Equipment

From a Fitter: Everything you need to know about wedge shafts

This is such a dark corner of the golf industry that I truly believe needs a lot of work. Hopefully, this article can shed some light on wedge shafts for you.

I will mention some standards, explain some of my experience, and hopefully, help you make some good choices.

Linking back to the first article on aspects of a wedge that I target when fitting, I place a lot of weight on the style, bounce, grind, and loft/lie/length to get my wedge fitting started. As we move into shaft options, I look at crossing T’s and dotting I’s to ensure a player enjoys their new wedge setup.

We carry a bunch of shaft options built into different heads. As yet we do not have a consistent way to swap shafts in wedges during a session that still allows them to play at a reasonable swing weight and perform as we would like. Moving forward, I will be looking to explore this area to see if we can deliver better service and experience.

Generic standards for wedge shaft setup

- Dynamic Gold “wedge flex”

- Matching exactly the same shaft in your irons to your wedges

- A slightly heavier shaft in your wedges

- Putting an 8-iron shaft in your wedges

- Using a wedge-specific shaft

During an iron fitting, we see a lot of variables in flight and feel, this is mainly because we use 6-irons as our demo clubs. When clients are hitting 6-iron shots, they are often looking for max carry, flight, and shot-shaping ability. This leads to hitting a lot of full swings and placing the shaft under a decent amount of load, therefore, we see some notable changes when we swap shafts. This will not show up as drastically in wedges as we are not always trying to hit the full shot.

As we get into wedge fitting, I discuss with my clients in-depth what they use each wedge for, how far they hit them, what is the most common shot they play, what are the most common bad shots, how does the ball react on the green and what shots do they feel they need in the bag. Basically, trying to get a good overview of their game in a short period. In very few cases do players mention the ‘full shot’ lets them down? Often players say they are more comfortable hitting “softer shots” or 3/4 swings, this gives them the flight/shot that they require on a regular basis and the niche shots and consistency lets them down.

Logic here says to me, you probably do not want exactly the same shaft in the irons all the way down to the lob wedge when you are hitting soft shots 95 percent of the time. When I look at shaft specs, I am trying to build a shaft that can easily put up with the stress of a full shot and handle a softer shot without feeling blunt (for all clubs in the bag).

When I merge this process into wedges, the only wedge a “matching iron” shaft seems to be applicable (for the majority) is the gap wedge or the wedge that is predominantly a full-swing club. This is the club you hit full and maybe knock-down shots with, but you’re rarely trying to hit “flicky” spinning shots. (Those shots are why you also have a sand and/or lob wedge in the bag).

It would then make sense that if you are rarely hitting any full shots with your sand wedge or lob wedge, you probably want a softer golf shaft in those (as they are not trying to put up with your “flat out” swing), still ensuring the shaft does not feel ‘blunt’ or hard work to play around the greens with.

This is not a one size fits all theory, but I think a lot of players would have success even thinking about their wedge shaft layout in this way.

