Equipment

How to remove an OEM adjustable sleeve for later use

Most golf equipment companies offer metal woods with adjustable features that allow golfers to change the loft, lie and face angle of the clubs. These clubs are made to be easy to adjust, but there are hurdles for golfers who wish to change the shaft of an adjustable club.

All of the current metal woods on the market that offer loft and face angle adjustability do so through an adapter or sleeve that is called an “adjustable tip.” So if golfers want to change the shaft of their adjustable clubs, they need to do one of two things:

- Buy another adjustable tip and install it on the new shaft.

- Remove the adjustable tip from the old shaft and install it on the new one.

Buying another adjustable tip is the best plan of action for golfers who want to try a new shaft, because it will allow them to compare the results of the shafts quickly and easily. But they’re not as cheap as many golfers might think — most OEM adjustable tips sell for between $25 and $40 each.

That’s why a lot of golfers, especially those who know the current shaft in their adjustable club isn’t right for them, might prefer to save the money and have their old adjustable tip put on their new shaft.

But removing an adjustable tip can be difficult due largely to the fact that the ferrule (on which most OEM’s print the loft adjustments) on can be ruined ruined in the process. That’s why I am going to share with you one method that I have found to work very well.

Supplies Needed

- Club Shield Paste (Jelly like substance that prevents burn marks)

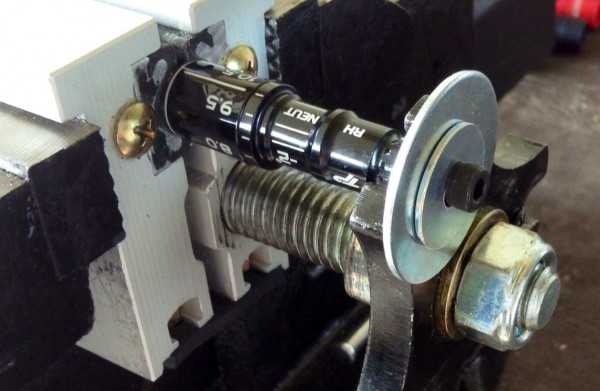

- Small washers and a small screw

- Shaft extractor

- Bore Brush

- Torch or Heat Gun

- Small Strip of Cotton

Prep

Apply the Club Shield Paste all around the ferrule. Place the washers on the small screw, and thread them into the tip of the sleeve. Secure your shaft in the shaft extractor. Take the small strip of cotton and soak it in some water and then wrap it around the ferrule. The club shield paste and wet cotton strip will protect the ferrule from heating up and getting damaged.

Step 1

Position the shaft extractor firmly against the washers to start just as you would to the head of a club for typical removal.

Step 2

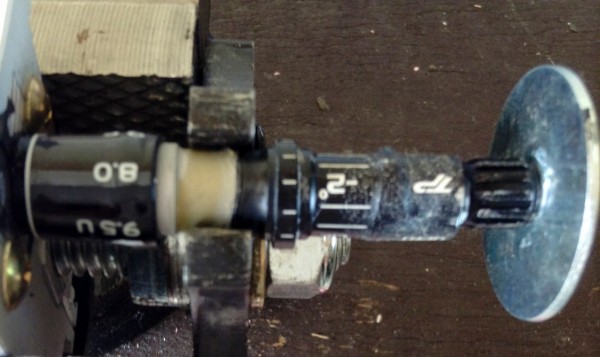

Apply heat to soften the epoxy and slowly apply pressure to the washers as you would when removing a club head (patience is the key for success). Slowly continue repeating this process. After a few applications, the adjustable tip will start to slide off the shaft. When there is enough room between the tip and the ferrule, reposition the shaft extractor to the top of the tip and continue to remove.

Step 3

Once the tip is off, clean the inside of it with your hosel brush. It is best to do so while the epoxy is still heated and soft.

Step 4

Remove the cotton strip and slide off the ferrule. Note: You may want to clean up your tip and ferrule before installing it onto the new shaft.

There are many ways to skin a cat. This process has yielded the best results for me. Take your time and you will be able to save most tips through this process.

- LIKE66

- LEGIT12

- WOW3

- LOL5

- IDHT1

- FLOP2

- OB3

- SHANK11

Whats in the Bag

Steve Stricker WITB 2024 (April)

- Steve Stricker WITB accurate as of the Zurich Classic. More photos from the event here.

Driver: Titleist TSR3 (9 degrees, C4 SureFit setting)

Shaft: Fujikura Motore Speeder VC 7.2 X

3-wood: Titleist 915F (13.5 degrees)

Shaft: Mitsubishi Tensei CK Pro White 80 TX

Hybrid: Titleist 816 H1 (17 degrees)

Shaft: Fujikura Motore Speeder VC 9.2 X

Irons: Titleist T200 (3, 4), Titleist T100 (5-9)

Shafts: Project X 6.5

Wedges: Titleist Vokey SM8 (46-10F @55), Titleist Vokey SM10 (54-10S @53), Titleist Vokey SM4 (60 @59)

Shafts: True Temper Dynamic Gold X100 w/Sensicore

Putter: Odyssey White Hot No. 2

Ball: Titleist Pro V1x

Grips: Golf Pride Tour Velvet Grip Rite

Check out more in-hand photos of Steve Stricker’s clubs here.

