Opinion & Analysis

Flex Appeal: An interview with shaft guru Robin Arthur

Life has a funny way of throwing people together. I was recently surfing the web, researching a new shaft for my driver. I sent off a few emails to shaft companies and OEM component companies asking for some advice. To my surprise, they all answered and had useful suggestions. But the response that captured my attention most was from Arthur Xtreme Engineering, a company that designs, tests and markets the Xcaliber brand of golf shafts. I received an email from Robin Arthur asking me a bunch of questions. Turns out he’s the CEO and President, so I was nice getting some VIP treatment!

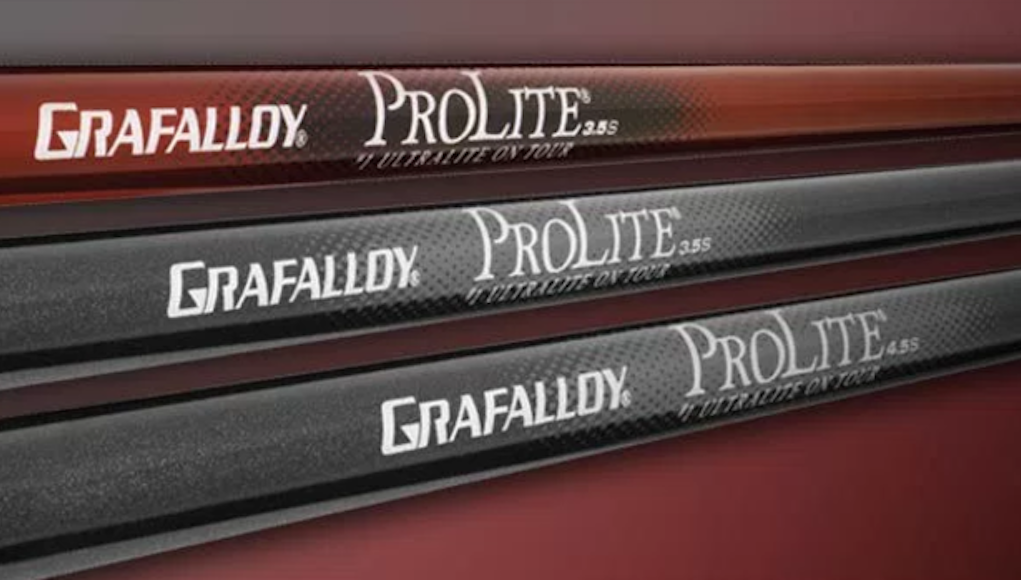

I did a bit of Googling on Robin and, to my surprise, a ton of stuff came up. He’s a bit of a rockstar in the world of golf shafts, known in golfing circles as the King of the Lightweight Shaft, as his Grafalloy Prolite shafts are tagged as the “winningest ultralite shaft in Tour history,” according to multiple sources.

He’s now his own boss at Arthur Xtreme Engineering and XCaliber Shafts (King Arthur, remember!) and some of his YouTube videos, like this one, make compelling viewing. But don’t let this self-styled, West Virginian fool you. He’s a smart guy with degrees in engineering, applied science and business from Yale.

I recently caught up with Robin in his office in San Diego. A scheduled 30-minute interview turned into a fascinating two-hour journey covering grounds on all sorts of interesting and educational topics. I have tensile strength, modularity, fiber and resin content coming out of my ears. It’s hard not to feel the sense of enthusiasm with “King Arthur.”

Editor’s Note: This Q&A has been edited for clarity and brevity.

Mark Donaghy: What’s your background, Robin?

Robin Arthur: After college I spent my early years working in the aerospace industry, joining General Dynamics in 1982. I was involved in many, many programs designing and manufacturing aerospace composite structures. The evolution of graphite and epoxy materials were critical keys. They led to advancements in reducing weight while maintaining strength, opening doors to next generation design and manufacturing techniques. And I was at the forefront of all that.

MD: It’s a big transition from rockets to golf shafts. So how did that come about?

