News

GolfWRX takes a behind-the-scenes look at the Callaway ball plant

In Chicopee, Massachusetts, there is an unassuming red brick building that predates the existence of every modern golf OEM. From the outside, it could be confused for any other American manufacturing facility if not for the proudly displayed Callaway sign. Inside, there are over 400 hard-working people producing the highest quality golf balls using state-of-the art manufacturing techniques and tools — this red brick building is the Callaway golf ball plant.

To understand what you see when you first enter the ball plant, it’s best to first understand why it is here in the first place. When I initially asked this question to one of my tour guides, Vincent Simonds, the Senior Director of Global Golf Ball Operations, his answer started with a story that predated cars…it was at this point I knew that these guys mean business.

The modern history, however, starts in 2003 when Callaway purchased Top-Flite brand and subsidiaries, and with it purchased the entire Top-Flite manufacturing facility. In its it heyday, Top-Flite/Spaulding was producing its full line of clubs and balls out of this building, and that included equipment made for Bobby Jones. Chicopee, Massachusetts, was essentially the center of the golf club technology universe.

Part of the original Spaulding golf club factory

Letter from Bobby Jones discussing the advantage of the newly designed ball

Page 2 of the Letter from Bobby Jones

When its comes to balls, most modern golfers don’t equate Top-Flite with premium equipment or breakthroughs, but during this time period the ball plant in Chicopee was responsible for just as many technology and scientific breakthroughs as its modern Callaway self.

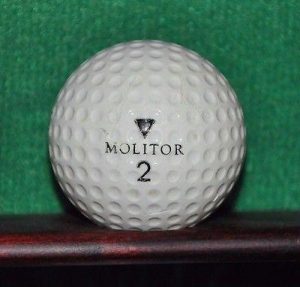

One Example is Bob Molitor. In 1972, Molitor developed the first two-piece golf ball with a Surlyn cover by combining the right amounts of various ionomers. This allowed golf balls to have much greater durability and along with it improved distance. This development is part of the reason the USGA had to establish the “One Ball Rule” because players would switch out depending on the hole since there was a huge distance advantage to this Solid Core Surlyn Cover design. Imagine that – the USGA having to change rules to accommodate a new technology, seems to me our current daily discussions about bifurcation aren’t something so new after all.

There were a lot of other great innovations over the years that lead to new technology making its way into the bags of players all over the world, one of which caused a revolution that we still benefit from today. In the 90s Top-Flite, under the Strata brand, cracked the code of merging the soft, high-spin “tour ball” performance with the lower-spinning, longer-flying, and more durable “distance ball”, this three-piece ball was like two balls in one. Strata’s design team accomplished this feat by placing a soft polyurethane cover on a Top-Flite distance ball, and then added a thin layer between the cover and the core that encased the ball’s already large and solid rubber core. In short, the modern golf ball was born.

This brings us back to the modern day Callaway ball plant, a facility where the average employee tenure exceeds 20 years, and where every single premium Callaway Ball on the planet is made. The thing I quickly realized upon entering the plant for the first time is the pride every person has for their role in making world class golf balls. This sense of pride, and a friendly, yet hard-working environment is something I witnessed before at Callaway’s Carlsbad facility too — a testament to the company’s corporate leadership and the culture that they promote everyday. The “Victory Flag,” as they call it, was flying high thanks to Xander Schauffele’s win just a few days before my visit.

The start of production begins with materials formulation

I was able to observe a pre-shift meeting, and you would think that based on the discussion of machine tolerances, quality control, & equipment inspections this plant is making parts for a yet-to-be-seen shuttle being sent into space, but they’re talking golf balls. Speaking to the tolerances the plant works within, the in-house machine shop had some amazing equipment, including some things I unfortunately could not share through pictures. This equipment works with the tolerances of less than the 1/30th the thickness of a Post-It Note. For example, each single side to a cover mold for the Chrome Soft line takes more than 30 hours of machine time to complete — an amount of time which might seem excessive, but when you think of the speed and forces impacting a golf ball from first driver strike and along its parabolic trajectory, we really are talking space shuttle physics.

