Equipment

New 2020 PXG 0311 Gen 3 P, T, and XP irons

2020 PXG 0311 Gen 3 irons: Real improvement

It’s been almost six years since Bob Parsons launched his passion project PXG, and it’s been as polarizing a golf equipment conversation as any out there. The only other company that generates that much conversation is when a TaylorMade driver hits the market, and from where I sit, it’s always a good time to see the reactions. I’ll be honest, PXG is progressing slowly but surely in the driver category, but one thing they have always done really well is irons.

Flashback to September of 2019 when I received an email from PXG inviting me down to see something new. I had no idea what to expect as their release cycles are a bit stretched out and the Gen 2 Irons had only been on the market for just over a year. Gen 2 Metal woods were out for an even shorter period of time, and besides putters and wedges, what else was there? Chief Product Officer Brad Schweigert had even mentioned earlier in the summer that he had no clue when a new iron would hit the market. And he’s the guy who makes ’em.

Needless to say, I was pleasantly surprised when I walked onto the back range at Scottsdale National and lead fitter Dave Cunningham unveiled what I now think is the best overall PXG iron line thus far: the PXG Gen 3 XP, P, and T irons.

2020 PXG 0311 Gen 3 P, T, and XP irons: The story

PXG has always utilized a high-end forging process in all of its lines, and with Gen 3 it’s cranked up a notch. Utilizing a 5x forging process (8620 Soft Carbon Steel), the team at PXG was able to create a face that is even thinner than the Gen 2. This process, in combination with their proprietary material to fill out the hollow body design (the foundation of PXG iron tech), creates an iron that is forgiving, feels amazing, and performs consistently.

These comments are a recurring theme with all high-end iron products, so overall it’s a familiar story. How does PXG add some honey to the pot to make ’em better and competitive? In this case, I can attest that the changes made to the Gen 3 legitimately made the PXG irons longer than previous models, and that’s across the board. So, to get this outta the way, yes, these irons are a step up as far as performance.

So what’s new and how did they do it?

It’s basically two main things:

- Impact Reactor Technolgy: PXG irons have always had an extremely thin hitting area. In the case of Gen 3, this has been ramped up with the addition of more mass behind the hitting area which equates to even higher launch across the line and significant distance gains. I saw this first hand in my testing, putting Gen 2 T against the Gen 3 T at the same specs. On average I gained 3 mph more ball speed, the launch went up a little and descent angle improved. After all that math, it equated to an increase in carry distance of six yards. That’s significant in the player’s irons category, and in my case, a welcome addition.

- New proprietary inner core material: It’s the PXG material inside the irons that has always been the secret sauce. This is where Bob and his team have excelled consistently. The simple way to explain what they did with Gen 3 is they added an even more elastic material to the core and added support for that material with the Impact Reactor. Obvious result: More distance, forgiveness, higher launch…you know how this goes.

The Looks

PXG 0311 Gen 3 P

The Gen 2 P was one of the best and most playable irons I had hit in years. It looked good, felt good, and it was an iron that had extreme forgiveness, all while giving better players all the playability they would want. In my opinion, the Gen 3 P took a step away from the player’s iron category and into a player’s distance iron, which is fine when you hear the report on the new T.

The Gen 2 P was one of the best and most playable irons I had hit in years. It looked good, felt good, and it was an iron that had extreme forgiveness, all while giving better players all the playability they would want. In my opinion, the Gen 3 P took a step away from the player’s iron category and into a player’s distance iron, which is fine when you hear the report on the new T.

The new PXG Gen 3 P iron has a more robust look at address and a longer blade length. I noticed they launch even higher with even more forgiveness than the predecessor. What I really like about this change is the ability to create a serious combo for those players looking for easy to hit launch monsters in the long irons and something more precise in the short irons.

