Opinion & Analysis

Paderson Shafts: Entering the market ‘with a sledgehammer’

Paderson Shafts has stepped out from “behind the beaded curtain,” in the words of CEO Jason Horodezky. The company has shifted its focus from OEM contract manufacturing to private label manufacturing.

Paderson was the company that developed shaft technology for Original ADAMS Golf Tight Lies and Orlimar Trimetal woods, as well as Rapport composites.

The company’s Kinetixx shafts feature breakthrough technology, according to the company, which compelled Paderson to hang a shingle and build a network of dealers, fitters and retail establishments to sells its wares.

Paderson specializes in carbon fiber and high and low modulus FRP Composites, resin matrix formulation and core process technologies.

The company presently offers four driver shafts: Kinetixx IMRT Green, Kinetixx IMRT Blue, Kinetixx VMT Vacuum Cured, Kinetiix IMRT Limited Edition. The Green and Blue shafts are available for woods and hybrids, as well as irons.

I spoke with CEO Jason Horodezky about company history, the shaft market, key technologies and Paderson’s product line.

Tell me about the decision to get into the crowded and competitive shaft space…

It’s a very convoluted and crowded marketplace. It looks a lot like it did in the 90s…between ‘96 and ‘99, except the volume-quantity turnover in the segment isn’t the same. There aren’t as many home builders as there were. We’ve been in the game the longest of almost anybody. We’ve been behind the beaded curtain. So we’re not new: we’re new to the consumer.

We’ve made a few significant breakthroughs, and we decided it was time to make our brand known, because we’ve been doing it for other people for so long.

We were the power behind two brands: a company called Rapport Composites, and they then spunoff into a company called Swing Science. So we’re coming into the market with a sledge hammer.

Why come out from behind the “beaded curtain” now?

The industry is stagnant in a lot of areas.

At the end of the day, honesty and integrity coupled with the transparent technology (the world’s only visible fiber technology)…was conducive to telling the world of golf…our story.

There’s a lot of people who have exploited us for their own gain, but not for ours, so to speak.

What is your take on the shaft market? It’s a convoluted space, as you indicated…

What we have is cutting edge. We have the only array of iron shafts in the world with true, concentric, spineless technology. We tailor it on three orders of measure; very high order of magnitude stuff. The science we use to model our products is extremely noble. Our methods and manufacturing enable us to do a lot of extraordinary things that other have tried and failed miserably and continuously with.

For instance, you hear people talk about xylon and liquid crystal polymers. It has a very high density and no modulus, therefore they don’t get the order of magnitude and the effect, and this becomes a very heavy weighted composite.

So from our perspective, we’re actually tailoring it to tension, damping, high-order resonance with impedance (and recovery in the shaft), and that’s on the merits of our wound platform, which is unlike any other in the world.

Tell me more about Paderson’s key technologies.