Some of the most impressive equipment has nothing to do with the performance of the balls but rather how they look. I’m talking here about the Truvis patterned balls. What was perceived by many golfers at first as a gimmick (and something than even some Callaway management believed would be a fad) has proven to be an absolute slam dunk. The pentagon pattern provides a tangible benefit by creating an optical illusion that makes the ball look bigger (and easier to hit) especially out of the rough, and also gives visual feedback for short game shots and putting.

Let’s just say that what started as a toe dip with one machine has turned into an area of the plant with more than a dozen machines, and Callaway is also producing Truvis balls with custom colors and logos — they’re not just printing pentagons anymore.

GolfWRX Truvis

For actual production, every ball starts as raw materials, and compounds are precisely mixed in house, allowing Callaway to control the entire production process. The amount of materials engineering and chemistry I witnessed was way beyond what I was expecting, and to be frank, I went in with already high expectations. After initial mixing each batch is tested and sent to the next step.

Mixing Station

Pre cut core “slugs” ready for baking

Ever wonder why the cores of various golf balls from a single OEM are so bright and differently colored? It’s actually done to make each material identifiable in the process and give production staff another way to make sure materials get to the right manufacturing line. Of all the questions I asked, this one had the most simple answer.

Callaway ERC ( Left ) vs. Chrome Soft ( Right )

The next step is the “cooking” process of the inner core. Each oven press is precisely controlled for pressure and temperature along multiple areas of each unit, this ensures a core that comes from the outer part of the press is formed and “cooked” to the exact same spec as one from the middle. The same process is used for both parts of the dual core.

Hydraulic press “oven” for producing cores

Cores post-pressing and still hot

Callaway utilized a proprietary manufacturing and molding technique to ensure exact specifications are met for centering the core and achieving correct cover thickness. Once the covers are in place, we officially have a golf ball, but we’re not done yet. There are still more quality control checks done by machine as well and humans to once again ensure each ball that leaves the plant is built to the highest quality standards and will perform just like the one before it.

Chrome Softs just after the cover process – Still very warm to the touch as the urethane cools

Even the final paint and clear coat are highly engineered to resist staining, sheering, and stay on during deformation. To quote of one my tour guides, “The force applied to the cover and paint on the ball by a wedge would be like taking a hatchet to the paint on the side of your house.” It might seem like a simple process, but to ensure full coverage of sphere requires some pretty unique tools to get the job done.

This brings us to the new Triple Track Alignment system and how it was developed to help golfers play better. The new system helps improve alignment on putts from all lengths and it also happens to be on Callaway’s longest ball to date: the ERC Soft.

The alignment aid wraps 160 degrees around the ball and offers three parallel lines with high contrast (no more need to try and draw that long Sharpie line around your ball). For those who choose to putt without the Triple Track alignment, Callaway considered you too, since the other 200 degrees around the ball unsure that you won’t see those lines from address.

Triple Track Alignment visible vs hidden

Every shot taken means something to someone, whether it be a golfer trying to break 100 for the first time, or a tour professional lining up a putt on Sunday afternoon of a major championship. The golf ball is the one piece of equipment a golfer will use on every shot, and each person at the Callaway ball plant in Chicopee, Massachusetts, is proud to put their name behind it, even if you don’t see those names on the box.

- LIKE171

- LEGIT19

- WOW10

- LOL0

- IDHT4

- FLOP0

- OB0

- SHANK8

Tour Photo Galleries

Photos from the 2024 Zurich Classic of New Orleans

GolfWRX is live on site this week at the Zurich Classic of New Orleans for the PGA Tour’s one-and-only two-man team event.

As usual, general galleries, WITBs, and pullout albums — including some pretty spicy custom putters and headcovers — await your viewing.

Be sure to check back for more photos from the Big Easy, as we’ll continue to update this page with additional galleries throughout the week.

