Shaft & Grip Reviews

Review: Garsen Putter Grips

Pros: A new take on the traditional pistol-style putter grip. Design minimizes wrist breakdown and lays the foundation for a more consistent stroke. Solid construction, comparable to grips from major manufacturers.

Cons: The necessary hand position may alter a golfer’s putting stroke. The different look and feel to gripping the putter will take getting used to.

Bottom Line: If you have the yips or wrist breakdown, are unhappy with your current grip or style, or are merely looking for something different, Garsen’s putter grips are worth a try.

Overview

A golfer since a young age, Bernerd Garsen has spent the past 12 years in the South Florida golf industry, most recently as an assistant golf pro.

It was during this time period that the idea behind his grips began to take shape. As Garsen says:

“Just by working with people and being around golf, I saw that people had a lot of wrist breakdown. The putter grip hasn’t been changed in ages except for size and material. This is a new shape, a new design.”

Garsen’s grip is designed with an inverted v-shape on its front, which according to the designer puts the hands in a neutral position by placing one thumb on each side of the grip. As a result, the elbows are pulled tighter to the body at address and the shoulders fall back and relax. That lays the foundation for a more stable, consistent stroke.

How does it work? Here’s the claim from Garsen:

“[The] patented, two-sided design, which places your hands into a neutral position, turns your elbows into your body and sets your shoulders back. This puts your body in a relaxed position and eliminates unnecessary wrist breakdown. This creates a more repetitive putting stroke. Together, these characteristics contribute to a more confident putting stroke, which will lead to making more putts.”

According to Garsen, top teachers Mike Bender, Pete Cowen and Mike Shannon, are promoting the grip and it has been favorably received by touring professionals.

Garsen has only been in the grip business for a year and he’s already making significant strides with tour players. J.B. Holmes won the Wells Fargo Championship earlier this year with a Garsen G-Pro EDGE on his putter (and picked up 1.4 strokes on the field with the flatstick for the tournament). World No. 2 Henrik Stenson is presently using the MAX.

The G-Pro EDGE retails for $19.95. It’s available in Black, White, Blue Red.

- Grip diameter: Semi Mid-Size

- Weight: 73 grams (+ 1 – 3 grams)

- Core Size: .580

- Firmness: Medium

- Shock Absorption: High

- Material: TPO

- Feel: Semi-tacky

- Profile: Semi-Tapered Paddle

The G-Pro MAX retails for $24.95 and is available in Black/White and White/Black styles.

- Grip diameter: 2 inches

- Weight: 60 grams

- Core Size: .60

- Firmness: Medium

- Shock Absorption: High

- Material: High-Tech PU Material

- Feel: Semi-tacky

- Profile: Semi-Tapered Pistol

Performance

Traditionally, evaluating the performance of a grip outside of looks and feel is difficult unless the grip makes a specific claim. For example, the SuperStroke is designed to minimize hand action and wrist breakdown.

Garsen makes the same claim.

Both the EDGE and MAX force a golfer’s elbows back against the body, which does create a greater feeling of stability and sense of connectedness in the putting stroke. To a degree, it also seems easier to grab your putter and set up squarely from the position.

As a result of the way a golfer is forced to hold the putter with the Garsen grip, wrist breakdown is virtually impossible, as is a significant amount of manipulation with the hands. This was certainly evident in testing Garsen grips on a couple of putters, and it’s easy to see why an historically iffy putter, J.B. Holmes, would be attracted to the model.

Looks and Feel

The feel of the EDGE and MAX are comparable to grips from any other major manufacturer. To a degree, rubber is rubber. Obviously, the EDGE is a standard size grip and the MAX is sized similarly to the SuperStroke Slim 2.0.

The distinct elements of both the look and feel of gripping a putter with a Garsen installed come from the way you grip the Garsen grip.

Some golfers may feel gripping the putter in the manner above alters the putting stroke stroke somewhat. While Garsen makes the argument the change is for the better, the determination is up to the individual golfer to make. Regardless, it’s important to stress that the grip necessitates a different grip, as it were.

