Equipment

Fourteen Golf’s new FH-900 Forged irons have mass appeal

Fourteen Golf’s new FH-900 irons have a compact head shape inspired by feedback from Tour players, but they’re loaded with distance-enhancing technologies to reach a wide range of golfers and ball-striking abilities. Everyone from PGA Tour players (John Rollins currently has them in the bag) to mid-handicappers can play them.

The irons are said to be 7 yards longer than the TC-888 irons (of the same lofts), the irons that they replace in Fourteen’s lineup. They’re forged from S20C carbon steel for a soft feel, and they have a nickel-chrome plating and a back face mirror for a “wow factor” in the bag.

For forgiveness, the cavity of the FH-900 irons is designed to provide stability at impact on off-center hits. For higher ball speeds across the face, the irons have a radial speed channel by way of a thin, 360-degree section surrounding the cavity that increases COR by moving weight to the perimeter of the club head. Like all of Fourteen’s forged iron offerings, the center of gravity in each of the FH-900 irons is individually developed for optimal placement. That means the longer irons have a lower CG to promote higher launch and lower spin, while the short irons have a higher CG to promote trajectory control.

Rusty Estes, the Director of Tour Operations at Fourteen Golf who also does the wedge/iron grinding on Tour for the company, says there is a “vast interest among Tour players, but [the irons] provide enough forgiveness for any mid-capper to play.”

“These are the best irons we’ve ever made, both aesthetically and performance-wise,” Estes says.

The soles of the FH-900 irons are built with high camber, or what Estes calls “bull nosing,” a southern term that describes how the club goes into the turf; big and slow, like a bull. These bull-nosed soles support a more downward angle of attack and won’t dig as much as Fourteen’s irons with sharper leading edges.

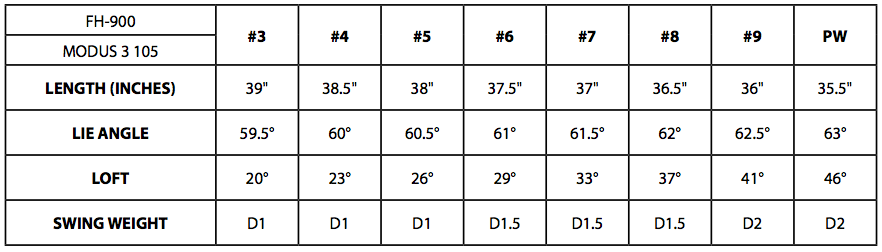

Specs and Pricing

The stock shaft offering in the FH-900 irons is the Nippon Pro Modus3 105, but custom shafts are also available. Full sets of the irons (4-PW) sell for $1,349.99.

Discussion: See what GolfWRX members are saying about the FH-900 irons

- LIKE136

- LEGIT17

- WOW12

- LOL6

- IDHT2

- FLOP1

- OB3

- SHANK26

Equipment

Masters gear roundup: Limited-edition bags, balls, and more

The Masters in itself is a huge tradition in the world of golf, but it also brings its own traditions with it. One of the big ones for us golf equipment fans is the limited edition gear that is influenced by the season’s first major championship.

Around tournament time, companies big and small offer bags, balls, and accessories that are designed with the colors and history of the Masters Tournament.

Here is some of the gear that we will see this weekend out on the lush, green grass of Augusta.

Callaway

The land Augusta National sits on was once a nursery. Callaway looks to be celebrating that history this year. Colorful flowers are used all over the side panels on the staff bag and on top of the headcovers. Callaway also did some limited edition Chrome Tour golf balls with azalea patterns.

Mizuno

There might not be a green bag here for Mizuno, but they know how to celebrate the Masters! This year, Mizuno is offering Mizuno Pro 241 “Azalea” irons to a limited number of lucky customers. A new green iridescent finish is applied to the heads and some beautiful colored ferrules bring some floral color to the irons. If you are lucky enough to grab a set, you will be impressed by the green display box the irons come in as well!

