Opinion & Analysis

Paderson Shafts: Entering the market ‘with a sledgehammer’

Paderson Shafts has stepped out from “behind the beaded curtain,” in the words of CEO Jason Horodezky. The company has shifted its focus from OEM contract manufacturing to private label manufacturing.

Paderson was the company that developed shaft technology for Original ADAMS Golf Tight Lies and Orlimar Trimetal woods, as well as Rapport composites.

The company’s Kinetixx shafts feature breakthrough technology, according to the company, which compelled Paderson to hang a shingle and build a network of dealers, fitters and retail establishments to sells its wares.

Paderson specializes in carbon fiber and high and low modulus FRP Composites, resin matrix formulation and core process technologies.

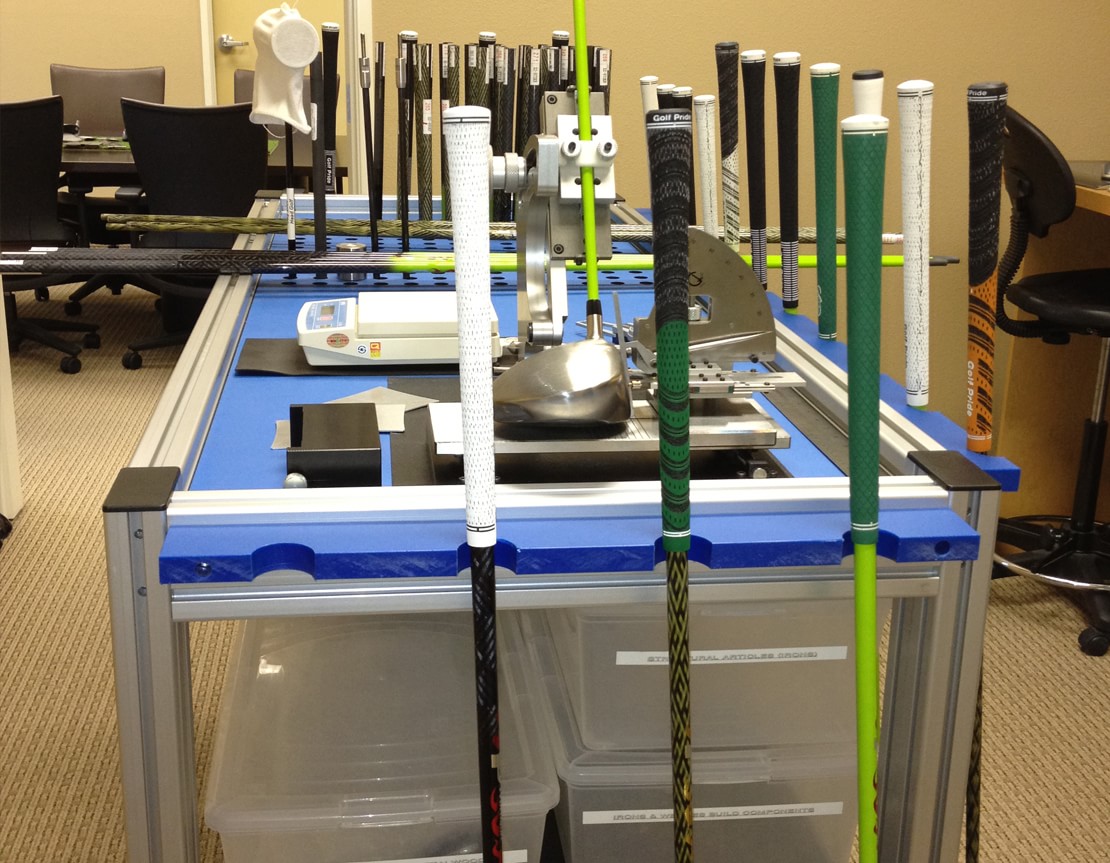

The company presently offers four driver shafts: Kinetixx IMRT Green, Kinetixx IMRT Blue, Kinetixx VMT Vacuum Cured, Kinetiix IMRT Limited Edition. The Green and Blue shafts are available for woods and hybrids, as well as irons.

