Equipment

That one time Tiger switched driver shafts and NOBODY noticed

It seems like pretty much everyone on the planet has an idea of what clubs Tiger has in play at any given moment. Especially now in the age of social media. However, his bag was still analyzed and tracked immensely from the beginning of his arrival on the golf scene. Point is, when the guy switches anything out, the world will know.

But did you know that, during the 2002 and into the 2003 season, he switched driver shafts? It was a pretty substantial switch too, but it fell completely under the radar. As a Tiger junkie myself, I noticed it, but in those days 1) The internet wasn’t what it is today and 2) I was bartending in Newport Beach and didn’t have access to info like I do today. So, it went in my Tiger vault…until now.

Always known to have a True Temper Dynamic Gold X100 shaft in his driver, Tiger and the Nike team wanted something a bit lighter, all while maintaining the stiffness profile of his X100.

We now introduce you to the 118-gram DGSLX100 Tiger Proto (a stock Dynamic Gold X100 shaft is 130 grams).

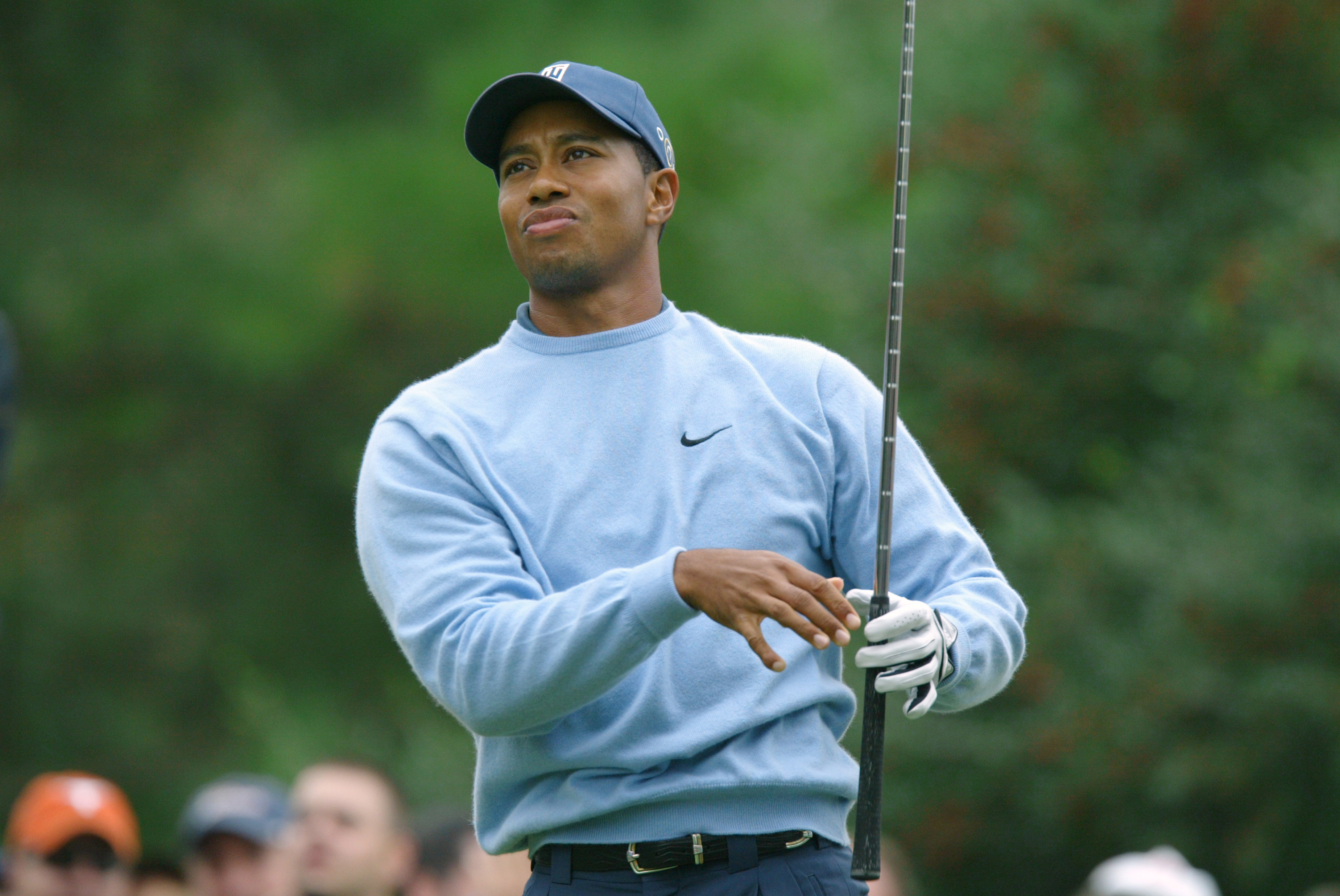

UNITED STATES – OCTOBER 28: Tiger Woods (Photo by Stan Badz/PGA)

A complete one-off made specifically for Tiger Woods. If you look at the pictures you will see an unfamiliar step pattern that starts off a bit wide towards the handle but gets progressively closer down towards the tip section. Basically, the step pattern (diameters) dropped lower to keep stiffness across the board.

“That’s the shaft we used to get him out of Titleist 975D and into Nike Blue 275cc driver in 2002.” – Anonymous Nike source

In theory, this was Tiger accepting the fact that he was going to have to get used to the feeling of a lighter shaft to begin the inevitable transition into graphite, which ultimately happened for good in 2004.