The Takeaway

While Garsen’s grips make take some getting used to, they’re certainly worth a shot for golfers who struggle with their putting, particularly those who deal with lead-wrist breakdown and general yippiness.

And of the above, there are many.

Those who prefer a thicker grip ought to try the MAX, while those who like the traditional pistol-style putter grip should consider the EDGE.

Whether the creatures of habit that walk our golf courses will get on board with something that looks different than the grip they’ve been playing forever and necessitates a new way of holding the putter remains to be seen.

Ultimately, Bernerd Garsen has created a variant of the traditional putter grip that does what it claims to do. And he’s not done innovating yet: Garsen told us that he’s just returned from China where he discussed the production of a new, three-sided grip.

[wrx_buy_now oemlink=”http://garsengolf.com/index.php/online-store” oemtext=”Learn more from Garsen Golf” amazonlink=”http://www.amazon.com/gp/product/B00K5978QU/ref=as_li_qf_sp_asin_il_tl?ie=UTF8&camp=1789&creative=9325&creativeASIN=B00K5978QU&linkCode=as2&tag=golfwrxcom-20&linkId=OURQMC6QIDYKW3R3″]

- LIKE36

- LEGIT6

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB2

- SHANK4

Equipment

Here’s why Jordan Spieth switched into a new Fujikura Ventus TR Blue shaft at Pebble Beach

When Fujikura’s new Ventus TR Blue shaft launched in January 2022, we learned all about the updated construction and potential performance benefits compared to the original Ventus Blue. It was unclear at the time, however, exactly who would make the switch into the new TR design on the PGA Tour.

Well, we’re starting to get some answers.

Jordan Spieth, who’s been relatively slow to change into new products throughout his career, is among a handful of names making the change. Spieth conducted recent testing with a Ventus Blue TR 7 X shaft in his Titleist TS2 15-degree fairway wood, and he put it in play this week at the 2022 AT&T Pebble Beach Pro-Am.

Titleist Tour representative J.J. Van Wezenbeeck, who works closely with Spieth on his equipment, said that Spieth came to the Titleist Performance Institute (TPI) on Friday before the 2022 Pebble Beach Pro-Am for a check-up on his equipment. Since Spieth was previously playing Ventus Blue shafts in his Titleist metalwoods, he was intrigued by the new TR version.

As it turned out, Spieth found the new shaft to help with his transition and directional control.

“Coming from Ventus Blue, anytime they update a shaft you’re just intrigued on that, and he liked how [the Ventus TR Blue] loaded compared to the original Ventus Blue for him,” Van Wezenbeeck told GolfWRX on Tuesday. “He felt like when he mishit it, there was a little more control. So that was a good option for him…we did a little bit of internal work on the head to make sure there’s enough spin, because want to make sure his 3 wood doesn’t have too low of spin. He liked how the TR reacted on mishits where the spin didn’t drop, and it had more consistent spin from swing to swing.”

Due to a new Spread Tow fabric in the butt-end section, which is essentially a checkerboard pattern of woven material, the torque on the TR version is 10 percent stiffer in the mid-to-grip end of the shaft. As a result, Fujikura says the TR shaft is designed to improve stability and consistency compared to the original Ventus Blue.

Based on Spieth’s results with the TR shaft during testing, it seems Fujikura’s case holds water.

Spieth is using a Ventus Blue TR 7 X version in his fairway wood.

Pat McCoy, Director of Tour Operations at Fujikura, spoke with GolfWRX about the new shaft, and what players are seeing in their testing out on Tour.

“Compared to the original Ventus Blue, the TR has a stiffer mid-section and lower torque,” McCoy said. “Basically what the shaft does is it eliminates some of the dynamic loft. It eliminates some of the rotation. Obviously, the Ventus Blue was a very stable shaft and one of the best launching shafts we’ve ever had. And we just made it better.

“As far as ball speed and launch and spin, I’m not going to say it’s faster, but we have seen players who have achieved faster speeds with it. It provides more consistency and the ability to turn swing speed into ball speed better. And that’s it. It’s a little stiffer than the original Blue, and it’s a little bit weaker than the [Ventus Black]. It’s a ‘tweener. It gives you something in the middle, and depending upon loft and impact location, you get a better fit.”