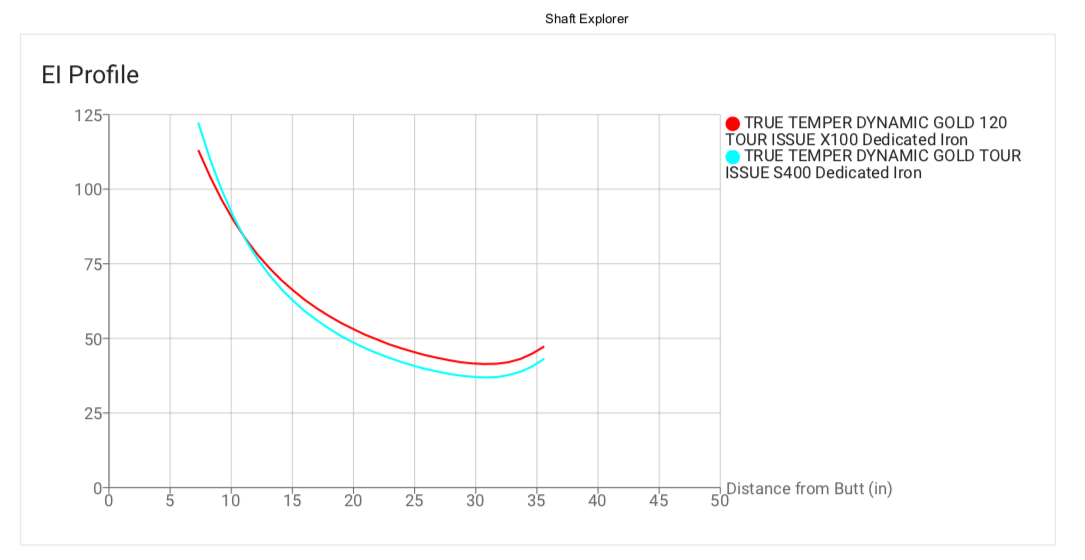

As an example: Personally, I am playing True Temper Dynamic Gold Tour Issue 120g X100 flex iron shafts. I hit a lot of full shots with my 50 and 54, so I have chosen to play the DG 120TI X100 shaft exactly the same way in those two clubs. My 60-degree however, I rarely hit the full shot, so I feel need it a little softer in stiffness, but I need the weight to get my tempo correct and to give me more control to hit lower shots. For this club, I play the Dynamic Gold S400 Tour Issue. I chose this shaft as the profile is very close to my iron shaft but it is 13g heavier and has a slightly softer tip section, which I feel gives me a little better response.

Please see the S3 shaft profile comparison below

(I am very lucky to have the S3 shaft data, it gives me an apples-to-apples comparison of shaft profiles and weights and make wedge shaft selection a lot easier).

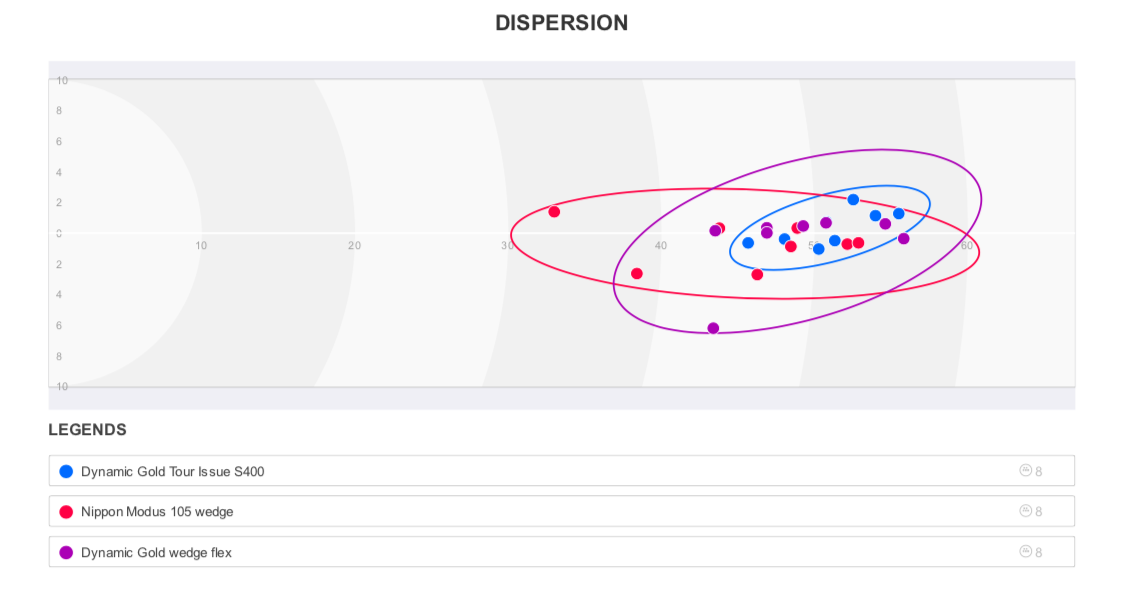

I also wanted to capture some data to highlight the difference wedge shafts have as simply as possible. Below is a graph showing a PGA pro’s shot grouping with a few shaft options. His 6-iron speed is about 94mph, and he has a sharp back-swing to down-swing ratio. This would put him at the quick end of people I fit. This generally means the player enjoys stiffer shafts, stiff style profiles, high swingweight, high total/shaft weight (and again not in all cases).

