Equipment

How the idea of shaft frequency began

Forty years ago, Kim Braly and his father Dr. Braly went down to West Palm Beach to visit Wilson Golf, and that trip forever changed the way the golf industry thinks about the shafts in golf clubs.

“My father and I invented frequency matching,” Kim told me.

“And what’s that?” I asked.

“It’s the process of matching the stiffness of the shafts in your clubs to the heads so you can hit a golf ball rather than snap the shaft or hit the ball all over the place,” Kim said.

OK, that got my attention. So I ask how he stumbled upon the idea.

“My dad was an engineer and got into golf,” Kim said. “Eventually, I got interested in golf as well. In the early 1980s, we went to see the original ‘Iron Byron.’”

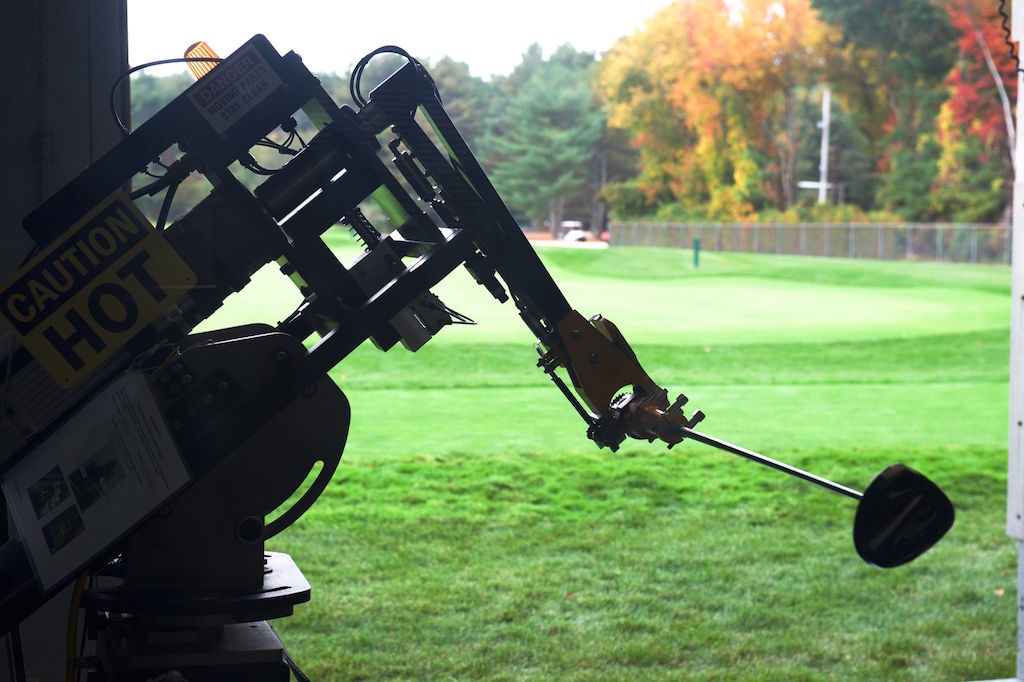

A modern-day golf robot at Titleist’s Manchester Lane Test Facility.

Iron Byron was the first club-testing machine, and it was modeled after smooth-swinging legend Byron Nelson. It’s basically an early robot — a motor in a box with an arm — built to use a regular golf club to hit a golf ball.

Kim and Dr. Braly watched the engineer operating Iron Byron put a club into the mechanical arm, place a ball in front of the club face and then press a button to swing the club. The result: perfection. It produced a high, piercing ball flight that was hit on a rope, not far removed from the storied ball flight of Nelson himself. This was followed by another and another. Kim and his father were ecstatic.

With great anticipation, they watched the engineer load the next club. The results were much different. Balls flew all over the place. The dispersion was awful. The Wilson engineer operating Iron Byron slowed down the machine. Balls flew shorter distances, but they landed closer together. The dispersion had been reduced. This was the inception of their game-changing idea; dispersion was a result of certain shaft characteristics matched with a club head and swing speeds. This “AH HA” moment changed how we fit and purchase golf clubs today.