The fairway wood shaft wasn’t the only potential change that Spieth will make in 2022, though.

In addition to putting the new Titleist Vokey SM9 wedges in the bag, Spieth is also considering adding another option to the top end of his bag.

Typically, Spieth changes between a hybrid and long irons, depending on course conditions. During the recent session at TPI, though, Spieth took a liking to Titleist’s U-505 wide-bodied driving iron. Ahead of the 2022 AT&T Pebble Beach Pro-Am, Spieth took a U-505 2-iron (Graphite Design AD-DI 105X shaft) out onto the course for testing.

“He’s experimenting with a U-505 this week (ahead of the event at Pebble Beach),” Van Wezenbeeck told GolfWRX. “He’s always gone between a hybrid and either a 2 iron, or a hybrid and 3 iron, and we brought out a 505 as kind of a third option on a week where he isn’t sure whether he should play an iron or a hybrid. The 505 being a wide body iron is kind of a blend between the two. And he was really intrigued with how high it launched on a standard shot, and he could flight it more off the tee, where as with a hybrid he can’t do.

“So on weeks he feels like there’s a lot of irons off the tee, he likes to play the iron. On weeks where there are a lot of shots into par 5s, he likes the hybrid. On weeks where there’s a little of both…he felt the 505 might be an option, so he was taking it on the golf course [on Tuesday] to see how it would react.”

While it’s unclear exactly when Spieth will break out the new U-505, it seems like it’ll certainly be in the rotation going forward. The Ventus TR Blue shaft, on the other hand, has already earned a starting spot in the bag this week.

These changes may seem minor to some, but it shows Spieth’s willingness to find small equipment tweaks to improve his game. For amateur golfers, use this as a lesson when gearing up for the new season. Go through your bag, test some of the new shaft and head options, and see where you can make improvements. Now is the perfect time to take inventory and get prepared.

- LIKE65

- LEGIT11

- WOW3

- LOL1

- IDHT0

- FLOP2

- OB0

- SHANK6

Shaft & Grip Reviews

MRC Shaft Shootout: Tensei CK Pro White, Kuro Kage XT and Diamana BF-Series

The Tensei CK Pro White is the latest release from Mitsubishi Rayon Composites (MRC), a low-launch, low-spin shaft with a multi-material design that the company says improves the performance and feel of the shaft. Whereas most golf shafts use between 3-6 different materials in their construction, the Tensei CK Pro White is made from 11 different materials, giving MRC engineers greater precision in the shaft’s design.

Like MRC’s Tensei CK Pro Blue shafts, which produce a slightly higher-launching, higher-spinning ball flight, the CK Pro White uses MRC’s Carbon Fiber DuPont Kevlar Weave in the handle section of the shaft. The company says it increases the strength and stability of that part of the shaft, leading to better feedback.

On the other end of the shaft, the tip section, MRC uses a boron-reinforced fiber. All low-launch, low-spin shafts have stiff-tip designs, but the addition of boron puts the Tensei CK Pro White in a class of its own when it comes to lowering launch angle and spin rate. The boron fiber also reduces torque, which can offer better energy transfer, more accuracy and better feedback — especially for skilled, high-swing-speed golfers.

Connecting and reinforcing those areas of the shafts is MRC’s low-resin content (LRC) prepreg. Prepreg is carbon fiber that’s been reinforced or “pre-impregnated” with resin, a glue that holds the material together when it’s formed into sheets and rolled into the form of a shaft. MRC says that its LRC has 15 percent more carbon fiber and 13 percent less resin than traditional prepregs, which allows MRC to make the Tensei CK Pro White stronger without adding extra weight to the shaft. MRC also uses high-modulus, 40-ton prepreg in the Tensei CK Pro White’s design, which like LRC is thinner, stronger and lighter than traditional prepregs.

The addition of boron helps MRC make the tip of Tensei CK Pro White shaft stiffer and lower in torque.

