Equipment

New 2020 Cleveland Launcher HB Turbo driver

The all-new-for-2020 Cleveland Launcher driver has been designed to hit the ball higher, straighter, and—thanks to a redesigned cup face, and higher balance point shaft—faster, too.

The Cleveland Launcher name is synonymous with distance. Multiple versions of the flagship Launcher driver found their way into players bags dating back to pre-400cc drivers, through composite products (Cleveland Comp, anyone?). It’s not an understatement to say the club transformed Cleveland’s metal wood segment.

After a bit of a hiatus, the Launcher name was relaunched (sorry, had to do it) two years ago to glowing reviews and positive player feedback. The engineers at Cleveland decided 2020 was the time to turbocharge the new Cleveland driver.

“(With the Launcher HB Turbo) We’ve squeezed discretionary weight out of every corner of the head in order to produce one of the most forgiving drivers we’ve ever made.”

-Vice President of Research and Development at Cleveland Golf Jeff Brunski

2020 Cleveland Launcher HB Turbo: Details

When talking about discretionary mass, every single gram matters. In a 200g driver head, every two grams saved is one percent more mass to move around. When talking about a driver head and collisions taking place at over 100 mph, every percentage point matters. One of the most wasteful parts of any clubhead is the hosel—whether it be because of adjustability or just a traditional glue in a non-adjustable head.

The original Cleveland Launcher HB was not adjustable, which meant it was already saving some mass, but the engineers at Cleveland went a step further with the new HB Turbo and implemented more than just one technology beyond the hosel to make this new Cleveland driver even faster.

- Ultralight hosel: By redesigning the hosel both inside and outside of the head, more mass was able to be distributed low and further away from the face to increase forgiveness.

- Turbocharged CupFace: OEMs cant make the center of the head faster— it’s the rules—but it doesn’t mean they cant speed up more of the face. The new Turbocharged CupFace, has been enhanced with a new variable face thickness to provide higher CT (characteristic time) over a larger area for increased ball speeds and more distance—because nobody hits the middle every time.

- HiBore Crown: The newly shaped crown on the Launcher HB Turbo lowers the CG (center of gravity) by a full 2.2mm when compared to the Launcher HB. This improves overall forgiveness and helps to better optimize launch parameters for shots hit all over the face.

When it comes to improvements, Cleveland isn’t stopping with the clubhead either. The new Launcher HB Turbo is being paired with a new proprietary high-balance point Miyazaki C. Kua shaft. By raising the center of gravity closer to the grip end of the club, players have the ability to swing the driver faster, even though more mass has been added to the head to give the Launcher HB Turbo an MOI boost.

This is where club designers are looking beyond just the driver head and analyzing the club as a whole system. The better the whole system works together, the better you are going to hit the ball. It’s also beneficial that Cleveland is under the SRI Sports Umbrella, which also includes Srixon and Miyazaki. Miyazaki shafts are extremely high quality and are all proprietary to SRI products.

New Cleveland driver: Options and availability

The Cleveland Launcher HB Turbo driver is available in two different models

Standard/neutral weighting will be available in lofts of 9, 10.5, and 12 degrees.

There will also be a Launcher HB Turbo Draw model with more discretionary weight placed towards the heel. It will come in a 10.5-degree loft.

The suggested retail price of both models will be $349.99, and the drivers will be available starting October 4.

- LIKE194

- LEGIT20

- WOW18

- LOL6

- IDHT3

- FLOP4

- OB2

- SHANK28

Whats in the Bag

Peter Kuest WITB 2024 (May)

- Peter Kuest what’s in the bag accurate as of CJ Cup Byron Nelson.

Driver: TaylorMade Stealth 2 Plus (8 degrees)

Shaft: Fujikura Ventus Black 7 X

5-wood: TaylorMade SIM Titanium (19 degrees)

Shaft: Project X HZRDUS Black 85 6.5

Irons: Srixon ZX U (2), Srixon Z-Forged II (3-PW)

Shafts: Nippon N.S. Pro Modus3

Wedges: Cleveland RTX6 ZipCore Tour Rack (52-MID 10, 56-MID 10, 60-FULL 9)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: TaylorMade Spider Tour

Grips: Golf Pride Tour Velvet Cord

Check out more in-hand photos of Peter Kuest’s clubs here.