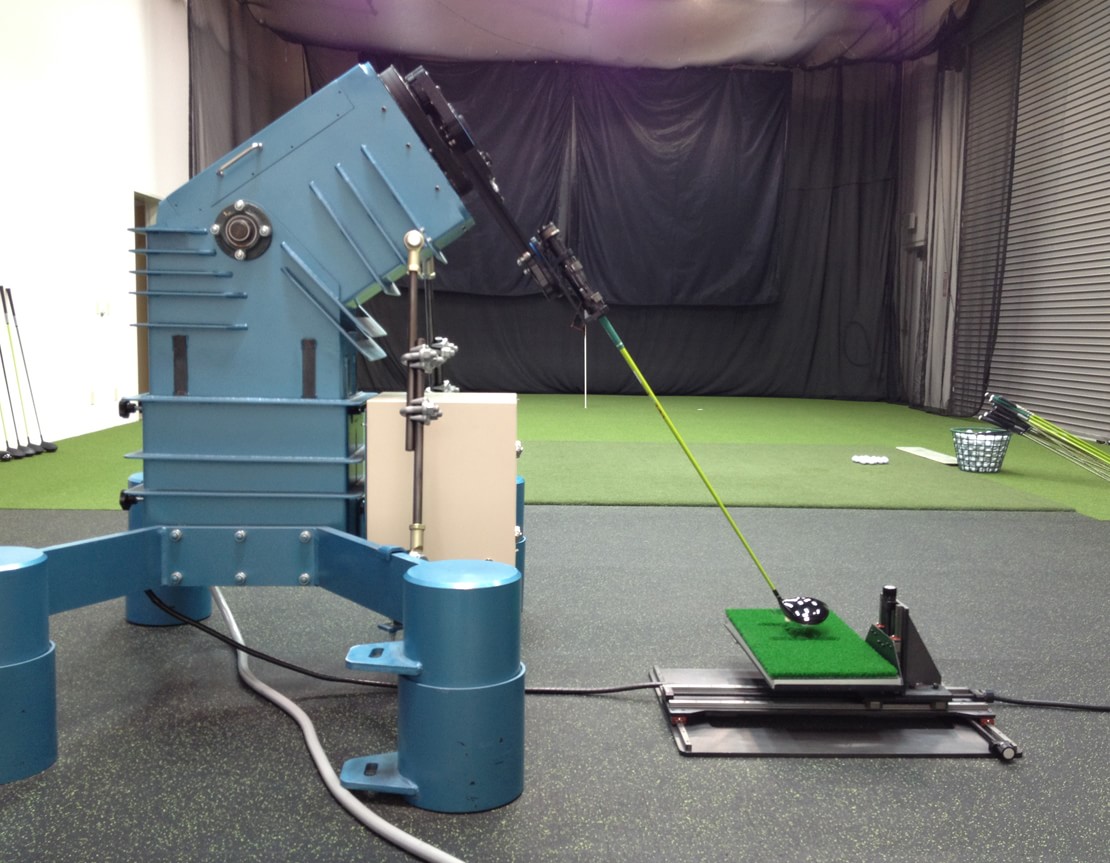

We had in excess of 50 permutations when we started in our R&D room. We reduced the lineup to be tailored to the commercial exploit. So, we have three construction platforms, and those get reduced per category segment.

Unlike any other shaft company, we provide three different constructions, because there isn’t a one-size-fits-all golf shaft. One of our three shafts will fit everybody. In essence, how you make something will determine what materials you use. Construction is the confluence of craftsmanship and materials. That’s why we’ve put into practice a couple of different materials no one else has.

Our flagship is that we’ve patented processes for wound technology. We’re the foremost leader in tension fiber structures: structural architecture that you can see. Think of a tennis racket with a pre-tension net head. You can see and feel the tension in our shafts. We have a pre-loaded shaft. It’s pre-loaded to respond to a golfer’s swing, and it’s visible in two of our three shafts.

Fitted with our shafts, golfers will see ball speed increase. When they start searching for things that are spin related and launch, it gets to be a different golfer speak phenomenon. Our shafts are designed to [increase speed].

Wound technology is the baseline of what we do. It’s because of wound technology that we have our vacuum curing system, and that benefits our laminated, cable-rolled structures.

And we’re transparent. We’re not making claims and hiding things under paint. You can see everything that we’re made of: visible technology.

Tell me about Paderson’s shaft offerings.

Each of our constructions separates themselves based on who they’re for. Our wound series, the Kevlar Green, fits every golfer. Our green table rolled vacuum cured amorphous is very similar, but it’s more tailored to someone who is flat/positive attack angle and is looking for a lighter weight alternative.

Our Kevlar Blue is tailored around someone who is smooth in transition but has a negative to flat attack angle. We’ve tailored all of the product line around a golfer’s swing and particularly arc and speed. So the length of someone’s arc and where they’re fastest: that’s the fitting paradigm from which we tailored our product.

So again, our Kevlar Green is capable of fitting all golfers, but golfers who may be looking for a lighter weight alternative would benefit from our table rolled component.

The wound series is available through the bag. There’s nothing that outperforms it; that’s why we reduced our line. We have three constructions in driver, two in fairways, and the reason for that is performance.

Going forward, are you more focused on relationships with OEMs? A tour presence? Appealing to clubmakers?

Our focus is on getting to the end user in the most efficient manner possible. And there are two forms of growth in the industry right now. You’ve got new retail, which is like the PGA Superstore. And then you’ve got the bespoken category.

We’re building that relationship with the dealer networks—they’re critical. But we really just want to get to the end consumer with the best technology and price relationship. Our paradigm there is incomparable. We have the world’s only polymer shaft, but we don’t charge $1000 for our shafts. Our shaft is the most expensive by way of materials and process of any golf shaft in the world. Yet because we are designing and making all organically, we don’t exploit consumer weakness or this “deep pocket opportunity.” That’s not our objective. We present unique, technical value propositions.

That all relates to where we go into the market. Some of the bespoken guys want the $500 shaft opportunity or a make-up program. There’s no real reason for a shaft to be $300 and installed at $500, but it helps them with their margins.

But consumers love our product. We have a 97 percent success rate in fitting golfers at arm’s length, and in the field it’s 100 percent. We’ll outperform anything that they have in our green grass demo events.

