Equipment

Classic Name, Max Performance: TaylorMade launches 2017 “M CGB” irons

TaylorMade is holding nothing back in terms of distance and forgiveness with its premium M CGB irons, which revive a name and concept from the company’s past.

In 2006, TaylorMade released super game-improvement irons with a high COR (coefficient of restitution, a measure of energy transfer) that sold for around $1,300 at retail. They were called r7 CGB, or “Center of Gravity Back.” These irons stood alone at the high-end of the market in terms of performance and pricing, after which the iron industry began shifting toward higher-COR irons, according to Tomo Bystedt, Senior Director of Product Creation (Irons) at TaylorMade. Even standard game-improvement irons were being built with high COR, like the company’s Burner 2009 irons, which sold for half the price. The demand for max performance at a premium price dissipated.

“The CGB name is iconic and represents some of the longest and most forgiving irons we’ve ever created at TaylorMade,” Bystedt said in a press release. “The concept has now been re-created with all our latest technology to bring never-before-seen performance to golfers of all skill levels.”

Flash forward to 2017, however, and that demand is back. The problem today is, according to Bystedt, is that super game-improvement irons that offer big distance, a high launch and maximum forgiveness are all delivered in iron heads that he said are too big, waving a red flag to a foursome.

“Super G.I. irons have always been huge,” Bystedt told me. “It signals to people that you’re not that good.”

TaylorMade’s 2006 r7 CGB (left) vs. its 2017 M CGB

With its new M CGB irons, TaylorMade sought to provide golfers with a high-end product that provides the performance of a super game-improvement iron, but doesn’t look like it’s the size of a woodshed. Bystedt and his product development team also wanted to offer better sound and feel than super-GI golfers are used to.

That being the case, TaylorMade packed the M CGB irons with technologies from the company’s past, and a few new features as well, to make them the most forgiving and longest irons in the company’s stable.

Like the M2 irons, the M CGB irons have a fluted hosel to help displace CG.

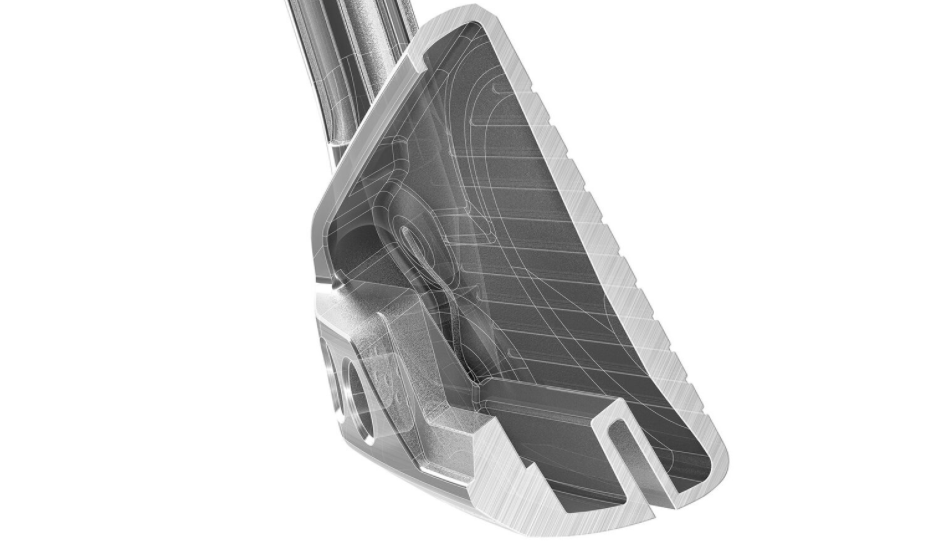

Each M CGB iron in the set has four metal-injection-molded tungsten weights that sit deep behind the face to increase MOI (moment of inertia, a measure of forgiveness) and move center of gravity (CG) rearward to increase launch and forgiveness. The irons also use TaylorMade’s Inverted Cone design and a newly designed “Speed Pocket” to help golfers create faster, more consistent ball speeds. The irons also use an “accordion-style” undercut to create more distance, along with the company’s “Face Slots” that help expand the sweet spot of the irons. For better sound and feel, the M CGB irons use the company’s familiar “Geocoustic” technology, which includes a special geometry and a material called Hybrar in the badging of the irons to dampen vibrations for a better sound and feel.