I spoke with CEO Jason Horodezky about company history, the shaft market, key technologies and Paderson’s product line.

Tell me about the decision to get into the crowded and competitive shaft space…

It’s a very convoluted and crowded marketplace. It looks a lot like it did in the 90s…between ‘96 and ‘99, except the volume-quantity turnover in the segment isn’t the same. There aren’t as many home builders as there were. We’ve been in the game the longest of almost anybody. We’ve been behind the beaded curtain. So we’re not new: we’re new to the consumer.

We’ve made a few significant breakthroughs, and we decided it was time to make our brand known, because we’ve been doing it for other people for so long.

We were the power behind two brands: a company called Rapport Composites, and they then spunoff into a company called Swing Science. So we’re coming into the market with a sledge hammer.

Why come out from behind the “beaded curtain” now?

The industry is stagnant in a lot of areas.

At the end of the day, honesty and integrity coupled with the transparent technology (the world’s only visible fiber technology)…was conducive to telling the world of golf…our story.

There’s a lot of people who have exploited us for their own gain, but not for ours, so to speak.

What is your take on the shaft market? It’s a convoluted space, as you indicated…

What we have is cutting edge. We have the only array of iron shafts in the world with true, concentric, spineless technology. We tailor it on three orders of measure; very high order of magnitude stuff. The science we use to model our products is extremely noble. Our methods and manufacturing enable us to do a lot of extraordinary things that other have tried and failed miserably and continuously with.

For instance, you hear people talk about xylon and liquid crystal polymers. It has a very high density and no modulus, therefore they don’t get the order of magnitude and the effect, and this becomes a very heavy weighted composite.

So from our perspective, we’re actually tailoring it to tension, damping, high-order resonance with impedance (and recovery in the shaft), and that’s on the merits of our wound platform, which is unlike any other in the world.

Tell me more about Paderson’s key technologies.