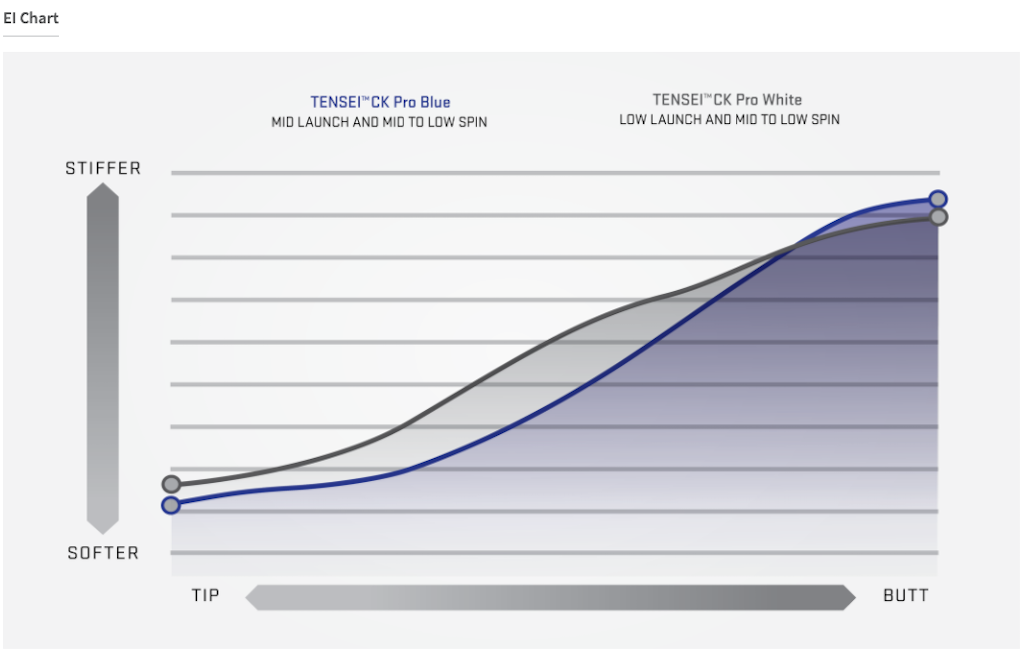

In the EI chart below, you can see how the Tensei CK Pro White’s bend profile compares to the CK Pro Blue. The main differences are its slightly stiffer tip and mid sections, as well as its slightly softer butt section. That gives the CK Pro White a higher “kick point” than the CK Pro Blue. Generally, the higher the kick point of a shaft, the lower its launch conditions. That’s why the Tensei CK Pro White is a lower-launching, lower-spinning shaft than the Tensei CK Pro Blue.

