Equipment

Can’t get up and down? It might be a sole problem

It’s not me; it’s the club.

Make that claim in front of experienced golfers and they’ll shy away from conversation with you for a while. That’s because they’ve learned one of golf’s hardest truths – golfers, not golf clubs, cause bad shots.

For the most part, I’ve been in agreement them. Sure, a properly fit driver can result in more yards and more accuracy. And a more forgiving set of irons will be… well, more forgiving. Such improvements can lead to slightly lower scores and more fun, but they’re changes that aren’t going to take a golfer to the next level. That’s because substantial improvement comes from practice, not product, right?

After talking to renowned wedge designer Bob Vokey and going through a wedge fitting at the Titleist Performance Institute in Oceanside, Calif., I was forced to reconsider. I learned that choosing the right wedge is about more than filling in distance gaps – it’s about finding one with the proper sole design. And selecting the right sole can be the difference between chunking pitches and pitching it to a few feet from the cup.

According to Vokey, the sole is the engine of a wedge. If a golfer hopes to play their best, they have to use a wedge with a sole configuration that matches their style of play. This is especially important for a golfer’s lob wedge, the most specialized wedge in a golfer’s bag.

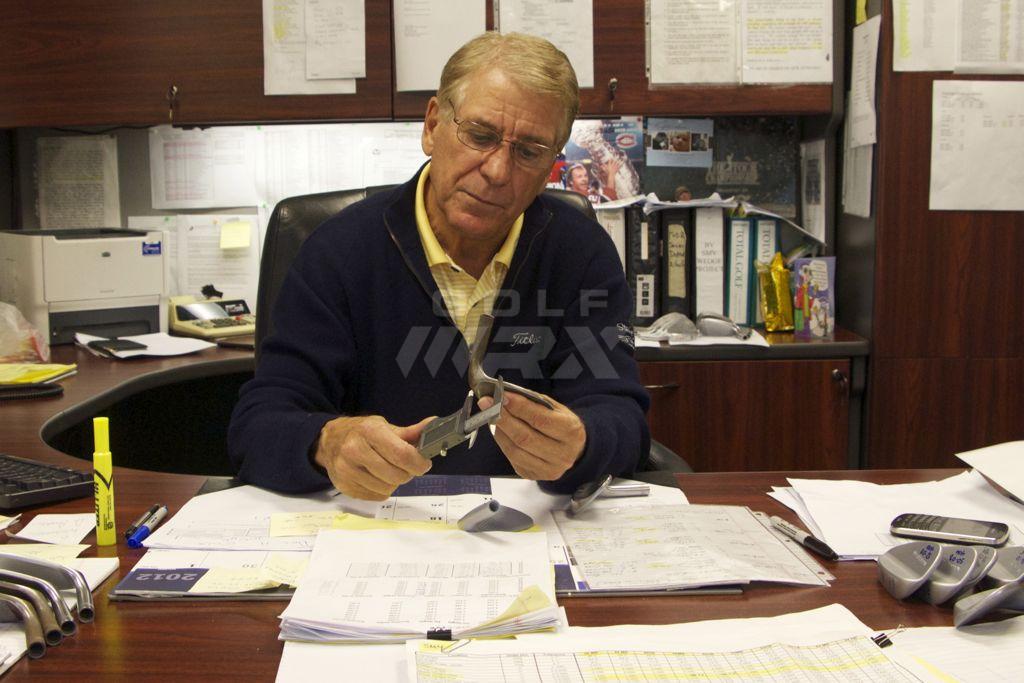

“A large part of the game is working with the player and getting feedback,” Vokey said. “Early in my career, my strength was knowing what the tour liked. I built trusting relationships with each player and that’s what it takes. They’d say, ‘Voke, you know what I want. Make me what I want.’”

When Vokey first opened a business as a custom clubmaker in 1976, sole configurations (also known as grinds) were much more limited than they are now, especially to the general public. But through the years, wedges have evolved from “get out of jail clubs” — designs that helped golfers escape bunkers and rough — to scoring tools that give golfers the green light to play a variety of shots from the fairway, rough, bunkers or wherever else their ball ends up.

Vokey gained expertise building equipment for some of the game’s best, such as Lee Trevino and Dave Stockton. After stints with TaylorMade and Founders Club, Vokey joined Titleist in 1996. His first project with the company was as a design assistant for the 975D driver. But his attention to detail and rapport with tour players made him a natural choice to lead Titleist’s wedge department. His sole focus became wedge design, which he mastered through his tinkering with tour players.

