Equipment

The Callaway ball plant: A legacy rooted in innovation

A little over two years ago, I had the opportunity to visit the Callaway golf ball plant in Chicopee, Massachusetts (GolfWRX behind the scenes at the Callaway ball plant). It gave me the chance to take a deep dive into the history of not just the physical structure that is the plant but a look into the people and the machines that work to produce Callaway’s tour line of golf balls.

The one thing that stood out during that visit beyond the massive scale of the operation was the people and the pride they have in producing something in the United States for golfers to enjoy.

Chicopee & Spalding Manufacturing History

The ball plant and surrounding area where it is located is rich in manufacturing history dating back to the American revolutionary war, and the facade of the historical red brick building in Chicopee has remained mostly unchanged since it was the original Spalding manufacturing plant dating all the way back to the late 1800s. It was during this time in history when the plant produced baseballs, gloves, footballs, basketballs, tennis rackets, persimmon woods, irons—and of course golf balls, starting in 1896.

A lot of innovations relating to various sports have occurred inside of these walls and the funny thing is, Callaway’s marketing slogan for Chrome Soft— “The ball that changed the ball” could apply to a multitude of sports including:

- Baseball – since Spalding developed the first Major League ball to become the official baseball of the National League in 1876.

- Football – with Spalding creating the first American football with a material and workmanship guarantee in 1887.

- Basketball – since Dr. James Naismith (Canadian—just wanted to get that in there—Go Raptors!) had the Spalding company develop the official basketball in 1894.

It is now 2020, and in the same building where all of these sporting innovations have taken place, an innovation of a new kind is underway because the ball plant has undergone multiple renovations and upgrades since 2018. Callaway has invested over $50 million in capital upgrades in order to increase quality control—and the ability to manufacture the newest Chrome Soft and Chrome Soft X balls to the highest level.

Investment in innovation

Although the plant has always operated to the highest possible level of quality control when it comes to balls, Callaway has admitted that, before 2018, there were some small holes in the production process that prevented them from reaching their potential as far as production standards go. The biggest consistency issues revolved around polymer compound mixing and the centeredness of the cores in dual-core golf balls. These weren’t wide-sweeping issues but they were enough of a problem, Callaway knew they needed to be addressed as quickly as possible, especially if they wanted to continue to innovate in the competitive golf ball market.

In an effort to not just be equal to the competition but to surpass them, the initial investment was in state-of-the-art machines that could take and process 3D X-Ray to measure ball construction and the core centeredness of every single ball. It is during this automated process, that if any ball shows an issue, then it is removed from the final stages of production and will never find its way into a golfer’s bag.

The biggest investment though came in the form of an all-new synthetic polymer mixer allowing Callaway engineers and plant staff to monitor parts of the process with a level of precision that they never could before. Now, if it wasn’t obvious by the pictures, this is not the type of machine that you can just pick up at a local “golf ball plant supply store”— these types of mixers are multiple stories high and offer the same type of precision you would find in the medical industry.

When it comes to the unassuming red brick building, it’s what’s inside that counts. And speaking of “inside,” Callaway engineers are now able to precisely control all of the compounds that go into producing golf ball cores. With the state-of-the-art mixer now in place on the factory floor, from the very start of production through to the final packaging, every Callaway ball is manufactured to the highest level of quality available in the industry.

The state of the art mixer now in place on the factory floor means that from the very start of production through to the final packaging, every Callaway ball is manufactured to the highest level of quality available in the industry.

