Equipment

Q&A: Mitsubishi Rayon answers questions about its new Tensei shafts

When Mitsubishi Rayon Composites releases a new shaft, serious golfers take notice. MRC has a history of producing some of the golf’s most popular shaft models, most notably with the best players in the world.

The company’s driver shafts were used to win 15 times on the PGA Tour in 2015 – that’s more than any other graphite shaft company. They were used to win 16 times on the European Tour – also more than any other graphite shaft company. A breakdown of the shafts used by the most famous golfers in the world is even more revealing: Jason Day, Rory McIlroy, Justin Rose, Sergio Garcia, Adam Scott, Phil Mickelson, Paul Casey and Tiger Woods all use MRC shafts.

In January, MRC will officially release its new TENSEI shaft family (pronounced TEN-SAY). Whereas most of the company’s shafts are made from three to six materials, TENSEI shafts combine 11 different materials, which helped engineers improve the performance and feel of the shafts from top to bottom.

Enjoy the Q&A below, in which MRC representatives answer questions from GolfWRX Editor Zak Kozuchowski about the company and its newest shaft.

Q: Before we talk about the TENSEI specifically, tell me about MRC’s process of creating a new shaft family. Does it start with a blank canvas, or is there a plan from the start of what kind of performance you want to achieve?

Mark Gunther, VP of Sales/Marketing: As a materials company at heart, we are always being exposed to and learning of new fiber, prepreg, and material applications from within our organization. Sometimes it comes from the carbon fiber division, sometimes from our prepreg division, and other times from within the golf group itself. As a result, the shaft group is constantly experimenting with ideas and designs lead by our extraordinary design team in Toyohashi, Japan.

That being said, the answer: there is usually a plan, or reason for prototyping. When we are looking to develop new families or profiles within our current lineup of shafts, we are typically focused on performance characteristics. What is missing from the lineup that we feel is needed by way of launch, spin, ball flight and even feel?

In addition, we are always trying to stay ahead of the curve by listening to our partners and accounts to understand where club development is headed. Sometimes this gives us clues on how to develop next-generation shafts that will help maximize performance of next-generation club heads.

Lastly, a new design concept can be as simple as a request from a tour player asking to experiment with a small tweak on a current shaft.

Q: How do the 11 different materials used to create TENSEI affect the shaft’s performance and feel?

MG: The TENSEI concept was a simple idea with a complicated development process. Two years ago, we decided to try to modernize, or “transform” our most classic bend profiles with a multi-material design. In fact, that’s how we got the name; TENSEI means “transformation” in Japanese.

Much like the auto racing industry, we wanted to maximize performance by using new MRC materials, as well as introducing some exotic materials where it made sense to the overall concept.