He tested three shafts all in the same wedge head, with the same length, loft, and lie.

Please see the grouping below

The three shafts tested were: Nippon Modus 105 Wedge specific, Dynamic Gold Wedge flex and Dynamic Gold Tour Issue S400.

In no way am I trying to demonstrate the DG S400 is the best shaft for wedges, but in this group of data all that shows up is, the stiffest profile, heaviest shaft (of the test group) gave the player the tightest grouping for his 55-degree wedge shot. His explanation was that he felt the club’s position in the swing better and the strike through the turf was much more consistent, producing more consistent land zones with the DG S400. This small test shows that the wedge shaft alone has an impact even for a skilled golfer.

There are however always exceptions to theories (especially in golf!)

When I have a player using, for example, C-Taper 130 X or Dynamic Gold X100 in their irons it is tough to find a profile that matches closely that is heavier and not any stiffer. In these cases, I tend to have them play the same shaft all the way down to their LW, but I try to increase swing weight and decrease FM in the niche shot wedges (SW and LW). This can just mean adding head weight to soften the shaft a little, or sometimes soft-stepping the product to get some ‘feel’ back.

The key take-away points

- Think about the shots you play with your wedges most and how hard you hit them

- Think about linking your shafts to your irons, but they do not always have to match

- Test options and measure: grouping, turf interaction and flight consistency

- Try and break down if the ‘”feel” of stiffness or weight help or hinder you making a consistent swing/strike

- Don’t just settle with the shaft the wedges come with… unless they match in with your setup!

Getting all the information in one article is always tough, and I hate generalizing, so feel free to shoot me some questions—I like to try to help and also hear your experience and ideas when I can!

- LIKE429

- LEGIT66

- WOW23

- LOL15

- IDHT10

- FLOP9

- OB5

- SHANK27

Whats in the Bag

Steve Stricker WITB 2024 (April)

- Steve Stricker WITB accurate as of the Zurich Classic. More photos from the event here.

Driver: Titleist TSR3 (9 degrees, C4 SureFit setting)

Shaft: Fujikura Motore Speeder VC 7.2 X

3-wood: Titleist 915F (13.5 degrees)

Shaft: Mitsubishi Tensei CK Pro White 80 TX

Hybrid: Titleist 816 H1 (17 degrees)

Shaft: Fujikura Motore Speeder VC 9.2 X

Irons: Titleist T200 (3, 4), Titleist T100 (5-9)

Shafts: Project X 6.5

Wedges: Titleist Vokey SM8 (46-10F @55), Titleist Vokey SM10 (54-10S @53), Titleist Vokey SM4 (60 @59)

Shafts: True Temper Dynamic Gold X100 w/Sensicore

Putter: Odyssey White Hot No. 2

Ball: Titleist Pro V1x

Grips: Golf Pride Tour Velvet Grip Rite

Check out more in-hand photos of Steve Stricker’s clubs here.

- LIKE4

- LEGIT0

- WOW0

- LOL0

- IDHT1

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Alex Fitzpatrick WITB 2024 (April)

- Alex Fitzpatrick what’s in the bag accurate as of the Zurich Classic.