RA: Well, not really. I saw the opportunity to bring my knowledge and experience into another industry, one that was crying out for it. At that time I had just started playing golf and I was obsessed by the game. I was headhunted for a role in Grafalloy, a relatively unknown company in California, to breathe some life into it with innovative R&D and manufacturing. Graphite shafts had really just taken off, so you could say I was in the right place at the right time.

MD: When starting out in the industry, what did you think you could bring to the game of golf that was different, and do you feel you accomplished that?

RA: When I first started in the golf industry, I met a lot of people and asked a lot of questions. I spoke with all the major OEMs and saw what was available in the market and the claims that some of the existing shaft companies were making. I quickly began to realize that there was huge opportunity to improve on what was out there. Both manufacturing and design processes were archaic and resulted in shaft inconsistencies. I knew with my materials, science and engineering background, and experience in the aerospace industry, I could develop something lighter and more consistent, but I had to put some fundamental processes in place first and that took a few years. I’ve always seen myself as an “imagineer” — seeing the art of the possible — and I am constantly challenging both myself and the industry with new concepts. A lot of the stuff I’ve come up with has never made it to market, but I think my lightweight designs have held their own in the industry and then some.

MD: Why lightweight shafts?

RA: Lightweight shafts were originally targeted at the Asian, senior and ladies markets. They allowed more speed to be generated and the dampening properties of graphite meant they were easier on the joints. I tested some of these shafts, and although really whippy, I thought once the guys on the senior tour got hold of them, they would take off. The problem was getting something to play in the No. 1 head on all Tours – The Great Big Bertha. It was a great, titanium head concept….except the distribution of mass wasn’t….ummm….optimal. What some of the shaft companies were doing was sanding down an X-flex shaft to an R-flex, sometimes all the way to an L-flex, taking off 20g of weight and making it almost impossible to do it consistently. Some OEMs were using lighter weight grips (The Bubble) and altering the distribution of mass in the clubhead. Remember the Great Big Bertha? The pros were still putting the ball in orbit with four and five degrees of loft. The problem Callaway was having with the Great Big Bertha was the mass distribution of properties (weight, etc.) of that head design. This was complicated by the distribution of stiffness along the length of the shaft that existing shaft companies used. It took a while to get it right, but when I did, things really took off.

MD: With all your successes at Grafalloy, what keeps you going?

RA: I love golf and I love helping people, be it a tour professional, a club maker or the regular guy on the street. I get a kick out of helping someone get the right shaft to match their game, making it a lot more enjoyable. I really enjoy getting feedback that a shaft has made a big difference. So the pursuit of designing and manufacturing the best shafts available on the market always drives me. Also, being able to offer that at a realistic price is a fundamental cornerstone to my philosophy.

But here’s the real bottom line. I grew up as an athlete and performed at a high level. Every day I worked on becoming a better athlete, every single day. I take this same approach of continuous improvement to my shaft designs, marketing approaches and even pricing. That’s what gets me out of bed in the morning!

MD: What’s next with Xcaliber?

RA: Since leaving Grafalloy, I’ve been involved in several projects. I’ve worked with shaft companies like Royal Precision, Wishon Golf, and Golfworks, and served as a consultant to smaller OEMs. I also took a bit of a hiatus to follow some personal ambitions. But I’m now energized to really get going again with Xcaliber. For a few years I was running a one-man show, doing the R&D, the manufacturing, sales and marketing all by myself. But I’ve turned a corner. I have a whole new line-up of shafts coming out for 2017, and I’m excited. In fact, I’m just back after some extensive player testing all over the U.S., and with Gene Parente at Golf Labs. The results look awesome! So I’m ready to start scaling up. I’ve invested a lot of resources in new management and marketing, and I want to set up channels not just in the U.S., but also Europe and Asia. And I want to take that to the world with a reasonably priced product. Watch out for me in Orlando at the PGA Merchandise show. I’ll be the guy with the big smile on his face!

MD: What do you see as the next shaft developments over the next 10-20 years?