PXG 0311 Gen 3 T

The new 2020 PXG Gen 3 T iron was the highlight of this launch for me. It took the best things about the Gen 2 P and put it into a T package. Although these are a tour iron, players who were a bit nervous about the ease of use in this line will be presently surprised with Gen 3 T. These irons have the soft feel and workability of a forged blade all while providing plenty of forgiveness on off-center shots.

Case in point, I tend to hit a lot of shots center thin. With Gen 2 T, I would lose on average seven to eight yards of carry distance, with Gen 3 my center strike distance increased seven yards (on avg) and my thin shots flew the same distance as my center strikes with Gen 2…make sense? For a player like myself, that type of gain in a forged tour club is a unicorn scenario.

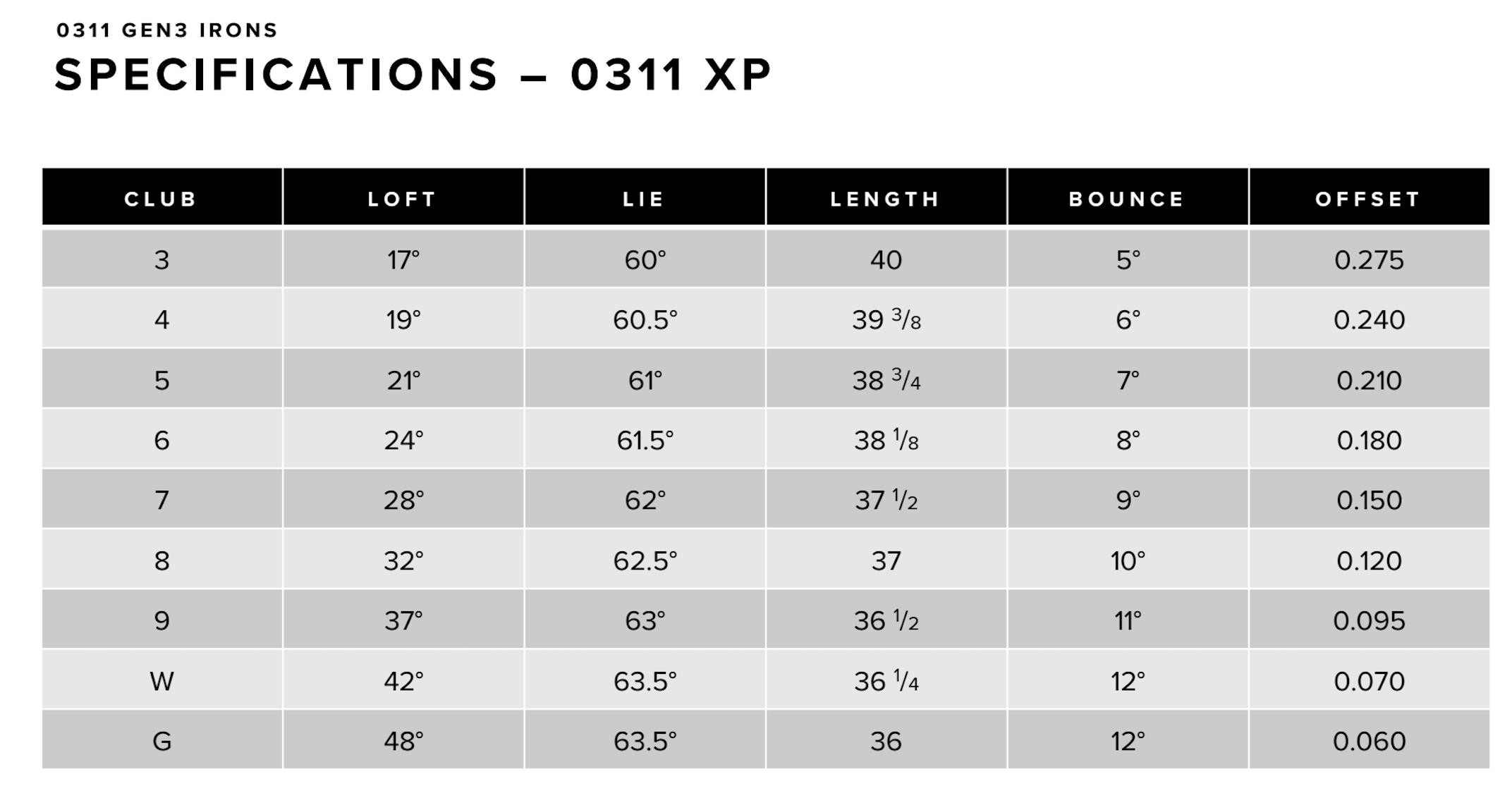

PXG 0311 Gen 3 XP

The two letters on the club say it XP: Xtreme Performance. These things are basically the T and “P” on steroids. The new 2020 PXG Gen 3 XP is a high-launch, high-MOI, distance machine in a very PXG package. This is the PXG iron for the slower speed player who wants to have 6 or 7 extra drivers in the bag. I will say that typically irons in this category tend to lose themselves from a looks category, but the OEMs seem to be slowly figuring this equation out. Gone are the days when the combination of distance and forgiveness had to live in a design that resembled a shovel.

The Feel/Sound

Solid. PXG irons have always felt and sounded amazing. The new 2020 PXG Gen 3 irons do feel and sound a little different. It’s a heavier hit now, especially in the T and P. In my experience with PXG, the hit with previous lines felt great but always lacked that sledgehammer feel that I look for. With the new inner core and Impact Reactor technology, PXG now has an iron that feels soft off the face and has that nice crunch at impact.

Overall

Very impressed with this launch. The new 2020 PXG Gen 3 irons offer everything Bob claims they do: quality, performance and most importantly they are fun to play. As I mentioned, the standout for me in this line is the T. That iron will catch a lot of attention in the player’s iron category due to how easy it is to hit—all while being a legit “tour” iron.

