Equipment

How the idea of shaft frequency began

Forty years ago, Kim Braly and his father Dr. Braly went down to West Palm Beach to visit Wilson Golf, and that trip forever changed the way the golf industry thinks about the shafts in golf clubs.

“My father and I invented frequency matching,” Kim told me.

“And what’s that?” I asked.

“It’s the process of matching the stiffness of the shafts in your clubs to the heads so you can hit a golf ball rather than snap the shaft or hit the ball all over the place,” Kim said.

OK, that got my attention. So I ask how he stumbled upon the idea.

“My dad was an engineer and got into golf,” Kim said. “Eventually, I got interested in golf as well. In the early 1980s, we went to see the original ‘Iron Byron.’”

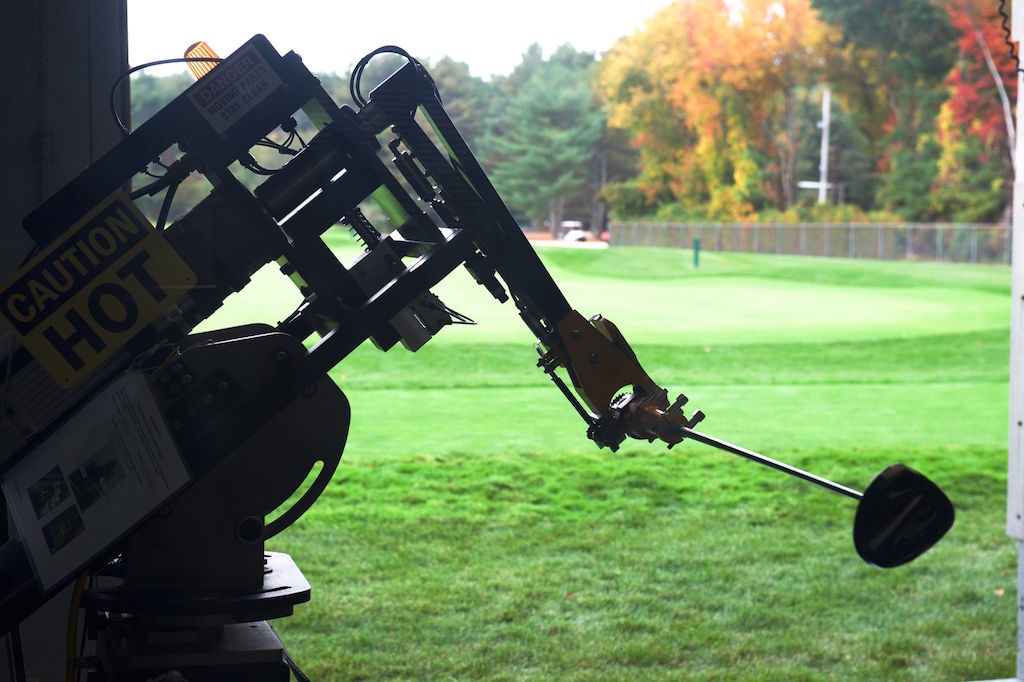

A modern-day golf robot at Titleist’s Manchester Lane Test Facility.

Iron Byron was the first club-testing machine, and it was modeled after smooth-swinging legend Byron Nelson. It’s basically an early robot — a motor in a box with an arm — built to use a regular golf club to hit a golf ball.

Kim and Dr. Braly watched the engineer operating Iron Byron put a club into the mechanical arm, place a ball in front of the club face and then press a button to swing the club. The result: perfection. It produced a high, piercing ball flight that was hit on a rope, not far removed from the storied ball flight of Nelson himself. This was followed by another and another. Kim and his father were ecstatic.

With great anticipation, they watched the engineer load the next club. The results were much different. Balls flew all over the place. The dispersion was awful. The Wilson engineer operating Iron Byron slowed down the machine. Balls flew shorter distances, but they landed closer together. The dispersion had been reduced. This was the inception of their game-changing idea; dispersion was a result of certain shaft characteristics matched with a club head and swing speeds. This “AH HA” moment changed how we fit and purchase golf clubs today.