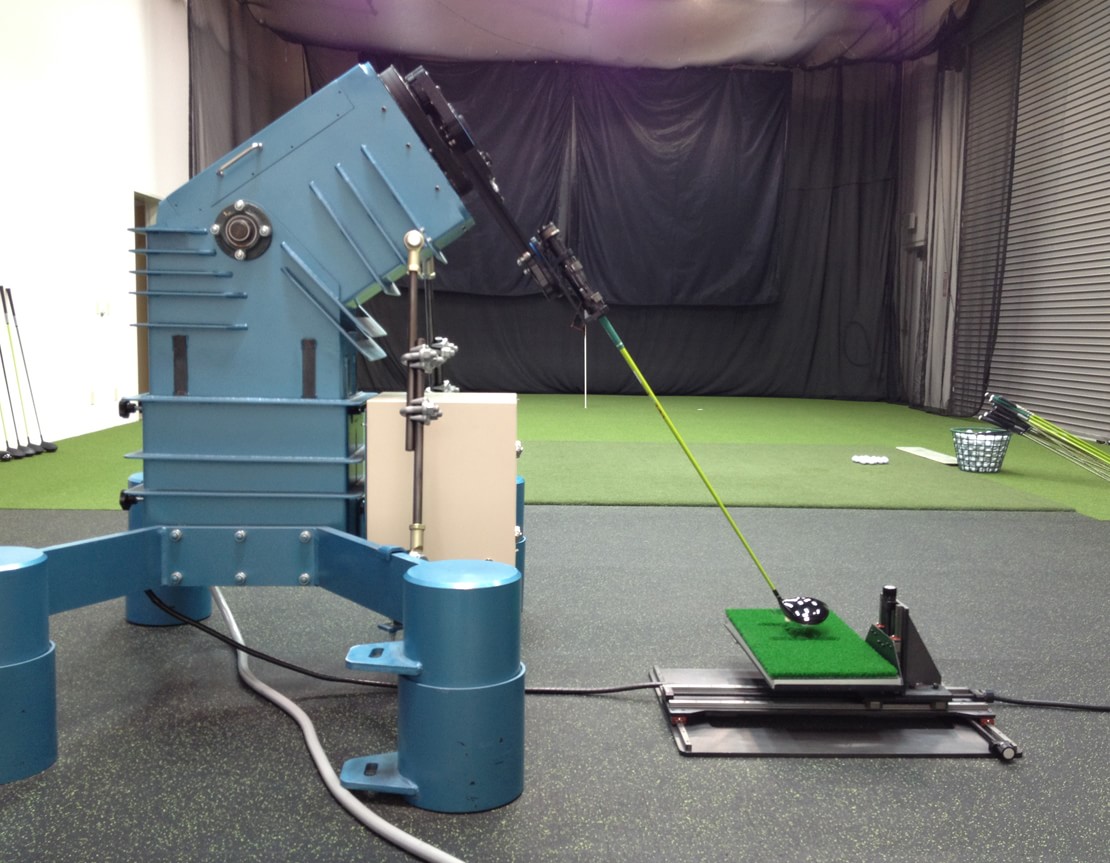

We had in excess of 50 permutations when we started in our R&D room. We reduced the lineup to be tailored to the commercial exploit. So, we have three construction platforms, and those get reduced per category segment.

Unlike any other shaft company, we provide three different constructions, because there isn’t a one-size-fits-all golf shaft. One of our three shafts will fit everybody. In essence, how you make something will determine what materials you use. Construction is the confluence of craftsmanship and materials. That’s why we’ve put into practice a couple of different materials no one else has.

Our flagship is that we’ve patented processes for wound technology. We’re the foremost leader in tension fiber structures: structural architecture that you can see. Think of a tennis racket with a pre-tension net head. You can see and feel the tension in our shafts. We have a pre-loaded shaft. It’s pre-loaded to respond to a golfer’s swing, and it’s visible in two of our three shafts.

Fitted with our shafts, golfers will see ball speed increase. When they start searching for things that are spin related and launch, it gets to be a different golfer speak phenomenon. Our shafts are designed to [increase speed].

Wound technology is the baseline of what we do. It’s because of wound technology that we have our vacuum curing system, and that benefits our laminated, cable-rolled structures.

And we’re transparent. We’re not making claims and hiding things under paint. You can see everything that we’re made of: visible technology.

Tell me about Paderson’s shaft offerings.

Each of our constructions separates themselves based on who they’re for. Our wound series, the Kevlar Green, fits every golfer. Our green table rolled vacuum cured amorphous is very similar, but it’s more tailored to someone who is flat/positive attack angle and is looking for a lighter weight alternative.

Our Kevlar Blue is tailored around someone who is smooth in transition but has a negative to flat attack angle. We’ve tailored all of the product line around a golfer’s swing and particularly arc and speed. So the length of someone’s arc and where they’re fastest: that’s the fitting paradigm from which we tailored our product.

So again, our Kevlar Green is capable of fitting all golfers, but golfers who may be looking for a lighter weight alternative would benefit from our table rolled component.

The wound series is available through the bag. There’s nothing that outperforms it; that’s why we reduced our line. We have three constructions in driver, two in fairways, and the reason for that is performance.

Going forward, are you more focused on relationships with OEMs? A tour presence? Appealing to clubmakers?

Our focus is on getting to the end user in the most efficient manner possible. And there are two forms of growth in the industry right now. You’ve got new retail, which is like the PGA Superstore. And then you’ve got the bespoken category.

We’re building that relationship with the dealer networks—they’re critical. But we really just want to get to the end consumer with the best technology and price relationship. Our paradigm there is incomparable. We have the world’s only polymer shaft, but we don’t charge $1000 for our shafts. Our shaft is the most expensive by way of materials and process of any golf shaft in the world. Yet because we are designing and making all organically, we don’t exploit consumer weakness or this “deep pocket opportunity.” That’s not our objective. We present unique, technical value propositions.