With the mystery of his bag completely gone these days with minute-to-minute reporting, I thought it kind of nice to still have a couple of nuggets to discover.

- LIKE127

- LEGIT25

- WOW21

- LOL14

- IDHT3

- FLOP4

- OB5

- SHANK62

Whats in the Bag

Peter Kuest WITB 2024 (May)

- Peter Kuest what’s in the bag accurate as of CJ Cup Byron Nelson.

Driver: TaylorMade Stealth 2 Plus (8 degrees)

Shaft: Fujikura Ventus Black 7 X

5-wood: TaylorMade SIM Titanium (19 degrees)

Shaft: Project X HZRDUS Black 85 6.5

Irons: Srixon ZX U (2), Srixon Z-Forged II (3-PW)

Shafts: Nippon N.S. Pro Modus3

Wedges: Cleveland RTX6 ZipCore Tour Rack (52-MID 10, 56-MID 10, 60-FULL 9)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: TaylorMade Spider Tour

Grips: Golf Pride Tour Velvet Cord

Check out more in-hand photos of Peter Kuest’s clubs here.

- LIKE2

- LEGIT2

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Kelly Kraft WITB 2024 (May)

- Kelly Kraft’s what’s in the bag accurate as of the CJ Cup Byron Nelson. More photos from the event here.

Driver: Callaway Paradym Ai Smoke Triple Diamond Max (9 degrees)

Shaft: Mitsubishi Tensei 1K Red 60 TX

3-wood: Callaway Paradym Ai Smoke Max (15 degrees)

Shaft: Project X Denali White 70 TX

Hybrid: Callaway Apex UW (21 degrees)

Shaft: Aldila Synergy Blue

Irons: Srixon ZX U Mk II (23 degrees), Callaway X Forged Star (5-PW)

Shaft: Project X IO 6.0

Wedges: Titleist Vokey Design SM10 (52-12F, 56-08M, 60-08M)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: Odyssey Versa 2-Ball Prototype

Grip: Odyssey Garsen Quad Tour

Grips: Golf Pride ZGrip Cord

Check out more in-hand photos of Kraft’s equipment here.

