black. This year, Cobra is offering the same driver, but with a matte black crown. All of the orange graphics have been replaced with gray.

Related: More in-hand photos of Cobra’s King LTD Black driver and fairway wood.

Cobra Connect will come stock in the King LTD Black driver, and Cobra will also offer a King LTD 3 wood with the same color scheme. The King LTD Black will come stock with an all-black Aldila Rogue Black shaft.

Cobra amps up the Carbon

Remember TeXtreme carbon fiber? It’s an Aerospace-grade carbon fiber that Cobra used in the crowns of the its King LTD drivers and fairway woods, which helped the company move weight from the top of the drivers and place it lower in the club heads, ultimately making the drivers longer and more forgiving. The material apparently did its job because Cobra has added crowns made from TeXtreme carbon fiber to the new King F7 and F7+ drivers as well.

Cobra says the material change allowed its engineers to save 7 grams of weight from the crowns of the King F7 drivers, which enabled them to add more adjustability to the clubs.

Related: More in-hand photos of Cobra’s King F7 driver

Also, the King F7 has a 5 percent larger club face than its predecessor, and is made with an updated E9 Ti 811 structure with variable face thickness, meaning the sweet spot will play effectively larger than the King F6.

The King F7 will be available in three colors (black, blue and silver).

The King F7+ is also made from forged 811 titanium with variable face thickness for higher ball speeds on off-center hits. Stock shafts will be Fujikura’s Pro XLR8 shafts, but 25 other shafts will be available at no upcharge through custom.

Addressing the draw

The heaviest weight (12 grams) is differentiated by color; the color of the weight depends on the model.

The first thing you may notice about the new King F7+ driver is that it doesn’t have the weight track that was featured on the King F6+ driver. According to Jose Miraflor, Director of Product Marketing at Cobra, that’s because Cobra could not improve on the consistency it wanted to provide to golfers with the track design.

The King F7 and King F7+, however, make strides to improve consistency with their new adjustable weight system. It uses three weight ports that house either the heavy 12-gram weight, or one of two 2-gram weights. They allow golfers two neutral settings — lower spin (heavy weight forward) and higher spin (heavy weight back) — and a draw-biased setting. The draw setting is new, and one that addresses a long-time problem in golf among amateurs, and even pros.

“Eighty percent of golfers still struggle with a slice,” Miraflor said. “The center of gravity (with the draw setting) will help them to close the club face at impact… Even guys like Rickie (Fowler) and Bryson (DeChambeau) said they wanted something they could turn over.”

So there’s no more weight track, but for slicers, this may be for their benefit.

King F7 and F7+: So what’s the difference?

Now that there’s more uniformity to the King F7 line of drivers, you may be wondering what the difference is between the F7 and F7+ drivers. While they are made with the same technologies, the F7+ is made with what Miraflor calls a “standard head,” instead of the “oversize head” the F7 uses. That means the King F7+ has the more compact look better players tend to favor.

Also, the F7+ is available in lower lofts, which will likely benefit those with higher swing speeds. The King F7’s MyFly hosel has settings ranging from 9-12 degrees, while the King F7+ ranges from 8-11 degrees.

Staying on the rails

Cobra’s King F7 hybrid

If you watch the PGA Tour, you may have seen an odd-looking utility club in Rickie Fowler’s bag. It’s called the Cobra F6 Baffler, and it features rails on its sole that look a lot like train tracks. The front of the rails are designed to improve turf interaction upon entry into the ground, while the back of the rails help the club glide out more smoothly.

Why not put that technology into all of the new King F7 fairway woods and hybrids? Well, that’s what Cobra did.

The fairway woods and hybrids use a progressive rail design where the rails get deeper as loft increases. That means the 3 wood has the most shallow rail design, because it’s intended to be hit using a sweeping motion, while hybrids have the deeper rails, because they’re designed to be hit with a more descending blow.

This graphic from Cobra below shows off the progressive design. See more in-hand photos of Cobra’s King F7 fairway woods and hybrids.

The King F7 fairway woods are made with a 475 high-strength steel face insert, and will be available in three different head models: 3-4 wood (13-16 degrees), 5-6 wood (17-20 degrees), 7-8 wood (21-24 degrees). Like the King F7 driver, the King F7 fairway woods have CG adjustability by way of two weight ports that house a 20-gram weight or a 2.5-gram weight. Cobra says flip-flopping the weights move CG either 3.5 millimeters forward (to create a lower ball flight) or backward (to create a higher ball flight).

The King F7 hybrids are also available in three models: 2-3 hybrid (16-19 degrees), 3-4 hybrid (19-22 degrees) and 4-5 hybrid (22-25 degrees). Each of the fairway woods and hybrids come stock with a Fujikura Pro XLR8 shaft.

Cobra’s King F7 fairway woods are available in black, blue or silver.

Fairway woods will be available in three colorways, while the hybrids are available only in black-and-orange.

- LIKE152

- LEGIT22

- WOW17

- LOL4

- IDHT1

- FLOP2

- OB2

- SHANK17

Whats in the Bag

Daniel Berger WITB 2024 (April)

- Daniel Berger what’s in the bag accurate as of the Farmers Insurance Open. More photos from the event here.