TaylorMade’s “Accordion” undercut helps create a higher launch.

Each of the irons were given maximum COR, according to Bystedt, so there’s no progression or “holding back” on distance or forgiveness throughout the set. With TaylorMade’s M2 2017 irons, which are currently the company’s most forgiving iron model, the mid and short irons were not given maximum COR to help golfers create more consistent distance gaps throughout the set. The M CGB irons were to create the highest ball flight possible through the set. The result, according to TaylorMade, is an iron that achieves the highest peak height of any TaylorMade iron since 2012, which will certainly benefit golfers with slower swing speeds who need help to hit the ball higher and farther so they can hit more greens.

Since these irons launch higher and are created for golfers who swing the club a bit slower, their loft progression looks a bit different compared to TaylorMade’s M2 irons. The longer irons have higher lofts than the long irons of the M2 set (1.5 degrees higher in the 4 iron), and the shorter irons and wedges (9-PW, AW, SW) have stronger lofts. According to Bystedt, this differentiation in loft progression helps golfers with slower swing speeds hit ideal launch windows to create max performance.

The M CGB irons will be available on September 29 (4-PW and AW or SW) for $1,199.99 for an eight-piece set with a Nippon N.S. Pro 840 steel shafts. The cost is $1,399.99 with the stock graphite shaft option, UST’s Recoil 460 ES. The irons come stock with a TaylorMade Dual Feel grip. Custom shaft and grip options will be available, many at no added charge.

- LIKE142

- LEGIT14

- WOW8

- LOL14

- IDHT4

- FLOP11

- OB6

- SHANK138

Whats in the Bag

Kevin Streelman WITB 2024 (April)

- Kevin Streelman what’s in the bag accurate as of the Zurich Classic.

Driver: Titleist TSR3 (10 degrees, D1 SureFit setting)

Shaft: Fujikura Ventus TR Black 6 X

3-wood: Titleist TSR3 (15 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus Blue 8 X

5-wood: Ping G (17.5 degrees)

Shaft: Graphite Design Tour AD DI 10 X

Irons: Wilson Staff Model CB (4-9)

Shafts: Project X 6.5

Wedges: Wilson Staff Model (48-08, 54-08), Titleist Vokey Design WedgeWorks (58-L @59)

Shafts: Project X 6.5 (48), True Temper Dynamic Gold Tour Issue S400 (54, 58)

Putter: Scotty Cameron TourType SSS TG6

Grips: Golf Pride Tour Velvet

Ball: Titleist Pro V1x

Check out more in-hand photos of Kevin Streelman’s clubs here.

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Choose Your Driver: Which 2012 driver was your favorite?

The year was 2012. Gangnam Style ruled supreme, its infectious beats and ludicrous horse-riding dance moves hypnotizing us with their stupidity. Everyone was talking about the Mayan calendar, convinced that the end of days was near. Superheroes soared on the silver screen, with the Avengers assembling in epic fashion. Katniss Everdeen survived The Hunger Games. And the memes! The memes abounded. Grumpy Cat triumphed. We kept calm and carried on.

In much the same way that automotive enthusiasts love classic cars, we at GolfWRX love taking a backward glance at some of the iconic designs of years past. Heck, we love taking iconic designs to the tee box in the present!

In that spirit, GolfWRX has been running a series inspired by arguably the greatest fighting game franchise of all time: Mortal Kombat. It’s not “choose your fighter” but rather “choose your driver.”

Check out some of the standout combatants of 2012 below.

View this post on Instagram

Nike VRS

Often harshly critiqued during its years releasing golf equipment (right, Phil Mickelson?), Nike’s tenure in the club-and-ball business gets a gloss of nostalgic varnish, with many of its iron and putter designs continuing to attract admirers. Among the company’s driver offerings, the 2012 VRS — or VR_S, if you will — drew high marks for its shaping and toned-down appearance. The multi-thickness, NexCOR face was no joke either.

Check out our coverage from 2012 here.

Callaway RAZR Fit

Callaway’s first foray into moveable weight technology (married with its OptiFit hosel) did not disappoint. With a carbon fiber crown, aerodynamic attention to detail, and variable and hyperbolic face technologies, this club foreshadowed the tech-loaded, “story in every surface” Callaway drivers of the present, AI-informed design age.