The Shootout

The Shootout

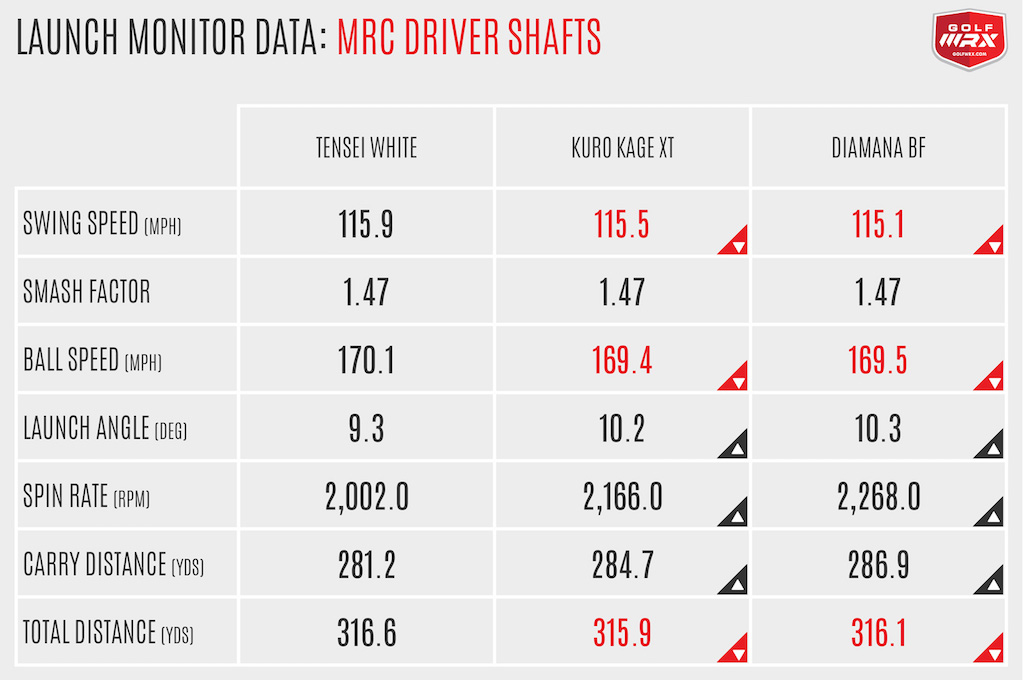

Just how much lower launching and lower spinning is the Tensei CK Pro White than MRC’s latest premium driver shafts? I put it to the test against the company’s Kuro Kage XT and Diamana BF-Series, which like the CK Pro White are PGA Tour-quality shafts that sell for about $400 each. All three shafts tested were built to my spec: 70TX, tipped 1 inch at a finished length of 45.5 inches.

I tested the three shafts on Trackman 4 at the Launch Pad at Carl’s Golfland in Bloomfield Hills, Mich. After warming up, I hit 10 drives with each shaft, and whittled my shots down to the most similar five to help illustrate the differences. Premium balls were used for the test, and results were normalized.

As expected, the Tensei CK Pro White was the lowest-launching, lowest-spinning shaft in the test. That’s impressive in its own right, but what will really excite golfers when they try a Tensei CK Pro White is the shaft’s feel. It’s noticeably smoother than the MRC White Board shafts I’ve played in the past. You could likely duplicate the launch conditions of the Tensei CK Pro White with similar products from other premium shaft makers, but I’m not sure its smoothness can be replicated in the category. It’s something special, and I expect a lot of serious golfers with above average club head speeds will be willing to pay a premium for it.

As expected, the Tensei CK Pro White was the lowest-launching, lowest-spinning shaft in the test. That’s impressive in its own right, but what will really excite golfers when they try a Tensei CK Pro White is the shaft’s feel. It’s noticeably smoother than the MRC White Board shafts I’ve played in the past. You could likely duplicate the launch conditions of the Tensei CK Pro White with similar products from other premium shaft makers, but I’m not sure its smoothness can be replicated in the category. It’s something special, and I expect a lot of serious golfers with above average club head speeds will be willing to pay a premium for it.

MRC’s Kuro Kage XT uses a stouter iteration of the company’s famed “Blue Board” bend profile, and in that regard it’s quite similar to the Diamana BF-Series. That’s what makes the shafts a little higher launching and higher spinning than the Tensei CK Pro White. The Kuro Kage XT has a much different feel than both, however, due to its use of an elastic wire made of Titanium and Nickel that MRC calls “TiNi” wire.

Related: Learn more about the Kuro Kage XT

In the Kuro Kage XT, the TiNi wire is added to the bottom 13 inches of the shaft, where it adds stability, but it also serves another purpose. Its elasticity allows the bottom end of the shaft to better load and unload during the downswing to help improve energy transfer. That’s what gives the Kuro Kage XT its more active feel, at least compared to the boron-infused tip section of the Tensei CK Pro White, which by design offer no elasticity.

The Diamana BF-Series also uses boron in its tip section, and its combined with a new, aerospace-grade fiber called MR-70 to create what MRC says is a first-of-its-kind hybrid prepreg. MR-70, which is manufactured by parent company Mitsubishi Chemical, is 20 percent stronger and has 10 percent more modulus than similar fibers, MRC says. The handle section of the BF-Series is reinforced with MRC’s Pitch Fiber, which functions to boost energy transfer like the CK Pro White’s Carbon Fiber DuPont Kevlar Weave.