- LIKE118

- LEGIT14

- WOW13

- LOL10

- IDHT8

- FLOP4

- OB1

- SHANK27

Opinion & Analysis

The Wedge Guy: What really makes a wedge work? Part 2

In my last post, I explained the basic performance dynamics of “smash factor” and “gear effect” as they apply to your wedges and your wedge play success. If you missed that post, you can read it here.

At the end of that post, I promised “part 2” of this discussion of what makes a wedge work the way it does. So, let’s dive into the other two components of any wedge – the shaft and the grip.

It’s long been said that the shaft is “the engine of the golf club.” The shaft (and grip) are your only connection to all the technologies that are packed into the head of any golf club, whether it be a driver, fairway, hybrid, iron, wedge or even putter.

And you cannot ignore those two components of your wedges if your goal is optimizing your performance.

I’ve long been an advocate of what I call a “seamless transition” from your irons into your wedges, so that the feel and performance do not disconnect when you choose a gap wedge, for example, instead of your iron-set-matching “P-club.” In today’s golf equipment marketplace, more and more golfers are making the investment of time and money to experience an iron fitting, going through trial and error and launch monitor measuring to get just the right shaft in their irons.

But then so many of those same golfers just go into a store and choose wedges off the retail display, with no similar science involved at all. And that’s why I see so many golfers with a huge disconnect between their custom-fitted irons, often with lighter and/or softer graphite or light steel shafts . . . and their off-the-rack wedges with the stock stiff steel ‘wedge flex’ shaft common to those stock offerings.

If your wedge shafts are significantly heavier and stiffer than the shafts in your irons, it is physically impossible for you to make the same swing. Period.

To quickly improve your wedge play, one of the first things you can do is have your wedges re-shafted with the same or similar shaft that is in your irons.

There’s another side of that shaft weight equation; if you don’t have the forearm and hand strength of a PGA Tour professional, you simply cannot “handle” the same weight shaft that those guys play to master the myriad of ‘touch shots’ around the greens.