That all relates to where we go into the market. Some of the bespoken guys want the $500 shaft opportunity or a make-up program. There’s no real reason for a shaft to be $300 and installed at $500, but it helps them with their margins.

But consumers love our product. We have a 97 percent success rate in fitting golfers at arm’s length, and in the field it’s 100 percent. We’ll outperform anything that they have in our green grass demo events.

- LIKE118

- LEGIT14

- WOW13

- LOL10

- IDHT8

- FLOP4

- OB1

- SHANK27

19th Hole

Vincenzi’s 2024 Zurich Classic of New Orleans betting preview

The PGA TOUR heads to New Orleans to play the 2023 Zurich Classic of New Orleans. In a welcome change from the usual stroke play, the Zurich Classic is a team event. On Thursday and Saturday, the teams play best ball, and on Friday and Sunday the teams play alternate shot.

TPC Louisiana is a par 72 that measures 7,425 yards. The course features some short par 4s and plenty of water and bunkers, which makes for a lot of exciting risk/reward scenarios for competitors. Pete Dye designed the course in 2004 specifically for the Zurich Classic, although the event didn’t make its debut until 2007 because of Hurricane Katrina.

Coming off of the Masters and a signature event in consecutive weeks, the field this week is a step down, and understandably so. Many of the world’s top players will be using this time to rest after a busy stretch.

However, there are some interesting teams this season with some stars making surprise appearances in the team event. Some notable teams include Patrick Cantlay and Xander Schauffele, Rory McIlroy and Shane Lowry, Collin Morikawa and Kurt Kitayama, Will Zalatoris and Sahith Theegala as well as a few Canadian teams, Nick Taylor and Adam Hadwin and Taylor Pendrith and Corey Conners.

Past Winners at TPC Louisiana

- 2023: Riley/Hardy (-30)

- 2022: Cantlay/Schauffele (-29)

- 2021: Leishman/Smith (-20)

- 2019: Palmer/Rahm (-26)

- 2018: Horschel/Piercy (-22)

- 2017: Blixt/Smith (-27)

2024 Zurich Classic of New Orleans Picks

Tom Hoge/Maverick McNealy +2500 (DraftKings)

Tom Hoge is coming off of a solid T18 finish at the RBC Heritage and finished T13 at last year’s Zurich Classic alongside Harris English.

This season, Hoge is having one of his best years on Tour in terms of Strokes Gained: Approach. In his last 24 rounds, the only player to top him on the category is Scottie Scheffler. Hoge has been solid on Pete Dye designs, ranking 28th in the field over his past 36 rounds.

McNealy is also having a solid season. He’s finished T6 at the Waste Management Phoenix Open and T9 at the PLAYERS Championship. He recently started working with world renowned swing coach, Butch Harmon, and its seemingly paid dividends in 2024.

Keith Mitchell/Joel Dahmen +4000 (DraftKings)

Keith Mitchell is having a fantastic season, finishing in the top-20 of five of his past seven starts on Tour. Most recently, Mitchell finished T14 at the Valero Texas Open and gained a whopping 6.0 strokes off the tee. He finished 6th at last year’s Zurich Classic.

Joel Dahmen is having a resurgent year and has been dialed in with his irons. He also has a T11 finish at the PLAYERS Championship at TPC Sawgrass which is another Pete Dye track. With Mitchell’s length and Dahmen’s ability to put it close with his short irons, the Mitchell/Dahmen combination will be dangerous this week.

Taylor Moore/Matt NeSmith +6500 (DraftKings)

Taylor Moore has quickly developed into one of the more consistent players on Tour. He’s finished in the top-20 in three of his past four starts, including a very impressive showing at The Masters, finishing T20. He’s also finished T4 at this event in consecutive seasons alongside Matt NeSmith.

NeSmith isn’t having a great 2024, but has seemed to elevate his game in this format. He finished T26 at Pete Dye’s TPC Sawgrass, which gives the 30-year-old something to build off of. NeSmith is also a great putter on Bermudagrass, which could help elevate Moore’s ball striking prowess.