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Fujikura Ventus Black 7 X

6-wood: TaylorMade Qi10 Tour (21 degrees)

Shaft: Fujikura Ventus Black 8 X

Irons: TaylorMade P770 (3), TaylorMade Tour Preferred MC 2011 (4-PW)

Shafts: Project X Denali Blue 105 TX (3), Project X 6.5 (4-PW)

Wedges: Titleist Vokey Design SM9 (50-12F), Titleist Vokey Design SM10 (56-14F), Callaway Jaws Raw (60-08C)

Shafts: Project X 6.5 (50), True Temper Dynamic Gold Tour Issue S400 (56, 60)

Putter: Odyssey Ai-One Jailbird Mini DB

Grip: SuperStroke Zenergy PistolLock 1.0

Grips: Golf Pride Tour Wrap

Ball: Titleist Pro V1

Check out more in-hand photos of Daniel Berger’s clubs in the forums.

- LIKE3

- LEGIT0

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB1

- SHANK0

Equipment

Heavy Artillery: A look at drivers in play at the Zurich Classic of New Orleans

What are the driver and shaft combinations of the best golfers in the world? For gearheads, it’s an endlessly interesting question — even if we can only ever aspire to play LS heads and 7 TX shafts.

At this week’s Zurich Classic of New Orleans, GolfWRX got in-hand looks at the driver setups of a wealth of players.

Check out some of the most interesting combos below, then head to the GolfWRX forums for the rest, as well as the rest of our galleries from New Orleans.

Rory McIlroy

Driver: TaylorMade Qi10 (9 degrees @8.25)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride MCC

Alex Fitzpatrick

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride MCC

Daniel Berger

Driver: Ping G430 LST (10.5 degrees @9)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride Tour Wrap

Rasmus Hojgaard

Driver: Callaway Paradym Ai Smoke Triple Diamond (10.5 degrees)

Shaft: Mitsubishi Tensei 1K Blue 60 TX

Grip: Golf Pride MCC

Alejandro Tosti

Driver: Srixon ZX5 Mk II LS (9.5 degrees @10.5)

Shaft: Project X HZRDUS T1100 75 6.5

Grip: Golf Pride MCC Plus4

James Nicholas

Driver: Titleist TSR3 (8 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 7 X

Grip: Golf Pride Tour Velvet

Kevin Streelman

Driver: Titleist TSR3 (10 degrees, D1 SureFit setting)

Shaft: Fujikura Ventus TR Black 6 X

Grip: Golf Pride Tour Velvet

Sang-moon Bae

Driver: Callaway Paradym Triple Diamond (9+ @8)

Shaft: Fujikura Ventus Blue 6 X

Grip: Golf Pride Tour Velvet

Russ Cochran

Driver: Callaway Paradym Ai Smoke (9 degrees)

Shaft: Graphite Design Tour AD TP 6 X

Grip: Golf pride MCC Align

MJ Daffue

Driver: Callaway Paradym Ai Smoke Max (10.5 degrees @9.5)

Shaft: Project X HZRDUS Smoke Green RDX 65 TX

Grip: Golf Pride ZGrip Cord Align

Check our more photos from the Zurich Classic here.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

Whats in the Bag

Rasmus Højgaard WITB 2024 (April)

- Rasmus Højgaard what’s in the bag accurate as of the Zurich Classic.

Driver: Callaway Ai Smoke Triple Diamond (10.5 degrees)

Shaft: Mitsubishi Tensei 1K Blue 60 TX

3-wood: Callaway Ai Smoke Triple Diamond Prototype (16.5 degrees)

Shaft: Mitsubishi Tensei 1K White 80 TX

Utility: Callaway Apex UW (21 degrees)

Shaft: Mitsubishi Tensei AV Raw White 85 TX

Irons: Callaway Apex Pro (3), Callaway X Forged (4-PW)

Shafts: KBS $-Taper 130

Wedges: Callaway Jaws Raw (52-10S, 56-10S, 60-06C)

Shafts: KBS Tour 130 X

Putter: Odyssey Ai One Milled Eight T DB

Grips: Golf Pride MCC

Check out more in-hand photos of Hojgaard in the forums.

- LIKE3

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 days ago

19th Hole2 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 days ago

19th Hole2 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

Matt W

Nov 2, 2016 at 11:06 pm

I have owned Cobra clubs in past, I detest the grips. Will there be different grip options?

josh

Nov 3, 2016 at 1:20 pm

you know, the same store you buy your cobra driver at has a boat load of grips for sale as well. there are endless options.

Jack

Nov 2, 2016 at 12:37 am

That’s a great idea. That gives people more of a reason to buy a complete set of their clubs. But really just buy different brands but also Arccos sensors to put on all the grips.

MP-4

Nov 1, 2016 at 2:19 pm

How does the head size of the Cobra F7 5-6 wood (17-20 degrees) compare to the Cobra F6 baffler?

Wonder if it is much larger. With the Cobra F6 baffler as a 5 wood, liked that the head size was smaller than a 3 wood and larger than a hybrid.