Technology on the inside and outside

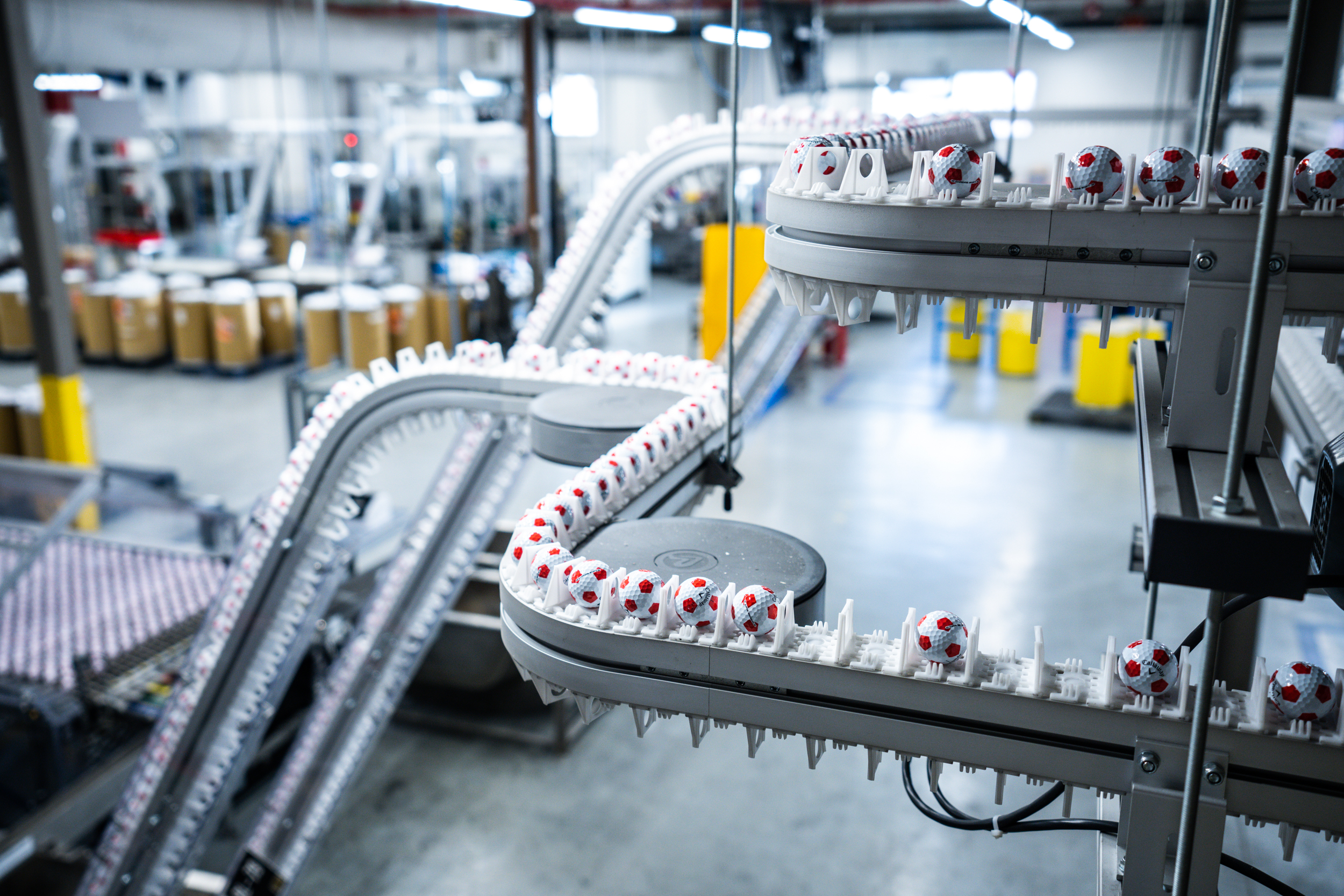

The other part of the plant that continues to see large investments is the Truvis and Triple Track printing area. As we touched on in the original piece, what was perceived by many to at first be a bit of a gimmick, including some of Callaway’s own employees, has proven to be an absolute slam dunk. The pentagon pattern provides a tangible benefit by creating an optical illusion that makes the ball look bigger and also gives visual feedback for short game shots and putting. If you haven’t tried chipping around a green with a Truvis ball, I highly suggest it—you can actually see how much difference in spin you create hitting various shots.