- LIKE3

- LEGIT0

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

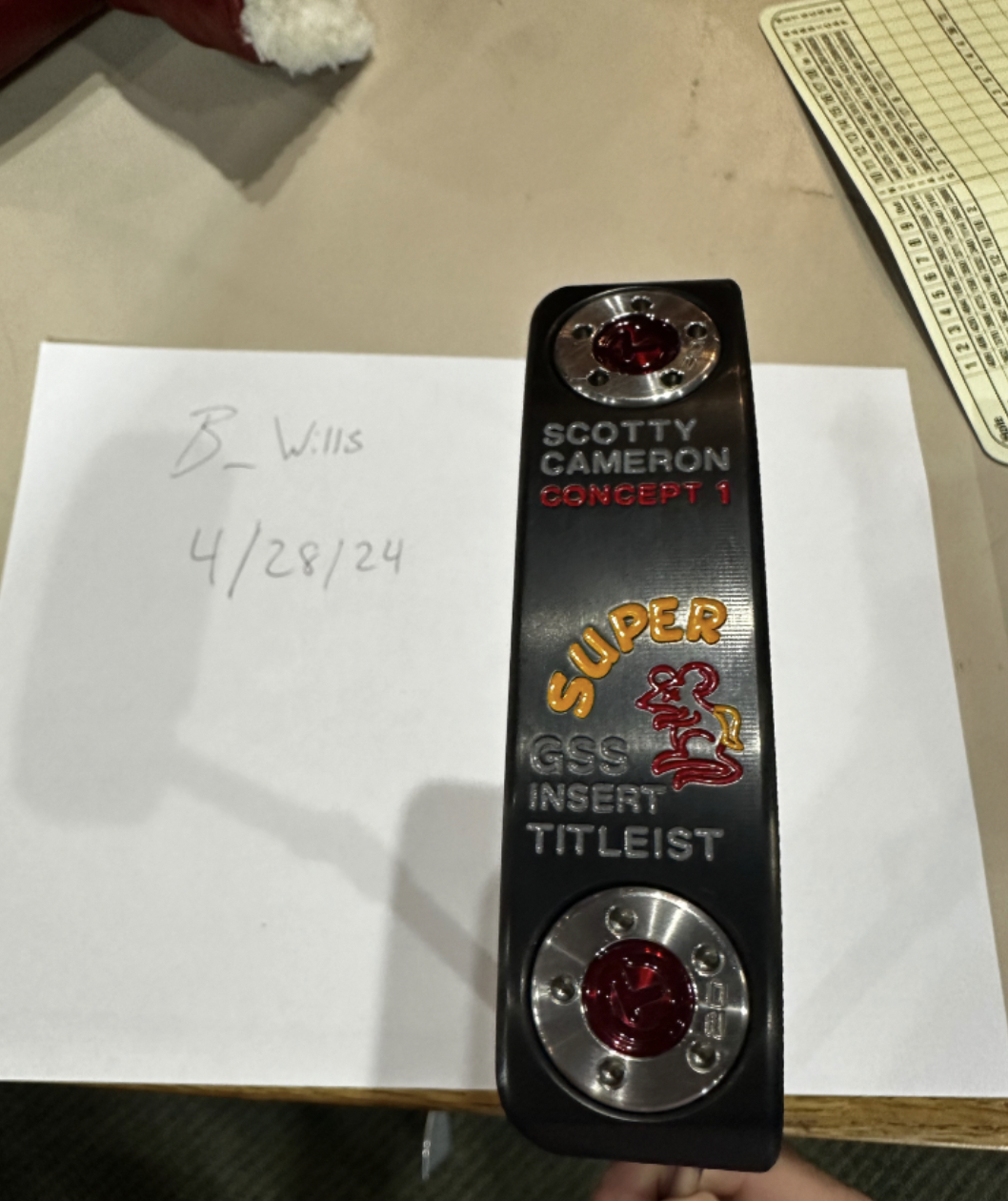

Coolest thing for sale in the GolfWRX Classifieds (5/6/24): Scotty Cameron Super Rat concept 1 putter