Related: Learn more about the Diamana BF-Series shafts

In terms of launch conditions, the best fit for me was the Diamana BF-Series. It launched the ball a little higher than the Tensei CK Pro White, and added a little spin to help keep my drives in the air. It was also easier to swing than the Tensei CK Pro White, helping me more easily hit a draw while offering an even smoother feel due to its less rigid tip and mid sections.

To recap, if you need to lower your launch conditions, the Tensei CK Pro White is one of the most intriguing new MRC options to help you do so. Need a higher ball flight? Try the Diamana BF-Series. And if you want a radically different feel, give the Kuro Kage XT a try.

Have a question? Let me know in the comments section below and I’ll do my best to answer as many as I can.

Weights and Flexes

- Tensei CK Pro White: 60 (R, S, TX), 70 (S, TX), 80 (TX)

- Kuro Kage XT: 50 (R, S, X, TX), 60 (R, S, X, TX), 70 (S, X, TX), 80 (S, X, TX)

- Diamana BF-Series: 50 (R, S, X), 60 (R, S, X, TX), 70 (S, X, TX), 80 (S, X, TX)

Related: GolfWRX Members review the Tensei CK Pro White

- LIKE132

- LEGIT15

- WOW3

- LOL5

- IDHT5

- FLOP3

- OB4

- SHANK8

Reviews

Review: KBS Tour FLT Shafts

Pros: FLT shafts use a flighted design, which helps golfers launch their long irons higher and with more spin. The FLT short-iron shafts provide a more penetrating trajectory for more control.

Cons: FLT shaft flexes correspond with weight, so golfers may not be able to match their desired shaft weight with their desired flex.

Who They’re For: Golfers who need more spin or more launch from their long irons to optimize their trajectory. Everyone from beginners to PGA Tour players can use the shafts effectively, but they’ll be most popular with golfers with moderate-to-slow swing speeds, or any golfer who generates low-spin launch conditions.

Overview

Selecting the proper iron shafts is one of the most important equipment decisions golfers make. It’s an issue of quantity. Most golfers carry about 7-8 irons in their bag, so if they choose the wrong iron shaft, they’ve made the game harder than it needs to be with half or more of their clubs.

The good news is that there’s a wider selection of quality iron shafts than there has ever been, with recent growth in models that are designed to help golfers hit their iron shots higher and farther, while still maintaining PGA Tour-quality consistency and feel.

KBS is one of the leading steel shaft manufacturers, and already offered a wide variety of models prior to its newest shaft launch. Company representatives felt KBS was lacking a product for a particular segment of golfers, however, so it developed its new FLT shafts.

FLT shafts ($31.95 each) have a flighted design, which helps certain golfers optimize the performance of each iron their bag. The long irons shafts have progressively softer tip sections, which helps golfers increase their launch angle and spin rates with those clubs. For the right golfer, the design will help them hit their iron shots farther, and stop shots on the green more quickly. In the short irons, where height and spin are easier for golfers to generate, the FLT shafts are stiffer, which creates the flatter trajectory most golfers prefer with their scoring clubs. The crossover point between the higher-launching long irons and lower-launching short irons is the 7 iron.

Like all KBS shafts, FLT models have a constant weight, which means that long iron shafts and short iron shafts will be roughly the same weight through the set. Shaft weight is dependent on flex, however, as softer-flex models are lighter than stiffer-flex models. So if you’re looking for a really heavy, regular-flex shaft or a really light, extra-stiff-flex shaft, these aren’t for you.

FLT Specs

Keep in mind that KBS shafts do not have reinforced tip sections like many other iron shafts, which gives them a slightly higher balance point and can decrease swing weight by 1-2 points. I personally like the feel of KBS shafts and their slightly higher balance point, but some golfers won’t.