- LIKE5

- LEGIT0

- WOW0

- LOL0

- IDHT1

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Alex Fitzpatrick WITB 2024 (April)

- Alex Fitzpatrick what’s in the bag accurate as of the Zurich Classic.

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Fujikura Ventus TR Black 7 X

Hybrid: Ping G430 (19 degrees)

Shaft: Fujikura Ventus Black HB 10 TX

Irons: Ping iCrossover (2), Titleist T100 (4-PW)

Shafts: Fujikura Ventus Black HB 9 TX (2), Nippon N.S. Pro Modus 3 Tour 120 X (4-9)

Wedges: Titleist Vokey Design SM10 (50-12F, 56-12D, 60-08M)

Shafts: Nippon N.S. Pro Modus 3 Tour 120 X

Putter: Bettinardi SS16 Dass

Grips: Golf Pride MCC

Check out more in-hand photos of Alex Fitzpatrick’s clubs here.

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

What’s the perfect mini-driver/shaft combo? – GolfWRXers discuss

In our forums, our members have been discussing Mini-Drivers and accompanying shafts. WRXer ‘JamesFisher1990’ is about to purchase a BRNR Mini and is torn on what shaft weight to use, and our members have been sharing their thoughts and set ups in our forum.

Here are a few posts from the thread, but make sure to check out the entire discussion and have your say at the link below.

- PARETO: “New BRNR at 13.5. Took it over to TXG (Club Champ but TXG will always rule) in Calgary for a fit. Took the head down to 12, stuck in a Graphite Design AD at 3 wood length and 60g. Presto- numbers that rivaled my G430Max but with waaaaay tighter dispersion. Win.”

- driveandputtmachine: “Still playing a MIni 300. The head was only 208, so I ordered a heavier weight and play it at 3 wood length. I am playing a Ventus Red 70. I play 70 grams in my fairways. I use it mainly to hit draws off the tee. When I combine me, a driver, and trying to hit a draw it does not work out well most of the time. So the MIni is for that. As an aside, I have not hit the newest BRNR, but the previous model wasn’t great off the deck. The 300 Mini is very good off the deck.”

- JAM01: “Ok, just put the BRNR in the bag along side a QI10 max and a QI10 3 wood. A load of top end redundancy. But, I have several holes at my two home courses where the flight and accuracy of the mini driver helps immensely. Mine is stock Proforce 65 at 13.5, I could see a heavier shaft, but to normal flex, as a nice alternative.”

Entire Thread: “What’s the perfect Mini-Driver/Shaft combo? – GolfWRXers discuss”

- LIKE3

- LEGIT1

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK4

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole4 days ago

19th Hole4 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole4 days ago

19th Hole4 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole2 weeks ago

19th Hole2 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole1 week ago

19th Hole1 week agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

chester event hire

May 15, 2014 at 3:24 am

I actually do consider all of the strategies you’ve got offered on your own submit. They are extremely convincing all of which will surely perform. Even so, your posts are far too speedy to begin with. May well you please prolong these a little bit out of next occasion? Was looking for article.

Golfer X

Sep 6, 2013 at 8:14 pm

You young guys have it way too easy. In my day, we played golf with the VC shooting at us. No time to waggle…

Regis Staley

Sep 5, 2013 at 9:00 pm

I’ve probably removed and re-used 20-30 tip adaptors. Mostly TM .Best result I’ve achieved is to use a torch and focus the flame on the very tip- The more pinpoint the better. The heat migrates up the adaptor at a reduced intensity. I can get sufficient epoxy breakup in less than a minute. Then if necessary Golfsmith or Billy Bobs sells just the plastic collar for about $4. You can either melt or cut off the damaged collar.

Freddy V.

Sep 5, 2013 at 9:58 pm

Seriously…spend the 20-30 bucks for a new TM tip or another 5 for a new ferrule. Trying to save the plastic tips are a waste of time and NEVER come off without damage in some form to the plastic. Stores don’t do it for 2 reasons. 1 the chance of pulling it cleanly is slim to none and if they gaurantee they can do it, they are on the hook for damage. 2. It takes more time to do and costs almost the same as a new tip. Kind of like paying 3-5 bucks to save a grip when it cost that much for a new grip. Don’t let this article fool you into thinking it is a flawless process. The plastic always gets damage on a TM tip because the plastic melts at a lower temp than the epoxy used by TM. Goodluck regardless.