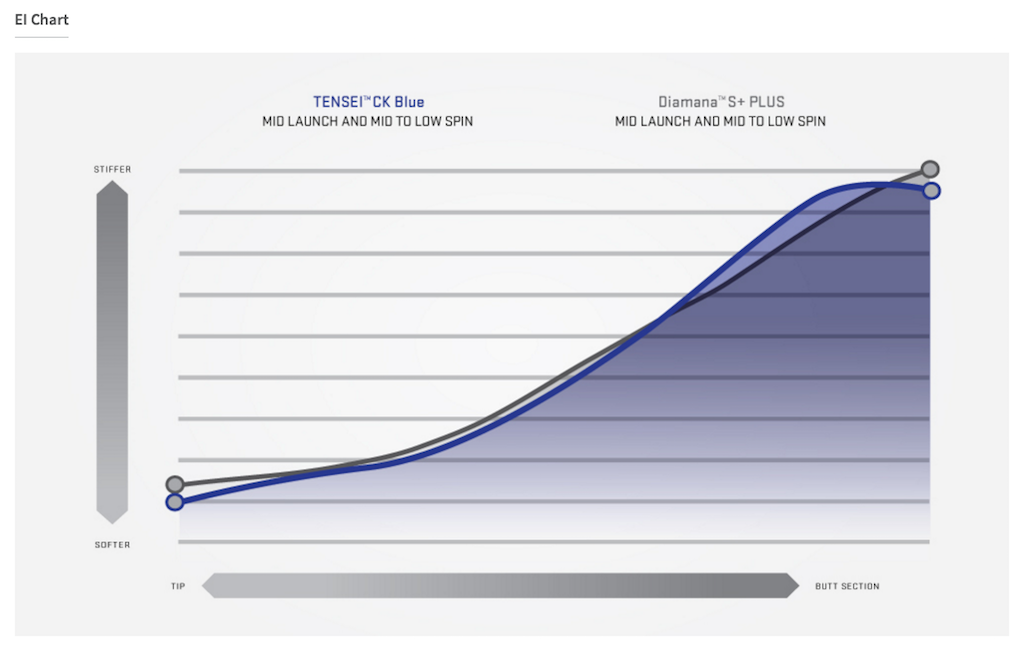

In the CK Blue Series, we are transforming our original, classic, smooth bend profile that has been so successful in product lines such as the original Diamana S-Series (Blue Board) and Bassara V-Series. The profile has been very popular for driver and fairway applications with players of all abilities. I often refer to it as our most “versatile” bend profile.

Q: What’s different about the materials used in TENSEI?

MG: With the TENSEI series, we’re using many newer ultra-thin prepregs. These newer prepregs are 50 micron in thickness or thinner, and were not available in the early 2000’s. By using several variations of this really thin material, and multiple layers throughout the shaft, we are able to more precisely hit our profile targets, creating a smoother overall shaft as it “loads” and “unloads” during the swing.

Related: See what GolfWRX Members had to say about the TENSEI CK Blue in our Official Testing Thread.

All shafts in the series are anchored by a Carbon-Kevlar Weave that we have placed in the butt section of the shaft, under the hands to do two things: (1) Further smooth the back end of the profile, and (2) provide increased feel and feedback to the player.

Q: I want to ask you more about the Carbon-Kevlar weave, but before I do let’s clarify a few things for our readers. Can you explain what “prepregs” and “high-modulus fibers” are?

Tsutomu Ibuki, President of MRC USA and designer of the original Diamana shafts: Yes, absolutely. Prepreg is simply a sheet of carbon fiber material that is impregnated with epoxy resin. MRC golf shaft are made from the prepreg by curing rolled materials on a mandrel. The thinner prepregs we are developing help greatly to minimize what is called the “spine” around the shaft, and also help achieve a smoother EI, or bend profile, along the entire length of the shaft – a core concept to TENSEI. Typical or standard prepreg is 100-125 micrometers in thickness. To manufacture prepreg with less than 50 micrometer in thickness and and low resin content (less than 25 percent resin content in weight) is very difficult. MRC can make prepreg as thin as 20 micrometers, however, allowing us to pursue very light and strong designs. You may see some exciting things in the near future in this area from MRC.

Regarding the term “High Modulus Fiber,” carbon fiber is classified by the modulus as following:

- Standard Modulus: 24 (or less) ton/mm2 (34 msi*)

- Intermediate Modulus: 30 ton/mm2 (43 msi)

- High modulus: 40 (or more) ton/mm2 (57 msi)

- Ultra-high modulus: 60 (or more) ton/mm2 (>85 msi)

* msi = megapound per square inch

So in golf shaft terms, the modulus of a material helps explain a particular fiber, or materials resistance to being deformed elastically. Typically higher modulus fiber makes it easier to make lower torque shafts and vice versa. And of course, the higher the modulus typically the higher the cost for the material. Today, MRC can manufacture prepreg at 95 ton.

Q: Back to the Carbon-Kevlar weave. Not often does MRC highlight specific technologies with graphics on its shafts, but that’s exactly what you did with TENSEI. Why?

MG: We like to develop technologies that actually do something for the shaft or player. Many times, we develop great technologies to accomplish our goal or hit our target, but the technology is not visible. For example, the TiNi Wire we use in Kuro Kage is almost black to the eye and very difficult to see, so we didn’t try to make it visible. In this instance, the Kevlar Fiber can be dyed to be visible, so we wanted to take the extra effort and cost to showcase the technology and our craftsmanship.

And just getting the material ready to use in the TENSEI Series is quite the process. MRC must first provide/ship our raw carbon fiber to a company that weaves it with the Kevlar. This woven product is then resin impregnated, creating the final prepreg material. Only then is the Carbon-Kevlar material ready for use in our shafts.

There are certainly easier ways to get such a woven product, but we at MRC feel our carbon fiber is superior to any on the market and taking the time to ensure the weave uses MRC fiber is a non-negotiable for us.