TaylorMade

This year’s staff bag goes a little heavier on a metallic green color to pay homage to the first major of the year. If you look closely at the details, you will notice shiny gold accent pieces, a small Amen Corner, and an inner lining with Georgia peaches. The headcovers are made from matching metallic green fabric and feature “88th” embroidery for the number of Masters tournaments that have been played. TaylorMade’s TP5x Pix golf balls come in a case that looks, and feels, like a peach!

Srixon

Srixon’s bag for the 2024 Masters goes heavy on green and white with a more simple and classic design on the outside. When you unzip the pockets you will treated to a hidden inner lining that has Georgia’s state fruit, the peach, printed all over. Heck, Srixon even included the pit! Headcovers are matching white and green but have a look that reminds you of the iconic Masters scoreboard.

- LIKE5

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK3

Whats in the Bag

WITB Time Machine: Tiger Woods’ winning WITB, 2019 Masters

At the 2019 Masters, Tiger Woods famously ended an 11-year major championship drought. When Francesco Molinari faltered during the final round, Woods pounced. With a Sunday 70, he captured his fifth green jacket and 15th major championship.

Check out what Tiger had in the bag below.

Driver: TaylorMade M5 (9 degrees)

Shaft: Mitsubishi Diamana D+ White 60 TX

3-wood: TaylorMade M5 (13 degrees)

Shaft: Mitsubishi Diamana D+ White 70 TX

5-wood: TaylorMade M3 (19 degrees)

Shaft: Mitsubishi Diamana D+ White 80 TX

Irons: TaylorMade P7TW (3-PW)

Shafts: True Temper Dynamic Gold Tour Issue X100

Wedges: TaylorMade Milled Grind Raw (56, 60)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: Scotty Cameron Newport 2 GSS

Ball: Bridgestone TourB XS

Grips: Golf Pride Tour Velvet Cord

- LIKE3

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Best irons in golf of 2024: Pure enjoyment

In our effort to assemble the 2024 best irons, we have again compiled an expert panel of fitters to help you find out which of the 2024 irons is best for your game.

Ultimately the best way to find your personal best iron set is to work with a professional fitter using a launch monitor. The difficult part is a lot of people don’t have easy access to fitters, launch monitors, and club builders — so at GolfWRX, we have done a lot of the work for you.

We are in the era of not just maximizing distance but also minimizing the penalty of common misses for each player — this applies to irons just as much as it does with any other club in the bag. And of course, proper set makeup and gapping is essential. This is why, now more than ever, custom fitting is essential to help you see results on every swing you make.

We are in the era of not just maximizing distance but also minimizing the penalty of common misses for each player — this applies to irons just as much as it does with any other club in the bag. And of course, proper set makeup and gapping is essential. This is why, now more than ever, custom fitting is essential to help you see results on every swing you make.

We want to give you the tools and information to go out and find what works best for you by offering recommendations for your individual iron set wants and needs with insight and feedback from the people who work every single day to help golfers get peak performance out of their equipment.

Best irons of 2024: The process

The best fitters in the world see all the options available in the marketplace, analyze their performance traits, and pull from that internal database of knowledge and experience like a supercomputer when they are working with a golfer.

It’s essentially a huge decision tree derived from experience and boiled down to a starting point of options—and it has nothing to do with a handicap!

Modern iron sets are designed into player categories that overlap the outdated “what’s your handicap?” model, and at GolfWRX we believe it was important to go beyond handicap and ask specific questions about the most crucial performance elements fitters are looking at.

These are the best iron categories we have developed to help you determine which category is most important for your swing and game.

Best irons of 2024: The categories

- Overall performance

- Easiest to launch/Slower swing speed

- Pure enjoyment

- Shotmakers

- Most technology-packed

- Best blade

2024 Best irons: Pure enjoyment

We continue to see an overlap in the way fitters in this category define the top irons. The most playable irons are the most likely to be higher launching, and shots that fly higher make the game more enjoyable for everyone. This reiterates our belief that your iron selection should not be defined by your handicap but instead by what gives you the best opportunity to play your best — and most enjoyable — golf.