General Albums

- 2024 Zurich Classic – Monday #1

- 2024 Zurich Classic – Monday #2

- 2024 Zurich Classic – Tuesday #1

- 2024 Zurich Classic – Tuesday #2

WITB Albums

- Alex Fitzpatrick – WITB – 2024 Zurich Classic

- Austin Cook – WITB – 2024 Zurich Classic

- Alejandro Tosti – WITB – 2024 Zurich Classic

- Davis Riley – WITB – 2024 Zurich Classic

- MJ Daffue – WITB – 2024 Zurich Classic

- Nate Lashley – WITB – 2024 Zurich Classic

- James Nicholas – WITB – 2024 Zurich Classic

- Kevin Streelman – WITB – 2024 Zurich Classic

- Rasmus Hojgaard – WITB – 2024 Zurich Classic

- Tom Whitney – WITB – 2024 Zurich Classic

- SangMoon Bae – WITB – 2024 Zurich Classic

- Daniel Berger – WITB – 2024 Zurich Classic

- Rory McIlroy – WITB – 2024 Zurich Classic

- Russ Cochrane – WITB – 2024 Zurich Classic

- Aldrich Potgieter – WITB – 2024 Zurich Classic

Pullout Albums

- MJ Daffue’s custom Cameron putter – 2024 Zurich Classic

- Cameron putters – 2024 Zurich Classic

- Swag covers ( a few custom for Nick Hardy) – 2024 Zurich Classic

- Custom Bettinardi covers for Matt and Alex Fitzpatrick – 2024 Zurich Classic

- Doug Ghim’s custom Cameron putter – 2024 Zurich Classic

- LIKE4

- LEGIT3

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

News

Morning 9: Tiger’s TGL teammates | Woosnam’s criticism of Cantlay | Rory’s return to tour policy board

|

- LIKE4

- LEGIT0

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK2

News

Tour Rundown: Six-pack of tourneys follows Masters

Brazil and Texas were kindred souls this week, at least when it came to weather. Both regions experienced torrential delays, and three tournaments were held up. The LPGA, PGA Tour Americas, and PGA Tour Champions were compelled to reduce play or work extra holes into Sunday. As if that weren’t enough, South Carolina and the PGA Tour fell victim to nature’s wrath, with lightning postponing the conclusion of the event to Monday.

The year’s first women’s major championship was celebrated in Texas. The Chevron is gaining a bit of tradition in its second year after relocation. This year’s event culminated in the continued coronation of the game’s current best. The Korn Ferry Tour saw a top-twenty performance from a 15-year old amateur, while the second event of the week on the big tour found a winner in the Dominican Republic. Six events is more than a handful, so let’s get right to it, with this week’s (delayed) Tour Rundown.

LPGA @ Chevron Championship: Korda corrals second major title

The winter of 2022-2023 seems so distant for current Nelly Korda. A mysterious ailment sapped all of her energy, just as the world appeared to have finally emerged from the pandemic. We never quite secured the complete information that we desired, but no one can say that any of us deserved to know more than Nelly wished to share. One thing is for certain: Nelly Korda has returned to top form, and the world number one golfer is at least one level above anyone else on tour.

Korda began her 2024 campaign with a January victory in the Drive One Championship. In her next start, in March, she continued her assault on the record books, with a win at the Se Ri Pak. She won again the following week, at the Ford, then defeated Leona Maguire in the final match at the T-Mobile Match Play, for a fourth consecutive victory. Would the increased hype around a major championship have an impact on her game? Well, no.

Korda began play at the Chevron Championship with a score of 68. She trailed Lauren Coughlin by two after 18 holes, but caught her with a second-round 69. Coughlin would ultimately tie for third spot with Brooke Henderson. Henderson played with Korda on day four, but the middle third of the round was her undoing. Making a late move was Maja Stark. House Stark closed with birdies at 17 and 18 to reach 11 under par. Both Korda and Strak played the final three days in identical numbers: 69 each day.

Korda held a firm hand on the tournament over the course of the final day. She stood minus-four for the round through ten holes, before a bit of sloppy play made things competitive again. Bogeys at 11 and 15 opened the door a wee bit for Stark. Korda was equal to the test, however, and closed stylishly with birdie at 18.

