Equipment

Spotted: Nippon “Graphite On Steel Technology” hybrid prototype shafts

Steel vs. graphite shafts, which is better for your game? It’s a question as old as the invention of graphite shafts for golf clubs.

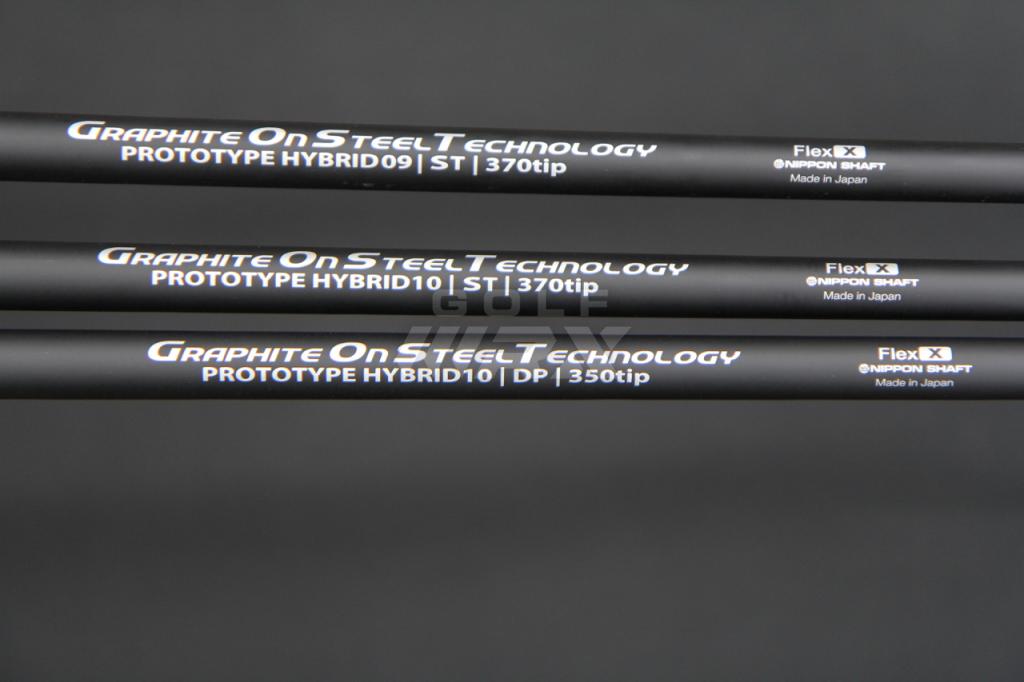

Well, it appears that Nippon is combining steel and graphite with its new hybrid prototype shaft, with technology called “Graphite On Steel.” Based on the nomenclature and the photos we captured at the 2018 AT&T Byron Nelson on Monday, it seems that there is a layer of graphite surrounding a steel hybrid shaft.

And for what purpose? GolfWRX Members are guessing that the design could be for reduced vibration, or for great stability, but we’re yet to know for sure.

We’ve reached out to Nippon representatives and will update this story with more information as it becomes available. For now, click here for more photos and discussion.

- LIKE58

- LEGIT7

- WOW8

- LOL5

- IDHT2

- FLOP6

- OB0

- SHANK16

Whats in the Bag

Webb Simpson WITB 2024 (May)

- Webb Simpson what’s in the bag accurate as of the Wells Fargo Championship. More photos from the event here.

Driver: Titleist TSR3 (10 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Black 6 X

3-wood: Titleist TS2 (15 degrees, B2 SureFit setting)

Shaft: Mitsubishi Tensei CK Blue 70 TX

5-wood: Titleist 913 Fd (18 degrees)

Shaft: UST Mamiya VTS Proforce 8 TX

Hybrids: Titleist TSR2 (24 degrees)

Shaft: Graphite Design Tour AD D1 Hybrid 105 X

Irons: Titleist T150 (5, 6), Titleist 680 (7-PW)

Shafts: True Temper Dynamic Gold Tour Issue X100

Wedges: Titleist Vokey Design SM9 (46-10F, 54-14F, 60-04L)

Shafts: True Temper Dynamic Gold Tour Issue X100 (46), True Temper Dynamic Gold Tour Issue S400

Putter: Odyssey Ai-One Jailbird Cruiser

Ball: Titleist Pro V1

Grips: Golf Pride Tour Velvet

Check out more in-hand photos of Webb Simpson’s clubs here.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Keegan Bradley WITB 2024 (May)

- Keegan Bradley’s WITB accurate as of the Wells Fargo Championship. >14 clubs pictured. Obviously, Bradley will reduce that number to 14 for competition. Check out more photos from the tournament here.

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (16.5 degrees)

Shaft: Aldila Rogue White 130 MSI 70 TX

Hybrid: Callaway Apex UW (19 degrees)

Shaft: Project X HZRDUS Smoke Black RDX 80 TX

Irons: Srixon ZX5 Mk II (3-5) Srixon ZX7 Mk II (6-PW)

Shafts: True Temper Dynamic Gold Tour Issue X100

Wedges: Cleveland RTX ZipCore (52-10 Mid, 58-6 Low)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: Odyssey Ai-One Jailbird Cruiser

Grip: SuperStroke Zenergy WristLock

Grips: Golf Pride Tour Velvet Plus4

Ball: Srixon Z-Star Diamond

Check out more in-hand photos of Bradley’s clubs here.