It would be quicker and less expensive to just paint over it, but because the Carbon-Kevlar weave is so important to the final product we believe highlighting it and showing the player it is actually there is worth our efforts.

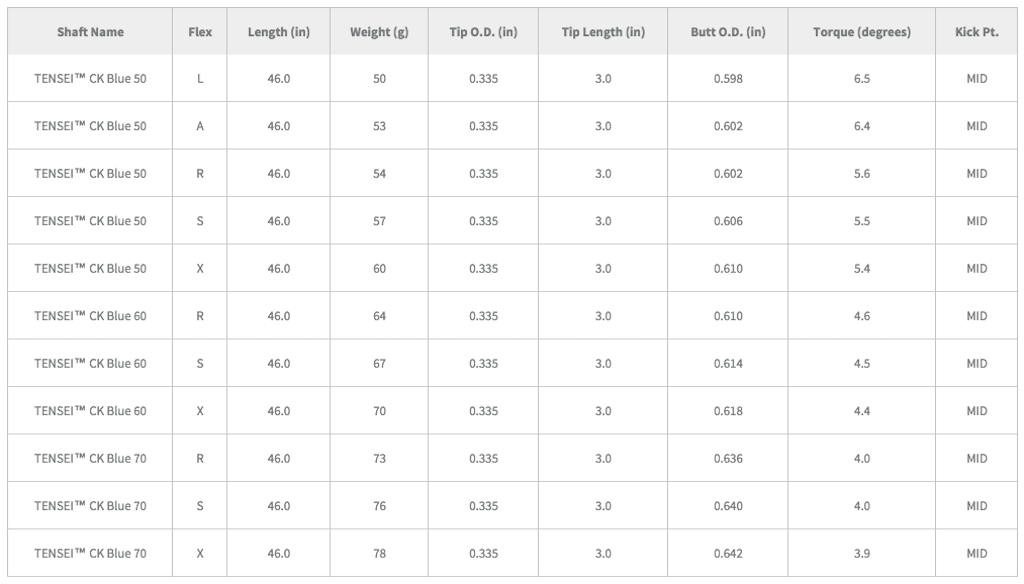

Q: Is it true that MRC uses different materials and designs for its lightweight shaft models than it does its heavier-weight shaft models? What I’m getting at is, how does performance change from a TENSEI CK Blue shaft at 50 grams to the same shaft at 70 grams?

MG: With TENSEI, as with all development at MRC, we consider the weight, spec and performance targets to make the final design. So yes, materials are going to vary from our lightest models to our heaviest products to help us achieve the optimal design to deliver the intended performance.

With TENSEI, for example, we are using more varieties of lightweight prepregs in the 50-gram series to help hit our lighter weight targets, yet provide the necessary strength for the overall shaft that we do in a 70-gram shaft.

Q: Last question. When can golfers expect the TENSEI CK Blue shafts to arrive at authorized dealers? Will the line be expanded?

MG: The formal plan is to have the entire line ready to go for the PGA Merchandise Show this coming January. Due to the early popularity of this product, however, we are working to get some limited inventory in-house for our dealers as soon as possible. And yes, you can expect this product line to expand in a few different ways. Stay tuned for that!

- LIKE66

- LEGIT10

- WOW9

- LOL0

- IDHT2

- FLOP0

- OB0

- SHANK3

Equipment

Titleist launches Pro V1, Pro V1x and Pro V1x Left Dash balls with enhanced alignment

Titleist has today introduced Pro V1, Pro V1x and Pro V1x Left Dash golf balls featuring enhanced alignment.

- LIKE3

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Cobra launches 3D-printed LIMIT3D irons

Cobra released its first commercially available 3D-printed steel putter in 2020. Now, the company is bringing its first 3D-printed irons to retail with new LIMIT3D irons, which Cobra’s vice president of product architecture, Jose Miraflor, calls “the most significant technological advancement to happen to the category in the past 20 years” and “a look into the future of golf club design and performance.”

Cobra leveraged the expertise of computational design software firm nTop to create an ambitious design: a compact players blade that offers similar forgiveness as a larger, game-improvement style club and forged iron feel.

Speaking on the partnership, Mike Yagley, Vice President of Innovation & AI, Cobra Golf said, “nTop’s computational design tools integrated with 3D printing, also known as additive manufacturing, allowed us to create an incredible new design that looks and feels like a forged blade but performs like a larger, game-improvement iron. No one has done this before, and we’re excited to introduce these unique irons to the world.”

