Equipment

Matrix Shafts Q&A: The new X3 “White Tie” shaft

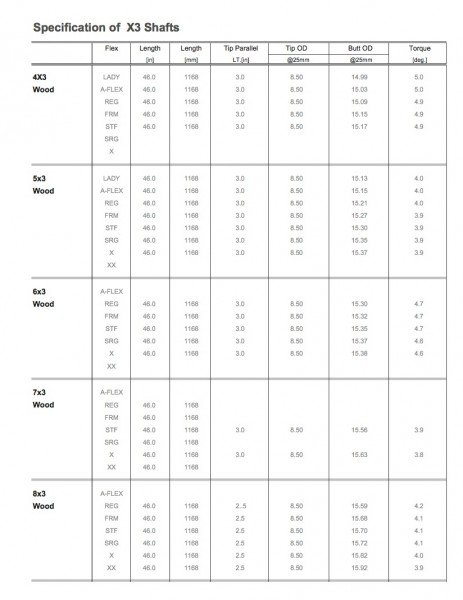

Joe Miera, Director of Tour Operations for Matrix Shafts, has been fitting tour players with Matrix shafts for 10 years. He took the time to answer questions from GolfWRX Managing Editor Zak Kozuchowski about his company’s new product line. Scroll to the bottom for specs.

ZK: Last year Matrix released its M3 “Black Tie” shaft. Now, we’re seeing photos of tour players testing the X3 “White Tie” shaft. Who do these shafts target and how do they differ?

JM: Every year Matrix strives to improve performance of all golfers through shaft innovations. We are continuing to fill our Matrix Flight System portfolio with shafts, the M3 “Black Tie” replaced the FM2 and is low-launch, low-spin shaft. The X3 “White Tie” replaced the X-Con, which is a high-launch, low-spin shaft. We will also be releasing the highly anticipated Q3 “Red Tie,” which replaces the HD Series, and is a mid-launch, mid spin shaft, completing the new Matrix Flight System (MFS).

ZK: What about these shafts make them perform in the way that they do, and where do the names come from?

JM: Aside from some of the structural patents like the 16-sided hexadecagonal internal chassis and our manufacturing techniques, we developed a DEC (Deformation of Energy Curve) modeling system that is vastly superior to designing on a traditional EI Curve. That’s what gives us the ability to leapfrog some older design ideas. The combination of color and letters in the new MFS allowed us to simplify things for greater understanding. For people that remember colors well, it’s red (mid-launch), black (low-launch) and white (high-launch), which happen to be our corporate colors. For those that can think of the Alphabet vertically off the ground — A being the lowest — they can picture the apex of the ball at the letter M, a bit higher for Q and higher yet for X. It’s comprehensive, but a simple memory tool for players, tour reps and fitters.

ZK: When will these shafts be available and how much will they cost?

JM: The OZIK M3 Black Tie and OZIK X3 White Tie shafts are available now and the OZIK Q3 Red Tie will be available in early January 2013. The MSRP for each will be $375.

ZK: What are the tolerances?

JM: As you may know, Matrix started as many years ago as a boutique product, available only through clubmakers. We have never wavered from the lessons learned along the way from them. The input helped Matrix become a leader in the field of shaft manufacturing and we are very proud of our reputation for having exacting standards. It may not be well known by some of your readers but our system is set up in such a way that all Matrix Shafts follow the same manufacturing process and procedures as the OZIK TP line.

ZK: We’ve heard from fitters that Matrix shafts tend to produce very good ball speeds for golfers. Why is this?

JM: Advanced design tools and materials are key ingredients in shaft development, while advanced production techniques allow companies to push the envelope of what is possible to produce. While it’s an open secret on tour that many players gain as much as 4 mph of ball speed using our shafts over conventionally designed shafts, (COO) Daniel You and his team are unlikely to give the recipe to the rest of the world. That being said, the structural design and manufacturing of our shafts is considerably different compared to how most traditional shafts are made. We don’t introduce and release products just to do it. We do it to build a better mousetrap, so to speak. The forward momentum of design, advancement of materials and the application of lessons learned help us incrementally move forward from previous models. We like to believe that our increments are just a bit bigger than expected.

ZK: There’s a lot of talk about shaft inconsistency – one company’s stiff flex can be another’s regular flex, and vice versa. How do you determine how stiff to make your regular flex, stiff flex, etc.?

JM: That’s a great question. It’s also a very difficult question to answer. As manufacturers, we each have to make our own decisions as to what we are going to design and implement as our flexes. There are no accepted standards for testing protocols or overseeing body in golf shafts. To decide on our flexes, we utilize player and robot testing and base our flexes on ideal maximum deflection at a given swing speed.

ZK: What do you see as being more important in the shaft industry going forward: materials or construction methods?

JM: Another great question, but you can’t separate the two. Our aim from day one has been to make the finest golf shafts available. In order to do that it has to be a holistic approach combined with sweating the small stuff. Using the very best materials in the world and combining it with mediocre manufacturing produces truly flawed products in our estimation. Alternately, if you are not willing to use cutting edge materials you won’t be able to produce the best shaft available. In simpler terms, a drag racer does not use fuel with a lower octane when trying to maximize performance. However, I believe that the key to producing the finest shafts in each class is having world-class design and manufacturing. At that point, a design engineer can choose materials to fit the price categories golfers are comfortable with.