Check out our coverage from 2012 here.

Cleveland Classic 310

Truly a design that came out of left field. Cleveland said, “Give me a persimmon driver, but make it titanium…in 460cc.” Our 2012 reviewer, JokerUsn wrote, “I don’t need to elaborate on all the aesthetics of this club. You’ve seen tons of pics. You’ve all probably seen a bunch in the store and held them up close and gotten drool on them. From a playing perspective, the color is not distracting. It’s dark enough to stay unobtrusive in bright sunlight…Even my playing partners, who aren’t into clubs at all…commented on it saying it looks cool.” Long live!

Check out our coverage from 2012 here.

Titleist 910

While there’s no disputing Titleist’s “Titleist Speed” era of drivers perform better than its 2010s offerings, sentimentality abounds, and there was something classically Titleist about these clubs, right down to the alignment aid, and the look is somewhere between 983 times and the present TS age. Representing a resurgence after a disappointing stretch of offerings (907, 909), The 910D2 was a fairly broadly appealing driver with its classic look at address and classic Titleist face shape.

Check out our coverage from 2012 here.

TaylorMade RocketBallz

The white crown. The name. You either loved ‘em or you hated ‘em. TaylorMade’s 2012 offering from its RocketBallz Period boasted speed-enhancing aerodynamics and an Inverted Cone Technology in the club’s titanium face. Technology aside, it’s impossible to overstate what a departure from the norm a white-headed driver was in the world of golf equipment.

Check out our coverage from 2012 here.

Ping i20

Long a quietly assertive player in the driver space, Ping’s i20 was more broadly appealing than the G20, despite being a lower-launch, lower-spin club. Ping drivers didn’t always have looks that golfer’s considered traditional or classic, but the i20 driver bucked that trend. Combining the classic look with Ping’s engineering created a driver that better players really gravitated toward. The i20 offered players lower launch and lower spin for more penetrating ball flight while the rear 20g tungsten weights kept the head stable. Sound and feel were great also, being one of the more muted driver sounds Ping had created up to that time.

Check out our coverage from 2012 here.

GolfWRXers, let us know in the comments who “your fighter” is and why!

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Coolest thing for sale in the GolfWRX Classifieds (4/29/24): Krank Formula Fire driver with AutoFlex SF505 shaft

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a Krank Formula fire driver with AutoFlex SF505 shaft.

From the seller: (@well01): “Krank formula fire 10.5 degree with AUtoflex SF505. $560 shipped.”

To check out the full listing in our BST forum, head through the link: Krank Formula Fire driver with AutoFlex SF505 shaft

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE3

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole3 weeks ago

19th Hole3 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole3 weeks ago

19th Hole3 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole1 week ago

19th Hole1 week ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole2 weeks ago

19th Hole2 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole2 weeks ago

19th Hole2 weeks agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

George

Sep 12, 2017 at 10:20 am

Gentlemen I purchased new & still play the 2006 R7 CGB irons, graphite, 12 h-cap & 69 years old. The new M CGBs look similar, I cannot wait to test them out, maybe it’s time for a new shiny set after 11 years.

steve2

Jan 4, 2018 at 1:15 am

Yes, they are the Viagra of golf clubs 😎

Otis

Sep 11, 2017 at 6:06 pm

I really love the TM cosmetic plaques on the back of the clubs. They give you that powerful blingy stature which is so important in golf.

dcorun

Sep 9, 2017 at 2:19 pm

I don’t care about playing irons that make people think I’m bad. I played the old Cleveland HiBore irons and hit it past the ones playing their pretty clubs. I’m going to get fitted for the new Cleveland Launcher HB irons and start hitting it long again. They will cost around $800 with a real deal Miyazaki C Kua shaft and I’ll keep the change to play more golf.

ob&chipolte&rnoobs

Sep 8, 2017 at 2:57 pm

I know, it’s crazy to think that people who like golf clubs would visit a site that mainly talks about new equipment.

Chipolte it seems foolish to visit a site that talks about what you don’t like.

Perhaps you could find a site more to your liking. Try Ilovebarbiedolls.com that should be more up your alley.