“That’s how all these grind came about,” Vokey said. “Working with tour players and getting the right grind for their particular technique.”

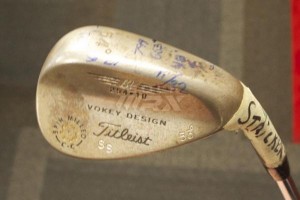

Gold-plated replicas of the Vokey wedges that were used to win major championships.

One of the most important aspects of a wedge’s grind is the bounce angle, which simply put is the measurement of how far the leading edge of a wedge sits off the ground. More bounce means the leading edge rests higher off the ground at address, and less bounce means the leading edge is closer to the ground. Bounce is impacted by several factors such as camber (the curvature of the sole) and sole relief (the shaping of the trailing edge), which makes it complicated to measure. But Vokey made the function of bounce easy to understand:

“The idea of bounce is to let the trailing edge hit and keep going forward.”

Good wedge players have mechanics that allow them to use wedges properly. They know how to use the bounce, which leads to more consistent wedge play because it prohibits the club from digging. Vokey has found that most regular golfers are not so skilled with their wedges. They don’t know how to use the bounce of a wedge, which leads to digging. That’s why more bounce is often better for them.

“There are more positives to a little more bounce than there are negatives,” Vokey said.

Click here for more discussion in the “Equipment” forum.

Wedge fitting at TPI

Zak Kozuchowksi being fit for wedges by Kurt Donahoo at Titleist’s Oceanside Test Facility

After my interview with Bob Vokey, I headed to TPI Oceanside for a wedge fitting with Kurt Donahoo, a Class A PGA Professional with more than a decade of club fitting experience at TPI. There, the entire line of Vokey wedges was available for me to test with shafts and lengths I liked. And thanks to an outdoor loft/lie machine, there was no guessing involved. The lofts and lies were dialed in, and I hit all shots with my preferred golf ball.

After I warmed up, Donahoo started by having me hit full shots using a 50-degree wedge with 8 degrees of bounce and my favorite shaft to a flag 125 yards away. After a few swings, he changed my target to a flag that was 65 yards away. As I was hitting the less-than-full shots at the new target, Donahoo directed my attention to the large divots I was making. Then he put a 50-degree wedge with 12 degrees of bounce in my hands and told me to hit the same shot. I was pleased to see my divots become significantly shallower.

“You’re always going to be pretty shallow on your full swings, so the bounce doesn’t matter as much,” Donahoo said. “But on your less-than-full swings, you get steeper, so you need more bounce.”

Donahoo was right. I’ve often been the victim of a good drive spoiled by a fat half-wedge shot. With more bounce, the flight of my less-than-full shots with the 50-degree wedge was more consistent, and it was a lot harder for me to hit a shot fat.

The fitting for my 55-degree wedge was similar. Vokey’s current SM4 wedge lineup is available in two-degree increments, from 46 to 64 degrees. This meant that I had the option of choosing a 54-degree bent 1 degree weak or a 56-degree bent 1 degree strong. Donahoo and I decided on the 54-degree with 14 degrees of bounce instead of the 56-degree with the same amount of bounce, because adding a degree of loft to the 54 also added a degree of bounce, whereas subtracting a degree of loft from the 56-degree subtracted a degree of bounce. As with the 50-degree, the extra bounce helped the trailing edge of the wedge hit and keep moving forward, keeping my divots smooth and shallow.

Donahoo also recommended that I try a different shaft in my 55-degree wedge. Instead of a Project X shaft, which offers a stiff tip section for a penetrating ball flight, he had me try a Dynamic Gold S400 shaft, which plays slightly heavier and has a softer tip.

“You’re going to hit mostly full shots with your 50-degree wedge, so it makes sense to use the same shaft you use with your irons,” Donahoo said. “But most of your shots are going to be less-than-full with your 55- and 60-degree, so a softer shaft makes sense.”

Finding the proper sole configuration in a 60-degree wedge proved to be the most time consuming process. Like the other two wedges, Donahoo and I agreed that the highest bounce options – a 60-degree with 10 degrees of bounce – was the best choice. But unlike my 50- and 55-degree wedges, my 60-degree would be used primarily around the greens and in bunkers.