Safely around the green on the 72nd hole

Watch @NellyKorda‘s historic finish now on NBC! pic.twitter.com/1zaAYtbaCz

— LPGA (@LPGA) April 21, 2024

PGA Tour 1 @ RBC: Scottie, so hottie!

Nelly isn’t the only golfer on fire, although Scottie Scheffler still has a ways to go to match her. Scheffler proved this week that he has a game for all courses. After winning comfortably at lengthy Augusta National, Scheffler shifted gears and game to the wee Sea Pines course, and won again. That’s two weeks in a row for the man from New Jersey/Texas, so let’s learn how he did it.

Scheffler totaled 69 on day one, and found himself six shots behind leader J.T. Poston. Scheffler revealed that his teacher, Randy Smith, would tell him that he didn’t need to be the best 15 year-old; just the best 25 year-old. It was easy, then, to play the long game and consider all 72 holes, instead of just 18. Scheffler improved to 65 on Friday, and then went even lower on Saturday. His 63 moved him to the top of the board, and caused the golfverse to wonder if Scheffler would win for a second consecutive week.

Sunday saw all the chasers fall away. Scores between 70 and 72 from Patrick Rodgers, Collin Morikawa, and Sepp Straka meant that others would need to seize the day, if Scheffler were to do more than coast. Wyndham Clark and Justin Thomas each moved inside the top five with fourth-round 65s, but no one ever got close enough to the world number one. The win was Scheffler’s 10th on tour, and made him the betting favorite for next month’s PGA Championship at Valhalla.

Scottie Scheffler can save par from just about anywhere.

Including the water ?

(Presented by @CDWCorp) pic.twitter.com/RUqL2sBrr9

— PGA TOUR (@PGATOUR) April 22, 2024

PGA Tour 2 @ Corales Puntacana: Baton Boy claims 8th Tour triumph

If you’ve ever seen Billy Horschel toss a club, you know that he doesn’t do so in anger. More likely is a calculated, soaring arc, paired with a look of fractured disbelief, followed by a quick catch of the cudgel. Ergo, Baton Boy. This week on the island of Hispaniola, the native of Grant, Florida, outworked and outhustled everyone else on Sunday. Horschel gathered seven birdies and an eagle, on the way to a 63 and a 23-under par total.

The former Florida Gator zipped past the four golfers in front of him, and left the remaining field in the rear-view mirror. Horschel’s round was two shots better than anyone else, and moved him two shots ahead of third-round leader Wesley Bryan. One of the famed Bryan Brothers, Wes closed with birdie at the last to post a 68 that would have won the week on any other day.

Walking it in with a fist pump ?@BillyHo_Golf is 9-under on the day and leads by two @CoralesChamp. pic.twitter.com/N6rjL1GGGA

— PGA TOUR (@PGATOUR) April 21, 2024

Korn Ferry Tour @ LeCom Suncoast: It’s Widing in extra holes

Miles Russell probably won’t have to serve detention for ditching class on Thursday and Friday. The high school freshman made his KFT debut, survived the 36-hole cut, and toyed with a top-ten finish. He ultimately tied for 20th at 14-under par, six shots behind the three co-leaders. My guess is that Epstein’s Mom will write him a note, and he’ll get a pass. By finishing top-25, Russell earned a spot in next week’s event. Yikes!

Back to the top of the board. Patrick Cover, Steven Fisk, and Tim Widing all found their way to the magic number of -20. Fisk made birdie at the last, after bogeys at 16 and 17. Cover had three bogeys on the back nine, but a birdie at 14 was enough to get him to overtime. Widing was plus-one on the day through four, but played interstellar golf over the final 14. Six birdies moved him from Russell-ville to extra time.

The trio scurried to the 18th tee, where Cover drove into a fairway bunker. He was unable to reach the green with his approach, made bogey, and exited the overtime session. Widing and Fisk returned to the final deck once more, and matters were resolved. Fisk was unable to convert a long par putt, and Widing (pronounced VEE-ding) tapped in for his first KFT title.