What started as a toe-dip with one machine has turned into an area of the plant with more than a dozen, with Callaway also producing Truvis balls with custom colors and logos.

What followed Truvis was the development of Callaway Triple Track, which is three high-resolution parallel lines printed onto the golf ball to help with alignment. It would not have been possible to print this alignment tool without the machines that were developed to precisely print the Truvis patterns. Triple Track has been so popular and effective for golfers that this year, Callaway even introduced the alignment tool onto a number of their Stroke Lab putter models.

Odyssey Stroke Lab 2-Ball with Triple Track

If history is any indication, this investment will continue to push golf ball innovation for Callaway, as well as continue to build on the strong legacy of proud American manufacturing in Chicopee, Massachusetts. To take an inside look inside of the newly renovated plant, as well as get a deeper understanding of the history and the people behind Callaway golf balls, check out their mini-documentary below.

The Ball that Changed a Town

- LIKE126

- LEGIT14

- WOW9

- LOL2

- IDHT0

- FLOP1

- OB1

- SHANK17

Whats in the Bag

Kris Kim WITB 2024 (May)

- Kris Kim what’s in the bag accurate as of the CJ Cup Byron Nelson. More photos from the event here.

Driver: TaylorMade Qi10 (9 degrees @7)

Shaft: Mitsubishi Tensei 1K White 60 TX

3-wood: TaylorMade Qi10 Tour (15 degrees @13.5)

Shaft: Mitsubishi Diamana WB 73 TX

Irons: TaylorMade P770 (2, 4), TaylorMade P7MB (5-PW)

Shafts: Mitsubishi Tensei 1K White 80 TX (2), Nippon N.S. Pro Modus3 Tour 120 X

Wedges: TaylorMade MG4 (50-09SB, 56-12SB, 60-11TW)

Shafts: Nippon N.S. Pro Modus3 WV 125

Putter: TaylorMade Spider Tour

Grips: Golf Pride Tour Velvet Cord

Check out more in-hand photos of Kris Kim’s equipment here.

View this post on Instagram

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Welcome to the family: TaylorMade launches PUDI and PDHY utility irons

TaylorMade is continuing its UDI/DHY series with the successor to the Stealth UDI and DHY utility irons: PUDI and PDHY (which the company styles as P·UDI and P·DHY). TaylorMade is folding the designs in with its P Series of irons.

TaylorMade outlined the process of developing its new utilities this way. The company started with the data on utility iron usage. Not surprisingly, better players — i.e. those who generate more clubhead speed and strike the ball more precisely — were found to gravitate toward the UDI model. DHY usage, however, covered a wider swath than the company might have expected with six-to-18 handicappers found to be bagging the club.

TaylorMade also found that the majority of golfers playing UDI or DHY utilities were playing P Series irons at the top of their iron configurations.

Can you see where this is going?

Matt Bovee, Director of Product Creation, Iron and Wedge at TaylorMade: “As we look to the future, beyond the tech and the design language, we are excited about repositioning our utility irons into the P·Series family. P·UDI is an easy pair for players that currently play P·Series product and P·DHY is an extremely forgiving option for players of all skill levels. It is a natural fit to give these players the performance in this category that they are looking for.”

View this post on Instagram

TaylorMade PUDI

TaylorMade PUDI technology cutaway (via TaylorMade)

Crafted with tour player input, TaylorMade sought to develop a confidence-inspiring utility iron that blends with the rest of the P Series irons. Also of note: Interestingly, the PUDI has a more compact head than the P790.

In comparison to past UDI products, the PUDI has a more traditional iron shape, slimmer toplines, and less offset with a little of the backbar visible at address.

TaylorMade PDHY

TaylorMade PDHY tech cutaway (via TaylorMade).