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Fujikura Ventus TR Black 7 X

Hybrid: Ping G430 (19 degrees)

Shaft: Fujikura Ventus Black HB 10 TX

Irons: Ping iCrossover (2), Titleist T100 (4-PW)

Shafts: Fujikura Ventus Black HB 9 TX (2), Nippon N.S. Pro Modus 3 Tour 120 X (4-9)

Wedges: Titleist Vokey Design SM10 (50-12F, 56-12D, 60-08M)

Shafts: Nippon N.S. Pro Modus 3 Tour 120 X

Putter: Bettinardi SS16 Dass

Grips: Golf Pride MCC

Check out more in-hand photos of Alex Fitzpatrick’s clubs here.

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

What’s the perfect mini-driver/shaft combo? – GolfWRXers discuss

In our forums, our members have been discussing Mini-Drivers and accompanying shafts. WRXer ‘JamesFisher1990’ is about to purchase a BRNR Mini and is torn on what shaft weight to use, and our members have been sharing their thoughts and set ups in our forum.

Here are a few posts from the thread, but make sure to check out the entire discussion and have your say at the link below.

- PARETO: “New BRNR at 13.5. Took it over to TXG (Club Champ but TXG will always rule) in Calgary for a fit. Took the head down to 12, stuck in a Graphite Design AD at 3 wood length and 60g. Presto- numbers that rivaled my G430Max but with waaaaay tighter dispersion. Win.”

- driveandputtmachine: “Still playing a MIni 300. The head was only 208, so I ordered a heavier weight and play it at 3 wood length. I am playing a Ventus Red 70. I play 70 grams in my fairways. I use it mainly to hit draws off the tee. When I combine me, a driver, and trying to hit a draw it does not work out well most of the time. So the MIni is for that. As an aside, I have not hit the newest BRNR, but the previous model wasn’t great off the deck. The 300 Mini is very good off the deck.”

- JAM01: “Ok, just put the BRNR in the bag along side a QI10 max and a QI10 3 wood. A load of top end redundancy. But, I have several holes at my two home courses where the flight and accuracy of the mini driver helps immensely. Mine is stock Proforce 65 at 13.5, I could see a heavier shaft, but to normal flex, as a nice alternative.”

Entire Thread: “What’s the perfect Mini-Driver/Shaft combo? – GolfWRXers discuss”

- LIKE3

- LEGIT1

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK4

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole4 days ago

19th Hole4 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole4 days ago

19th Hole4 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole2 weeks ago

19th Hole2 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole1 week ago

19th Hole1 week agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

ChipNRun

Sep 22, 2021 at 7:47 pm

Jack,

Superb article. I have transferred it to a PDF (in case bad thins happen) and sent it to my brother.

I have tried to use a modified Pelz matrix for my wedges. One thing I h ave found: when it comes to LWs, I don’t have good luck with full shots. This is always the case for 60* LW, and mostly the case for 58*, which is much more reliable.

My new irons have arrived, and the PW is 43*, and left-over wedges are 48*, 54* and 58*.

Two questions I have:

1. Is it OK just to use the LW for close-in shots around the green?

2. I find 3/4 wedge shots the hardest to control for distance. Why is this?

Anton Manuel Gonzalez Sundewall

Jan 14, 2021 at 10:54 am

Helo Jack, very informative article thanks for all of the information, just what I was looking for, just one thing I need to know about, how do I know what shaft flex should have on my wedges (club speed wise), and is it better to have little too soft or stiff wedge shafts??

Best Regards Anton!

Eddy

Nov 13, 2020 at 8:04 pm

Hi Jack, as a master fitter, can you please help me out, I am using UD + 2 from 7 iron to 8,9,P and A ( NS pro Zelos 77.5 g Regular shaft, and 52,56,60 Mack Daddy 4 with DG 8200, recently I bought PXG 0311XP 6-9 G and W, I also got the 0311 Gen 2 Wedges 52,56 and 60, after fixing it with KBS tour(120g) I just lost the feel of the wedges completely, whats your suggestions?

Cliff L

Nov 13, 2020 at 1:51 pm

If I was fit for true temper Dynamic Gold R300 105’s in irons 5-PW, what shaft would you recommend for 52 and 58 wedges?

bl

Feb 11, 2020 at 5:12 pm

Great article!