The feeling of relief when you know you won. ???

Tim Widing is now a champion on the #KornFerryTour. pic.twitter.com/K0vgiZ21UG

— Korn Ferry Tour (@KornFerryTour) April 21, 2024

PGA Tour Americas @ Brasil Open: Mr. Anderson finds a way

Golf is a funny game. Matthew Anderson held a lead with one round to play. He made six pars on Sunday, and sprinkled the rest of his card with birdies and bogeys. In complete contrast, Ollie Osborne played consistently on the day, posting four birdies and zero bogeys. Connor Godsey was not far off Osborne’s pace, with seven birdies and but two bogeys on the scorecard. So, of course, Matthew Anderson won by a stroke over Osborne and Godsey.

Not how, but how many, is another one of those platitudes that we all learn early on. Despite five bogeys through his first 14 holes, Anderson summoned the defiant grit to make birdie at the 71st and 72nd holes. After making deuce at the penultimat hole, Anderson’s swerving effort at the last looked as if it should miss low, but it had enough pace to stay inside the hole and fall for a closing four at the par-five finisher.

Birdie-birdie finish to secure the ?

Mississauga-native Matthew Anderson is your 69th ECP Brazil Open Champion. pic.twitter.com/ONE8hIUjeS

— PGA TOUR Americas (@PGATOURAmericas) April 21, 2024

PGA Tour Champions @ Invited Celebrity: Broadhurst stands tall

What do you call a tournament that begins on Friday, takes Saturday off, and finishes on Sunday? Fortunate is one adjective to use. A weather system moved through Texas this weekend, and made a mess of things in Irving. After Thomas Bjorn signed for 64 on day one, rain and all things counter-productive moved through the Las Colinas resort, ensuring that Saturday would be nothing more than a rest day. When Sunday arrived, conditions had improved, and the game was on. Bjorn was unable to preserve his Friday magic, although he did record a 70 for -8. He finished in a third-place tie with Y.E. Yang.

David Toms, the 2001 PGA Championship victor, presented Sunday’s low round, and moved to 10-under par. Toms made one mistake on the day. He lived in the rough on the 9th hole, ultimately making bogey. The rest of the day was immaculate, as seven birdies came his way, resulting in a six-under par 65. Only one golfer was able to surpass Toms, and that was Paul Broadhurst.

Broadhurst nearly matched Toms for daily honors. His mistake came early, with bogey at the second. He bounced back with eagle at the third, and added three more birdies for 66 and 11-under par. Over his first three seasons on the Tour Champions, Broadhurst won five times, including two major titles. His fifth win came in 2018, making this win his first in six years. A long time coming, for sure, but well earned.

Looking at the hole is working for @PBroadhurstGolf ?

He leads by one after a clutch birdie on 15 @InvitedCC. pic.twitter.com/S0rhcVwaeE

— PGA TOUR Champions (@ChampionsTour) April 21, 2024

- LIKE0

- LEGIT0

- WOW0

- LOL1

- IDHT0

- FLOP1

- OB1

- SHANK1

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole3 days ago

19th Hole3 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole3 days ago

19th Hole3 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

DanT

Mar 14, 2019 at 7:52 pm

PROBLEM – NOT ALL CALLAWAY BALLS ARE PRODUCED IN THE US!!

The SuperSoft is made in Taiwan!!

In my opinion – this story makes you think – all Callaway balls are made in the US –WRONG!!

Perplexed

Jan 20, 2019 at 1:08 pm

Did the USGA come up with the one ball rule? I don’t recall having ever seen it in the USGA rules. It seemed like a PGA Tour rule to me.

Mark

Jan 19, 2019 at 11:26 am

I’m curious if you asked if they run special batches for their tour players and what % play one of the standard production balls?

Willie Carmichael

Jan 19, 2019 at 11:01 am

It’s spelled Spalding.

Bill C

Jan 19, 2019 at 8:58 am

Golf balls are very fascinating. They seem so simple, yet the amount of engineering which goes into their design and manufacture always amazes me.