Donahoo had me hit several different 60-degree wedges from a bunker that surrounded one of TPI’s perfectly manicured practice greens. I liked all of them, but there was one that I felt was slightly better than the rest. Donahoo smiled, and dropped a few balls for me to hit behind the bunker. He wanted me to hit lob shots with the club to a pin that was 15 yards away, tucked close to the bunker’s lip. I chunked the first one into the middle of the bunker.

“I hit it fat,” I said, for some reason feeling the need to explain what I though was completely obvious.

“Don’t change anything,” Donahoo said. “Hit another one.”

The same thing happened again, at which point Donahoo rushed in with another wedge — the 60-degree with 10 degrees of bounce, an “M” grind.

“Don’t change anything,” he repeated.

So I didn’t, and my next shot came off crisp – it landed high and soft, and landed close to the pin.

Fitting to a miss

The wedge I chunked twice was a 60-degree with 4 degrees of bounce — an “L grind” — the same model played by Rory McIlroy. The wedge has very little camber (read flat sole) and a narrow forward bounce section, making it good for players like McIlroy who have great hands and a shallow angle of attack with their wedges. But there’s another reason why McIlroy plays a wedge with only 4 degrees of bounce – he grew up in Northern Ireland, an area of the world with firm golf courses that require low-bounce wedges.

The 60-degree with 4 degrees of bounce was great for me out of the bunker because its bounce is situated in the rear portion of the sole, the part I was using to hit bunker shots. But when it came to hitting pitch shots that brought the leading edge into play, I was sunk.

Donahoo saw that I shifted my weight on pitch shots more than most good wedge players he works with, which is one of the reasons why I require so much bounce. But he also pointed out that I grew up playing courses with very soft conditions in Michigan, which is where I currently reside. Because of where I live, the extra bounce doesn’t hurt me. And even as I work to improve my wedge mechanics, Donahoo said that my wedge needs are not likely to change.

“With wedges, we’re fitting to a miss,” he said. “Most of your good shots are going to be good with most wedges, so we need to find the wedge that helps you with the bad shots. Almost all of your bad shots are going to be steep, so more bounce is going to help you.”

Team Vokey uses these models to make new wedges for Steve Stricker, who has a very shallow angle of attach with little wrist action. He prefers an “S” grind on his 60-degree wedge, which offers a medium amount of bounce and is available on Vokey models 58-09 and 60-07.

Doing better

One of the most important advancements in wedge design since Vokey’s arrival at Titleist were the aggressive grooves that the USGA and R&A outlawed for professional golfers in 2010. Although the spin of Vokey’s most recent line of wedges is essentially unchanged on dry lies in the fairway, they’ve lost performance in wet conditions and in the rough because of the mandatory reduction on groove volume and sharpness.

Vokey said testing showed that his first conforming models, the SM3 wedges, added 5 degrees of launch angle and lost 3000 rpm of spin out of the rough. The SM4 wedges added three grooves to the face (from 14 to 17) to return the launch angle back to where it was with the now non-conforming SM2 wedges. But the SM4s are still 1500 rpm short of the SM2’s spin standard out of the rough.

“We’re always looking at different metals, different shapes and different face textures and patterns to get the spin back,” Vokey said. “But the USGA and R&A did their homework.”

Even though shots hit with wedges with the new grooves have less spin, they react more consistently for talented wedge players. This has forced players to plan their wedge shots with a bias toward trajectory instead of spin, making sole configuration even more crucial.

One way Vokey said his wedges can improve is by offering more lofts and more sole configurations, which will help players further dial in their wedge fitting. He sees more options, not less, as a key for serious golfers to improve their score.

“I would love to design the perfect wedge before I go to the fairway in the sky,” Vokey said. “But I don’t know if I’ll ever make it. Every wedge I look at I say, God, I know I can do better. And I keep trying.”

10 wedge tips from Bob Vokey

Bob Vokey defines a serious golfer as someone who is dedicated to the game.

“You can be a serious golfer and not break 90 or 100,” he says.

Here’s 10 tips that Vokey offered to help serious golfers. They’ll help everyone, whether you’re playing to beat your buddies or beat the world.

- The lofts of your wedges should have gaps of 4 to 6 degrees — no more, no less.