- LIKE8

- LEGIT3

- WOW1

- LOL1

- IDHT0

- FLOP3

- OB1

- SHANK1

19th Hole

Vincenzi’s 2024 LIV Adelaide betting preview: Cam Smith ready for big week down under

After having four of the top twelve players on the leaderboard at The Masters, LIV Golf is set for their fifth event of the season: LIV Adelaide.

For both LIV fans and golf fans in Australia, LIV Adelaide is one of the most anticipated events of the year. With 35,000 people expected to attend each day of the tournament, the Grange Golf Club will be crawling with fans who are passionate about the sport of golf. The 12th hole, better known as “the watering hole”, is sure to have the rowdiest of the fans cheering after a long day of drinking some Leishman Lager.

The Grange Golf Club is a par-72 that measures 6,946 yards. The course features minimal resistance, as golfers went extremely low last season. In 2023, Talor Gooch shot consecutive rounds of 62 on Thursday and Friday, giving himself a gigantic cushion heading into championship Sunday. Things got tight for a while, but in the end, the Oklahoma State product was able to hold off The Crushers’ Anirban Lahiri for a three-shot victory.

The Four Aces won the team competition with the Range Goats finishing second.

*All Images Courtesy of LIV Golf*

Past Winners at LIV Adelaide

- 2023: Talor Gooch (-19)

Stat Leaders Through LIV Miami

Green in Regulation

- Richard Bland

- Jon Rahm

- Paul Casey

Fairways Hit

- Abraham Ancer

- Graeme McDowell

- Henrik Stenson

Driving Distance

- Bryson DeChambeau

- Joaquin Niemann

- Dean Burmester

Putting

- Cameron Smith

- Louis Oosthuizen

- Matt Jones

2024 LIV Adelaide Picks

Cameron Smith +1400 (DraftKings)

When I pulled up the odds for LIV Adelaide, I was more than a little surprised to see multiple golfers listed ahead of Cameron Smith on the betting board. A few starts ago, Cam finished runner-up at LIV Hong Kong, which is a golf course that absolutely suits his eye. Augusta National in another course that Smith could roll out of bed and finish in the top-ten at, and he did so two weeks ago at The Masters, finishing T6.

At Augusta, he gained strokes on the field on approach, off the tee (slightly), and of course, around the green and putting. Smith able to get in the mix at a major championship despite coming into the week feeling under the weather tells me that his game is once again rounding into form.

The Grange Golf Club is another course that undoubtedly suits the Australian. Smith is obviously incredibly comfortable playing in front of the Aussie faithful and has won three Australian PGA Championship’s. The course is very short and will allow Smith to play conservative off the tee, mitigating his most glaring weakness. With birdies available all over the golf course, there’s a chance the event turns into a putting contest, and there’s no one on the planet I’d rather have in one of those than Cam Smith.

Louis Oosthuizen +2200 (DraftKings)

Louis Oosthuizen has simply been one of the best players on LIV in the 2024 seas0n. The South African has finished in the top-10 on the LIV leaderboard in three of his five starts, with his best coming in Jeddah, where he finished T2. Perhaps more impressively, Oosthuizen finished T7 at LIV Miami, which took place at Doral’s “Blue Monster”, an absolutely massive golf course. Given that Louis is on the shorter side in terms of distance off the tee, his ability to play well in Miami shows how dialed he is with the irons this season.

In addition to the LIV finishes, Oosthuizen won back-to-back starts on the DP World Tour in December at the Alfred Dunhill Championship and the Mauritus Open. He also finished runner-up at the end of February in the International Series Oman. The 41-year-old has been one of the most consistent performers of 2024, regardless of tour.

For the season, Louis ranks 4th on LIV in birdies made, T9 in fairways hit and first in putting. He ranks 32nd in driving distance, but that won’t be an issue at this short course. Last season, he finished T11 at the event, but was in decent position going into the final round but fell back after shooting 70 while the rest of the field went low. This season, Oosthuizen comes into the event in peak form, and the course should be a perfect fit for his smooth swing and hot putter this week.