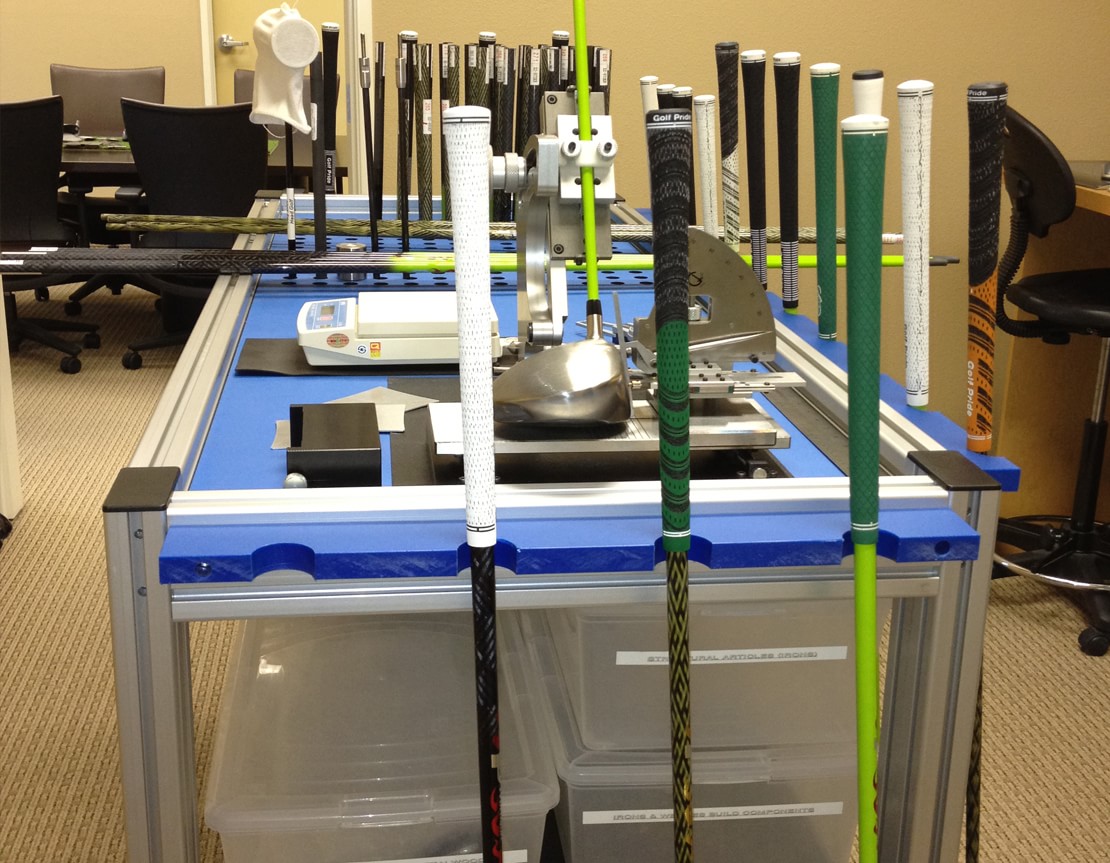

Now, let’s move on to the third and other key component of your wedges – the grips. If those are not similar in shape and feel to the grips on your irons, you have another disconnect. Have your grips checked by a qualified golf club professionals to make sure you are in sync there.

The one caveat to that advice is that I am a proponent of a reduced taper in your wedge grips – putting two to four more layers of tape under the lower hand, or selecting one of the many reduced taper grips on the market. That accomplishes two goals for your scoring.

First, it helps reduce overactive hands in your full and near-full wedge swings. Quiet hands are key to good wedge shots.

And secondly, it provides a more consistent feel of the wedge in your hands as you grip down for those shorter and more delicate shots around the greens. And you should always grip down as you get into those touch shots. I call it “getting closer to your work.”

So, if you will spend as much time selecting the shafts and grips for your wedges as you do choosing the brand, model, and loft of them, your scoring range performance will get better.

More from the Wedge Guy

- The Wedge Guy: What really makes a wedge work? Part 1

- The Wedge Guy: The easiest-to-learn golf basic

- The Wedge Guy: Golf mastery begins with your wedge game

- LIKE3

- LEGIT3

- WOW0

- LOL1

- IDHT1

- FLOP0

- OB0

- SHANK4

19th Hole

Vincenzi’s 2024 Wells Fargo Championship betting preview: Tommy Fleetwood ready to finally land maiden PGA Tour title

The PGA Tour season ramps back up this week for another “signature event,” as golf fans look forward to the year’s second major championship next week.

After two weaker-field events in the Zurich Classic and the CJ Cup Byron Nelson, most of the best players in the world will head to historic Quail Hollow for one of the best non-major tournaments of the year.

Last season, Wyndham Clark won the event by four shots.

Quail Hollow is a par-71 measuring 7,521 yards that features Bermudagrass greens. The tree-lined, parkland style course can play quite difficult and features one of the most difficult three-hole stretches in golf known as “The Green Mile,” which makes up holes 16-18: two mammoth par 4s and a 221-yard par 3. All three holes have an average score over par, and water is in play in each of the last five holes on the course.

The field is excellent this week with 68 golfers teeing it up without a cut. All of the golfers who’ve qualified are set to tee it up, with the exception of Scottie Scheffler, who is expecting the birth of his first child.

Past Winners at Quail Hollow

- 2023: Wyndham Clark (-19)

- 2022: Max Homa (-8)

- 2021: Rory McIlroy (-10)

- 2019: Max Homa (-15)

- 2018: Jason Day (-12)

- 2017: Justin Thomas (-8) (PGA Championship)

- 2016: James Hahn (-9)

- 2015: Rory McIlroy (-21)

Key Stats For Quail Hollow

Strokes Gained: Approach

Strokes gained: Approach will be extremely important this week as second shots at Quail Hollow can be very difficult.

Total SG: Approach Over Past 24 Rounds

- Akshay Bhatia (+1.16)

- Tom Hoge (+1.12)

- Corey Conners (+1.01)

- Shane Lowry (+0.93)

- Austin Eckroat (+0.82)

Strokes Gained: Off the Tee

Quail Hollow is a long course on which it is important to play from the fairway. Both distance and accuracy are important, as shorter tee shots will result in approach shots from 200 or more yards. With most of the holes heavily tree lined, errant drives will create some real trouble for the players.

Strokes Gained: Off the Tee Past 24 Rounds:

- Ludvig Aberg (+0.73)

- Rory McIlroy (+0.69)

- Xander Schauffele (+0.62)

- Viktor Hovland (+0.58)

- Chris Kirk (+0.52)

Proximity: 175-200

The 175-200 range is key at Quail Hollow. Players who can hit their long irons well will rise to the top of the leaderboard.

Proximity: 175-200+ over past 24 rounds:

- Cameron Young (28’2″)

- Akshay Bhatia (29’6″)

- Ludvig Aberg (+30’6″)

- Sam Burns (+30’6″)

- Collin Morikawa (+30’9″)

SG: Total on Tom Fazio Designs

Players who thrive on Tom Fazio designs get a bump for me at Quail Hollow this week.