Ping G430

Their story: Billed as Ping’s “longest iron ever,” the G430 irons combine a lower CG with stronger, custom- engineered lofts and a thinner face that delivers up to two more mph of ball speed, per the company. At the heart of the new addition is the PurFlex cavity badge, an innovation that features seven flex zones that allow more free bending in design to increase ball speed across the face. In combination with a lower CG, the badge aims to contribute to a solid feel and pleasing impact sound.

Fitter comments:

- “The best G.I. iron on the market. Easy to hit and launch while making great ball speed for distance.”

- “The best iron in the game improvement category. High launch and packed with forgiveness on those off-center hits. It’s one of the easiest irons to hit. So easy to hit and look at for the average golfer.”

- “Yeah, I mean, that’s definitely a go-to and in the matrix for sure. I mean, it’s just super easy to hit, super forgiving. They don’t mess that iron up.”

- “Ping does a great job of building golf clubs. Their design is fantastic and it’s not for everybody, you know, it’s not the lowest-spinning club…but it sure is one of the most forgiving golf clubs and most consistent golf clubs. Ping G430 in that category of club, you can have something that a good player who needs a little help maybe can use because it’s consistent across the face, and you can’t do that with some of the other clubs because they’re not as consistent across the face for the ball speeds. It is a monster for us.”

- “The best iron in the game improvement category. It’s one of the easiest irons to hit.”

For more photos/info, read our launch piece.

TaylorMade P790

Their story: Engineers utilized the variables of tungsten weighting, SpeedFoam Air, and internal mass — with an assist from AI — to precisely give golfers what they need in each iron. For example, launch and forgiveness in the long irons. More specifically, TaylorMade is using what the company calls FLTD CG (flighted CG) to strategically position CG throughout the set (lower in the long irons, higher in the short irons). CG is positioned almost a millimeter lower in the long irons compared to previous generations. In the shorter irons, the higher CG positions allowed engineers to dial in spin and promote accuracy.

Fitter comments:

- “Best combination of everything. The amalgamation of all irons on the market blended into one mathematically perfect design.”

- “I think people recognize the name. It’s a very popular club. It stands up to every model in a category.”

- “That’s the staple in the players distance category. It’s year-in, year-out. It’s tough to beat TaylorMade — they don’t go wrong with that iron, for sure. They make little refinements, but it’s almost like, yeah, just keep making little refinements. Don’t kind of mess that up just because the, I mean, it, it fits such a wide range of players and it’s just such a good iron that fits a wide, wide range of handicaps.”

- “I think where TaylorMade kind of struggled over the past is getting that spin on the golf club, and I think each generation it just keeps getting better. I think they did an awesome job.”

- “If it’s not our best-selling iron in the fitting center, it’s always like number two. It’s such a great, great performer across the board. And yeah, it just keeps getting better every year. It’s really awesome; crazy distance on that thing too.”

For more photos/info, read our launch piece.

Srixon ZX5 Mk II

Their story: MainFrame v2 was developed with an Automated Intelligence process, flex-maximizing variable thickness pattern of grooves, channels, and cavities carefully milled into the backside of Z ZX5 iron faces for high ball speeds. Not only does MainFrame boost COR, but it also repositions mass away from the face and into the toe and sole for a lower CG for easier launch, more consistency, and forgiveness.

Fitter comments:

- “I’m a big believer in the V-Sole. For high-speed guys who want a little forgiveness and are steep, it just doesn’t stick in the ground. Super soft and high launching. Not a ton of offset. It’s also been a good fit for moderate-to-high handicappers.”

- “So I would say it, it kind of stands out in its category because it does launch higher than its competitors. It also sits in between some of the models, like, it doesn’t directly compete with a hollow cavity and it doesn’t compete with, like the Cobra King Tour. Like, it’s a degree stronger. For a forged iron, it performs great for us. The only problem is that it is a little bit light in a swing weight, so we have to be careful of who we fit.”

- “It’s definitely one of our more popular irons for sure. You know, you get a guy who wants to play something small but still wants something more forgiving, and they don’t want kind of that full hollow body iron. I mean, that’s definitely one of our best sellers for sure. We’re seeing that a lot of combos — that’s a one iron that you can definitely combo with the ZX7 for sure.”