The Test

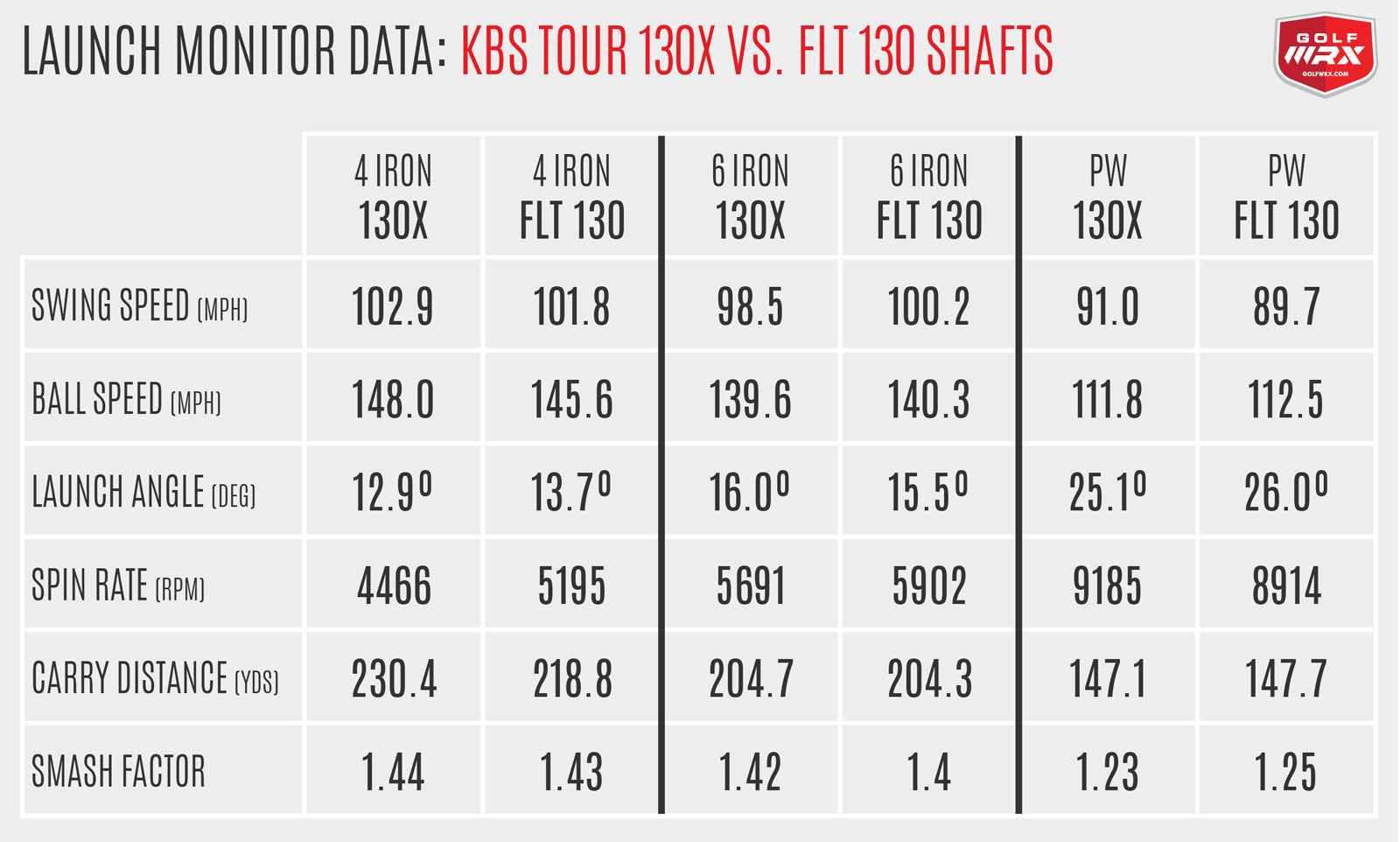

For this review, I tested the new FLT shafts head to head against KBS Tour shafts of the same flex and weight (130X) in 4 irons, 6 irons and pitching wedges. Each of the shafts were installed in Callaway’s Apex Pro ’16 irons, and were built to my specifications (standard grips, standard length, 1-degree strong lofts, 1-degree flat lie angles).