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

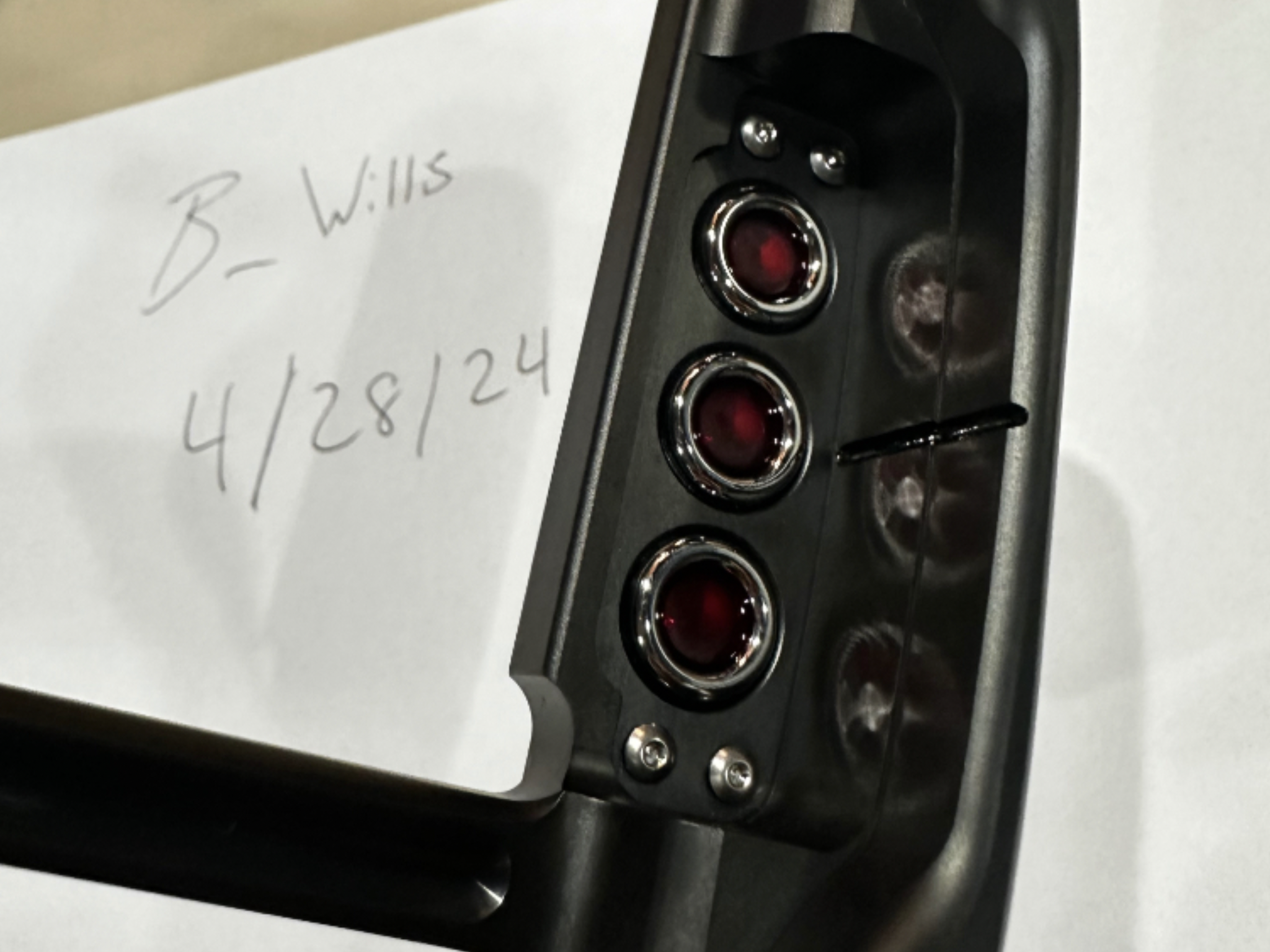

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a Scotty Cameron Super Rat concept 1 putter

From the seller: (@BWillis): “Scotty super rat concept 1 gss insert 35”, pulled from tour van at St. Jude’s in 2014 only carpet rolled. $7000 obo PayPal g&s, open to offers can send more pics.”

To check out the full listing in our BST forum, head through the link: Scotty Cameron Super Rat concept 1 putter

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole3 weeks ago

19th Hole3 weeks agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

-

19th Hole2 weeks ago

19th Hole2 weeks agoLET pro gives detailed financial breakdown of first week on tour…and the net result may shock you

-

Equipment3 weeks ago

Equipment3 weeks agoJason Day on his recent switch into Srixon ZX5 and ZX7 Mk II irons

-

19th Hole6 days ago

19th Hole6 days agoGary Player claims this is what ‘completely ruined’ Tiger Woods’ career

-

Whats in the Bag1 week ago

Whats in the Bag1 week agoTeam McIlowry (Rory McIlroy, Shane Lowry) winning WITBs: 2024 Zurich Classic

Ronaldleacy

Feb 20, 2020 at 7:42 pm

i recommend to visit new service for download instagram stories- https://dis.im

Dill Pickelson

Feb 18, 2020 at 7:31 am

I changed shafts last Thursday. I’ll check back in 2038 for you all to recollect.

dixiedoc

Feb 17, 2020 at 10:00 am

So much for the promoted fallacy that the public can play the same equipment as the pros.