Based on this observation, Kim and Dr. Braly designed a method to measure the performance of a golf shaft. Later, this led to the concept of frequency: very simply, stiffness is not the letter on the shaft, but a measurement based on characteristics like weight of shaft, weight of the head, length of the shaft and several other characteristics. The year was 1977 and they submitted a patent on this idea called “Frequency Matching.”

Armed with the power of measurement, Kim was ready to change golf shafts forever. He and his father started traveling the PGA Tour, and in doing so became the first “PGA Tour Van.” Over the last 40 years, Kim has worked as a researcher and designer, mastering the golf shaft. He’s worked at True Temper, Royal Precision and is currently as the head designer of research and development at KBS Golf Shafts.

In 2008, Kim launched a shaft company called KBS, which became the fastest growing shaft company in golf. Since that time, the company has gotten some of the best golfers in the world to use its shafts products, including Rickie Fowler, Justin Rose and Phil Mickelson.

The next time you’re struggling with shots that fly sideways, think about Kim and Dr. Braly. You might want to try try being fit for shafts if you haven’t already, because they may just be the most important part of your golf club.

- LIKE217

- LEGIT33

- WOW16

- LOL6

- IDHT1

- FLOP4

- OB0

- SHANK14

Whats in the Bag

Sahith Theegala WITB 2024 (July)

- Sahith Theegala what’s in the bag accurate as of the 3M Open.

Driver: Ping G430 LST (10.5 degrees @9)

Shaft: Project X HZRDUS Black 60 TX

3-wood: Ping G430 Max (15 degrees @13.5)

Shaft: Graphite Design Tour AD DI 8 TX

5-wood: Ping G430 Max (18 degrees @17.5)

Shaft: Graphite Design Tour AD DI 8 TX

Irons: Ping i210 (3), Ping Blueprint S (4-W)

Shafts: Graphite Design Tour AD DI Hybrid 85 X (3), Project X 6.5 (4-W)

Wedges: Ping s159 (50-12S, 54-12S), Ping Glide 2.0 (58-06TS)

Shafts: Project X 6.5 (50), True Temper Dynamic Gold Tour Issue S400 (54, 58)

Putter: Ping TR 1966 Anser 2 prototype

Grip: SuperStroke Zenergy Flatso 2.0

Grips: Golf Pride Tour Velvet

Ball: Titleist Pro V1

See more photos of Sahith Theegala’s WITB in the forums.

- LIKE3

- LEGIT1

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Billy Horschel WITB 2024 (July)

- Billy Horschel what’s in the bag accurate as of the 3M Open. More photos from the event here.

Driver: Titleist GT3 (9 degrees, C1 SureFit setting)

Shaft: Fujikura Ventus TR Black 6 X

3-wood: Titleist TSi2 (15 degrees, C1 SureFit setting)

Shaft: Project X HZRDUS Smoke Black 70 6.5 TX

5-wood: Titleist TSi2 (18 degrees, B1 SureFit setting)

Shaft: Project X HZRDUS Smoke Black 80 6.5 TX

Irons: Titleist T100 (3, 5), Titleist 620 MB (6-9)

Shafts: True Temper Dynamic Gold 120 X100 (3-9)

Wedges: Vokey Design SM10 (46-10F @45, 52-12F, 56-08M), WedgeWorks (60-V @62)

Shafts: True Temper Dynamic Gold 120 X100 (46), Dynamic Gold Tour Issue Onyx S400 (52-60)

Putter: Ping Sigma 2 Tyne 4

Grips: Golf Pride Tour Velvet Cord, Golf Pride Tour Velvet

Ball: Titleist Pro V1x+ Prototype

Check out more in-hand photos of Billy Horschel’s clubs in the forums.

- LIKE3

- LEGIT1

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

GolfWRX member testing: Reviewing Cleveland CBX 4 ZipCore wedges

Our forum faithful are well acquainted with the incredible giveaways and review opportunities in the realm of threads and comments, but we want to ensure front-page readers are involved as well.

