Equipment

The “real” firsts of the golf industry

Any time a new club is introduced, the phrase “for the first time ever…” is usually not far behind. In some groundbreaking cases, the statement is completely true and applies to the entirety of the modern golf industry, while in other cases it’s only a “first” for that particular manufacturer—so watch for the asterisk.

This ultimately begs the question: What were the true firsts of modern golf technology, and how did they change the direction of design?

After some in-depth research here is my list of true firsts.

The first metal driver: TaylorMade Original (1979)

As the story goes, Gary Adams took out a $24,000 loan against his house to found TaylorMade Golf. The focus of this new endeavor was to create a driver made from metal and to make persimmon a thing of the past. The first product to market was a 12-degree metal driver; the very first of it’s kind. It still took more than a decade to make persimmon obsolete, but as they say, the rest is history.

Moveable weight: TaylorMade R7 (2004)

TaylorMade engulfed the driver space when it launched the 300 Series metal woods and went on an ever further tear when it introduced the 500 series (they skipped the 400 names). Interesting fact—the number four is mostly avoided in global marketing because “four” is pronounced almost exactly the same as the word “death” in Chinese. It’s the same reason Callaway went from FT3 to FT5.

When the R7 Quad debuted, it was a game-changer because it was the very first driver to offer the consumer easily adjustable weights to help golfers fine-tune ball flight. I say “consumer” because club builders and tour vans had been using hotmelt to adjust CG for some time, but on a consumer level, the ability to tweak your driver on the range was unheard of. It was a lot of weight too: 24g total—more than 10 percent of the clubhead’s mass. After the R7 Quad, drivers would never be the same!

Sliding weight: Mizuno MP-600 (2007)

When it comes to drivers, Mizuno’s reputation for irons overshadows its history of producing innovation in the metal woods space. The MP-600 was the very first driver to offer a sliding weight track to fine-tune CG. Although the weights were only 8g a piece is was extremely innovative at the time and created new options for OEMs to help reposition mass around larger heads.

They have utilized the technology on and off over the years, but the newest ST200G is by far the most adjustable Mizuno driver yet.

Graphite (composite) shaft: Golfcraft (1954)

In 1954, Golfcraft (the same Golfcraft discussed here: Greatest Titleist Irons of all Time) announced a breakthrough in golf shaft technology: a shaft made from fiberglass that could one-day make steel obsolete, the same way steel made wood obsolete.

Beyond just the promise of more consistent shots, Golfcraft also declared the shaft vibration-proof, rust-proof, and almost unbreakable, something that modern club throwers would know is quite untrue. Although they never took off like the steel they promised to replace, it was the very first non-steel shaft to enter the market.

Soon after, a few other companies started to enter the market to offer these new fiberglass shafts for golfers, but it wasn’t until the late 1960s when Frank Thomas (yes, the same Frank Thomas that went on to be the technical director of the USGA ) used graphite to produce shafts for Shakespeare—the fishing rod company.

This is when the market completely evolved, and not long after its introduction, graphite shaft manufactures started to pop up to get into the game. Thanks to a better understanding of materials, and the physics of the golf swing with the help of highspeed camera and tracking tools, graphite shafts have never been more advanced than they are today.

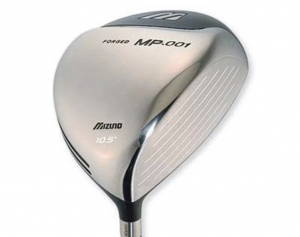

Carbon composite crown: Mizuno MP-001 (2003)

The Mizuno MP-001 was released the year after the much talked about, but often ridiculed, Callaway C4—the very first (and only) carbon composite driver. It came in three different models released in succession; 360cc, 400cc, and then eventually 460cc, which if you are on the lookout for a value, the 460cc driver is still high on the list.

Beyond what Callaway was up to with Fusion Technology, the MP-001 was the very first driver to utilize a multi-material crown to save weight, and the results speak for themselves. It sounds extremely solid, offered low spin, boosted MOI—and looked really cool too.