So how do the new 2020 PXG Gen 3 irons stack up against the market? Honestly, it’s hard to say. All the OEMs are bringing the heat this year in the iron category. I will say PXG has the iron thing dialed—like TaylorMade with drivers and Titleist with balls. Some companies just do certain things better than most. My normal advice, get fit, hit ’em all, and decide for yourself. The Gen 3 will be in every conversation, I can say that, and it’s hard to deny what PXG has done. The new 2020 PXG Gen 3 are the best overall lineup the company has offered, and that’s saying a lot.

Well done, PXG crew.

PXG 0311 Gen 3 P, T, and XP irons: Pricing/availability

Pricing: $425 per club

Available: January 9

Specs per PXG below

- LIKE153

- LEGIT33

- WOW22

- LOL8

- IDHT1

- FLOP10

- OB6

- SHANK56

Equipment

Spotted: Tony Finau’s driver shaft change at the 2024 Texas Children’s Houston Open

Tony Finau has always been known as one of the longest players on the PGA Tour, but he has recently been working on adding a little more distance. Last year, Finau averaged 118.3 mph club head speed and 178.08 mph ball speed, all while playing a Mitsubishi Diamana D+ Limited 70 TX driver shaft. This year, he has increased his club head speed to 123.93 mph and his ball speed to 183.32 mph.

However, Finau’s overall distance has decreased by two yards in that time. From a fitting perspective, something was up. We asked Tony about the shaft change at the Texas Children’s Hospital Open.

“[I’m seeing] better numbers with the spin. My driver’s been a little high spin for me over the last month or so, and so I just figured it was time to probably check out the equipment,” Finau said. “And it definitely showed me that I was using a shaft that’s maybe a little too tip-stiff for me, the way I load the club now. [I’m seeing] better numbers with the spin.”

Finau switched from the Mitsubishi Diamana D+ Limited 70 TX into the Diamana GT 70 TX. The newer Diamana GT has a slightly different profile than the D+ Limited with the stiffest handle section in the Diamana lineup. The mid sections between the two are similar stiffness but the tip is just slightly stiffer in the Diamana GT. Both shafts are within one gram of each other in the 70 TX. The torque rating on the GT is 0.1 higher than the D+Limited’s 2.7 measurement.