SG: Total on Tom Fazio Designs over past 36 rounds:

- Patrick Cantlay (+2.10)

- Rory McIlroy (+1.95)

- Tommy Fleetwood (+1.68)

- Austin Eckroat (+1.60)

- Will Zalatoris (+1.57)

Strokes Gained: Putting (Bermudagrass)

Strokes Gained: Putting has historically graded out as the most important statistic at Quail Hollow. While it isn’t always predictable, I do want to have it in the model to bump up golfers who prefer to putt on Bermudagrass.

Strokes Gained: Putting (Bermudagrass) Over Past 24 Rounds:

- Taylor Moore (+0.82)

- Nick Dunlap (+.76)

- Wyndham Clark (+.69)

- Emiliano Grillo (+.64)

- Cam Davis (+.61)

Course History

This stat will incorporate players that have played well in the past at Quail Hollow.

Course History over past 36 rounds (per round):

- Rory McIlroy (+2.50)

- Justin Thomas (+1.96)

- Jason Day (+1.92)

- Rickie Fowler (+1.83)

- Viktor Hovland (+1.78)

Wells Fargo Championship Model Rankings

Below, I’ve compiled overall model rankings using a combination of the five key statistical categories previously discussed — SG: Approach (27%), SG: Off the Tee (23%), SG: Total on Fazio designs (12%), Proximity: 175-200 (12%), SG: Putting Bermuda grass (12%), and Course History (14%).

- Wyndham Clark

- Rory McIlroy

- Xander Schauffele

- Shane Lowry

- Hideki Matsuyama

- Viktor Hovland

- Cameron Young

- Austin Eckroat

- Byeong Hun An

- Justin Thomas

2024 Wells Fargo Championship Picks

Tommy Fleetwood +2500 (DraftKings)

I know many out there have Tommy fatigue when it comes to betting, which is completely understandable given his lack of ability to win on the PGA Tour thus far in his career. However, history has shown us that players with Fleetwood’s talent eventually break though, and I believe for Tommy, it’s just a matter of time.

Fleetwood has been excellent on Tom Fazio designs. Over his past 36 rounds, he ranks 3rd in the field in Strokes Gained: Total on Fazio tracks. He’s also been incredibly reliable off the tee this season. He’s gained strokes in the category in eight of his past nine starts, including at The Masters, the PLAYERS and the three “signature events” of the season. Tommy is a golfer built for tougher courses and can grind it out in difficult conditions.

Last year, Fleetwood was the first-round leader at this event, firing a Thursday 65. He finished the event in a tie for 5th place.

For those worried about Fleetwood’s disappointing start his last time out at Harbour Town, he’s bounced back nicely after plenty of poor outings this season. His T7 at the Valero Texas Open was after a MC and T35 in his prior two starts and his win at the Dubai Invitational came after a T47 at the Sentry.

I expect Tommy to bounce back this week and contend at Quail Hollow.

Justin Thomas +3000 (DraftKings)

It’s been a rough couple of years for Justin Thomas, but I don’t believe things are quite as bad as they seem for JT. He got caught in the bad side of the draw at Augusta for last month’s Masters and has gained strokes on approach in seven of his nine starts in 2024.

Thomas may have found something in his most recent start at the RBC Heritage. He finished T5 at a course that he isn’t the best fit for on paper. He also finally got the putter working and ranked 15th in Strokes Gained: Putting for the week.

The two-time PGA champion captured the first of his two major championships at Quail Hollow back in 2017, and some good vibes from the course may be enough to get JT out of his slump.

Thomas hasn’t won an event in just about two years. However, I still believe that will change soon as he’s been one of the most prolific winners throughout his PGA Tour career. Since 2015, he has 15 PGA Tour wins.

Course history is pretty sticky at Quail Hollow, with players who like the course playing well there on a regular basis. In addition to JT’s PGA Championship win in 2017, he went 4-1 at the 2022 Presidents Cup and finished T14 at the event last year despite being in poor form. Thomas can return as one of the top players on the PGA Tour with a win at a “signature event” this week.

Cameron Young +3500 (DraftKings)

For many golf bettors, it’s been frustrating backing Cam Young this season. His talent is undeniable, and one of the best and most consistent performers on the PGA Tour. He just hasn’t broken through with a victory yet. Quail Hollow has been a great place for elite players to get their first victory. Rory McIlroy, Anthony Kim, Rickie Fowler and Wyndham Clark all notched their first PGA Tour win at Quail.