Larger in profile than the PUDI, the PDHY seeks to position center of gravity (CG) lower in the club for ease of launch. The toe height is larger and the profile is larger at address — roughly five millimeters longer than PUDI — the sole of the club is wider for improved forgiveness.

Club Junkie’s take

Golfers who feel like they are missing something at the top of the bag could find the PUDI or PDHY a great option. The look of the PUDI should fit the most discerning eye with a more compact look, less offset, and a thinner topline. If you want a little more confidence looking down the P-DHY will be slightly larger while still being a good-looking utility iron.

For being small packages both models pack a pretty good punch with fast ball speeds, even off-center. The feel is soft and you get a solid feel of the ball compressing off the face when you strike it well. Your ears are greeted with a nice heavy thud as the ball and club come together. The PDHY will launch a little higher for players who need it while the PUDI offers a more penetrating ball flight. Both utility irons could be the cure for an open spot in the top end of the bag.

PUDI, PDHY, or Rescue?

TaylorMade offers the following notes to assist golfers in filling out their bags:

- PUDI has mid-CG right behind the center face to create a more penetrating mid-to-low ball flight

- PDHY has a lower center of gravity to produce an easier-to-launch mid-to-high ball flight.

- Both PUDI and PDHY are lower-flying than the company’s hybrid/Rescue clubs.

- PUDI is more forgiving than P790.

- PDHY is the most forgiving iron in the entire TaylorMade iron family

Pricing, specs, and availability

Price: $249.99

At retail: Now

Stock shafts: UST Mamiya’s Recoil DART (105 X, 90 S and 75 R – only in PDHY)

Stock grip: Golf Pride’s ZGrip (black/grey)

PUDI lofts: 2-17°, 3-20°, 4-22° in both left and right-handed

PDHY lofts: 2-18°, 3-20° and 4-22° in both left and right-handed

- LIKE12

- LEGIT4

- WOW3

- LOL2

- IDHT1

- FLOP1

- OB1

- SHANK3

Equipment

Coolest thing for sale in the GolfWRX Classifieds (5/3/24): Scotty Cameron Champions Choice 2.5+ putter

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a Scotty Cameron Champions Choice 2.5+ putter

From the seller: (@wwcl): “Has been gamed as pics show. 33.5 includes original h/c and grip. $575 includes shipping and PP fees.”

To check out the full listing in our BST forum, head through the link: Scotty Cameron Champions Choice 2.5+ putter

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE1

- LEGIT1

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole3 weeks ago

19th Hole3 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole2 weeks ago

19th Hole2 weeks agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

-

19th Hole1 week ago

19th Hole1 week agoLET pro gives detailed financial breakdown of first week on tour…and the net result may shock you

-

Equipment2 weeks ago

Equipment2 weeks agoJason Day on his recent switch into Srixon ZX5 and ZX7 Mk II irons

Pingback: Callaway Chrome Soft: Building a better golf ball – GolfWRX

Paul Runyan

Aug 7, 2020 at 12:11 pm

Call -a- way we’re always a little off in QC.

I bought a dozen and the seam was not finished and stuck out about an 1/8 of an inch around the call. I can’t believe those actually made it out the door! Unbelievable!!

joe

Aug 5, 2020 at 11:13 am

your point being?

Dave

Aug 5, 2020 at 10:14 am

I’ve been playing the Chromesoft triple track this season and I absolutely love it. Long off the tee and mid irons and performs extremely well from 140-in.

Reid Thompson

Aug 5, 2020 at 9:58 am

Highest possible level of QC….. hahaha

Boydenit

Aug 5, 2020 at 9:20 am

Is this the same plant that made all those Callaway balls that were “Off”

Hpw

Aug 5, 2020 at 5:55 pm

Yes, troll. It is the same plant. They’ve updated the equipment to make sure of the quality of the product. Did you actually read the articles?

Tigergor

Aug 6, 2020 at 6:35 am

If this promotional advert says so, it must be true!

Then again, go cut open a few balls and see what you find!