Based on this observation, Kim and Dr. Braly designed a method to measure the performance of a golf shaft. Later, this led to the concept of frequency: very simply, stiffness is not the letter on the shaft, but a measurement based on characteristics like weight of shaft, weight of the head, length of the shaft and several other characteristics. The year was 1977 and they submitted a patent on this idea called “Frequency Matching.”

Armed with the power of measurement, Kim was ready to change golf shafts forever. He and his father started traveling the PGA Tour, and in doing so became the first “PGA Tour Van.” Over the last 40 years, Kim has worked as a researcher and designer, mastering the golf shaft. He’s worked at True Temper, Royal Precision and is currently as the head designer of research and development at KBS Golf Shafts.

In 2008, Kim launched a shaft company called KBS, which became the fastest growing shaft company in golf. Since that time, the company has gotten some of the best golfers in the world to use its shafts products, including Rickie Fowler, Justin Rose and Phil Mickelson.

The next time you’re struggling with shots that fly sideways, think about Kim and Dr. Braly. You might want to try try being fit for shafts if you haven’t already, because they may just be the most important part of your golf club.

- LIKE217

- LEGIT33

- WOW16

- LOL6

- IDHT1

- FLOP4

- OB0

- SHANK14

Whats in the Bag

WITB Time Machine: Billy Horschel’s winning WITB, 2017 CJ Cup Byron Nelson

The tournament bearing the name of one of golf’s all-time greats is now known as the CJ Cup Byron Nelson. Back in 2017, it was still the AT&T Byron Nelson and Billy Horschel was still a full-bag PXG staffer. The Florida Gator leveraged those wares to a playoff victory over Jason Day securing his fourth PGA Tour win in the process.

Check out the clubs Horschel had in play seven years ago in Texas.

Driver: PXG 0811X (9 degrees)

Shaft: Fujikura Atmos Tour Spec Black 6 X

3-wood: PXG 0341X (15 degrees)

Shaft: Project X HZRDUS Black 75 6.5

5-wood: PXG 0341 (18 degrees)

Shaft: Project X HZRDUS Black 75 6.5

Irons: PXG 0311T (3, 5-PW)

Shafts: True Temper Dynamic Gold Tour Issue X100

Wedges: PXG 0311T Milled (52-10, 56-10, 60-07)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: PXG Bat Attack

Grip: SuperStroke Flatso 1.0

Ball: Titleist Pro V1x

Check out more in-hand photos of Billy Horschel’s gear from 2017 here.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP1

- OB0

- SHANK1

Equipment

How Cleveland Golf’s wedge selector tool improves the wedge buying process

More than most golfers would care to admit, confusion often reigns when it comes to selecting a wedge — let alone configuring an entire wedge setup. Make? Model? Loft? Grind? Finish? Two wedges? Three wedges? Four? The questions abound!

While it’s easy to get off the fairway and deep into the rough quickly, the framework question for choosing wedges is the same as the entirety of the golf bag: How should I set up my golf bag to shoot the lowest score possible?

Manufacturers, in addition to, well, manufacturing golf clubs, also understand that golfers need to make informed decisions to get the most out of their equipment. It’s with this in mind, and to help golfers answer the aforementioned foundational question about their wedge setup, that Cleveland Golf has launched its wedge selector too.

To learn more, we talked with Cleveland’s Senior Product Manager, Casey Shultz.

GolfWRX: What was Cleveland seeing in the marketplace that led to the development of the wedge selector? How do golfers benefit?

Casey Shultz: Currently, there is a lot of talk about what grind players should play and what is right for their game in that aspect of selecting a wedge. But there is more to improving wedge play than finding the proper grind. We would even argue it’s one of the smaller dials for improvement. Players can find more success with wedges designed from head shape to shaft, sole width, gapping, and then the grind. Putting a system in place that makes the process of selecting the right wedge easier is something we feel can have a massive impact, especially for recreational players.

GolfWRX: Now, in breaking down Cleveland’s wedge selector tool, the point of departure is figuring out whether you’re an RTX or CBX player. Can you briefly spell out who each of these wedges is for?

CS: For lower handicappers, the RTX series is our tour-validated line of blade wedges. These are for players looking to play a lot of open-faced shots around the green, prioritize workability, and like to flight their wedges. CBX wedges are designed to make the short game easier, while still offering some level of versatility for the mid-high handicapper looking for a wedge that will reduce chunks and add forgiveness on all strikes. CBX’s are also a great option due to them blending well in weight and shaping with more cavity back iron sets.