RA: The (golf) head guys have so many restrictions these days that it’s hard to see any major developments there in the near future. The only real way to improve is with the shaft. Luckily the launch monitors are getting so good these days that measuring shaft performance has become a lot more scientific. This is great because it allows me to give the golfing community objective differences in shaft designs. When this info is combined with subjective feedback from extensive player testing, which is just as important as in-lab testing, I can feel confident putting my name on an Xcaliber golf shaft. That’s because I know it’s the best, high-performance shaft I can make for a particular golfer.

I’m always experimenting with new, exotic materials no one has ever heard of before and continuing to blend existing materials such as steel, fibreglass and graphite epoxy in innovative ways. So lighter, stronger shafts will continue to grow in popularity. Also geometry will be a major development but I can’t say too much about that for now. Watch this space!

MD: Where do you get your inspiration?

RA: I already described myself as an imagineer. Technically I’m pretty good across the board, but I’m more of a concepts guy. My latest project came from watching a Zorro movie. When Antonio Banderas cracked his bull whip, it got me thinking about the angular acceleration of the lower portion a shaft, and immediately I was off developing a new concept. I also get ideas from the questions I ask. But like they say, genius is only 1 percent inspiration and 99 percent perspiration. It’s funny…I’m constantly doing the perspiration part. Maybe someday I’ll get a glimpse of that genius thing.

MD: Over the years, have you worked on any special projects with any high-profile golfers?

RA: I’ve been lucky to have worked with a bunch of PGA Tour players, and of course, players of all abilities. I’ve learned from them all. But one of the biggest highlights in my career was working with Gary Player at Augusta. Mr. Player was in his early 60s and could still hit the snot out of his driver. He had heard about the Prolite shaft and asked me to get him a couple for his Bridgestone heads. He wanted to do a head-to-head comparison with his current gamer, and at the start he was skeptical. It came down to four shots, two with his current set up and two with the Prolite. He asked Peter Brooks, the CFO of Grafalloy at the time, to head down to the fairway to measure and mark the shots. Mr. Player hit his first two shots about 250 yards down the fairway and then indicated he was going to try my Prolite. I watched as his first drive sailed over Pete’s head! After Peter walked to the longer mark, Mr. Player’s second shot sailed over his head again! I wish I could have videoed Gary’s expression…and my smile. He leaned over to me afterwards and whispered, “Robin, I think you may be onto something big here with this shaft. I’ll take ‘em.” They weren’t even for sale!

MD: What sort of golfer are you?

RA: I’d love to tell you I was a scratch golfer, but the truth is that these days I play off about a 10 index. At one point I played to about 4, but right now all my energy is going into developing the business. Twelve- to 14-hour days mean I don’t get to play as often as I like, maybe only two or three times per month. It’s around the greens where I suffer. But I test a bunch of clubs. I’m a “testaholic,” and I can hit a ball well enough to know the difference. I then pass along those shafts I think are good enough to my testing teams who help me either continue the design process or say, “We’ve got it!”

MD: What clubs/shafts do you currently game?

RA: As you might expect, all my clubs have Xcaliber shafts in them, but because I am continuously testing clubs my bag is never the same. I do always carry a Maltby Tricept 58-degree with one of my Spin Wedge shafts in it. I’m getting 2000 rpm more spin with setup because of whip action in the shaft. I love that club! I can stop it on a dime. But I’m forever testing new heads with new shaft combinations so I’m usually grabbing what’s near, or what’s in test and heading out.

MD: Thanks, Robin. My brain hurts. Can I go now?

RA: Yes, go forth, newly appointed Sir Knight. The battle rages, so spread the word.

Have shaft questions for Arthur? He can be contacted at [email protected].

- LIKE194

- LEGIT18

- WOW8

- LOL1

- IDHT1

- FLOP1

- OB0

- SHANK11

19th Hole

Vincenzi’s LIV Golf Singapore betting preview: Course specialist ready to thrive once again

After another strong showing in Australia, LIV Golf will head to Sentosa Golf Club in Singapore looking to build off of what was undoubtedly their best event to date.