- Golfers come in three types: diggers (high bounce), sliders (low bounce) and neutral (medium bounce). When being fit, start with a neutral wedge and go from there.

- You probably need more bounce.

- Know what wedges you really need to hit. If you play on courses with fast, elevated greens surrounded by pot bunkers, you probably need a 60-degree wedge. If you play courses with slow, flat greens, you might be able to get away with a 56-degree as your highest loft.

- Wedges are the only clubs that golfers use in the open position. Choose one that looks good when it sits square and when you open it up.

- Play a shaft in your sand and/or lob wedge that allows for the proper feedback. Vokey has had success fitting average golfers into True Temper Dynamic Gold S200 shafts, which give the right amount of feedback but are firm enough for a full shot for most golfers.

- Pitching wedge replacements (46, 48, 50) are designed with the loft of a pitching wedge but the versatility of a scoring wedge. They won’t go as far as the wedges from your iron set and that’s OK. If you want them to go further, opt for less loft.

- Wedges wear to your swing print. A new wedge will not feel the same as the old wedge because you’ve got to break it in.

- Practice more from 125 yards and in. Most golfers will never swing like Adam Scott, but according to Vokey, with practice they can execute the same wedge shots he can.

- Another reason to practice wedges — a tour player hits 13 to 14 greens per round. The average golfer hits only 6 or 7. That means wedge play is more important for average golfers than it is for tour players.

Click here for more discussion in the “Equipment” forum.

Note: This article was edited to clarify that Vokey’s SM3 wedges lost 3000 rpm of spin out of the rough when compared to the now non-conforming SM2 wedges. The article previously stated that the SM4 lost 3000 rpm of spin when compared to the SM2 wedges. The SM4 wedges lost approximately 1500 rpm of spin when compared to the SM2 wedges.

- LIKE97

- LEGIT9

- WOW4

- LOL2

- IDHT1

- FLOP3

- OB2

- SHANK5

Equipment

A shocking Backstryke putter appearance + 7 interesting gear photos from the Zurich Classic

Welcome to New Orleans, where TPC Louisiana plays host to the 2024 Zurich Classic. In between breakfast beignets and nightly Creole feasts, PGA Tour players are also competing in the unique two-man format at the Zurich this week.

Although the vibes in Nawlins are a bit lighter-fare than the recent back-to-back competitions the Masters and the RBC Heritage signature event), the gear news was no less serious this week.

We spotted some recent changes from Rory McIlroy, a very rare Odyssey Backstryke putter, dove into the bag of legendary New Orleans Saints quarterback Drew Brees, and spotted Patrick Cantlay continuing to test new equipment.

Get your beads out and crack your crawfish, because it’s time for an equipment rundown from The Big Easy (meaning New Orleans, of course, not Ernie Els).

See all of our photos from the Zurich Classic here

Rory’s on-and-off lob wedge

Since the end of 2023, Rory McIlroy has had an on-again, off-again relationship with a Titleist Vokey K-Grind lob wedge. In his last start, it was on, and the wedge is back in the bag again this week. We got a great look at the complicated grind that McIlroy uses.

View this post on Instagram

A full look into McIlroy’s bag above also shows that he switched out of the TaylorMade BRNR Mini Copper that he used at the RBC Heritage, and he’s back into the Qi10 core 3-wood. As we discussed last week, McIlroy will likely keep the BRNR around as a course-specific club, trading it in and out for the 3-wood.

See Rory McIlroy’s full 2024 WITB from the Zurich here

Turning Back the clock

Unless Tommy Gainey is in the field, it’s unlikely you’ll ever see Odyssey’s Backstryke technology make an appearance on the PGA Tour.

But then, when you least expect it, Russ Cochran shows up.

For more than a decade – since the 2013 Sony Open in Hawai’i – Cochran has been stuck on 599 PGA Tour starts. This week will be his 600th.

Cochran is in the field at the Zurich this week playing alongside Eric Cole, whose regular caddie is Reed Cochran, Russ’s son.

The Backstryke putter was first released back in 2010, and its unique design helps shift the axis point of the putter closer to the CG of the head. And, the putter is getting a nod this week at the Zurich Classic, thanks to Cochran’s 600th career PGA Tour start.

The putter is certainly awesome, but don’t forget to check out Cochran’s full WITB from this week.