- LIKE0

- LEGIT1

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Kelly Kraft WITB 2024 (May)

- Kelly Kraft’s what’s in the bag accurate as of the CJ Cup Byron Nelson. More photos from the event here.

Driver: Callaway Paradym Ai Smoke Triple Diamond Max (9 degrees)

Shaft: Mitsubishi Tensei 1K Red 60 TX

3-wood: Callaway Paradym Ai Smoke Max (15 degrees)

Shaft: Project X Denali White 70 TX

Hybrid: Callaway Apex UW (21 degrees)

Shaft: Aldila Synergy Blue

Irons: Srixon ZX U Mk II (23 degrees), Callaway X Forged Star (5-PW)

Shaft: Project X IO 6.0

Wedges: Titleist Vokey Design SM10 (52-12F, 56-08M, 60-08M)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: Odyssey Versa 2-Ball Prototype

Grip: Odyssey Garsen Quad Tour

Grips: Golf Pride ZGrip Cord

Check out more in-hand photos of Kraft’s equipment here.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

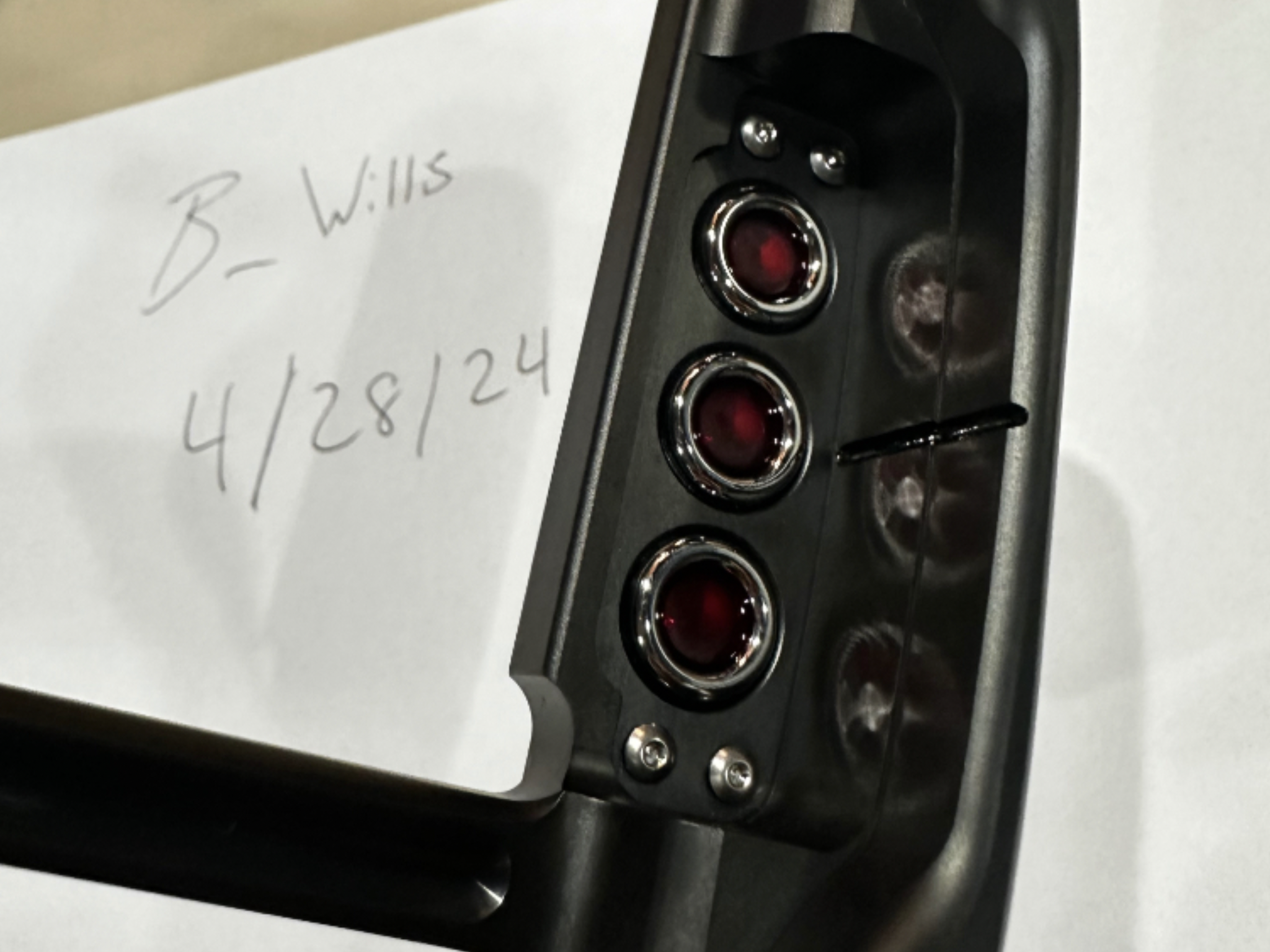

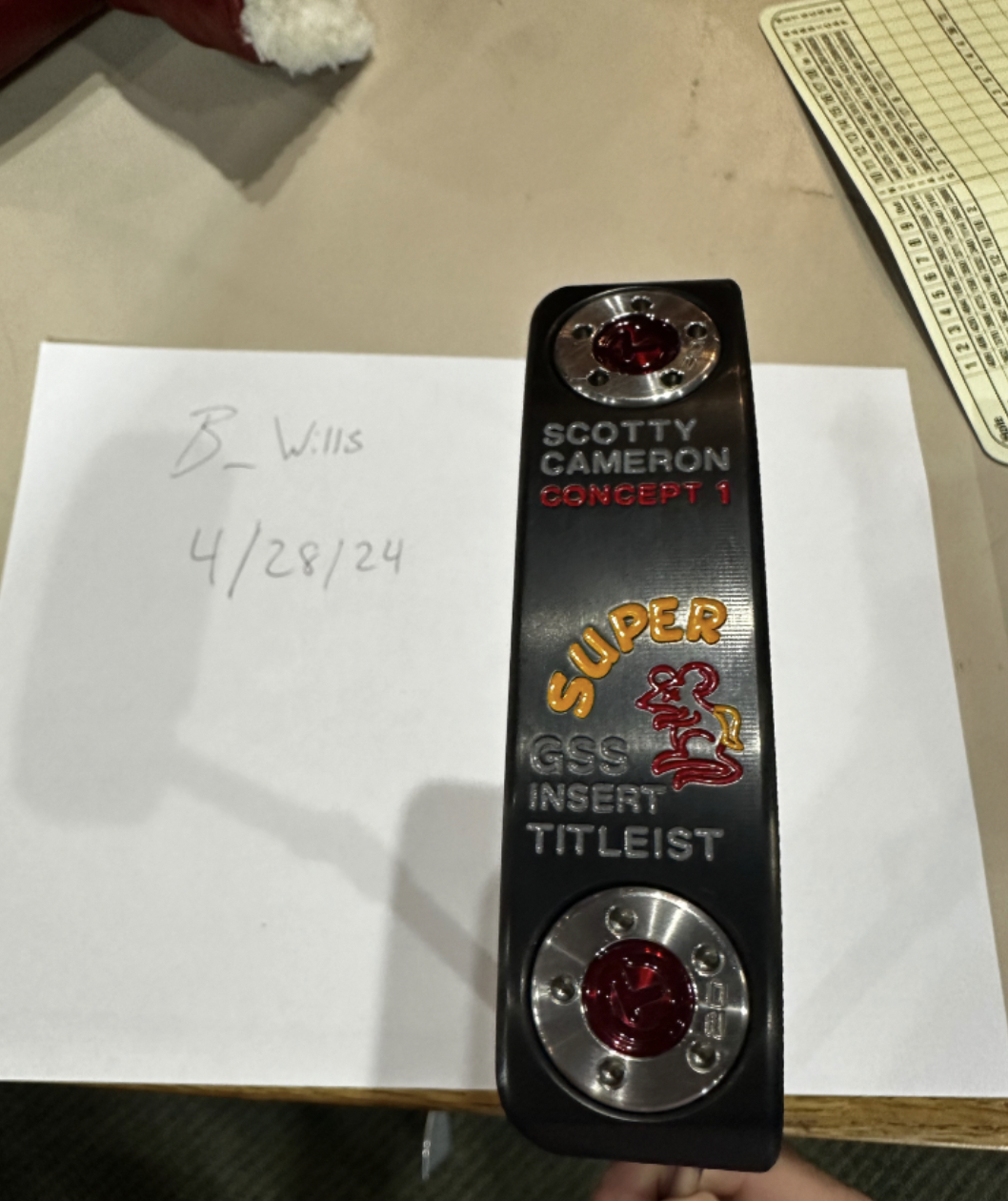

Coolest thing for sale in the GolfWRX Classifieds (5/6/24): Scotty Cameron Super Rat concept 1 putter

