Equipment

Grooves on Grooves: Callaway launches new Mack Daddy 4 wedges

“Let’s do something else,” said Callaway’s Chief Designer and wedge-making legend, Roger Cleveland when talking about designing the new Callaway Mack Daddy 4 wedges.

And something else, he did.

Callaway’s Mack Daddy 4 wedges, which the company officially launched on Tuesday, use a new “groove-in-groove” technology that features raised micro-ridges between the main grooves on the faces. Rather than these ridges going below the surface, however, they’re actually “surface positive,” as Callaway explains it; that means they protrude above the surface. Therefore, the grooves and micro-ridges create more points of contact for the golf ball, and they create additional friction to induce more backspin.

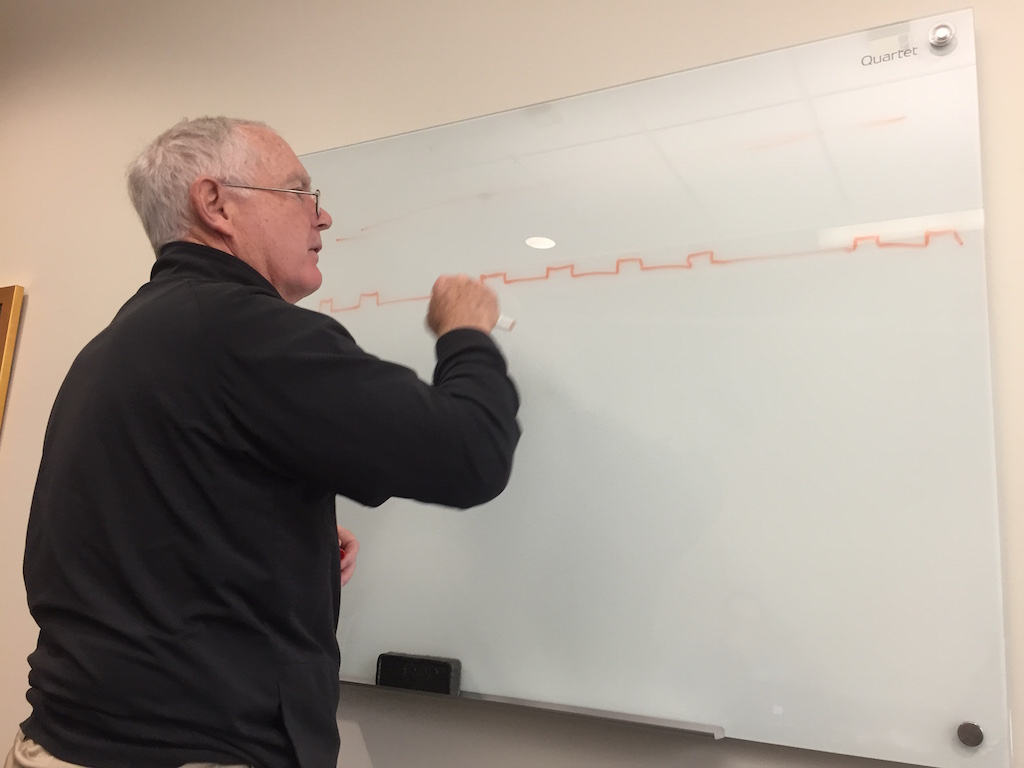

In fact, Cleveland himself was so excited about the design, he stood up during our interview and drew out the design on a whiteboard. Professor Cleveland, if you will.

Related: For more insight from Roger Cleveland himself, click here to listen as he joins our 19th hole!

Using new, proprietary cutters, it takes 12 minutes per head to cut the grooves, according to Cleveland. Using a progressive design throughout the set, the lower-lofted wedges — 52 degrees and below — use “20D” grooves, while higher-lofted wedges — 54 degrees and above — use 5D grooves. That means, overall, the higher-lofted wedges are designed to create more spin for greater control around the greens, and the lower-lofted wedges will behave more like your shortest iron. Each of the wedges also have an added groove — Callaway calls it a “nip it” groove — near the leading edge that’s designed to induce more spin when you catch the ball a bit thin.

Maybe the new groove design is why so many PGA Tour players are switching into the wedges so quickly. Sergio Garcia already won with them in the bag at the Andalucía Masters, and Brendan Grace won using them at the Nedbank Golf Challenge. In the 2017 RSM Classic, in fact, there were 30 Mack Daddy 4 wedges already in play.

Grooves aren’t the only difference you’ll notice in the new Mack Daddy 4 wedges, however. Based on Tour feedback, Callaway has designed the wedges with a more compact shape, straighter leading edges, tighter leading edge radii, and slightly more offset throughout the line, according to Callaway.

The MD4 wedges have a progressive offset in the set in order to better blend looks-wise into your set of irons.