Drew Brees with a Super Bowl winning Scotty Cameron putter

Drew Brees, a legendary retired quarterback for the hometown New Orleans Saints, made an appearance at the Zurich’s Wednesday Pro-Am, playing alongside Zach Johnson, Ryan Palmer, and current Saints QB Derek Carr.

Brees’ bag included a TaylorMade Stealth2 Plus driver, a BRNR Mini 13.5-degree, a Stealth 5-wood, a mixed set of P-790 and P-760 irons, Milled Grind Hi-Toe wedges, and a custom Scotty Cameron “New Orleans Saints” putter, which Scotty made for Brees following his Super Bowl MVP-winning performance in 2010.

View this post on Instagram

It should also be noted that Brees has his Venmo QR code as a bag tag.

If you’re gambling with Brees on the course, just know that not having cash won’t work as an excuse.

Brilliant.

See Drew Brees’ full WITB from the Zurich here

Stricker’s unrecognizable putter

Steve Stricker has made numerous upgrades to his bag recently, including a new TSR3 driver and T100 irons, but his longtime Odyssey White Hot No. 2 putter is still going strong. It’s the most recognizable unrecognizable putter ever.

Here’s a better look at Stricker’s flatstick, which he started using back in 2007.

View this post on Instagram

Patrick Cantlay has opened the equipment-switching floodgates

Over on the PGA Tour’s Equipment Report this week, we covered Cantlay’s recent switch into Ping Blueprint S irons, and a Titleist TSR2 driver.

Cantlay hadn’t switched irons for about seven years, so the iron switch he made at The 2024 Masters came as a shock to the norm. He simply isn’t one to change gear very often, so anytime Cantlay makes a switch, it’s news.

It seems the floodgates of equipment testing have opened up a bit for Cantlay, who was also spotted testing a custom Scotty Cameron blade putter on Tuesday this week. By Wednesday, Cantlay was back practicing with his familiar Scotty Cameron T5 Proto mallet, but it’s certainly something to keep an eye on going forward.

Daniel Berger’s custom Jailbird site lines

Berger, who’s currently using Odyssey’s Ai-One Mini Jailbird mallet putter, has a unique 3-dot, 2-line alignment on the crown of his navy-white-navy-white mallet putter. Looking down at the putter, it’s easy to see why this alignment system would help; it just seems impossible to set up to the ball off-center, or misaligned to the target.

Also, for anyone worried, you can rest easy. Yes, he’s still playing the 2013 TaylorMade TP MC irons, which we highlighted in our recent “Modern Classics: Old vs. New” video testing series.

FitzMagic teams back up

Brothers Matthew and Alex Fitzpatrick are teaming up once again at the Zurich this year, and Bettinardi Golf hooked them up with some festive “FitzMagic” headcovers to match this week.

See what else is in Alex Fitzpatrick’s WITB here

And, with that, we say goodbye to the Zurich Classic in New Orleans. Don’t forget to check out all of our photos from this week, including 30 unique photo galleries full of equipment photos.

We’ll see you next week in Texas for the 2024 CJ Cup Byron Nelson!

- LIKE8

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Alejandro Tosti WITB 2024 (April)

- Alejandro Tosti what’s in the bag accurate as of the Zurich Classic.

Driver: Srixon ZX5 Mk II LS (9.5 degrees @10.5)

Shaft: Project X HZRDUS T1100 75 6.5

3-wood: TaylorMade Qi10 Tour

Shaft: Project X HZRDUS Black 80 TX

Hybrid: TaylorMade Qi10 Tour Rescue (22 degrees)

Shaft: Project X HZRDUS Smoke Black RDX 6.5 100

Irons: Srixon ZX7 Mk II (4-PW)

Shafts: True Temper Dynamic Gold Mid Tour Issue X100

Wedges: Cleveland RTX6 ZipCore Tour Rack (50-10 MID, 54-10 MID, 58-10 MID, 60-06 LOW)

Shafts: True Temper Dynamic Gold Mid Tour Issue X100, S400

Putter: Scotty Cameron

Grips: Golf Pride MCC Plus4

Check out more in-hand photos of Alejandro Tosti’s WITB in the forums.