Multilayer solid core urethane ball

This is the one breakthrough that has a hard-to-find solid start date—no pun intended. The first multilayer performance balls were the Precept (Bridgestone brand) EV Extra Spin and Extra Distance. At the time of its introduction around 1995, the Precept EV was competing against the Titleist Professional, which was still a wound ball. The EV offered more distance and great control while still not quite competing from a short game control perspective.

The biggest mainstream change came when Mark O’Meara won the 1998 Masters with a multi-layer Strata ball and then went on to win the Open Championship the same year. Many attribute his win in part to the fact that he was using a new Strata multi-layer urethane ball that offered less spin off the driver and more spin around the greens.

A year later, in 1999, a year before Titleist introduced the Pro V1 (October 2000), Nike launched the Tour Accuracy ball (manufactured by Bridgestone), and with it came this…

Soon after, the Pro V1 arrived, and as the market leader, the impact was a seismic shift. The wound ball was officially dead, but we can’t forget the change that Precept/Bridgestone pioneered half a decade before.

What other “firsts” of the golf industry do you think are notable, GolfWRXers?

- LIKE256

- LEGIT42

- WOW8

- LOL5

- IDHT4

- FLOP2

- OB3

- SHANK16

Whats in the Bag

David Lipsky WITB 2024 (April)

- David Lipsky what’s in the bag accurate as of the Valero Texas Open. More photos from the event here.

Driver: TaylorMade Qi10 (9 degrees)

Shaft: Mitsubishi Tensei AV Raw Blue 65 TX

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Mitsubishi Tensei AV Raw Blue 75 TX

5-wood: TaylorMade Qi10 (18 degrees)

Shaft: Mitsubishi Tensei AV Raw Blue 85 TX

Irons: PXG 0311T Gen5 (4), PXG 0317 ST (5-PW)

Shafts: KBS Tour FLT 125

Wedges: PXG 0311 Sugar Daddy II (50-10C), Titleist Vokey Design SM10 (56-10S, 58-04T)

Shafts: KBS 610 Wedge 120

Putter: TaylorMade Spider Tour

Grip: SuperStroke Zenergy Flatso 1.0

Grips: Golf Pride MCC

Check out more in-hand photos of David Lipsky’s clubs in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Ben Taylor WITB 2024 (April)

- Ben Taylor what’s in the bag accurate as of the Valero Texas Open. More photos from the event here.

Driver: Titleist TSR3 (9 degrees, B2 SureFit setting)

Shaft: Fujikura Ventus TR Blue 7 X

2-wood: Titleist TSR (B2 SureFit setting)

Shaft: Fujikura Ventus TR Blue 7 X

3-wood: Titleist TSR3 (15 degrees, D4 SureFit setting)

Shaft: Fujikura Ventus TR Blue 8 X

Hybrid: Titleist TSi3 (20 degrees)

Shaft: UST Mamiya Recoil Prototype Utility 110F5

Irons: Titleist T100 (4-9)

Shafts: True Temper Dynamic Gold Tour Issue X100

Wedges: Titleist Vokey Design SM10 (46-10F, 50-12F, 56-10S, 60-04T)

Shafts: True Temper Dynamic Gold Tour Issue X100

Putter: Scotty Cameron T-9 Proto

Grip: SuperStroke Zenergy Tour 3.0

Grips: Golf Pride MCC

Ball: Titleist Pro V1x

More photos of Ben Taylor’s WITB in the GolfWRX forums.

- LIKE4

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Aretera officially launches Alpha One shafts, available at Club Champion

As we reported earlier this year, Alex Dee, along with a group of industry veterans, have officially launched their own golf shaft company, leading with the Alpha One. Now you can get your hands on that shaft at Club Champion.

The Alpha One Blue and Gray series are debuting Aretera’s PowerGrid technology. Aretera is the first company to use spread tow woven carbon fabric in multiple layers at full length comprising over 50 percent of the shafts weight in design for maximum stability with a uniform feel.

These materials, novel in their application at this level, aim to offer high-level structural benefits compared to traditional unidirectional composites.