Sentosa Golf Club sits on the southern tip of Singapore and is one of the most beautiful courses in the world. The course is more than just incredible scenically; it was also rated 55th in Golf Digest’s top-100 courses in 2022-2023 and has been consistently regarded as one of the best courses in Asia. Prior to being part of the LIV rotation, the course hosted the Singapore Open every year since 2005.

Sentosa Golf Club is a par 71 measuring 7,406 yards. The course will require precise ball striking and some length off the tee. It’s possible to go low due to the pristine conditions, but there are also plenty of hazards and difficult spots on the course that can bring double bogey into play in a hurry. The Bermudagrass greens are perfectly manicured, and the course has spent millions on the sub-air system to keep the greens rolling fast. I spoke to Asian Tour player, Travis Smyth, who described the greens as “the best [he’s] ever played.”

Davis Love III, who competed in a Singapore Open in 2019, also gushed over the condition of the golf course.

“I love the greens. They are fabulous,” the 21-time PGA Tour winner said.

Love III also spoke about other aspects of the golf course.

“The greens are great; the fairways are perfect. It is a wonderful course, and it’s tricky off the tee.”

“It’s a long golf course, and you get some long iron shots. It takes somebody hitting it great to hit every green even though they are big.”

As Love III said, the course can be difficult off the tee due to the length of the course and the trouble looming around every corner. It will take a terrific ball striking week to win at Sentosa Golf Club.

In his pre-tournament press conference last season, Phil Mickelson echoed many of the same sentiments.

“To play Sentosa effectively, you’re going to have a lot of shots from 160 to 210, a lot of full 6-, 7-, 8-iron shots, and you need to hit those really well and you need to drive the ball well.”

Golfers who excel from tee to green and can dial in their longer irons will have a massive advantage this week.

Stat Leaders at LIV Golf Adelaide:

Fairways Hit

1.) Louis Oosthuizen

2.) Anirban Lahiri

3.) Jon Rahm

4.) Brendan Steele

5.) Cameron Tringale

Greens in Regulation

1.) Brooks Koepka

2.) Brendan Steele

3.) Dean Burmester

4.) Cameron Tringale

5.) Anirban Lahiri

Birdies Made

1.) Brendan Steele

2.) Dean Burmester

3.) Thomas Pieters

4.) Patrick Reed

5.) Carlos Ortiz

LIV Golf Individual Standings:

1.) Joaquin Niemann

2.) Jon Rahm

3.) Dean Burmester

4.) Louis Oosthuizen

5.) Abraham Ancer

LIV Golf Team Standings:

1.) Crushers

2.) Legion XIII

3.) Torque

4.) Stinger GC

5.) Ripper GC

LIV Golf Singapore Picks

Sergio Garcia +3000 (DraftKings)

Sergio Garcia is no stranger to Sentosa Golf Club. The Spaniard won the Singapore Open in 2018 by five strokes and lost in a playoff at LIV Singapore last year to scorching hot Talor Gooch. Looking at the course setup, it’s no surprise that a player like Sergio has played incredible golf here. He’s long off the tee and is one of the better long iron players in the world when he’s in form. Garcia is also statistically a much better putter on Bermudagrass than he is on other putting surfaces. He’s putt extremely well on Sentosa’s incredibly pure green complexes.

This season, Garcia has two runner-up finishes, both of them being playoff losses. Both El Camaleon and Doral are courses he’s had success at in his career. The Spaniard is a player who plays well at his tracks, and Sentosa is one of them. I believe Sergio will get himself in the mix this week. Hopefully the third time is a charm in Singapore.

Paul Casey +3300 (FanDuel)

Paul Casey is in the midst of one of his best seasons in the five years or so. The results recently have been up and down, but he’s shown that when he’s on a golf course that suits his game, he’s amongst the contenders.