Cody_gateway

Aug 14, 2014 at 1:43 pm

Freddy V sounds like the type of person with no patience. this tip worked out great don’t let this hot head tell you otherwise

Linkerpan

Sep 5, 2013 at 12:34 am

Both Golf Galaxy and Golfsmith have ruined the adaptor on my Callaway. The lesson I learned is that if you buy a new shaft, you buy a new adapter. I hope all store managers print this article and quiz the employees later.

cha4218

Sep 5, 2013 at 9:18 am

I guess it all depends on who is working on it. I recently had the adaptor for my Nike Covert Tour taken out and installed in another shaft. A guy named Tom (Paramous, NJ) did a killer job on it. I couldn’t thank him enough. Kudos to him at Golf Galaxy.

Ross Bailey

Sep 4, 2013 at 5:49 pm

I would recommend using a heat gun and not an open flame to get the

adaptor hot enough to remove. The rest of the sequence is great.

Ga

Sep 4, 2013 at 5:27 pm

9 out of 10, that plastic degree sleeve gets melted. They should just make it out of aluminum. I don’t understand why they didn’t.

Chester

Sep 4, 2013 at 1:46 pm

I work at a golf store, and run the club tech department. I’ve found that heat gun is much more tip friendly when it comes to saving the plastic ferrule on the TM adaptors, although I do cover the plastic with heat shield as well. I recommend pointing the heat gun away from the ferrule, and towards the tip to avoid melting the ferrule at all. The tips that are first time pulls from the manufacturers are much easier pull, than 2nd time installs that potentially use stronger bonding glue. Great article though.

Kadin Mahmet

Sep 4, 2013 at 2:00 pm

Thank You! I agree first time pulls are much easier.

Mo

Sep 5, 2013 at 3:28 am

That’s not necessarily true. It also depends on the kind of epoxy used and how much of it got to seal up the very top of the adaptor. For example, if, in this case of the TM adaptor, if the adaptor is fairly stuck on with a lot of hardened, strong epoxy near the top, no amount of heat shield or wrapping is going to break the bond of the epoxy enough to be able to pull that thing off safely without melting the numbers on the plastic, let alone the plastic itself.

It all depends on the amount of epoxy, what kind of epoxy and how much of the hard epoxy was used to make the shaft really hold firm inside the adaptor.

At some point the adaptors will become cheap enough like ferrules, as this is where everything is headed, and, they will also have figured out a way to do away with the plastic so we don’t keep ruining these things.

Mateo

Sep 4, 2013 at 12:11 pm

Not bad. You should never use a blowtorch though. Use a heat gun to avoid damaging the tip. The tip that was pulled is not the same as the tip in the final picture. You can see the damage to the paint in the second to last picture. Looks like he pulled the old switcharoo.

🙂

leif

Sep 4, 2013 at 1:09 pm

Actually, that is the Hear Shield residue still on the tip after it dried…just need to wet it down and wipe it off.

leif

Sep 4, 2013 at 1:10 pm

Heat Shield…sorry.

Joe Golfer

Sep 5, 2013 at 12:08 am

Yes, I think Golfworks.com sells that stuff to protect hosels and such that are painted, so I can see why it would be used here.

If using a torch, use Butane and not Propane, as butane burns at a lower temperature.

A heat gun will work, but it sometimes seems like it takes forever to get the job done. And some epoxies simply won’t break down with a heat gun, so then you wind up resorting to the torch anyway.

Mateo

Sep 4, 2013 at 3:21 pm

Oh. Didn’t think of that. I don’t use heat shield because I’ve never really needed to. 😉

Kadin Mahmet

Sep 4, 2013 at 1:11 pm

Thanks for taking the time to read and post…

This is the tip that was removed…

“Note: You may want to clean up your tip and ferrule before installing it onto the new shaft.”

I see now that it’s a little vague. I clean the tip and use a “sharpie” style marker to touch up any scratches or paint blems.

Deck

Sep 4, 2013 at 2:22 pm

Heat shield is a wonderful thing. You might want to try it. Agree with the above poster. Residue. Have you ever used it before you comment on it?

Mateo

Sep 4, 2013 at 3:22 pm

Don’t use it because I don’t need to. Only amateurs do. Lol

kirk

Sep 4, 2013 at 11:49 am

any golf store can remove to tip and put onto another shaft

Brian

Sep 4, 2013 at 12:02 pm

Actually, ‘many’ stores will not remove the tip and put it onto another shaft. Either because they don’t know how, have had an issue with customer being satisfied with the result, or just prefer not to. Good to have this bit of ‘how-to’ available when the stores won’t do it.

Kadin Mahmet

Sep 4, 2013 at 1:14 pm

The shops in my area will not provide this service though a lot of shops will.

The idea behind this topic was geared towards the DIY’er

Thanks for taking the time to post! 🙂

kirk

Sep 4, 2013 at 2:48 pm

well every store around me will do this, rather pay some 10-15 bucks,than n screw around doing in my self

AJ Jensen

Sep 4, 2013 at 4:10 pm

And I’d rather do it myself. This was a great step-by-step article for a guy like me.

AJ Jensen

Sep 4, 2013 at 11:46 am

OK, for what it’s worth, I’m giving this one the award for “How-To Article of the Year.” Very well done, sir.

Kadin Mahmet

Sep 4, 2013 at 1:06 pm

Thanks AJ ! I appreciate that!