Throughout Cam Young’s career, he has thrived at tougher courses with strong fields. This season, he finished T16 at Riviera and T9 at Augusta National, demonstrating his preference of a tough test. His ability to hit the ball long and straight off the tee make him an ideal fit for Quail Hollow, despite playing pretty poorly his first time out in 2023 (T59). Young should be comfortable playing in the region as he played his college golf at Wake Forest, which is about an hour’s drive from Quail Hollow.

The 26-year-old has played well at Tom Fazio designs in the past and ranks 8th in the field in Strokes Gained: Total on those courses in his last 36 rounds. Perhaps most importantly, this season, Young is the best player on the PGA Tour in terms of proximity from 175-200 in the fairway, which is where a plurality and many crucial shots will come from this week.

Young is an elite talent and Quail Hollow has been kind to players of his ilk who’ve yet to win on Tour.

Byeong Hun An +5000 (FanDuel)

Byeong Hun An missed some opportunities last weekend at the CJ Cup Byron Nelson. He finished T4 and played some outstanding golf, but a couple of missed short putts prevented him from getting to the winning score of -23. Despite not getting the win, it’s hard to view An’s performance as anything other than an overwhelming success. It was An’s fourth top-ten finish of the season.

Last week, An gained 6.5 strokes ball striking, which was 7th in the field. He also ranked 12th for Strokes Gained: Approach and 13th for Strokes Gained: Off the Tee. The South Korean has been hitting the ball so well from tee to green all season long and he now heads to a golf course that should reward his precision.

An’s driver and long irons are absolute weapons. At Quail Hollow, players will see plenty of approach shots from the 175-200 range as well as some from 200+. In his past 24 rounds, Ben ranks 3rd in the field in proximity from 175-200 and 12th in proximity from 200+. Playing in an event that will not end up being a “birdie” fest should help An, who can separate from the field with his strong tee to green play. The putter may not always cooperate but getting to -15 is much easier than getting to -23 for elite ball strikers who tend to struggle on the greens.

Winning a “signature event” feels like a tall task for An this week with so many elite players in the field. However, he’s finished T16 at the Genesis Invitational, T16 at The Masters and T8 at the Arnold Palmer Invitational. The 32-year-old’s game has improved drastically this season and I believe he’s ready to get the biggest win of his career.

- LIKE8

- LEGIT4

- WOW1

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK1

19th Hole

Vincenzi’s LIV Golf Singapore betting preview: Course specialist ready to thrive once again

After another strong showing in Australia, LIV Golf will head to Sentosa Golf Club in Singapore looking to build off of what was undoubtedly their best event to date.

Sentosa Golf Club sits on the southern tip of Singapore and is one of the most beautiful courses in the world. The course is more than just incredible scenically; it was also rated 55th in Golf Digest’s top-100 courses in 2022-2023 and has been consistently regarded as one of the best courses in Asia. Prior to being part of the LIV rotation, the course hosted the Singapore Open every year since 2005.

Sentosa Golf Club is a par 71 measuring 7,406 yards. The course will require precise ball striking and some length off the tee. It’s possible to go low due to the pristine conditions, but there are also plenty of hazards and difficult spots on the course that can bring double bogey into play in a hurry. The Bermudagrass greens are perfectly manicured, and the course has spent millions on the sub-air system to keep the greens rolling fast. I spoke to Asian Tour player, Travis Smyth, who described the greens as “the best [he’s] ever played.”

Davis Love III, who competed in a Singapore Open in 2019, also gushed over the condition of the golf course.

“I love the greens. They are fabulous,” the 21-time PGA Tour winner said.

Love III also spoke about other aspects of the golf course.

“The greens are great; the fairways are perfect. It is a wonderful course, and it’s tricky off the tee.”

“It’s a long golf course, and you get some long iron shots. It takes somebody hitting it great to hit every green even though they are big.”

As Love III said, the course can be difficult off the tee due to the length of the course and the trouble looming around every corner. It will take a terrific ball striking week to win at Sentosa Golf Club.

In his pre-tournament press conference last season, Phil Mickelson echoed many of the same sentiments.

“To play Sentosa effectively, you’re going to have a lot of shots from 160 to 210, a lot of full 6-, 7-, 8-iron shots, and you need to hit those really well and you need to drive the ball well.”

Golfers who excel from tee to green and can dial in their longer irons will have a massive advantage this week.