“Tour pros like only a subtle amount of leading-edge radius,” said Cleveland, according to a press release. “In the Mack Daddy 4 we gave them enough to make a performance difference while still pleasing the eye.”

As part of the Mack Daddy 4 wedge line, there are now 4 grinds: C-grind, S-grind, W-grind and a new X-grind that has a narrow sole but with high-bounce. Here is the rundown of what each of the grinds delivers, according to Callaway:

- C-Grind: “Increased relief, especially at the heel, making it easier to play shots with the face open. Ideal for medium-to-shallow attack angles and/or firm course conditions. 8-degrees of bounce.”

- S-Grind: “Medium-width sole with slight chamfer at the back and moderate heel relief to keep the leading edge low through impact, promoting solid contact on open-faced shots. 10-degrees of bounce.”

- W-Grind: “Sole is wider at the center and toe and narrower at the heel, with moderate heel relief and generous front-to-back camber. That prevents digging without increasing bounce, and keeps the leading edge close to the turf at impact. Great for open-faced shots. More versatile than our previous W Grind. 12-degrees of bounce.”

- X-Grind: “The newest grind features a narrow, high-bounce crescent sole, with the low point near the front. Excellent for moderate-to-steep attack angles and medium-to-soft course conditions. 12-degrees of bounce.”

The Mack Daddy 4 wedges, which are made from 8620 carbon steel, come in both Platinum Chrome and Matte Black finishes. Like the previous Mack Daddy 3 wedges, the Mack Daddy 4 wedges have four weight ports, and they have milled-aluminum medallions that progressively raise CG (center of gravity) as loft increases to help dial in ball flight, spin and feel appropriately for each loft.

Available lofts include 46, 48, 50, 52, 54, 56, 58, 60 and 64-degree options, totaling 21 loft-bounce combinations. The wedges will come stock with True Temper’s Dynamic Gold Tour Issue 115 shafts and Lamkin UTx grips. Mack Daddy 4 wedges will be in stores on January 26 and will sell for $149 apiece.

See what GolfWRX members are saying about the Mack Daddy 4 wedges in our forums.

- LIKE184

- LEGIT15

- WOW10

- LOL5

- IDHT1

- FLOP5

- OB1

- SHANK18

Whats in the Bag

Daniel Berger WITB 2024 (April)

- Daniel Berger what’s in the bag accurate as of the Farmers Insurance Open. More photos from the event here.

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Fujikura Ventus Black 7 X

6-wood: TaylorMade Qi10 Tour (21 degrees)

Shaft: Fujikura Ventus Black 8 X

Irons: TaylorMade P770 (3), TaylorMade Tour Preferred MC 2011 (4-PW)

Shafts: Project X Denali Blue 105 TX (3), Project X 6.5 (4-PW)

Wedges: Titleist Vokey Design SM9 (50-12F), Titleist Vokey Design SM10 (56-14F), Callaway Jaws Raw (60-08C)

Shafts: Project X 6.5 (50), True Temper Dynamic Gold Tour Issue S400 (56, 60)

Putter: Odyssey Ai-One Jailbird Mini DB

Grip: SuperStroke Zenergy PistolLock 1.0

Grips: Golf Pride Tour Wrap

Ball: Titleist Pro V1

Check out more in-hand photos of Daniel Berger’s clubs in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Heavy Artillery: A look at drivers in play at the Zurich Classic of New Orleans

What are the driver and shaft combinations of the best golfers in the world? For gearheads, it’s an endlessly interesting question — even if we can only ever aspire to play LS heads and 7 TX shafts.

At this week’s Zurich Classic of New Orleans, GolfWRX got in-hand looks at the driver setups of a wealth of players.

Check out some of the most interesting combos below, then head to the GolfWRX forums for the rest, as well as the rest of our galleries from New Orleans.

Rory McIlroy

Driver: TaylorMade Qi10 (9 degrees @8.25)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride MCC

Alex Fitzpatrick

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride MCC

Daniel Berger

Driver: Ping G430 LST (10.5 degrees @9)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride Tour Wrap

Rasmus Hojgaard

Driver: Callaway Paradym Ai Smoke Triple Diamond (10.5 degrees)

Shaft: Mitsubishi Tensei 1K Blue 60 TX

Grip: Golf Pride MCC

Alejandro Tosti

Driver: Srixon ZX5 Mk II LS (9.5 degrees @10.5)

Shaft: Project X HZRDUS T1100 75 6.5

Grip: Golf Pride MCC Plus4

James Nicholas

Driver: Titleist TSR3 (8 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 7 X

Grip: Golf Pride Tour Velvet

Kevin Streelman

Driver: Titleist TSR3 (10 degrees, D1 SureFit setting)