As Cobra explains, more forgiving irons are traditionally larger and sacrifice feel. Due to the limitations of casting and forging, creating a more compact, better-feeling iron that still delivers forgiveness was only possible with 3D printing. The resulting profile of Cobra’s LIMIT3D irons is smaller than Cobra’s King Tour irons.

LIMIT3D irons are 3D printed for 316L stainless steel with an internal lattice structure, which allowed engineers to position 33 percent of the iron’s overall weight to the exterior for greater MOI. 100 grams of tungsten is positioned in the heel and toe of each clubhead for low CG for ease of launch and high MOI for greater forgiveness.

Additionally, using nTop’s design software and additive manufacturing allowed for a substantially faster prototyping process, which enabled engineers to test more designs and mass placements for a superior finished product.

Cobra LIMIT3D irons: Pricing, specs, availability

- 350 individually numbered sets available in the U.S. and Canada (500 sets total worldwide)

- Available for custom order June 7

- Price: $3,000

- Set: 4-PW, RH only

- Full range of aftermarket shafts, grips

- LIKE7

- LEGIT3

- WOW6

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK4

Equipment

Coolest thing for sale in the GolfWRX Classifieds (5/14/24): Mizuno Pro 241 Azalea Edition irons

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a set of Mizuno Pro 241 Azalea Edition irons.

From the seller: (@ayc25): “Brand new in box / plastic. 4-PW. Custom shaft bands, grips, ferrules. Dynamic Gold S200 Tour Issue. NO TRADES. Ships next day UPS Ground from Northern Virginia. $1695 shipped or best offer.”

To check out the full listing in our BST forum, head through the link: Mizuno Pro 241 Azalea Edition irons

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE0

- LEGIT0

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole3 weeks ago

19th Hole3 weeks agoLET pro gives detailed financial breakdown of first week on tour…and the net result may shock you

-

19th Hole7 days ago

19th Hole7 days agoReport: LIV star turns down PGA Championship invite due to ‘personal commitments’

-

19th Hole2 weeks ago

19th Hole2 weeks agoGary Player claims this is what ‘completely ruined’ Tiger Woods’ career

-

Equipment6 days ago

Equipment6 days agoDetails on Justin Thomas’ driver switch at the Wells Fargo Championship

-

Whats in the Bag2 weeks ago

Whats in the Bag2 weeks agoTeam McIlowry (Rory McIlroy, Shane Lowry) winning WITBs: 2024 Zurich Classic

-

Whats in the Bag7 days ago

Whats in the Bag7 days agoKeegan Bradley WITB 2024 (May)

-

Equipment2 weeks ago

Equipment2 weeks agoGolf fans left surprised by LIV’s choice of course for its 2024 individual championship event

-

Equipment2 weeks ago

Equipment2 weeks agoWhy Wesley Bryan is playing two 4-irons this week

Geekaya

May 11, 2016 at 3:15 pm

Just played 18 holes with a tensei ck blue 50 S fitted M2 at stock 9.5*, very smooth and easy to hit club/ shaft combo, I loved it. Ss 100mph, aa +5

KK

Nov 14, 2015 at 8:42 am

Nothing special about the weight or torque. We’ll have to see about the feel.

Dj

Nov 15, 2015 at 12:00 pm

Feel is second to none.

JuNiOR

Nov 14, 2015 at 6:30 am

TENSEI CK WHITE if I like the Whiteboard feel?

Jay

Nov 13, 2015 at 9:40 am

So looks like Dealers will be able to order these in limited numbers now?

john

Nov 12, 2015 at 5:31 pm

let me guess they’ll sell them to Taylormade for $1.14 but to the public they’ll be $400

Dj

Nov 12, 2015 at 6:32 pm

I’ve heard 250

Christestrogen

Nov 13, 2015 at 9:11 am

Buy a million or so shafts every decade and I bet u can get that figure down…

john

Nov 15, 2015 at 8:33 pm

I dont expect them for the insanely low price TM/callaway buy them for

but if they want aftermarket sales to exist they need to be reasonable.

Dj

Nov 12, 2015 at 1:21 pm

Very nice shaft!!!!

Mat

Nov 12, 2015 at 5:24 pm

That’s what she said.

Dj

Nov 12, 2015 at 6:32 pm

Was hoping someone would throw that out there