This season, Casey has finishes of T5 (LIV Las Vegas), T2 (LIV Hong Kong), and a 6th at the Singapore Classic on the DP World Tour. At his best, the Englishman is one of the best long iron players in the world, which makes him a strong fit for Sentosa. Despite being in poor form last season, he was able to fire a Sunday 63, which shows he can low here at the course.

It’s been three years since Casey has won a tournament (Omega Dubai Desert Classic in 2021), but he’s been one of the top players on LIV this season and I think he can get it done at some point this season.

Mito Pereira +5000 (Bet365)

Since Mito Pereira’s unfortunate demise at the 2022 PGA Championship, he’s been extremely inconsistent. However, over the past few months, the Chilean has played well on the International Series as well as his most recent LIV start. Mito finished 8th at LIV Adelaide, which was his best LIV finish this season.

Last year, Pereira finished 5th at LIV Singapore, shooting fantastic rounds of 67-66-66. It makes sense why Mito would like Sentosa, as preeminent ball strikers tend to rise to the challenge of the golf course. He’s a great long iron player who is long and straight off the tee.

Mito has some experience playing in Asia and is one of the most talented players on LIV who’s yet to get in the winner’s circle. I have questions about whether or not he can come through once in contention, but if he gets there, I’m happy to roll the dice.

Andy Ogletree +15000 (DraftKings)

Andy Ogletree is a player I expected to have a strong 2024 but struggled early in his first full season on LIV. After failing to crack the top-25 in any LIV event this year, the former U.S. Amateur champion finally figured things out, finished in a tie for 3rd at LIV Adelaide.

Ogletree should be incredible comfortable playing in Singapore. He won the International Series Qatar last year and finished T3 at the International Series Singapore. The 26-year-old was arguably the best player on the Asian Tour in 2023 and has been fantastic in the continent over the past 18 months.

If Ogletree has indeed found form, he looks to be an amazing value at triple-digit odds.

- LIKE3

- LEGIT3

- WOW1

- LOL2

- IDHT0

- FLOP2

- OB0

- SHANK0

Opinion & Analysis

Ryan: Lessons from the worst golf instructor in America

In Tampa, there is a golf course that boasts carts that do not work, a water range, and a group of players none of which have any chance to break 80. The course is overseen by a staff of crusty men who have succeeded at nothing in life but ending up at the worst-run course in America. However, this place is no failure. With several other local courses going out of business — and boasting outstanding greens — the place is booked full.

While I came for the great greens, I stayed to watch our resident instructor; a poor-tempered, method teacher who caters to the hopeless. At first, it was simply hilarious. However, after months of listening and watching, something clicked. I realized I had a front-row seat to the worst golf instructor in America.

Here are some of my key takeaways.

Method Teacher

It is widely accepted that there are three types of golf instructors: system teachers, non-system teachers, and method teachers. Method teachers prescribe the same antidote for each student based on a preamble which teachers can learn in a couple day certification.

Method teaching allows anyone to be certified. This process caters to the lowest caliber instructor, creating the illusion of competency. This empowers these underqualified instructors with the moniker of “certified” to prey on the innocent and uninformed.

The Cult of Stack and Jilt

The Stack and Tilt website proudly boasts, “A golfer swings his hands inward in the backswing as opposed to straight back to 1) create power, similar to a field goal kicker moving his leg in an arc and 2) to promote a swing that is in-to-out, which produces a draw (and eliminates a slice).”

Now, let me tell you something, there is this law of the universe which says “energy can either be created or destroyed,” so either these guys are defying physics or they have no idea what they are taking about. Further, the idea that the first move of the backswing determines impact is conjecture with a splash of utter fantasy.

These are the pontifications of a method — a set of prescriptions applied to everyone with the hope of some success through the placebo effect. It is one thing for a naive student to believe, for a golf instructor to drink and then dispel this Kool-Aid is malpractice.