Shaft: Fujikura Ventus TR Black 6 X

Grip: Golf Pride Tour Velvet

Sang-moon Bae

Driver: Callaway Paradym Triple Diamond (9+ @8)

Shaft: Fujikura Ventus Blue 6 X

Grip: Golf Pride Tour Velvet

Russ Cochran

Driver: Callaway Paradym Ai Smoke (9 degrees)

Shaft: Graphite Design Tour AD TP 6 X

Grip: Golf pride MCC Align

MJ Daffue

Driver: Callaway Paradym Ai Smoke Max (10.5 degrees @9.5)

Shaft: Project X HZRDUS Smoke Green RDX 65 TX

Grip: Golf Pride ZGrip Cord Align

Check our more photos from the Zurich Classic here.

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Rasmus Højgaard WITB 2024 (April)

- Rasmus Højgaard what’s in the bag accurate as of the Zurich Classic.

Driver: Callaway Ai Smoke Triple Diamond (10.5 degrees)

Shaft: Mitsubishi Tensei 1K Blue 60 TX

3-wood: Callaway Ai Smoke Triple Diamond Prototype (16.5 degrees)

Shaft: Mitsubishi Tensei 1K White 80 TX

Utility: Callaway Apex UW (21 degrees)

Shaft: Mitsubishi Tensei AV Raw White 85 TX

Irons: Callaway Apex Pro (3), Callaway X Forged (4-PW)

Shafts: KBS $-Taper 130

Wedges: Callaway Jaws Raw (52-10S, 56-10S, 60-06C)

Shafts: KBS Tour 130 X

Putter: Odyssey Ai One Milled Eight T DB

Grips: Golf Pride MCC

Check out more in-hand photos of Hojgaard in the forums.

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 days ago

19th Hole2 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 days ago

19th Hole2 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

HDTVMAN

Jan 10, 2018 at 4:02 pm

I like the look, but will stay with my PM Grind wedges. I don’t understand why more wedges do not have grooves across the entire face, like the PM Grind. Even if I miss off the toe, the shot is still acceptable.

Uhit

Jan 9, 2018 at 4:38 pm

Funny, the Bridgestone Tour B wedges have also that “new “groove-in-groove” technology”,

already mentioned in a press release in august last year:

http://www.bridgestonegolf.de/content/node_15813.htm

and already reviewed on WRX in november:

http://www.golfwrx.com/forums/topic/1563642-bridgestone-tourb-xw-1-wedges/

Blop

Jan 9, 2018 at 9:42 pm

Cleveland/Srixon have been using this for a while now.

stan

Jan 9, 2018 at 10:38 am

These hi-tech wedges are only effective for tour players with higher speed swings. Only the top 1% of golfers, which includes gearhead wannabes, will entertain buying these contraptions.

Btw, in the 1967 book Search for a Perfect Swing (SPS) they tested a smooth grooveless wedge and found insignificant differences in performance compared to a grooved wedge. The testing was done under scientific condition of that time so perhaps the results would be different with these Cally wedges with the fancy face milling.

Paul G

Jan 9, 2018 at 11:13 am

I think wedges are one of the few areas of most amateur golfers games that can be in any way like a Tour player. Not the full swing shots, but those around the green are well within the reach of a normal golfer. If you look at a 30 yard pitch, the speed a Tour player uses and an amateur will be very close (providing they are playing the same kind of shot) as the goal isn’t about maximum yardage but the correct yardage. Of all the gear in your bag, wedges and your putter are the clubs that allow you to play a “tour players” game as they don’t rely on physical strength and speed to work

Grooves are useful once there is anything in the way of the contact between ball and club, so a grooveless wedge is fine from a perfect clean lie, but poor everywhere else, hence all wedges have grooves.

Huh?

Jan 9, 2018 at 11:28 am

Stan – Where or how are you coming up with this nonsense?

Dan

Jan 9, 2018 at 1:31 pm

The groves are for poor lies. A grove wedge in the rain removes about 2 tsp of water from between the club face and ball. The groves also improve spin out of the rough.

stan

Jan 9, 2018 at 5:28 pm

So, if you hit different types of wedges off a clean tight lie there would be no significant difference between their performance results?

The dude

Jan 9, 2018 at 8:27 pm

I buy that….isn’t there an old article that proves that??

dlygrisse

Jan 12, 2018 at 11:59 am

Flawed study.

Grooveless wedges only perform good under perfectly clean conditions. Like off a turf mat and a perfectly dry/clean ball. If any moisture gets on the ball or clubface the whole thing goes haywire.

Wedges are designed for slower swing speeds, unlike drivers. Along with putters they are the most relevant.

Travis

Jan 9, 2018 at 10:23 am

Groove-ception