- “I think a lot of guys like the concept of the V-Sole with them…If you’re talking an overall package, you know, for the guy that is looking for something clean. That’s a spectacular golf club. Good looks and good feel and great, you know, great performance, and it fits a lot of categories.”

- “I think the one struggle a lot of companies have with that category is getting something to spin, so to try and give like guys so they don’t get those knuckleball shots or that fly out of the rough that goes 20 yards longer. I kind of think that that’s what I think makes that item so good is you get some spin on it, and I think it, it looks and feels good enough that like it, a guy that’s a mid-single digit can play it and be like, yeah, that’s good enough for me. But it’s also forgiving enough that a guy that’s in that kind of 12-to-15 kind of category if he wants to reach a little bit and play something that might look a little bit better. It just fits such a huge, huge range of players. I think it’s just awesome.”

For more photos/info, read our launch piece.

Mizuno JPX923 Hot Metal

Their story: “With the JPX923 Hot Metal, Mizuno introduces “4355 nickel chromoly,” which is 35 percent stronger than the original Hot Metal material and allows for an eight-percent thinner clubface. Cup face construction works in tandem with a deep center of gravity for high launch with stopping power. Mizuno developed Hot Metal Pro, Hot Metal and Hot Metal HL (High Launch) from 175,000 real golf swings recorded via Mizuno’s Swing DNA system.”

Fitter comments:

- “These are great for a player who flips at the ball but also needs some help and forgiveness. The strong lofts help reduce a player’s launch and spin.”

- “Great forgiveness with the feel that Mizuno is known for.”

- “Great looking and great feeling irons.”

- “If I had a player come in, that’s just your, you know, your average golfer. It’s one that is like, “Hey, this is, this is one to try.” This is gonna produce a lot of ball speed and is super forgiving. You can combo it really well. Mizuno does a great job where you can do combo sets just with lofts.”

- “It’s very good. It’s one of the most popular. Always in the mix of game improvement irons when people come in and they want to hit something that’s forgiving and that also still feels less clicky.”

For more photos/info, read our launch piece.

Titleist T200

Their story: If there were gripes about the previous generation of T200 irons, it was probably because of feel and sound at impact. Titleist heard your feedback on the previous T200 irons, and it listened. The new 2023 T200 irons have a reengineered chassis to create a stiffer structure and create a more stable feeling and muted sound. They also refined the Max Impact Technology within the head to sit closer to the L-face, further solidifying the feel.

Fitter comments:

- “Best overall for us. Great looks, workability. Plenty of forgiveness.”

- “I like the great look of these and they are easy to play for the average golfer.”

- “That’s a big combo iron for sure, especially, but it’s also, you know, in that player distance category, it’s one of the higher launching ones, and it’s gonna spin a little bit more. I would say some of those irons in that category they launch, you know, they’ve launched a little bit lower and they don’t spin, which it is great for some players, but also some still want to play a smaller package.”

- “I think it was definitely a big jump from the previous one. Yeah, I mean, one thing I’ve noticed is compared to some of the other irons, even kind of equal loft, it tends to get a little bit more height on it.”

- “It’s great for one of those guys that if I get in there that’s kind of hitting a little low. It’s one to kind of throw in my hands…you’re seeing that initial launch kind of pick up a little bit compared to some of the other ones.”

For more photos/info, read our launch piece.