Stat Leaders at LIV Golf Adelaide:

Fairways Hit

1.) Louis Oosthuizen

2.) Anirban Lahiri

3.) Jon Rahm

4.) Brendan Steele

5.) Cameron Tringale

Greens in Regulation

1.) Brooks Koepka

2.) Brendan Steele

3.) Dean Burmester

4.) Cameron Tringale

5.) Anirban Lahiri

Birdies Made

1.) Brendan Steele

2.) Dean Burmester

3.) Thomas Pieters

4.) Patrick Reed

5.) Carlos Ortiz

LIV Golf Individual Standings:

1.) Joaquin Niemann

2.) Jon Rahm

3.) Dean Burmester

4.) Louis Oosthuizen

5.) Abraham Ancer

LIV Golf Team Standings:

1.) Crushers

2.) Legion XIII

3.) Torque

4.) Stinger GC

5.) Ripper GC

LIV Golf Singapore Picks

Sergio Garcia +3000 (DraftKings)

Sergio Garcia is no stranger to Sentosa Golf Club. The Spaniard won the Singapore Open in 2018 by five strokes and lost in a playoff at LIV Singapore last year to scorching hot Talor Gooch. Looking at the course setup, it’s no surprise that a player like Sergio has played incredible golf here. He’s long off the tee and is one of the better long iron players in the world when he’s in form. Garcia is also statistically a much better putter on Bermudagrass than he is on other putting surfaces. He’s putt extremely well on Sentosa’s incredibly pure green complexes.

This season, Garcia has two runner-up finishes, both of them being playoff losses. Both El Camaleon and Doral are courses he’s had success at in his career. The Spaniard is a player who plays well at his tracks, and Sentosa is one of them. I believe Sergio will get himself in the mix this week. Hopefully the third time is a charm in Singapore.

Paul Casey +3300 (FanDuel)

Paul Casey is in the midst of one of his best seasons in the five years or so. The results recently have been up and down, but he’s shown that when he’s on a golf course that suits his game, he’s amongst the contenders.

This season, Casey has finishes of T5 (LIV Las Vegas), T2 (LIV Hong Kong), and a 6th at the Singapore Classic on the DP World Tour. At his best, the Englishman is one of the best long iron players in the world, which makes him a strong fit for Sentosa. Despite being in poor form last season, he was able to fire a Sunday 63, which shows he can low here at the course.

It’s been three years since Casey has won a tournament (Omega Dubai Desert Classic in 2021), but he’s been one of the top players on LIV this season and I think he can get it done at some point this season.

Mito Pereira +5000 (Bet365)

Since Mito Pereira’s unfortunate demise at the 2022 PGA Championship, he’s been extremely inconsistent. However, over the past few months, the Chilean has played well on the International Series as well as his most recent LIV start. Mito finished 8th at LIV Adelaide, which was his best LIV finish this season.

Last year, Pereira finished 5th at LIV Singapore, shooting fantastic rounds of 67-66-66. It makes sense why Mito would like Sentosa, as preeminent ball strikers tend to rise to the challenge of the golf course. He’s a great long iron player who is long and straight off the tee.

Mito has some experience playing in Asia and is one of the most talented players on LIV who’s yet to get in the winner’s circle. I have questions about whether or not he can come through once in contention, but if he gets there, I’m happy to roll the dice.

Andy Ogletree +15000 (DraftKings)

Andy Ogletree is a player I expected to have a strong 2024 but struggled early in his first full season on LIV. After failing to crack the top-25 in any LIV event this year, the former U.S. Amateur champion finally figured things out, finished in a tie for 3rd at LIV Adelaide.

Ogletree should be incredible comfortable playing in Singapore. He won the International Series Qatar last year and finished T3 at the International Series Singapore. The 26-year-old was arguably the best player on the Asian Tour in 2023 and has been fantastic in the continent over the past 18 months.

If Ogletree has indeed found form, he looks to be an amazing value at triple-digit odds.

- LIKE3

- LEGIT3

- WOW1

- LOL2

- IDHT0

- FLOP2

- OB0

- SHANK0

-

19th Hole3 weeks ago

19th Hole3 weeks agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole3 weeks ago

19th Hole3 weeks ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoLET pro gives detailed financial breakdown of first week on tour…and the net result may shock you

-

19th Hole3 days ago

19th Hole3 days agoReport: LIV star turns down PGA Championship invite due to ‘personal commitments’

-

19th Hole1 week ago

19th Hole1 week agoGary Player claims this is what ‘completely ruined’ Tiger Woods’ career

-

Whats in the Bag2 weeks ago

Whats in the Bag2 weeks agoTeam McIlowry (Rory McIlroy, Shane Lowry) winning WITBs: 2024 Zurich Classic