Click here for more discussion in the “Tour/Pre-release equipment” forum.

- LIKE7

- LEGIT1

- WOW1

- LOL0

- IDHT1

- FLOP0

- OB0

- SHANK1

Whats in the Bag

Steve Stricker WITB 2024 (April)

- Steve Stricker WITB accurate as of the Zurich Classic. More photos from the event here.

Driver: Titleist TSR3 (9 degrees, C4 SureFit setting)

Shaft: Fujikura Motore Speeder VC 7.2 X

3-wood: Titleist 915F (13.5 degrees)

Shaft: Mitsubishi Tensei CK Pro White 80 TX

Hybrid: Titleist 816 H1 (17 degrees)

Shaft: Fujikura Motore Speeder VC 9.2 X

Irons: Titleist T200 (3, 4), Titleist T100 (5-9)

Shafts: Project X 6.5

Wedges: Titleist Vokey SM8 (46-10F @55), Titleist Vokey SM10 (54-10S @53), Titleist Vokey SM4 (60 @59)

Shafts: True Temper Dynamic Gold X100 w/Sensicore

Putter: Odyssey White Hot No. 2

Ball: Titleist Pro V1x

Grips: Golf Pride Tour Velvet Grip Rite

Check out more in-hand photos of Steve Stricker’s clubs here.

- LIKE26

- LEGIT2

- WOW0

- LOL1

- IDHT1

- FLOP0

- OB0

- SHANK1

Whats in the Bag

Alex Fitzpatrick WITB 2024 (April)

- Alex Fitzpatrick what’s in the bag accurate as of the Zurich Classic.

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Fujikura Ventus TR Black 7 X

Hybrid: Ping G430 (19 degrees)

Shaft: Fujikura Ventus Black HB 10 TX

Irons: Ping iCrossover (2), Titleist T100 (4-PW)

Shafts: Fujikura Ventus Black HB 9 TX (2), Nippon N.S. Pro Modus 3 Tour 120 X (4-9)

Wedges: Titleist Vokey Design SM10 (50-12F, 56-12D, 60-08M)

Shafts: Nippon N.S. Pro Modus 3 Tour 120 X

Putter: Bettinardi SS16 Dass

Grips: Golf Pride MCC

Check out more in-hand photos of Alex Fitzpatrick’s clubs here.

- LIKE12

- LEGIT0

- WOW0

- LOL1

- IDHT1

- FLOP0

- OB0

- SHANK0

Equipment

What’s the perfect mini-driver/shaft combo? – GolfWRXers discuss

In our forums, our members have been discussing Mini-Drivers and accompanying shafts. WRXer ‘JamesFisher1990’ is about to purchase a BRNR Mini and is torn on what shaft weight to use, and our members have been sharing their thoughts and set ups in our forum.

Here are a few posts from the thread, but make sure to check out the entire discussion and have your say at the link below.

- PARETO: “New BRNR at 13.5. Took it over to TXG (Club Champ but TXG will always rule) in Calgary for a fit. Took the head down to 12, stuck in a Graphite Design AD at 3 wood length and 60g. Presto- numbers that rivaled my G430Max but with waaaaay tighter dispersion. Win.”

- driveandputtmachine: “Still playing a MIni 300. The head was only 208, so I ordered a heavier weight and play it at 3 wood length. I am playing a Ventus Red 70. I play 70 grams in my fairways. I use it mainly to hit draws off the tee. When I combine me, a driver, and trying to hit a draw it does not work out well most of the time. So the MIni is for that. As an aside, I have not hit the newest BRNR, but the previous model wasn’t great off the deck. The 300 Mini is very good off the deck.”

- JAM01: “Ok, just put the BRNR in the bag along side a QI10 max and a QI10 3 wood. A load of top end redundancy. But, I have several holes at my two home courses where the flight and accuracy of the mini driver helps immensely. Mine is stock Proforce 65 at 13.5, I could see a heavier shaft, but to normal flex, as a nice alternative.”

Entire Thread: “What’s the perfect Mini-Driver/Shaft combo? – GolfWRXers discuss”

- LIKE6

- LEGIT1

- WOW0

- LOL0

- IDHT2

- FLOP1

- OB0

- SHANK7

-

19th Hole3 weeks ago

19th Hole3 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole6 days ago

19th Hole6 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole3 weeks ago

19th Hole3 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole6 days ago

19th Hole6 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole2 weeks ago

19th Hole2 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole2 weeks ago

19th Hole2 weeks agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

Joe Perez

Jul 28, 2021 at 3:09 pm

Why doesn’t the spec chart list the shaft’s weight?

Jim Haire

Dec 5, 2012 at 4:06 pm

Great shaft! Had it about 3-4 weeks now in a ping anser. High long bombs. It kicked the graphite design tour ad di 6 out of the bag. The feel is also sweet