- LIKE12

- LEGIT3

- WOW1

- LOL1

- IDHT0

- FLOP1

- OB1

- SHANK1

Opinion & Analysis

The Wedge Guy: What really makes a wedge work? Part 1

Of all the clubs in our bags, wedges are almost always the simplest in construction and, therefore, the easiest to analyze what might make one work differently from another if you know what to look for.

Wedges are a lot less mysterious than drivers, of course, as the major brands are working with a lot of “pixie dust” inside these modern marvels. That’s carrying over more to irons now, with so many new models featuring internal multi-material technologies, and almost all of them having a “badge” or insert in the back to allow more complex graphics while hiding the actual distribution of mass.

But when it comes to wedges, most on the market today are still single pieces of molded steel, either cast or forged into that shape. So, if you look closely at where the mass is distributed, it’s pretty clear how that wedge is going to perform.

To start, because of their wider soles, the majority of the mass of almost any wedge is along the bottom third of the clubhead. So, the best wedge shots are always those hit between the 2nd and 5th grooves so that more mass is directly behind that impact. Elite tour professionals practice incessantly to learn to do that consistently, wearing out a spot about the size of a penny right there. If impact moves higher than that, the face is dramatically thinner, so smash factor is compromised significantly, which reduces the overall distance the ball will fly.

Every one of us, tour players included, knows that maddening shot that we feel a bit high on the face and it doesn’t go anywhere, it’s not your fault.

If your wedges show a wear pattern the size of a silver dollar, and centered above the 3rd or 4th groove, you are not getting anywhere near the same performance from shot to shot. Robot testing proves impact even two to three grooves higher in the face can cause distance loss of up to 35 to 55 feet with modern ‘tour design’ wedges.

In addition, as impact moves above the center of mass, the golf club principle of gear effect causes the ball to fly higher with less spin. Think of modern drivers for a minute. The “holy grail” of driving is high launch and low spin, and the driver engineers are pulling out all stops to get the mass as low in the clubhead as possible to optimize this combination.

Where is all the mass in your wedges? Low. So, disregarding the higher lofts, wedges “want” to launch the ball high with low spin – exactly the opposite of what good wedge play requires penetrating ball flight with high spin.

While almost all major brand wedges have begun putting a tiny bit more thickness in the top portion of the clubhead, conventional and modern ‘tour design’ wedges perform pretty much like they always have. Elite players learn to hit those crisp, spinny penetrating wedge shots by spending lots of practice time learning to consistently make contact low in the face.

So, what about grooves and face texture?

Grooves on any club can only do so much, and no one has any material advantage here. The USGA tightly defines what we manufacturers can do with grooves and face texture, and modern manufacturing techniques allow all of us to push those limits ever closer. And we all do. End of story.

Then there’s the topic of bounce and grinds, the most complex and confusing part of the wedge formula. Many top brands offer a complex array of sole configurations, all of them admittedly specialized to a particular kind of lie or turf conditions, and/or a particular divot pattern.

But if you don’t play the same turf all the time, and make the same size divot on every swing, how would you ever figure this out?

The only way is to take any wedge you are considering and play it a few rounds, hitting all the shots you face and observing the results. There’s simply no other way.

So, hopefully this will inspire a lively conversation in our comments section, and I’ll chime in to answer any questions you might have.

And next week, I’ll dive into the rest of the wedge formula. Yes, shafts, grips and specifications are essential, too.

- LIKE33

- LEGIT7

- WOW1

- LOL1

- IDHT2

- FLOP3

- OB1

- SHANK3

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole3 days ago

19th Hole3 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole3 days ago

19th Hole3 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole1 week ago

19th Hole1 week agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

BOB

Sep 11, 2015 at 7:39 pm

I HAVE LOOKED AT THEIR WEBSITE AND HAVE READ ALL THEIR COMMENTS . I AM WILLING TO TRY ONE OF THEIR SHAFTS AND MAKE MY JUDGEMENT FROM HOW IT PERFORMS FOR ME AND MY CUSTOMERS. I AGREE THAT THERE IS TOO MUCH TECHNICAL JARGON IN THE ARTICLE BRING IT ALL DOWN TO WHERE THE LAYMAN CAN UNDERSTAND ABOUT THE SHAFTS.