-

Equipment1 week ago

Equipment1 week agoGolf fans left surprised by LIV’s choice of course for its 2024 individual championship event

-

19th Hole1 week ago

19th Hole1 week agoLIV star splits with swing coach after working together for 14 years

BOB

Sep 11, 2015 at 7:39 pm

I HAVE LOOKED AT THEIR WEBSITE AND HAVE READ ALL THEIR COMMENTS . I AM WILLING TO TRY ONE OF THEIR SHAFTS AND MAKE MY JUDGEMENT FROM HOW IT PERFORMS FOR ME AND MY CUSTOMERS. I AGREE THAT THERE IS TOO MUCH TECHNICAL JARGON IN THE ARTICLE BRING IT ALL DOWN TO WHERE THE LAYMAN CAN UNDERSTAND ABOUT THE SHAFTS.

I WILL POST ANOTHER COMMENT AFTER I RECEIVE MY SHAFT AND HAVE TRIED ITS PERFORMANCE FOR MYSELF.

myron miller

Aug 26, 2015 at 6:04 pm

From this article, I have no clue if these shafts would work for my game or not. I really didn’t understand the verbiage. Non-standard shaft terminology doesn’t help us end-users. Where’s the kick point? What are the flexes at head, butt, middle?

According to the website, the torque is not what I’d call low torque by any means. 5.7 to 5.9 is not low torque when lots of shafts are available with 3.5 or even lower. Fujikura has them down to 2.8 and most are 3.5 or less. I thought advanced tech made torque lower not higher.

Charlie

Aug 19, 2015 at 2:04 pm

http://www.golfworks.com/product.asp?pn=PK0009&gclid=CNTMwbfctccCFZKKaQodgyMCvw

$199.00 here.

Allen

Aug 16, 2015 at 9:51 pm

I would love to try these, but at almost $90 a shaft for the irons, I am not sure I can justify the money. I cant believe they will give me $90 worth of improvement, or very much improvement.

other paul

Aug 16, 2015 at 9:44 pm

Sounds like the steel fiber shafts to me… Aerotech has been around for quite some time.

Mac n Cheese

Aug 26, 2015 at 9:58 am

If they actually found a way to create a shaft out of woven steel fibers, it could be a potential game changer considered steel fibers would have a stronger resistance to twisting upon impact. Especially if they drop the weight over traditional steel shafts.

KK

Aug 16, 2015 at 3:10 pm

Some of the tech sounds great, some of the phrasing seems a bit too much like meaningless rhetoric; e.g. the virtues of showing the carbon structure underneath vs painting over it. It’s like saying your car is better because the hood is made of glass and you can see the engine vs other car companies who don’t have glass hoods.

Mac n Cheese

Aug 26, 2015 at 10:04 am

The theory is more in line with carbon fiber hoods vs. traditional hoods. Basically with carbon fiber you don’t have to paint over it, and some people like the look of just carbon fiber in general over painted. Also by having some carbon fiber visible it shows that the product is actual carbon fiber instead of taking their word for it. Really the paint scheme or lack there of is an aesthetic marketing campaign to make their shafts look cooler. Which they do. I want green shafts! lol

Mo

Aug 15, 2015 at 8:29 pm

Some independent reviews would mean a lot.

Tom Duckworth

Aug 15, 2015 at 6:48 pm

I must admit he doesn’t talk like a sales department guy. He’s deeply into the construction of his shafts. I found that refreshing.

Tom Duckworth

Aug 15, 2015 at 6:28 pm

Very cool reminds me of Eminence Speaker Co. they made speakers for all kinds of guitar amps and PA systems for other people. One of the largest speaker makers in the world. Now they make them under their own name some of the best on the market. It can only be a good thing for Paderson to enter the marketplace. It will be interesting to see how they do.

Matthew

Aug 15, 2015 at 3:04 pm

Gotta echo Mark. Less infomercial and more substance.

Christosterone

Aug 15, 2015 at 12:27 pm

Not to nitpick but they’ve been doing golf shafts with polymer in Japan for years:

https://books.google.com/books?id=kAqKgu0AQK0C&pg=PA173&lpg=PA173&dq=polymer+golf+shaft&source=bl&ots=Z4zQEfCgs5&sig=AMMQbyck8Km-iWtSnUunK4czqog&hl=en&sa=X&ved=0CCEQ6AEwAWoVChMI5ryx9r-rxwIVRtWACh28xg2D#v=onepage&q=polymer%20golf%20shaft&f=false

Mac n Cheese

Aug 26, 2015 at 10:06 am

Yes, but they found a new method of doing so, as the article pointed out.