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a Scotty Cameron Super Rat concept 1 putter

From the seller: (@BWillis): “Scotty super rat concept 1 gss insert 35”, pulled from tour van at St. Jude’s in 2014 only carpet rolled. $7000 obo PayPal g&s, open to offers can send more pics.”

To check out the full listing in our BST forum, head through the link: Scotty Cameron Super Rat concept 1 putter

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole3 weeks ago

19th Hole3 weeks agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

-

19th Hole1 week ago

19th Hole1 week agoLET pro gives detailed financial breakdown of first week on tour…and the net result may shock you

-

Equipment3 weeks ago

Equipment3 weeks agoJason Day on his recent switch into Srixon ZX5 and ZX7 Mk II irons

-

19th Hole5 days ago

19th Hole5 days agoGary Player claims this is what ‘completely ruined’ Tiger Woods’ career

-

Whats in the Bag1 week ago

Whats in the Bag1 week agoTeam McIlowry (Rory McIlroy, Shane Lowry) winning WITBs: 2024 Zurich Classic

Carolina Golfer

Sep 10, 2019 at 7:54 am

Another WRX article with negative replies. Do you guys like anything or just like to complain?

JP

Sep 11, 2019 at 3:16 am

I like to complain about poor golf design ideas.

SV

Sep 9, 2019 at 4:51 pm

I don’t see the lack of adjustability as a problem. As a whole most people are probably better off without it. Find the right loft and leave it alone (says the guy always adjusting). But come on Cleveland, only one option for lefties? At least give us two (9* & 12* or 10.5* & 12*).

George Steer

Sep 9, 2019 at 2:52 pm

All of the writing on the clubhead comes off as cheap. If they feel the need to explain the features, utilize peel of stickers.

Donn

Sep 14, 2019 at 7:27 pm

peel off stickers seem cheapo to me. I prefer them writing on the clubhead. a few years down the line and you are shopping used, the info written on the clubhead helps you to know what’s the important design stuff.

JP

Sep 9, 2019 at 2:10 pm

Turbo? Why? Why? Why?

Do they actually know what a turbo is?

DukeOfChinoHills

Sep 9, 2019 at 12:32 pm

I had a Launcher back around 2004-05ish and really liked it. This new one looks cool, but I’m not in the market now.

Getemgoose

Sep 9, 2019 at 12:24 pm

So the Cleveland Turbo threw on some Ping turbulators. Cool story.

Jarnio Bubly

Sep 9, 2019 at 11:49 am

It’s always faster than last year! The faster we say it is the more consumers will get over how hideous it looks. Get out your pocket book! ????

15th Club

Sep 9, 2019 at 11:21 am

Wait just a minute. Is this a non-adjustable hosel? If so; uh, yeah it will be lighter. A lot lighter. At the cost of any adjustability. If I am wrong about this, somebody please correct me ASAP.

Also; this is just me talking but how many players who are GolfWRX readers want and need a higher-launching driver? For my part, a driver head that launches LOWER is usually better, all other things being equal. I would love to own a driver with 10.5 degrees of loft. But I would hit it way too high. More static loft = more control and more straight. Like a 7-iron. But that kind of loft produces balloon drives. I want the highest loft possible, in the lowest-hitting driver possible.

PI

Sep 9, 2019 at 10:05 am

I’ve been testing this driver out for the last year or so and I have to say it is right up there with the best drivers. I have the TS3 in play now and this club in testing was just as good if not better than the TS3.

JP

Sep 9, 2019 at 9:47 am

Seriously?!? Writing on the crown?!? And why do they all have to copy each other with raised fins on top? It’s busy and ugly.

Angus

Sep 9, 2019 at 3:11 pm

What on earth has the writing got to do with anything, you can’t even see it when using the club, how it performs is what is important

JP

Sep 12, 2019 at 3:55 am

You’re blind if you can’t read all about the hibore tech on the crown at address…