Check out what GolfWRXers are saying about Cleveland’s new CBX 4 ZipCore wedges after putting them through their paces.

We have five GolfWRX members testing Cleveland’s CBX 4 ZipCore wedges.

Cleveland on CBX 4 ZipCore wedges

“New CBX 4 ZipCore wedges bring premium versatility and elite forgiveness together in a highly refined, sharp-looking design that blends perfectly in the bag with modern cavity back or hollow iron sets. And now, these CBX series wedges get all of Cleveland Golf’s latest tour caliber technologies to create our finest cavity back wedge yet.”

How we choose our testers

GolfWRX staff evaluates each entry against the criteria laid out in the testing thread to determine the best fit for each specific product — For example, if a game-improvement iron is being tested, game-improvement iron-playing golfers will be considered.

Member testers

- @mikes919

- @ALTSean

- @awtryau89

- @vsabre

- @rbilramz

Review themes

- Forgiveness

- Ease of use out of bunkers

- Easy to play from a square position

- Surprisingly compact given the amount of cavity technology

- Impressive spin

Member review highlights

@mikes919

“Initial impression is that these wedges are very clean and high quality in appearance. They have a durable-looking satin finish, and the cavity back insert blends nicely with the steel; you barely notice that it’s an insert. Shafts and ferrules are pristine. The stock Lamkin Crossline grips are more rubbery than the tour velvets I’m used to, but the tread pattern gives a nice locked-in feel. The face milling is very pronounced, and the grooves feel ridiculously sharp. They are quite chunky from the back. The soles are big and wide, with a lot of leading and trailing edge relief. If you’re a digger with wedges, you are going to love these things. Comparing the soles and overall profile to my Vokeys, the difference is most obvious on the 54*. The CBX4 sole is much wider than anything I’ve played in this loft range before. While they’re both S-grinds, the CBX4 grind is much more pronounced on both the leading and trailing edge.”

“Flip the wedges over to the normal address position and it’s a totally different story. You would never know there’s so much sole and tech behind this club! While the topline is slightly thicker on the CBX4, I was pleasantly surprised that the appearance is much more “player” oriented than I would have thought. They don’t feel nearly as big here. The only thing I notice at address is that the CBX4 leading edge sits a little higher, because of that leading edge relief…”

“The other thing you’ll notice at address is the milling and groove pattern of the wedges. The HydraZip face technology is really cool to see and feel. Just rubbing your fingers across the face of the wedge, you know these are going to shred some ball covers! Zooming in on the grooves themselves is even more impressive, with a slightly different pattern between the low and high lofts:

…”My practice areas are sandy and the balls are hard as a rock, but I haven’t noticed any wear whatsoever on the wedge faces yet. Still spinning great, they really grab the ball.

…”These wedges like to be played square. Just line it up, focus on making reasonably clean contact, and you’ll be rewarded with a consistent flight and great spin.”

…”Today I put the Cleveland’s back in the bag for a rainy round. It started off drizzling and was just absolutely pouring by about the 5th hole. I was extremely impressed with the amount of spin I was able to generate with the CBX4’s. I found myself needing to adjust and fire at the pin much more than with my Vokeys; I was getting one hop stops, even in a heavy downpour.”

@ALTSean

“I got the wedges out for another round this morning. It’s been raining and warm here in NOVA so the conditions are on the softer side at the moment and the forgiveness of the soles shines in these kind of conditions. We don’t ever really get super firm or fast conditions so the extra bounce and size of the soles probably will work well here year round.”

@awtryau89

“As you can see, these wedges have some serious grinds. The pre-worn leading edge is on the 54 & 60. Even though these are larger than my Vokeys, they can be manipulated to hit any shot you like.”

“Looks are subjective but these look great. No real offset and not too rounded. They are on the larger side but unless you put them next to a smaller wedge, you’d never know they are a bit on the large side.”