I performed my testing at the Launch Pad at Carl’s Golfland in Bloomfield Hills, Mich., where I hit the 4 irons, 6 irons and pitching wedges on Trackman IV with premium golf balls. I hit 3-6 solid shots with each iron, and then removed the outliers from the final data in an attempt to compare only the most similar strikes. Results were normalized.

As you can see from the data, there was a significant difference in the flight of the 4 irons with the two different shafts, but less of a difference with the 6 irons and pitching wedges.

As expected, the FLT shafts caused 4 iron shots to launch higher (0.8 degrees) and with more spin (729 rpm) than the KBS Tour shafts. I’m not a low-spin player, which is one of the target audiences for this shaft, so the added launch and spin of the FLT shafts caused my 4 iron shots to fly shorter. Golfers who launch their irons too low or with too little spin, however, will likely see a distance increase when using the FLT shafts.

As I moved closer to the short end of the set, the two shafts started to perform more similarly. Theoretically, the 6 iron shots with the FLT shafts should have launched slightly higher and spun more than 6 iron shots with the KBS Tour shafts, but I actually saw a slightly lower launch angle (0.5 degrees) with the FLT. The spin was higher, though, by 211 rpm. With the pitching wedges, the results were again quite similar. The FLT launched 0.9 degrees higher, but actually spun 271 rpm less than the KBS Tour shafts.

Takeaways

Stepping back from the numbers, I was impressed with how similar the feel was between the KBS Tour and FLT shafts. Yes, I could feel that the FLT shafts were more active in the tip with the 4 irons, but they felt nearly the same in the 6 irons. By the time I got to the pitching wedges, the two shafts were indistinguishable. The KBS Tour is considered one of the better-feeling iron shafts currently available, so KBS’ ability to replicate that feel in the FLT will be a plus for the majority of interested golfers.

Looking more broadly, trends in shaft design tends to go hand-in-hand with trends in club head design, and the FLT shafts are no exception. Equipment manufacturers continue to strengthen the lofts of their distance irons; they have to in order balance the launch equation, as their faster ball speeds create a higher launch angle and more spin.

While the improvements to iron design have allowed golfers to hit their mid and short irons farther, many golfers continue to struggle to hit their long irons high enough or consistently enough for them to be effective. And based on my testing results, it’s clear that the FLT shafts can make long irons more playable for certain golfers, and maybe even keep long irons in a golfer’s bag that might otherwise be kicked out for higher-flying hybrids or fairway woods.

As always, I recommend that golfers get properly fit for iron shafts, which means visiting a reputable club fitter in your area. So if you’re in the market for new irons or iron shafts, you can get started by going through KBS’ Online Fit System, which upon completion lists KBS-certified dealers in your area.

- LIKE100

- LEGIT12

- WOW6

- LOL6

- IDHT3

- FLOP3

- OB4

- SHANK22

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole4 days ago

19th Hole4 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole3 days ago

19th Hole3 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole2 weeks ago

19th Hole2 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole1 week ago

19th Hole1 week agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

Stan

Feb 22, 2015 at 12:58 am

Best grip i have ever used.. I will never go back to the standard putter grip!!!

Todd

Feb 6, 2015 at 10:00 am

i’v been using the Max grip for about 6 months now I will never go back to a standard

putter grip.

Tomm

Jul 28, 2014 at 8:24 pm

what is “semi-midsize”? smaller than midsize, a little bigger, same but different shape???

Al385

Jul 13, 2014 at 4:27 am

I got the G-Pro Edge and since then, my putting improved considerably. I got used to the grip in minutes, in few words it is not a big change that brings great benefits. This is not a big change as switching from a standard putter to a belly or even a broomstick. Of course, if you are not open to changes, perhaps this is not the grip for you but I suggest to give it a try.

Pingback: Review: Garsen Putter Grips | Spacetimeandi.com

Jeremy

Jul 11, 2014 at 3:59 pm

Stop giving everything 4+ stars WRX!!!

RValdez

Jul 11, 2014 at 1:56 pm

I tried one of the Garsens for a couple of rounds and I can see where it would be helpful, but I know personally I could never get comfortable with it. I would recommend people try it and see if it works for them.