Best irons of 2024: Meet the fitters

- Adam Rathe: Club Champion

- Adam Scotto: Club Champion

- Adam Seitz: Club Champion

- Aidan Mena: Club Champion

- Alex Dice: Carl’s Golfland

- Alex Praeger: Club Champion

- Ben Giunta: The Tour Van

- Blake Smith, PGA: True Spec

- Bo Gorman: True Spec

- Brad Coffield: Carl’s Golfland

- Brett Ott: Club Champion

- Brian Riley: Club Champion

- Cameron Scudder: Club Champion

- Carmen Corvino: True Spec

- Christian Sandler: Club Champion

- Clare Cornelius: Cool Clubs

- Dan Palmisano: Club Champion

- Dane Byers: Club Champion

- Darren Joubert: Club Champion

- Dennis Huggins: Club Champion

- Drew Koch: Club Champion

- Eric Touchet: Touchet Performance Golf

- Erik Gonzales: Club Champion

- Evan Morrison: Club Champion

- Gus Alzate: True Spec

- Jake Medlen: Stripe Show Club Fitters

- Jake Woolston: Club Champion

- Jake Wynd: Club Champion

- Jay Marino: Club Champion

- Jeremy Olsen: Club Champion

- Jim Yenser: Club Champion

- Joe Stefan: Club Champion

- Joey Simon, PGA: Club Champion

- Jonathan Kaye: Club Champion

- Jordan Patrick: True Spec

- Jordan Rollins: Club Champion

- Kevin Arabejo: Club Champion

- Kevin Downey: Club Champion

- Kirk Oguri: Pete’s Golf

- Kyle Lane: Club Champion

- Kyle Murao: Club Champion

- Marc Roybal: True Spec

- Mark Hymerling: Club Champion

- Mark Knapp: Carl’s Golfland

- Matt Miller: Club Champion

- Matt Rish: Club Champion

- Matthew Gandolfi: Club Champion

- Mike Martysiewicz: Club Champion

- Mike Weis: Club Champion

- Mitch Schneider: Club Champion

- Nicholas Barone: Club Champion

- Nick Sherburne: Club Champion

- Nick Waterworth: Haggin Oaks

- Preston Vanderfinch: Club Champion

- Rick Lane: Club Champion

- Rob Anderson, PGA: Club Champion

- Russell Hubby: Club Champion

- Ryan Fisher: Grips Golf

- Ryan Grimes: Club Champion

- Ryan Johnson: Carl’s Golfland Bloomfield Hills

- Sam Kim: True Spec

- Scott Sikorski: Club Champion

- Scott Felix: Felix Club Works

- Scott Trent: Club Champion

- Sean Pfeil: Club Champion

- Shaun Fagan: True Spec

- Steve Harrow: Club Champion

- Tad Artrip: Club Champion

- Thomas Mattaini: Pull the Pin

- Tony Rhode: True Clubs

- William Buse: Club Champion

- William Cho: NovoGolf

- William Fields: Club Champion

RELATED: Best driver 2024

- LIKE8

- LEGIT2

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK8

-

19th Hole2 weeks ago

19th Hole2 weeks agoJohn Daly stuns fans into silence with brutal opening tee shot on PGA Tour Champions

-

19th Hole1 week ago

19th Hole1 week agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

-

19th Hole6 days ago

19th Hole6 days agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole3 weeks ago

19th Hole3 weeks ago2-time major champ announces shock retirement from the sport at age of 33

-

19th Hole3 weeks ago

19th Hole3 weeks agoEdoardo Molinari reveals the latest PGA Tour golfer to turn down ‘good offer’ from LIV Golf

-

19th Hole2 weeks ago

19th Hole2 weeks agoCharlie Woods finds it tough going on American Junior Golf Association debut

-

19th Hole1 week ago

19th Hole1 week agoAddiction, spinal fusion, and scam artists – Everything Anthony Kim revealed in candid interview with David Feherty

-

19th Hole5 days ago

19th Hole5 days agoAnthony Kim says doctors told him that he ‘may not have much time left’ ahead of LIV return

golfraven

Jul 2, 2017 at 4:23 am

The FH-900 irons don’t have as much meet (compared to Bridgestone TourB X-CB) in the back but still sexy appearance. I will add those to the list of contenders for an upgrade. The Modus3 105 is certainly a shaft I am looking at right now.

Grits

Jul 1, 2017 at 6:27 pm

so rad —- so wicked —- so pretty

Paul

Jul 1, 2017 at 8:03 am

Hit these a few weeks ago. They really are lovely irons; setup and looks are top notch. The feel is very soft, yet solid. I hit them against the 888 and 770. The shaft wasn’t the shaft for me, but the distance over the 888 is easily seen from the range. Would have loved some on course time with them too. In the end, my 745s performed very similarly but if I were hunting for a new iron, I would put a lot of weight behind the 900.