“Feel is really good for cast and cavity back. They have a sharp click and aren’t muted but feel solid. The shafts are KBS Hi Rev 2.0. I play KBS C Taper Lite 110s in my irons so these mesh very well. Overall the pairing of the shafts and heads work very well. You won’t mistake them for soft forgings but overall they are softer feeling than my SM 9 KBS Tour 130 wedges.”

“Spin is exceptional. My Vokeys aren’t old but these definitely have much more bite than the SM9s. The hydro treatment is real. We played very soggy fairways and the spin I saw was crazy. One hop and stop pitches from short distances were the norm. It will be interesting to see what they offer when our course drys out.”

“Forgiveness is what these wedges are all about. I didn’t have any bad misses today that the wedges saved me strokes but I did notice some shots that weren’t perfect ended up being a good bit closer to pin high than expected.”

“Played again today and basically learned these wedges are a cheat code out of bunkers. So easy to hit any shot. I hit it close 2-3 times green side but my best shot may have been from a fairway bunker 127 out, up against a lip, with the 50 degree. Hit it to about 12 feet and promptly 3 putted. Oh well.”

“These wedges have stayed in my bag. Having played Vokeys for so long, I had to convince myself to commit for a while and put the ego aside. One big thing that has stood out to me is full shots and the better results I have seen there. These wedges offer so much more forgiveness that I have to be careful. I’ve had to adjust my yardages since they just play longer. I even took them to have the lofts checked because I thought they were strong and they were spot on so its just helping the ball go farther on those slight misses around the face.”

“I’ve stated they are just so easy out of the sand. I have hit some great shots and even holed out a few times from bunkers. I have to be careful on wet sand with the larger surface area on the soles but overall they just make the game easier.”

“Chipping is also so easy. I go against the grain so many times playing on Bermuda and the pre-worn leading edge just helps the wedge from sticking. I work very hard on shaft lean and keeping the hands ahead while chipping. The leading edge helps me play square face shots this way but you can also open them up.”

“I’ve had playing partners comment on my short game a few times the last few weeks and then ask to look at my wedges. Every one of them are surprised. I play to a 7 but one of my buddies who is a 1 has had some chipping issues lately and he started playing out of my bag one round. He plays ZipCores and probably won’t let his ego buy some but he had to admit he hit some of his best chips and shots with them. Great wedges for the common man.”

@vsabre

“Wedges arrived well packaged and perfect to the requested spec…super clean look and very appealing over the ball.”

“Performance – Range 3/4 Swings…Our practice range turf is slightly sandy from continuous repair with tight lies that are not forgiving for either chunky or blade swings. A really good wedge test and the CBX4s did not disappoint. For not having touched a club for two weeks the CBX4s were incredibly easy to hit. Like cheat code easy to hit as someone else mentioned.”

“Over to the practice green and hit a variety of shots with each wedge and honestly it’s nearly impossible to chunk one (which I can do from time to time). Soft feel coming off the club and I had forgotten what great wedges Cleveland makes, and of course, having a consistent fit spec through the entire iron set makes a huge difference. I will say we’ll see how they fare on tighter, firmer lies around the greens as we approach summer.”

“They will be staying in the bag and I’m sure I’ll be adding a 60 in the next few weeks with the same specs.”

@rbilramz

“My first impression upon receiving the CBX4 was how much cleaner they looked than the previous version. The lack of black plastic badging really makes them look more like players’ irons. I don’t have the CBX3 to compare them with, but I think the footprint is smaller than the previous generation.”

“The comparison to my RTX6 is interesting as well. The CBX4 clearly has a much larger and more rounded sole and bounce. However, from the address, the size difference is pretty minimal. They both frame the ball nicely without looking oversized. I can also manipulate CBX4 in my hand really easily; the sole doesn’t cause any issues with the turf.”

“I am lucky to have a simulator in my basement (Foresight GCQuad) and a putting/chipping green in my backyard. This is where my first round of testing occurred. I started at the putting green, rotating between each club. I do 90% of my chipping with my 54, but I hit a few with all of them. There was an immediate improvement with the CBX4, as poor turf interaction was not punished as much. My putting green isn’t very large (not enough space for any pitches), so I quickly made my way to the basement.”