OBnoob

Sep 9, 2017 at 6:31 pm

yes, this is a ‘safe space’ for gearheads to slobber all over the latest and greatest new equipment and fantasize with ignorant opinions like ‘love’ and ‘feel’.

Chipolte

Sep 8, 2017 at 11:52 am

SGI clubs for hackers, duffers and assorted gearhead teens and struggling seniors.

rgk5

Sep 8, 2017 at 7:00 am

This looks like the end for the M2 and M1 irons. Why have three that are very close to the same?

Steve S

Sep 8, 2017 at 8:10 am

Not sure that will happen. The price points for the M series is a lot lower. These irons are targeted to the golfer who has more money than brains…which seems to be a growing demographic. Full disclosure, I play 2016 M2’s.

OBnoob

Sep 9, 2017 at 6:29 pm

“… the golfer who has more money than brains…”, but that covers all the gearheads on this fine forum!

skull

Sep 7, 2017 at 10:57 pm

Nope, not at that price

David

Sep 7, 2017 at 7:44 pm

ok I like these!! but side by side I would like to see how much they DON’T outperform the 2006 model!! guarantee they don’t by much if at all.

also why is the graphite shaft cheaper than that spinner Nippon?? way cheaper. they never happens. has ust just sold itself out to every iron set for dirt cheap?

They don’t make ping’s shafts anymore so they must have to do something for the average golfer??

IDK man!! but ill take that m cgb 2 iron with a c taper 130x pronto. new beat stick.

Also, soon we will see rossa cgb putters!!!!!!!!!! and those were always a good look.

thumbs up

JDS

Sep 8, 2017 at 9:15 am

Uhhh. It’s $200 more for graphite.

OBnoob

Sep 9, 2017 at 6:33 pm

Udaman, gearhead.

Matt Hardy

Sep 7, 2017 at 5:13 pm

Delete

Shallowface

Sep 9, 2017 at 8:45 pm

Wonderful!

Ns

Sep 7, 2017 at 11:29 am

These are going to be the shiznit

Steve

Sep 7, 2017 at 10:44 am

JPX 900 Hot Metal with Recoil Shaft (or any shaft they offer) are the BEST GI clubs I’ve ever hit hands down. They are by far the longest, hottest, best feeling iron I’ve ever hit. Head to Head nothing beat it, not Apex, not the p series from TM, not the PING, and definitely not the new AP1 or AP3’s. It was also more forgiving and much better looking than any SGI club I’ve ever hit….. I also paid only $899 for 4-GW with REA, taper tip, Recoil shafts – not a ‘made for TM parallel tip cheap version’.

Now TM wants to compete with the JPX 900 Hot Metal by charging consumers $1200 for the blatant garbage fire of a head above?! Oh and also charge an extra $200 for a made for TM Recoil bs shaft?!

Good Luck TM, your decision making skills are impeccable….

– that was sarcasm by the way.

I guess that’s why I’ve seen more Mizuno sticks being used this year than I ever have before, while seeing less and less TM sticks at my club. Mizuno is back and growing fast. TM continues to spend outrageously in marketing, hoping consumers are dumb enough to listen.

I strongly URGE consumers to try the JPX 900 HM or JPX 900 Forged instead. Stop falling victim to over amplified marketing.

– Steve OUT (Mic-drop)

OB

Sep 7, 2017 at 11:40 am

YES YES YES!!!! I’m going out this evening to buy these new club contraptions with all the undercuts filled with elastomer and embedded with fantastic hi-density tungsten plugs…. not to mention the cool bling graphics. I want that soft buttery feel that I lost with my old clubs.

I will retire my old Hogan Radials with the big bottom flange that lowers the club CG but it has little MOI to correct for my really bad toe and heel hits. I need drastic help for my awful off-center hits and these new club designs should really really help… I hope.

OBnoob

Sep 7, 2017 at 5:09 pm

What a fool. Sarcasm is not your forte. By the way it is certain some new technology will benefit your game. Those ratty old Hogans you hit are beater sticks for people that can’t play.

Chipolte

Sep 8, 2017 at 11:50 am

Gearheads slobbering over golf clubs are fools.

OBnoob

Sep 9, 2017 at 6:27 pm

I agree gearheads are fools, but that’s no reason to insult them with sarcasm about new technology. Newer is always better.

Shallowface

Sep 9, 2017 at 8:46 pm

Mizark.