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Drew Brees WITB 2024 (April)

View this post on Instagram

Driver: TaylorMade Stealth 2 Plus (10.5 degrees)

Mini driver: TaylorMade BRNR Mini Copper (13.5 degrees)

5-wood: TaylorMade Stealth Plus (19 degrees)

Irons: TaylorMade P790 (4-8, PW), TaylorMade P760 (9)

Wedges: TaylorMade MG Hi-Toe (52-09, 56-10, 60)

Putter: Scotty Cameron Select Newport 2 Prototype

Check out more in-hand photos of Drew Brees’ clubs here.

- LIKE4

- LEGIT1

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole4 days ago

19th Hole4 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole4 days ago

19th Hole4 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole2 weeks ago

19th Hole2 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole1 week ago

19th Hole1 week agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

ray

Apr 29, 2013 at 10:26 am

does anyone know of zero tolerance wedges and if anyone makes a wedge like the 1 zt made

thanks

ray

Lou

Mar 25, 2013 at 12:20 am

I carry SM4 54-11 and 60-10 both bent 1* strong and a 64-07 stock loft. Best wedge setup yet. I’ve been using the 60-10 as my main greenside bunker club.

Troy Vayanos

Jan 19, 2013 at 8:26 pm

Great post Zak,

It’s interesting because I never would have placed much importance on bounce when it comes to wedges from 125 yards in. I have always understood it’s importance when playing bunker shots but not for general fairway wedge play.

The right advice would be for all golfers to get this sort of testing done.

Do you know if Titleist do this sort of testing worldwide and just for wedges and working out ideal bounce settings?

Cheers

Sean Mashinter

Jan 18, 2013 at 9:05 pm

Great read. Gives me another excuse to head to Golftown!

goodgolfer64

Jan 1, 2013 at 2:31 pm

great article only down fault being really picky is Northern ireland is SOFT :)!!!!! bar a handful of links none of which are near holywood…40 minute drive to a links track from rorys hometown……

Goober

Dec 30, 2012 at 12:58 pm

What the touring pros have done to their wedges is immaterial to my game. I must buy off the rack and get no after-market tweaks free of charge.

I have a simple test for a wedge in-store. If the leading edge doesn’t fit super-tight to the floor, it’s quickly eliminated from consideration.

The best I found from 2012 models were the Callaway Forged. I bought the 52 & 56 degrees. Distance and finesse are excellent. No regrets whatsoever.

goodgolfer64

Jan 1, 2013 at 2:29 pm

surely Goober buyin wedges that have a tight leading edge gives you less bounce…goes against most of the recomedations above…..

barkydog1

Dec 29, 2012 at 1:15 pm

Great little article.

Zak Kozuchowski

Dec 29, 2012 at 9:21 am

Our Edel story from last year

http://www.golfwrx.com/4767/finding-their-groove-edel-golf’s-new-wedge-and-the-james-patrick-controversy/

Tony Wright

Dec 29, 2012 at 7:51 am

Good article. Most players can get improvement in their wedge play by playing with wedges with more bounce. I hope you will consider a similar article on the Edel wedges. You may find that they are much more forgiving on all shots that Vokey wedges are. I play with a 21 degree bounce 60 degree Edel wedge – it is the most forgiving wedge I have ever played. The Edel wedge design is much different than traditional wedge designs. Golfers also get improvement in their wedge play by improved technique…..keeping their weight on their forward foot during the swing.

MARKETING

Dec 28, 2012 at 9:16 pm

Looks like SCRATCH Golf has a big influence.

Zak, did you ask the obvious question of how Scratch’s model has influenced the marketing and design of wedges for the past few years as companies offer more options for sole grinds?

Peter

Dec 28, 2012 at 6:26 pm

Agree with you on the importance of sole grind…it’s a revelation when you find one that works for you. The same swing produces very different results when you find a sole that fits your swing. Looking at PGA.com stats, tour pros don’t hit 13-14 GIR on average. More like 11-12 over a season…hence wedge play is crucial to winning/making money. First time I heard about diggers vs sliders was the Scratch Golf fitting system, which has helped me out a lot.

Sean

Dec 28, 2012 at 5:10 pm

Very well done Zak. Thanks for the article and an inside look.

chris

Dec 28, 2012 at 2:42 pm

some of the worst sole grinds I have had have been from Vokey. They work for some but I find the Mizuno grinds to be much more versatile.

Philip

Dec 28, 2012 at 1:58 pm

Love the article! It’s nice to hear from the club making gurus of today.