“After getting warmed up, I compared each club against my current gamer with 12 full-swing shots. I would throw away the worst 2 and then average the remaining. The results here kind of surprised me. Despite identical specs, the CBX4 was consistently 2-3 yards (or more) further than the RTX6. I was expecting more forgiveness and consistency but not additional distance. I should add that I am not looking for any additional distance either, I like my current gapping. I am guessing the distance is due to increased forgiveness as I rarely hit the ball in the exact center of the face.”

“Spin numbers were basically identical. There wasn’t enough difference between the two for any conclusion to be made. The lowest ones were around 8,000rpm with the 48 degree and consistently around 10,000rpm with the 54 and 60 degrees. The UtilZip grooves and face milling really work great. I wouldn’t have any problem stopping and even backing shots up with these wedges.”

“The dispersion of the CBX4s was a little tighter, but not drastically. On good strikes, they were probably identical. The only noticeable difference came on really bad strikes, where the additional stability of the CBX4 became obvious. It won’t save you from a bad strike, but the CBX4 stayed a little straighter and went farther when I put a bad swing on them. I was slightly surprised by this, as I expected the difference to be larger. I guess the shorter distances of wedges make the forgiveness less obvious.”

“Distance/spin/dispersion aside, it would be impossible to ignore the difference in feel between the RTX6 and CBX4. On good strikes, the RTX6 simply feels amazing. It’s very solid while equally soft. I think that’s the feeling that people love about traditional wedges. I don’t have a problem with the feeling of the CBX4, but it’s just not as pure. It is clearly a cavity-back feeling. Feel isn’t overly important to me, so I wouldn’t have a problem with that. I just want to point it out.”

“My next test was taking them to the course and getting real-world impressions. Before playing, I put the wedges through a pretty decent warm-up that included full swing, pitches, chips, and a bunch of sand shots. This is where the CBX4 shined for me. Off of imperfect lies and out of the sand, the more forgiving sole was impossible to ignore. I headed to the Par 3 course at Green Valley Ranch to put them both into action. I didn’t keep score because I wanted to hit basically every shot with both clubs, and putting shouldn’t matter. The par 3 course at GVR is short, but it is NOT easy. By starting every hole with two balls, and then hitting every subsequent shot with each wedge, I was able to get a pretty good comparison between the two. In the end, the CBX4 simply performed better for me. And by the last few holes, I was noticeably more confident over the ball with the CBX4. That may be the largest benefit for me. I simply approached tough angles or bad lies with less apprehension. I was less afraid of hitting it fat or blading a chip.”

“Long story short, I may be the ideal player for the CBX4 wedges. The 54 and 60 degree clubs are securely in my bag. I am going to stick with the ZX5 A wedge over the CBX4 48, but that’s mostly due to my preference to have my gap wedge match my irons. I almost always use it for full-swing shots, so I like them to match. The cavity back design adds some forgiveness (and distance?) on full-swing shots, but the real difference for me comes around the green. The sole design is simply easier to work with. No question about it. I truly recommend the CBX4 to anyone who struggles with their short game. At least for me, my biggest inclination to use them historically has been based on pride. The improved looks make that easier to get past, but the improved playability makes it impossible to ignore. I am deeply on team CBX for now.”

Bonus comment

“We played this afternoon after getting about 4 inches of rain yesterday and late night. It was soggy. These wedges are forgiving and the tagline “chunk a little less” is real. Today was a good day to have more forgiving wedges.” – @awtryau89

More about GolfWRX member testing

Member testing gives our forum members the opportunity to put the latest golf equipment through the paces. In exchange for getting a product to test (and keep), forum members are expected to provide in-depth product feedback in the forums, along with photos, and engage with the questions of other forum members.

For brands, the GolfWRX member feedback and direct engagement is a vital window into the perceptions of avid golfers.

You can find additional testing opportunities in the GolfWRX forums.