Fooled by Randomness

In flipping a coin, or even a March Madness bet, there is a 50-50 chance of success. In golf, especially for new players, results are asymmetric. Simply put: Anything can happen. The problem is that when bad instructors work with high handicappers, each and every shot gets its own diagnosis and prescription. Soon the student is overwhelmed.

Now here’s the sinister thing: The overwhelming information is by design. In this case, the coach is not trying to make you better, they are trying to make you reliant on them for information. A quasi Stockholm syndrome of codependency.

Practice

One of the most important scientists of the 20th century was Ivan Pavlov. As you might recall, he found that animals, including humans, could be conditioned into biological responses. In golf, the idea of practice has made millions of hackers salivate that they are one lesson or practice session from “the secret.”

Sunk Cost

The idea for the worst golf instructor is to create control and dependency so that clients ignore the sunk cost of not getting better. Instead, they are held hostage by the idea that they are one lesson or tip away from unlocking their potential.

Cliches

Cliches have the effect of terminating thoughts. However, they are the weapon of choice for this instructor. Add some hyperbole and students actually get no information. As a result, these players couldn’t play golf. When they did, they had no real scheme. With no idea what they are doing, they would descend into a spiral of no idea what to do, bad results, lower confidence, and running back to the lesson tee from more cliches.

The fact is that poor instruction is about conditioning players to become reliant members of your cult. To take away autonomy. To use practice as a form of control. To sell more golf lessons not by making people better but through the guise that without the teacher, the student can never reach their full potential. All under the umbrella of being “certified” (in a 2-day course!) and a melee of cliches.

This of course is not just happening at my muni but is a systemic problem around the country and around the world, the consequences of which are giving people a great reason to stop playing golf. But hey, at least it’s selling a lot of golf balls…

- LIKE18

- LEGIT2

- WOW0

- LOL4

- IDHT1

- FLOP4

- OB1

- SHANK23

19th Hole

Vincenzi’s 2024 Zurich Classic of New Orleans betting preview

The PGA TOUR heads to New Orleans to play the 2023 Zurich Classic of New Orleans. In a welcome change from the usual stroke play, the Zurich Classic is a team event. On Thursday and Saturday, the teams play best ball, and on Friday and Sunday the teams play alternate shot.

TPC Louisiana is a par 72 that measures 7,425 yards. The course features some short par 4s and plenty of water and bunkers, which makes for a lot of exciting risk/reward scenarios for competitors. Pete Dye designed the course in 2004 specifically for the Zurich Classic, although the event didn’t make its debut until 2007 because of Hurricane Katrina.

Coming off of the Masters and a signature event in consecutive weeks, the field this week is a step down, and understandably so. Many of the world’s top players will be using this time to rest after a busy stretch.

However, there are some interesting teams this season with some stars making surprise appearances in the team event. Some notable teams include Patrick Cantlay and Xander Schauffele, Rory McIlroy and Shane Lowry, Collin Morikawa and Kurt Kitayama, Will Zalatoris and Sahith Theegala as well as a few Canadian teams, Nick Taylor and Adam Hadwin and Taylor Pendrith and Corey Conners.

Past Winners at TPC Louisiana

- 2023: Riley/Hardy (-30)

- 2022: Cantlay/Schauffele (-29)

- 2021: Leishman/Smith (-20)

- 2019: Palmer/Rahm (-26)

- 2018: Horschel/Piercy (-22)

- 2017: Blixt/Smith (-27)

2024 Zurich Classic of New Orleans Picks

Tom Hoge/Maverick McNealy +2500 (DraftKings)

Tom Hoge is coming off of a solid T18 finish at the RBC Heritage and finished T13 at last year’s Zurich Classic alongside Harris English.

This season, Hoge is having one of his best years on Tour in terms of Strokes Gained: Approach. In his last 24 rounds, the only player to top him on the category is Scottie Scheffler. Hoge has been solid on Pete Dye designs, ranking 28th in the field over his past 36 rounds.

McNealy is also having a solid season. He’s finished T6 at the Waste Management Phoenix Open and T9 at the PLAYERS Championship. He recently started working with world renowned swing coach, Butch Harmon, and its seemingly paid dividends in 2024.