Speaking on the new shafts, Alex Dee stated:

“A lot of shafts have had to sacrifice feel to get stability. We’ve found ways to get it back. And it’s not a compromise.”

Aretera launches on April 1, 2024 at all Club Champion locations nationwide.

- LIKE3

- LEGIT0

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole1 week ago

19th Hole1 week agoJohn Daly stuns fans into silence with brutal opening tee shot on PGA Tour Champions

-

19th Hole2 weeks ago

19th Hole2 weeks ago2-time major champ announces shock retirement from the sport at age of 33

-

19th Hole1 week ago

19th Hole1 week agoCharlie Woods finds it tough going on American Junior Golf Association debut

-

19th Hole2 weeks ago

19th Hole2 weeks agoEdoardo Molinari reveals the latest PGA Tour golfer to turn down ‘good offer’ from LIV Golf

-

Equipment3 weeks ago

Equipment3 weeks agoBest driver 2024: The best driver for you, as recommend by expert club fitters

-

19th Hole2 weeks ago

19th Hole2 weeks agoScottie Scheffler had an interesting response when asked how he ‘quiets the noise’ following Players victory

-

19th Hole2 weeks ago

19th Hole2 weeks agoJon Rahm dealt fresh blow to hopes of qualifying for 2025 Ryder Cup

-

19th Hole23 hours ago

19th Hole23 hours agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

Delbert

May 31, 2020 at 10:45 pm

The first sand wedge by Gene Sarazen

Psarro

May 29, 2020 at 11:15 pm

I would think range finders should be on the list?

storm319

May 18, 2020 at 11:40 pm

Correction: The Precept EV Extra Spin was a 2-piece with a TPU cover. The first multilayer solid core ball was the Top Flite Strata in 1996 (cover was synthetic, but not urethane).

arnaud

May 16, 2020 at 4:28 pm

Tom Wishon (for SNAKE EYES, GOLFSMITH then WISHON GOLF) :

1st driver with adjustable hosel sleeve (1994)

1st heel weighted / draw bias driver (1996)

1st metal wood with cup face construction (1997)

1st driver with moveable weight for CG / draw / fade bias (2005)

1st illegal driver to achieve a COR of 0.900 (2006)

1st fairway wood to achieve a COR of 0.830 (2004)

1st hybrid to achieve a COR of 0.830 (2008)

1st set of irons to achieve a COR of 0.830 (2009)

and this is a short list …

andrew_s

May 14, 2020 at 5:18 am

COBRA E9 face technology (dual roll)

ColinKelvin

May 13, 2020 at 11:54 am

Ping Anser – a headshape with bumpers and a plumber’s neck which has been #1 in golf ever since, copied by all the leading putter makers over and over and over again.

Ping irons – peripheral weighting / game improvement through the ages.

Jin Teh

May 13, 2020 at 9:40 am

You missed the world’s first two piece ball…the first non core wound golf ball…Dunlop

DDH around 1980…I was the first to break the ball in half on with a driver!!!

Another first bring launched today…Face thickness fitting…drivers with different face thickness for different swing speeds 20-40 yards more 1st swing..who cares if they are not USGA Conforming…go to http://www.krankgolf.com

Delbert

May 31, 2020 at 10:41 pm

My college golf team was given the DDH. They were workin out great until some started break in half.

D

May 13, 2020 at 9:21 am

Ping putters

Ping irons

Adjustable hosels, who started that?

Ping Hoofer with dual strap

J-Dog

May 12, 2020 at 7:08 pm

I thought the Callaway C4 would technically be the first driver to have a carbon crown.

Nicklaus#1

May 12, 2020 at 1:09 pm

I could of sworn Northwestern made the 1st metal driver.

alexva

May 12, 2020 at 11:51 am

Precept Flying Lady was hot for a while among better men players

matt

May 14, 2020 at 7:43 am

haha i remember that

Brandon

May 11, 2020 at 11:23 pm

How about that powerbilt driver with the nitrogen inside?