- LIKE6

- LEGIT1

- WOW1

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK0

-

Product Reviews2 weeks ago

Product Reviews2 weeks agoThree Swing Challenge: Testing the Edel Array F-2 putter

-

Equipment2 weeks ago

Equipment2 weeks agoWhat clubs do equipment free agents choose to use on tour? We found out

-

News2 weeks ago

News2 weeks agoHighlights from the Wilson Golf Product Testing and Fitting Experience at Pinehurst

-

News2 weeks ago

News2 weeks agoDavis Thompson’s winning WITB: 2024 John Deere Classic

-

19th Hole2 weeks ago

19th Hole2 weeks agoMajor champ ‘disappointed’ not to be chosen as U.S. Ryder Cup captain

-

Whats in the Bag4 days ago

Whats in the Bag4 days agoXander Schauffele’s winning WITB: 2024 Open Championship

-

19th Hole2 weeks ago

19th Hole2 weeks agoLIV pro explains how he believes players are ‘cheating’ on DP World Tour

-

19th Hole2 weeks ago

19th Hole2 weeks agoIan Poulter explains decision to skip Open Championship qualifying

TeeBone

Jun 7, 2017 at 5:34 pm

Further, frequency matching a set doesn’t mean that the clubs all have the SAME shaft flexibility, only that the DIFFERENCE in flexibility is uniform from club to club. As the clubs get shorter, frequency and stiffness increase. Add to this the fact that as the clubs get shorter and heavier, they are swung at a slower speed. In the end, each shaft in a set flexes more and more overall as the clubs get longer. This silly “dispersion” theory suggests that a shaft must flex a specific amount to behave consistently.

TeeBone

Jun 7, 2017 at 2:39 pm

Tour players, unless they have a specific shaft manufacturer deal, are free to play whatever shaft they want. Their decision to play graphite over steel has to do with performance, not money.

TeeBone

Jun 7, 2017 at 2:27 pm

So Iron Byron, set at any particular swing speed, only reproduces the same ball flight with one specific shaft flex? This “dispersion” theory would mean that the same shaft can behave quite differently, from swing to swing, for an otherwise same swing input. Nonsense. There is no mention of this in any of the best-regarded scientific studies of shaft flexibility. This is a made-up marketing story designed to sell equipment.

Ned

Jun 6, 2017 at 8:06 am

Brunswick Golf developed the Frequency Matching System in 1981!

Rico

Jun 6, 2017 at 4:04 pm

The article states that the Braly’s submitted a patent for “Frequency Matching” in 1977.

J.

Jun 5, 2017 at 7:15 pm

And stiffness of an EI profile may be invisible to CPM matching? Does SST PURE shaft alignment work better?

Skip

Jun 7, 2017 at 1:18 pm

SST pure is pure Kool-Aid. Drink it if you so choose.

tim crider

Jun 5, 2017 at 4:05 pm

There is no doubt that shots can be saved every round by every player with changes from the shaft to the swing weight to the compression of your golf ball,,, hell practicing on the driving range could improve your game. There is a lot to know about this game and if you have the money and the time you may be able to cash in on these findings. Think how much better play got when shafts changed to steel from hickory. A lot to know and even more to learn. How much more can be found and improved, it was a very good article.

Charles Bartholomew

Jun 5, 2017 at 3:38 pm

Interesting article. A little history lesson now and then is a good thing.

cgasucks

Jun 5, 2017 at 8:20 am

If the Iron Byron can make crappy shots with a shaft that isn’t compatible with its swing speed, imagine it with a human being.

talljohn777

Jun 5, 2017 at 12:14 pm

Yes, if you have a club shaft that is too soft you can slow your swing down to allow the clubhead time to catch up and square, but why would you want to do that? The preference would be to hit a club that matches your top swing speed allowing you to get the most out of your swing.

artie j

Jun 5, 2017 at 6:59 am

I didn’t know the backstory. Very cool article Ryan

SH

Jun 4, 2017 at 10:25 am

Yup, awesome