GolfWRX: Proceeding through the RTX wedge selector, one of the first forks in the road is wedge finish. Can you break down the finish options and the considerations for a golfer in making their selection?

CS: With the RTX series we offer Tour Satin, Black Satin, and Tour Rack finishes. Tour Satin is our most popular finish and offers the most grind options. With HydraZip face blasts on the newest RTX Wedges, glare is significantly reduced at address compared to other silver finish offerings. Black Satin offers custom skin options as personalization and is one of the more durable black finishes on the market but will have some visible wear over time especially on the sole. Finally, Tour Rack is our tour authentic raw finish that will rust over time. The Tour Rack finish also comes with the option of applying any of our Tour Crafted leading edge and sole grind offerings to the Wedge for players really looking to fine-tune their performance.

GolfWRX: Can you walk us through the rest of the RTX wedge fitting process?

CS: Once players have selected their preferred finish, we gather information on their iron set and loft preferences to determine proper gapping. A properly gapped set of wedges, both with each other and transitioning from a player’s last iron, is key to ensuring their set covers a wide range of approach yardages well. We then ask specific questions about the performance the player is looking to achieve in their sand and lob wedges to determine proper grinds for each of those wedges. Lastly, we confirm a preference for traditional or Full-Face grooves at each loft. Full-Face grooves offer a new level of versatility, especially with open-face shots, but it’s up to the player if they want to transition to this groove design. Our algorithm will then take these results and determine a set of wedges best suited to the player’s game.

GolfWRX: Let’s circle back to grinds. Is there a grind configuration across their wedges you’re seeing the majority of players choose or is it pretty evenly divided?

CS: The MID grind is certainly the most popular grind across all lofts, with the blend of versatility and forgiveness in a wide range of conditions suiting many players. In sand wedge lofts, the second most popular grind is our FULL, which has a little more bounce than the MID and is especially effective out of the sand or rough. In lob wedge lofts, the popular alternative to the MID is the LOW grind, offering max versatility around the greens. We’re also seeing more amateur and tour players opt for our Full-Face models, especially in the lob wedge lofts where they are planning to open the face and get creative around the greens.

GolfWRX: Can you take us through the CBX wedge selector?

CS: In the CBX selector, we start by determining if a player is looking to play a lob wedge or not. For many recreational golfers, a lob wedge may not be necessary for the consistent short-game performance they are looking to achieve. Next, the CBX selector focuses on ensuring players end up with a set that transitions well into their irons, while also staying within the constraints of a player’s bag setup. With new players distance, game improvement, and super game improvement iron lofts becoming stronger than those of the past, creating a properly gapped set of wedges is trickier than ever for these players. The selector tool takes the guesswork out of the equation, while also considering a player’s set makeup and interest in replacing a wedge. Finally, players are given the option of when or if they would like to transition into a Full-Face design for added spin on strikes all over the face.

GolfWRX: Is there anything else you think GolfWRXers need to know about Cleveland’s wedge selector tool?

CS: Our wedge selector tool is designed to be used in concert with our set builder webpages. At completion of the selector, a player’s recommended wedge set will automatically be applied to the appropriate set builder. From there, they can easily adjust components or build specs to every Wedge all in one place. Players can also add Tour Crafted sole and leading edge grinds to refine their performance on our Tour Rack wedges, or personalize custom characters, skins, and paintfill in the same place. It’s a one-stop shop to build the perfect wedge set for any player’s game.

This article was presented in partnership with Cleveland Golf. Check out the wedge selector here.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Golf fans left surprised by LIV’s choice of course for its 2024 individual championship event

On Tuesday, LIV announced their individual championship will be held at Bolingbrook Golf Club just outside of Chicago. The event will take place September 13-15.

The late announcement is seemingly due to LIV looking for the right course in the Chicago area that has the infrastructure that can accommodate a professional event.

The choice of Bolingbrook Golf Club has received some feedback on social media.

Maybe Rich Harvest Farms wasn't available? RHF is 50miles from Chicago but at least it's surrounded by farm land so plenty of space to set up

— Crawf_Indiana (@captaincrawf) April 30, 2024

Awful course choice, it's a dog track!