But…. that test seems fishy. You tried a really poorly fit shaft vs. an okay shaft vs. a properly fit one to prove the properly fit one is better?

Jack

Feb 13, 2020 at 10:10 pm

Hi BL,

This was to prove my point that you do need to think about a wedge shafts.

Do not just grab anything. Make an effort to get something that helps you get better results.

This article is not about the shafts that were selected, it is demonstrating there is a variable here.

Marc Boghosian

Feb 7, 2020 at 8:03 am

Jack – might be a stupid question but what kind of affect would hard/soft stepping the shafts have? ie hard stepped shafts in irons, with the same shaft soft stepped in wedges

Jack Gilbert

Feb 13, 2020 at 10:14 pm

Definitely not stupid.

HS or SS give the player the option to play the same weight shaft slightly stiffer or softer than maybe they are playing.

My experience as a general rule is: Too soft and the player may loose strike consistency and dispersion widens up…. Too stiff and it can feel a bit “blunt” / there can be implications on spin.

Chris

Jan 23, 2020 at 11:07 pm

Great article Jack. I play X100 in my irons 4 thru Gap wedge, and was recommended the Modus Wedge 125 last year. I noticed a great improvement, hitting the ball closer to the hole and able to control my trajectory much better throughout the year. My question is why did you use the Modus Wedge 105 shaft with your pro player in the example, and not use the heavier 115 (122g) or 125 (133g) options. Also wondering which iron shafts your pro player is using in his set. Thanks.

Pg

Feb 1, 2020 at 11:52 am

He cherry picked a lightweight shaft to prove his point.

Jack Gilbert

Feb 13, 2020 at 10:16 pm

Hi Chris,

I was not trying to demonstrate the performance of a specific product in this segment, just trying to highlight that there is a reasonable difference in wedge shafts that can have positive and negative effects.

Rickey Di Dio

Jan 21, 2020 at 10:48 am

While I appreciate what you are trying to do, there are a few things I would like to point out. Your data size is too small and your data has to been “cleaned”. There are 3 shots in your chart that would be classified as outliers. Remove those and the charts get very similar. I work with players on bag analysis and club gapping. If we are hitting 7 irons and a player hits one fat that only carries 110 yards, that shot is thrown out of the “probable average carry distance”.

Lars Mountgoaschen

Jan 20, 2020 at 4:22 pm

I was not aware that the X100 profile was like the S300/S400 profile as you seem to indicate in your EI graph….(?) I thought the s300/s400 has a stiff tip & softer butt compared (relative to profile) of the X100. In fact I still have the EI data by inch increments somewhere.

You seemed to contradict yourself by choosing a heavier shaft in your wedge, you state you need the weight for your tempo(?) – why would you choose such a significantly heavier shaft to maintain your tempo?

Generally with wedges the most sure bet is to use an 8 iron shaft and soft-step. This retains the same shaft profile ‘DNA’ for the player through the set and keeps weight within a tight parameter.

Speedy

Jan 20, 2020 at 1:11 pm

For 56 and 60 wedges, I like S400, D4, Tour Velvet Midsize.

golfraven

Jan 19, 2020 at 3:29 pm

I play the same shaft in my wedges as in irons (Modus 105 regular although 1/4 inch shorter, even down to the wedges). Works fine for me.

Paddy

Jan 18, 2020 at 11:37 pm

Would you suggest Masterfit shafts for my Mizuno wedges?

Mike

Jan 18, 2020 at 5:52 pm

i have always read that most pros use a stiff shaft, TT S400, which is softer than their usual X200 that they use in their irons, in their wedges. Yet almost all wedge shafts sold are the same S400 that is obviously stiffer than most golfers out there need. Most average golfers HAVE to use stiff shafts, even though the vast majority of golfers do not swing the club well enough to use stiff shafts. That is probably why everyone has a bunch of wedges in their garage that just did not feel right! I wised up and put a lightweight steel regular flex shaft in my forged Vokey and love it.