I WILL POST ANOTHER COMMENT AFTER I RECEIVE MY SHAFT AND HAVE TRIED ITS PERFORMANCE FOR MYSELF.

myron miller

Aug 26, 2015 at 6:04 pm

From this article, I have no clue if these shafts would work for my game or not. I really didn’t understand the verbiage. Non-standard shaft terminology doesn’t help us end-users. Where’s the kick point? What are the flexes at head, butt, middle?

According to the website, the torque is not what I’d call low torque by any means. 5.7 to 5.9 is not low torque when lots of shafts are available with 3.5 or even lower. Fujikura has them down to 2.8 and most are 3.5 or less. I thought advanced tech made torque lower not higher.

Charlie

Aug 19, 2015 at 2:04 pm

http://www.golfworks.com/product.asp?pn=PK0009&gclid=CNTMwbfctccCFZKKaQodgyMCvw

$199.00 here.

Allen

Aug 16, 2015 at 9:51 pm

I would love to try these, but at almost $90 a shaft for the irons, I am not sure I can justify the money. I cant believe they will give me $90 worth of improvement, or very much improvement.

other paul

Aug 16, 2015 at 9:44 pm

Sounds like the steel fiber shafts to me… Aerotech has been around for quite some time.

Mac n Cheese

Aug 26, 2015 at 9:58 am

If they actually found a way to create a shaft out of woven steel fibers, it could be a potential game changer considered steel fibers would have a stronger resistance to twisting upon impact. Especially if they drop the weight over traditional steel shafts.

KK

Aug 16, 2015 at 3:10 pm

Some of the tech sounds great, some of the phrasing seems a bit too much like meaningless rhetoric; e.g. the virtues of showing the carbon structure underneath vs painting over it. It’s like saying your car is better because the hood is made of glass and you can see the engine vs other car companies who don’t have glass hoods.

Mac n Cheese

Aug 26, 2015 at 10:04 am

The theory is more in line with carbon fiber hoods vs. traditional hoods. Basically with carbon fiber you don’t have to paint over it, and some people like the look of just carbon fiber in general over painted. Also by having some carbon fiber visible it shows that the product is actual carbon fiber instead of taking their word for it. Really the paint scheme or lack there of is an aesthetic marketing campaign to make their shafts look cooler. Which they do. I want green shafts! lol

Mo

Aug 15, 2015 at 8:29 pm

Some independent reviews would mean a lot.

Tom Duckworth

Aug 15, 2015 at 6:48 pm

I must admit he doesn’t talk like a sales department guy. He’s deeply into the construction of his shafts. I found that refreshing.

Tom Duckworth

Aug 15, 2015 at 6:28 pm

Very cool reminds me of Eminence Speaker Co. they made speakers for all kinds of guitar amps and PA systems for other people. One of the largest speaker makers in the world. Now they make them under their own name some of the best on the market. It can only be a good thing for Paderson to enter the marketplace. It will be interesting to see how they do.

Matthew

Aug 15, 2015 at 3:04 pm

Gotta echo Mark. Less infomercial and more substance.

Christosterone

Aug 15, 2015 at 12:27 pm

Not to nitpick but they’ve been doing golf shafts with polymer in Japan for years:

https://books.google.com/books?id=kAqKgu0AQK0C&pg=PA173&lpg=PA173&dq=polymer+golf+shaft&source=bl&ots=Z4zQEfCgs5&sig=AMMQbyck8Km-iWtSnUunK4czqog&hl=en&sa=X&ved=0CCEQ6AEwAWoVChMI5ryx9r-rxwIVRtWACh28xg2D#v=onepage&q=polymer%20golf%20shaft&f=false

Mac n Cheese

Aug 26, 2015 at 10:06 am

Yes, but they found a new method of doing so, as the article pointed out.