Keith Mitchell/Joel Dahmen +4000 (DraftKings)

Keith Mitchell is having a fantastic season, finishing in the top-20 of five of his past seven starts on Tour. Most recently, Mitchell finished T14 at the Valero Texas Open and gained a whopping 6.0 strokes off the tee. He finished 6th at last year’s Zurich Classic.

Joel Dahmen is having a resurgent year and has been dialed in with his irons. He also has a T11 finish at the PLAYERS Championship at TPC Sawgrass which is another Pete Dye track. With Mitchell’s length and Dahmen’s ability to put it close with his short irons, the Mitchell/Dahmen combination will be dangerous this week.

Taylor Moore/Matt NeSmith +6500 (DraftKings)

Taylor Moore has quickly developed into one of the more consistent players on Tour. He’s finished in the top-20 in three of his past four starts, including a very impressive showing at The Masters, finishing T20. He’s also finished T4 at this event in consecutive seasons alongside Matt NeSmith.

NeSmith isn’t having a great 2024, but has seemed to elevate his game in this format. He finished T26 at Pete Dye’s TPC Sawgrass, which gives the 30-year-old something to build off of. NeSmith is also a great putter on Bermudagrass, which could help elevate Moore’s ball striking prowess.

- LIKE8

- LEGIT3

- WOW1

- LOL1

- IDHT0

- FLOP3

- OB1

- SHANK2

-

19th Hole2 weeks ago

19th Hole2 weeks agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole3 weeks ago

19th Hole3 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole3 weeks ago

19th Hole3 weeks agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

-

19th Hole1 week ago

19th Hole1 week agoLET pro gives detailed financial breakdown of first week on tour…and the net result may shock you

-

Equipment3 weeks ago

Equipment3 weeks agoJason Day on his recent switch into Srixon ZX5 and ZX7 Mk II irons

-

19th Hole5 days ago

19th Hole5 days agoGary Player claims this is what ‘completely ruined’ Tiger Woods’ career

W

Jul 10, 2017 at 6:13 pm

Did something happen to Robin, saw him at the PGA show and was looking forward to his new products.

Donna Greco

Nov 30, 2016 at 2:19 pm

Very cool Robin, Im proud of you!

Jafar

Nov 30, 2016 at 1:28 pm

Great interview, had no idea about these shafts and have been playing for several years now trying to digest all of the information and nuances about golf shafts. Very refreshing to hear his story and even better to have his products affordable. Can’t wait for my XCaliber hybrid shaft to come in.

Jim

Nov 25, 2016 at 5:07 pm

Reshafted 2 hybrids for a gentleman seeking to seriously limit cost. Found XCaliber in Maltbie catalog and gave them a try (less than 40 ea? – can’t recall exact $). Anyway, while doing a manual FLO install & Freq analysis, was amazes to find virtually no spine and uniform readings with both 454gr weight chuck or clubhead.

Exceptionally well constructed shaft, felt great. They’ve become our recommended ‘budget’ replacement shaft for most average repairs

Dave R

Nov 23, 2016 at 7:56 pm

Smiz smiz smiz.

Blue Man

Nov 23, 2016 at 7:17 pm

Mr Arthur is a hero to me! The Grafalloy Blue is the best shaft ever made! I play the Blue 65 X which is stiff as a board and I love it!

I also play the Xcalibur Tour as well and it’s also awesome. For the price, it’s amazing!

I’m looking forward to

Grizz01

Nov 23, 2016 at 7:11 pm

Not a lot of new innovation/performance enhancing in clubs. But its the shaft! The shaft in the engine of the club. You get that right, just about any club will play well.

Shortside

Nov 23, 2016 at 4:29 pm

Aside from the driver (which is only a matter of time) every club in my bag is Xcaliber. Like Robin I LOVE my wedge shafts. Not in a hurry to rebuild the bag but looking forward to seeing his ’17 offerings.