Benny

Feb 16, 2020 at 4:59 pm

Great indo JW. Thanks for sharing and awesome comments fellas. Crazy!

MCoz

Feb 16, 2020 at 2:49 am

I noticed this back then. I reported it on another older golf site back then.

I was in LV at Butch Harman’s place at Rio Secco with he and Adam Scott. Butch told me about it and showed it to me. He had a duplicate set of TW’s clubs in his office. The stepdowns were closer together very similar to the old Rocket shafts of the 60’s/70’s. Butch wanted one for Adam Scott’s Titleist driver. True Temper insisted that TW give his okay for Scott to use one. At that time most had gone to graphite, but TW and AS continued to prefer steel, at least this shaft. Interestingly Scott seemed to hit a lot of drivers that drifted quite a bit to the right when I was with them.

MCoz

Feb 16, 2020 at 1:58 am

I can confirm this shaft. Butch Harmon told me about it and showed it to me. To everyone else it was just pushed off as an X-100 Dynamic. But in reality the stepdowns were more similar to the old Rocket shafts of the 60’s/70’s. I reported it on another old golf site about 15 yrs ago. Butch introduced me to Adam Scott in LV at that time. it was just the three of us and Adam was hitting his Titleist driver with that same “tiger” driver shaft. Butch told me that True Temper insisted that TW gave the okay for them to get that shaft for Adam Scott to use.

Mike Honcho

Feb 17, 2020 at 5:32 am

True story MCoz. I remember like it was yesterday! Tiger asked me if he should let Adam use it. I said to Tiger “who cares bro?” but we all know Tiger, ever the competitor, lol. Who really knows what the golf world would be like if it wasnt for me convincing Tiger to let Adam put it in play. So, Tiger threw me his phone and called True Temper to give the ok. Tiger and I still laugh about it to this day.

Ahh the good ol’ days..

Mike Honcho

Feb 17, 2020 at 6:00 am

True story MCoz. I remember it like it was yesterday. Tiger was asking me if he should let Adam try the shaft out and I said “sure, why not” so Tiger threw me his phone and I called True Temper and told them it was ok. Tiger and I laugh about that to this day. I can’t remember what we did after that. We may have went car shopping or something. Those were the good ol’ days!

TacklingDummy

Feb 16, 2020 at 1:00 am

Tiger has switch driver shafts many times the last few years. He was using a Graphite Design Tour AD DI, Tensi shaft, and probably several others. However, he keeps going back to the Diamana Whiteboard.

Christopher

Feb 15, 2020 at 7:47 pm

I think a lot of WRXers remember this, but I can’t remember if this one was linked to MacGregor, wasn’t there a steel shaft pulled or designed for one of their clubs?

Bruce

Feb 15, 2020 at 4:58 pm

One has to wonder if True Temper went ahead and marketed the DG 118g, or even a 105g steel. But then, I guess the writing on the wall with graphite.

Jo

Feb 15, 2020 at 3:15 pm

A lot of people noticed this.

Ty Webb

Feb 15, 2020 at 11:52 am

Other Nike staffers had that shaft in play to mostly in fairway woods. I personally built a Sonartec 3 wood for a staffer with that shaft.

Jbone

Feb 15, 2020 at 10:52 am

USGA and R&A clowns should reduce the head size and not mess with the ball. The 975J or D would be a good size to revert back to

Bacon Pants

Feb 15, 2020 at 6:22 pm

Not disputing your idea but these guys can still hit strong lofted 3 woods over 300 yards so IMO it wouldn’t do a whole lot just shrinking driver head size

Jbone

Feb 16, 2020 at 8:47 am

Maybe the elite distance guys get it out there 300 but not many. Crank the loft down and that size head gets a lot less forgiving.