— Rob (@piratedwight) April 30, 2024

????#LOOK: Bolingbrook GC in Illinois, site of LIV Golf’s just announced Individual Championship has tee times available around the $50 mark.

Are you teeing it up here? pic.twitter.com/b8Lgv9ZzhK

— NUCLR GOLF (@NUCLRGOLF) April 30, 2024

LIV fans were quick to point out that Bethpage Black, which is hosting the 2025 Ryder Cup, can also be played for a reasonable price, making the point the greens fees don’t always equate to the quality of the golf course.

During LIV’s first two seasons, LIV utilized Rich Harvest Farms in Chicago. It’s unclear why that course is off the rotation in favor of Bolingbrook.

More from the 19th Hole

- The wild reason why Mark Wahlberg was initially denied entry to an Australian golf club

- 2-time major champ announces shock retirement from the sport at age of 33

- Edoardo Molinari reveals the latest PGA Tour golfer to turn down ‘good offer’ from LIV Golf

New here?

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

-

19th Hole3 weeks ago

19th Hole3 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole1 week ago

19th Hole1 week ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole2 weeks ago

19th Hole2 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole2 weeks ago

19th Hole2 weeks agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

-

Equipment3 weeks ago

Equipment3 weeks agoWhat we know about Bryson DeChambeau’s 3D-printed Avoda irons

TeeBone

Jun 7, 2017 at 5:34 pm

Further, frequency matching a set doesn’t mean that the clubs all have the SAME shaft flexibility, only that the DIFFERENCE in flexibility is uniform from club to club. As the clubs get shorter, frequency and stiffness increase. Add to this the fact that as the clubs get shorter and heavier, they are swung at a slower speed. In the end, each shaft in a set flexes more and more overall as the clubs get longer. This silly “dispersion” theory suggests that a shaft must flex a specific amount to behave consistently.

TeeBone

Jun 7, 2017 at 2:39 pm

Tour players, unless they have a specific shaft manufacturer deal, are free to play whatever shaft they want. Their decision to play graphite over steel has to do with performance, not money.

TeeBone

Jun 7, 2017 at 2:27 pm

So Iron Byron, set at any particular swing speed, only reproduces the same ball flight with one specific shaft flex? This “dispersion” theory would mean that the same shaft can behave quite differently, from swing to swing, for an otherwise same swing input. Nonsense. There is no mention of this in any of the best-regarded scientific studies of shaft flexibility. This is a made-up marketing story designed to sell equipment.

Ned

Jun 6, 2017 at 8:06 am

Brunswick Golf developed the Frequency Matching System in 1981!

Rico

Jun 6, 2017 at 4:04 pm

The article states that the Braly’s submitted a patent for “Frequency Matching” in 1977.

J.

Jun 5, 2017 at 7:15 pm

And stiffness of an EI profile may be invisible to CPM matching? Does SST PURE shaft alignment work better?

Skip

Jun 7, 2017 at 1:18 pm

SST pure is pure Kool-Aid. Drink it if you so choose.

tim crider

Jun 5, 2017 at 4:05 pm

There is no doubt that shots can be saved every round by every player with changes from the shaft to the swing weight to the compression of your golf ball,,, hell practicing on the driving range could improve your game. There is a lot to know about this game and if you have the money and the time you may be able to cash in on these findings. Think how much better play got when shafts changed to steel from hickory. A lot to know and even more to learn. How much more can be found and improved, it was a very good article.

Charles Bartholomew

Jun 5, 2017 at 3:38 pm

Interesting article. A little history lesson now and then is a good thing.

cgasucks

Jun 5, 2017 at 8:20 am

If the Iron Byron can make crappy shots with a shaft that isn’t compatible with its swing speed, imagine it with a human being.

talljohn777

Jun 5, 2017 at 12:14 pm

Yes, if you have a club shaft that is too soft you can slow your swing down to allow the clubhead time to catch up and square, but why would you want to do that? The preference would be to hit a club that matches your top swing speed allowing you to get the most out of your swing.

artie j

Jun 5, 2017 at 6:59 am

I didn’t know the backstory. Very cool article Ryan

SH

Jun 4, 2017 at 10:25 am

Yup, awesome