Mitsubishi lists the Diamana GT as a shaft between the mid-launching Diamana TB and the new low-launch Diamana WB shafts. For most players, it would be considered a mid/low launch and low-spin shaft option. Mitsubishi’s Xlink Tech Resin System makes sure the maximum carbon fiber content is there for smooth feel without reducing the strength of the shaft. MR70 carbon fiber is used for reinforcing the shaft and boron is used in the tip for its high strength and compression properties.

Finau is still using his trusty Ping G430 LST driver in 9 degrees and has the adjustable hosel set to -1 degree of loft (standard lie angle). Finau’s long-time favorite Lamkin UTX Green grip is installed. He definitely has a few extra wraps of tape under that grip as you can see the bulge down where the grip meets the shaft.

- Check out the rest of our pictures from the 2024 Texas Children’s Houston Open

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Zac Blair WITB 2024 (March)

- Zac Blair what’s in the bag accurate as of the Texas Children’s Houston Open. More photos from the event here.

Driver: Titleist TSR2 (10 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Red 6 X

3-wood: TaylorMade M5 Rocket 3 (14 degrees)

Shaft: Fujikura Speeder 757 Evolution V1 X

Utility: Titleist U510 (3)

Shaft: Aldila Tour Blue 85 X

Irons: Ping i210 (4-6), Miura MB-001 (7-9)

Shafts: Nippon N.S. Pro Modus3

Wedges: Titleist Vokey Design SM10 (46-10F, 58-08M @57, 60 @61), Vokey Design WedgeWorks (52-M)

Shafts: Nippon N.S. Pro Modus3 Tour 105 X

Putter: Scotty Cameron prototype

Grips: Golf Pride Tour Velvet

Ball: Titleist Pro V1

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Martin Trainer WITB 2024 (March)

- Martin Trainer what’s in the bag accurate as of the Texas Children’s Houston Open. More photos from the event here.

Driver: Wilson Staff Staff Model (6.5 degrees)

Shaft: Mitsubishi Kai’li Blue 70 TX

3-wood: Wilson Staff WLabs Prototype (13 degrees)

Shaft: Mitsubishi Tensei CK Orange 80 TX

Irons: Wilson Staff Staff Model (2, 4-9)

Shafts: True Temper Dynamic Gold Tour Issue X100

Wedges: Wilson Staff Staff Model (52, 56, 60)

Shafts: True Temper Dynamic Gold Tour Issue X100

Putter: Bobby Grace Greg Chalmers Prototype

Grips: Golf Pride Tour Velvet

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 days ago

19th Hole2 days agoJohn Daly stuns fans into silence with brutal opening tee shot on PGA Tour Champions

-

19th Hole6 days ago

19th Hole6 days ago2-time major champ announces shock retirement from the sport at age of 33

-

19th Hole1 week ago

19th Hole1 week agoEdoardo Molinari reveals the latest PGA Tour golfer to turn down ‘good offer’ from LIV Golf

-

19th Hole1 week ago

19th Hole1 week agoScottie Scheffler had an interesting response when asked how he ‘quiets the noise’ following Players victory

-

19th Hole1 week ago

19th Hole1 week agoJon Rahm dealt fresh blow to hopes of qualifying for 2025 Ryder Cup

-

Equipment2 weeks ago

Equipment2 weeks agoBest driver 2024: The best driver for you, as recommend by expert club fitters

-

19th Hole2 days ago

19th Hole2 days agoCharlie Woods finds it tough going on American Junior Golf Association debut

-

19th Hole5 days ago

19th Hole5 days agoWhy Kevin Streelman sought USGA approval to use this equipment tool as he leads Valspar after round one

doesnotno

Jan 14, 2020 at 9:02 am

“With Gen 2 T, I would lose on average seven to eight yards of carry distance, with Gen 3 my center strike distance increased seven yards (on avg) and my thin shots flew the same distance as my center strikes with Gen 2”

So a Gen 2 thin strike cost you 7 or 8 yards, and.a Gen 3 thin strike cost you 7 yards.