Stanley

May 11, 2020 at 10:52 pm

Pxg and their foam filled irons

Jack

May 12, 2020 at 8:20 am

Not a first . Taylor made , and maybe even someone before that.

Nack Jicklaus

May 31, 2020 at 4:35 pm

And their woods were foam filled before they made the foam filled irons too.

C

May 11, 2020 at 9:52 pm

Scotty Cameron Putter Headcovers changed everything in what a headcover could be…seems trivial but he certainly upped the ante…Inspired a whole new generation of designers over the years in the process!

Holla

May 11, 2020 at 7:47 pm

Pedersen began making metal headed woods back in 1927.

KP

May 11, 2020 at 7:45 pm

Let’s not forget PING and the innovation of perimeter weighted irons!

Steve

May 13, 2020 at 9:24 am

This!!

Daniel Howard

May 11, 2020 at 7:22 pm

Spalding Tour Edition

Gary

May 13, 2020 at 11:46 am

Yep, first urethane cover.

Think A. Little

May 11, 2020 at 6:12 pm

First driver with removable/sliding weight???

Whoever used lead tape first on whatever they were using.

Eric Seatvet

May 11, 2020 at 6:05 pm

Adams Golf – Hybrids. They may have not been the first, but they made category big.

BodineJCS

May 11, 2020 at 5:51 pm

Taylormade Golf …founded in Mchenry Illinois , my hometown were I still live … Those were the days …

Lou Cesarek

May 11, 2020 at 2:55 pm

Investment cast irons.

Titleist AC 108 and Ram Accubar .

The Accubar had the largest sweet spot of irons during this time frame .

Regis

May 11, 2020 at 2:50 pm

First rescue (hybrid for non TMAG) Taylormade

Richard Douglas

May 11, 2020 at 2:29 pm

Hogan Edge: the first perimeter-weighted, forged iron

Cleveland VAS 792: the first set of garden tools to be converted into golf clubs

Ping Anser

TM Rocketbladz

Polara Ball

SoftSpikes

Nack Jicklaus

May 11, 2020 at 9:53 pm

I think I was one of about 10 people who thought the VAS irons were beautiful back then! I still laughed out loud when I read your comment though…

dwayne bretzky

May 11, 2020 at 2:18 pm

tough luck for Mizuno making those great innovative moves in the driver industry and really never getting a hold of the market share at all over the years. I have used multiple mizuno drivers over the years and they were all great..I guess this really proves how marketing campaigns help a product.

Nick

May 11, 2020 at 1:29 pm

I think you’d have to include the r11. First white driver, sparked a market frenzy. This club and Taylormade’s marketing made everyone seriously question “Should I be playing a white driver?” It allowed companies to see the success that selling a product predominantly a different color than black or grey. This same idea holds true to Taylormade’s red putters…now Odyssey had their own line of red putters too.

The thing that always makes me chuckle is how they are such masterful marketers. Not only did they convince the golfers around the world that the coolest drivers are white, they flip the market on it’s head and come out with the R1 SPECIAL EDITION BLACK DRIVER! I mean how genius…like it or not they know how to play the game, literally and figuratively!

stam

May 11, 2020 at 6:10 pm

COBRA made the first white driver..

Holla

May 11, 2020 at 7:30 pm

MacGregor made a white driver in the 50’s

Kep

May 11, 2020 at 1:12 pm

I have an old Yonex Super ADX 0 driver with a pressure molded graphite head. I believe this was before the composite Callaway C4 mentioned here but i cant seem to find any info about it.

JIM

May 11, 2020 at 6:21 pm

My wife still has a C4 sitting in the garage, I know for a fact it lasted 2 rounds in her bag….I had to take her out to buy a new driver right away. Also the instructor at the range I use was the first to show us that grip pressure took most of the good away from movable weights in driver heads….his slog-gen the tighter the grip the more money you waste on movable weights in your driver.

Mark M

May 13, 2020 at 9:21 am

That’s exactly the club I was thinking of when I read the C4 listing. I think it was mid to late 90s – came out the same time as the Yonex Super ADX tour Forged cavity back irons which were magic.