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Coolest thing for sale in the GolfWRX Classifieds (5/7/24): Mizuno 245 irons

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a set of Mizuno 245 irons.

From the seller: (@JB_007): “1. Mizuno Pro 245 – $1000 –> 950/obo

- Purchased brand new – they have 36 holes on them, with probably 10 premium range balls. Great set of irons, I just am looking to go another way right now.

- 5-PW –> stock L/L/L

- Project X LS 6.5

- Stock MCC Mizuno Grips.”

To check out the full listing in our BST forum, head through the link: Mizuno 245 irons

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE2

- LEGIT0

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

-

19th Hole2 weeks ago

19th Hole2 weeks agoLET pro gives detailed financial breakdown of first week on tour…and the net result may shock you

-

19th Hole6 days ago

19th Hole6 days agoGary Player claims this is what ‘completely ruined’ Tiger Woods’ career

-

Whats in the Bag1 week ago

Whats in the Bag1 week agoTeam McIlowry (Rory McIlroy, Shane Lowry) winning WITBs: 2024 Zurich Classic

-

19th Hole3 weeks ago

19th Hole3 weeks agoTaylorMade signs 15-year-old AJGA Rolex Junior Player of the Year to an NIL contract

-

19th Hole1 week ago

19th Hole1 week agoLIV star splits with swing coach after working together for 14 years

Dave Bryce

May 19, 2018 at 1:52 pm

In the 90s I reshafted the bimatrix shaft for many customers. That shaft incorporated the same principles and proved to be more hype then substance! With that shaft I found the swingweights to be too high!

KenW

May 16, 2018 at 9:56 pm

I too have a set of the Aerotech SteelFiber shafts which have steel thread wrapped around a graphite core and they were great, but a couple years ago I put Fujikura’s Metal Composite shafts (MCI) on my Calloway Apex irons and Wow! they are terrific shafts. Like the Nippon shafts, they have a graphite sleeve over a steel core shaft. Don’t know there’s a ton of difference but the Fujikura seem to have the perfect Flex and torque for my swing.

~j~

May 16, 2018 at 12:43 pm

A side from perhaps the steelfibers (never tried), has anyone even had much success intertwining steel and graphite?? Would think the extra labor/technology involved would largely go unnoticed by many and likely to be not worth the production cost.

Buck Futter

May 16, 2018 at 12:22 pm

Graphite Hybrid On Steel Technology or GHOST for short

Should make them in white

Really Big Mike

May 16, 2018 at 12:00 pm

This technology looks to be very similar to Aerotech Steelfiber, who advertises that their shafts are longer and straighter with less effort and they avoid injury or aggravating previous injury.

cinch bugs

May 15, 2018 at 8:34 am

Don’t knock it till you’e tried it…. just kidding knock away!

Deadpool

May 15, 2018 at 2:21 am

Lets just go back to hickory. I like wood. My wood is good.

steve

May 15, 2018 at 3:53 pm

so yer regressing back to woodies and abandoning stiff steel and floppy graphite?

steve

May 14, 2018 at 6:08 pm

SteelFiber shafts have filament-wound steel fibers over and internal graphite shaft… and now Nippon is putting the graphite over the steel shafting. Why are they doing this expensive solution to compensate for the failings of plain graphite shafts with floppy soggy tips with a sloppy dynamic response going through final release and impact?

For SteelFiber: https://aerotechgolfshafts.com/

steve

May 14, 2018 at 6:15 pm

Furthermore.. most graphite shafts are oven-cured to harden the epoxy mix holding the graphite fibers. Not with Seven Dreamers graphite shafts which are autoclave cured that sucks out the excess epoxy plastic that causes the tip instability of other graphite shafts.

Seven Dreamers: http://www.golfwrx.com/489200/a-qa-with-seven-dreamers-about-its-1200-shafts/

Deadpool

May 15, 2018 at 2:22 am

Yeah I am so intelligent and knowledgeable too, that Google lets me know everything too, steve

steve

May 15, 2018 at 3:50 pm

go back to the main WRX forum with all the gearheadbaters…

steve

May 15, 2018 at 10:01 pm

Yer the Google gearheadbater who can only tap twitter-sized blurts from yer shrunken brainlet.. so sooo obvious …. ????

Dan

May 15, 2018 at 3:59 pm

Does this guy just copy paste this app the time?

steve

May 15, 2018 at 10:00 pm

I remember all that scientific stuff because my smart brain is not ruined with a twitter blurting mentality…. just go to the main WRX forum and look at the juvenile comments in less than 140 characters… sooo pa thetic…

Not Steve

May 15, 2018 at 11:14 pm

Your smart brain and scientist stuff is on the wrong site for that you will incurred a stroke penalty and another for slow play

Josh

May 14, 2018 at 11:29 pm

Steelfiber convert here… I agree why put the graphite on top of the steel? Doesn’t make as much sense as the steel-fiber-weave wrapped around a traditional graphite shaft…