Josh

Jan 20, 2020 at 8:22 am

FYI Vokey wedges are not forged. They are cast.

MS

Jan 20, 2020 at 4:51 pm

Not true. I’ve been using forged Vokeys for the past 8 years. They are made only in/for Japanese domestic market, but can be easily delivered to the US via specialized online sellers. I’m in my 4th set of Vokeys now, worth it.

MG

Jan 18, 2020 at 5:37 pm

Serious question: How can a “wedge flex” s200 play much different than an s400? It’s only a 3 gram weight difference. I don’t see how anyone except (maybe) a tour player could notice a difference.

Hugh B. Gnecks

Jan 18, 2020 at 6:38 pm

Say it with me……

MAR-KET-ING!!!!!!!!!!!

Jack Gilbert

Jan 20, 2020 at 3:22 am

I do not believe there would be a wild difference.

I just used a Tour issue S400 in my lob wedge because I could. I had the wedge as a head without a shaft, so I opted for the S400. If I had fit someone into DG 120 shafts I would have recommended “stock” dynamic gold wedge shaft as their most economical and best performing option.

Dan

Jan 20, 2020 at 11:54 am

Im a 45yr old former scratch player and I absolutely notice the diff between s200 and s400. Personally I couldn’t feel the head with an S400. Just my $.02

JB

Jan 18, 2020 at 3:36 pm

I think you can go ahead and say that TI DG S400 is the best wedge shaft on the market. I thought Cleveland made a great decision when they made this the stock option in their RTX wedges.

Matt

Jan 18, 2020 at 4:44 pm

I agree

Alex

Jan 18, 2020 at 3:07 pm

X100 4-9 S400 46 50 55 59. Could probably go either way and used to have x100 in PW and GW. When I switched to all vokey wedges I just went S400 throughout cause they all look the same. I like the feel in them.

24Linc

Jan 18, 2020 at 2:22 pm

Great article by Jack. My take away is try different shafts for your wedges but keep the weight similar or slightly heavier than your iron shafts and use slightly softer shafts for wedges that’s used primarily finess shots. Makes great sense.

My question would be do you see any benefit of using slightly lighter shafts in wedges? Also how currently many iron sets have stock steel shafts of around 90g but still use s200 as a stock wedge?shaft how that would influence the players since the s200 would be quite a bit heavier and also stiffer say comparing to the AMT Red s300.

Jack Gilbert

Jan 20, 2020 at 3:33 am

Thanks 24Linc,

You’re right people that are playing 70g graphite for example probably need lighter shafts in their wedges, such as 80g. They would probably not enjoy a DG wedge shaft as it would be labored and probably feel blunt and hard to get “feel” from (I see this a lot when players getting great results with light graphite try to demo heavy steel wedge shafts). It’s all relative to the best iron shaft.

I have not had much success with using lighter shafts in wedges compared to irons as the swing weight can be hard to balance correctly and the shaft is often a fair amount softer which can result in inconsistent striking.

e.g playing 100g KBS Reg iron shafts – either play the same in the wedges maybe a Hi rev 115g but do not drop down to the KB90 as this will probably be too soft.

There is no one size fits all formula and there are always anomalies (that’s why I do a bunch of testing with my clients) but I hope this helps.

Brian

Jan 18, 2020 at 1:14 pm

Great article Jack, you’ve keyed in on something that has continued to bother myself as for getting fitted with wedges. Everyone preaches get fitted but everywhere I “get fitted” for wedges the default on shaft is ALWAYS the stock “wedges offering.” Seems to partially hurt the “fit process” of wedges in my mind.

As a side question, and as it relates to you play of 120g X100 flex in your irons…….may I ask what are your typical 6 or 7 iron numbers? I ask as I’ve not been fit for my Modus 120 Stiff flex in my irons, my 6 iron trackman numbers are 91-93mph and have questioned the playing the same shafts you are playing currently.

Great article and we thank you!