I’m not seeing that as worth shouting about.

Clutch Putman

Jan 10, 2020 at 5:14 pm

G3 PXG = Perfection. No long iron picks the ball up as well from a tight lie.

WS

Jan 10, 2020 at 5:08 pm

Sorry but not worth $425/, plus they don’t look good – look cheap to me – yes they feel nice and the seem go far – strong lofts, I know i’ve been down this road before I sure wouldn’t go down it again

Clutch Putman

Jan 10, 2020 at 6:40 pm

G3 PXG is a dollar well spent

19_Majors

Jan 28, 2020 at 10:05 am

Actually the Gen 3 0311T are not really strong lofted compared to most iron sets. Maybe a degree or 2 from traditional. Also, go see the 0311 in person. Photos don’t do them justice. I don’t own a set but hit them at a fitter last week. In person they look ultra premium.

Pelling

Jan 10, 2020 at 4:45 pm

So $425 per iron for a Taylormade RACMB TP knockoff!

Cay

Jan 9, 2020 at 10:19 pm

they released the t zoid true MP. MP means moron preferred.

Shawn

Jan 9, 2020 at 6:37 pm

So ugly.

Speedy

Jan 9, 2020 at 6:36 pm

Anyone buying this brand?

Karsten's Ghost

Jan 9, 2020 at 6:19 pm

They’ve even “borrowed” Ping’s 5/8″ lengths. Do these guys have no shame? They should just call themselves Samsung Golf.

Fou

Jan 25, 2021 at 9:57 am

Bro, are you serious? Their lead designer at PXG was poached over from Ping. Jeeze my guy.

Fredo

Jan 9, 2020 at 5:22 pm

Ugly? That’s debatable, but who cares if they rock your world! It will be hard to give up my Gen 1 irons, but I might give these a spin.

Connor

Jan 9, 2020 at 4:05 pm

The T’s look pretty good I can’t lie. Probably will test these to see if anything has changed but price tag is still just not in my price range

Rich Douglas

Jan 9, 2020 at 12:17 pm

Would you play them if money was no object? Are they objectively better than other irons, with their cost being the only barrier to universal acceptance?

I doubt it.

The cost will knock out most players from even considering them, but there are other considerations, too (for those who can pay). Other irons might be better for you.

Now, if they come out with a single-length set….

Cody Reeder

Jan 9, 2020 at 10:46 am

I would love to try their blades, but they are just too far out of my price range.

Kenny

Jan 9, 2020 at 10:39 am

Go practice and dig it out of the dirt….

Chris

Jan 9, 2020 at 9:54 am

Those look awesome! My game has improved dramatically with the Gen2s. I look forward to trying these.

Dyson Bochambeau

Jan 9, 2020 at 9:53 am

Ugly

Will

Jan 9, 2020 at 9:33 am

Would buy them if I could, but for now will stick with my i200’s. Don’t understand the hate that PXG gets sometimes. I actually like the looks of them.

dat

Jan 9, 2020 at 9:21 am

How can you make a product better when it was already the best in golf, PERIOD? lol. $3500+ a set?Oh well, a sucker born every minute – although very few suckers can afford these.

Tyler Durden

Jan 9, 2020 at 6:41 pm

Look at this pathetic person, whining about how someone else spends their own money

dat

Jan 9, 2020 at 9:10 pm

Nice comment, ad hominem as well.

Travisty

Jan 11, 2020 at 1:19 pm

@dat You can say the same thing about your original comment.

Anthony

Jan 9, 2020 at 9:05 am

Those irons are so pretty.

I hit them and you are correct John, +3mph ball speed, +6yards

Rob

Jan 9, 2020 at 7:36 am

Yikes! Those are hideous.