Equipment

Callaway redesigns Odyssey R-Ball Prototype using GE’s additive manufacturing

Callaway has announced the company has signed a consultancy agreement with GE Additive’s AddWorks team, with the aim of improving its equipment through the potential of additive manufacturing. According to GE Additive’s website, additive manufacturing is a process that creates a physical object from digital design, enabling the creation of lighter, stronger parts and systems.

What does this mean for Callaway’s equipment?

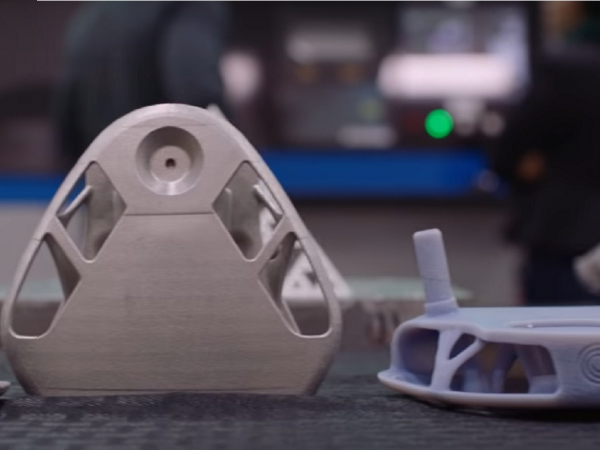

The opening project from the agreement is a redesigned Odyssey R-Ball Prototype putter head. Callaway originally developed the Odyssey R-Ball Prototype as a tour preferred model in Japan, which consisted of removing the front ball from the original 2-ball design. Callaway, through additive manufacturing, has optimized the acoustics of the putter while retaining the preferred shape and performance.

Brad Rice, director – R&D, Advanced Engineering at Callaway, speaking about the process, stressed that the use of additive manufacturing is the future to the production of equipment in the game of golf, stating

“Additive manufacturing is a new tool; which is quickly going beyond the aspirational phase, and into the functionalization phase of the technology. Callaway needs to learn how to use this tool well because it is inevitable that 3D-Printing of production parts is going to happen – it is the production method of the future.”

So just how has Callaway and GE Additive collaborated to create the ideal acoustics on the Odyssey R-Ball Prototype putter head? Well, the answer is by adding geometry that made it difficult for conventional casting methods, which you can get a feel for in this short video.

For the Odyssey Prototype putter to retain its optimal design and shape while altering the acoustic signature of the putter head, Callaway and GE Additive’s AddWorks’ design and engineering teams implemented additive manufacturing through the following process:

- AddWorks provided guidance to Callaway, based on decades of additive design background spanning several industries.

- The team refined existing designs to the build direction to ensure all features were self-supported or easily supported during the build. The AddWorks team designed supports for thermal stresses and overhang constraints.

- Topology optimization was used in conjunction with acoustical mapping to create the optimal design.

According to GE Additive AddWorks general manager, Chris Schuppe, additive manufacturing is a method which we are going to be hearing of a lot down the line, and he is expecting this to be the first of many collaborations with Callaway

“We’re taking away many new learnings from our first project together, especially around aesthetics. We have also used additive technology to create an acoustic map, which is certainly a first for us. We’re looking forward to driving more successful projects with Callaway, as they continue their additive journey.”

What the future holds for Callaway’s products through the use of additive manufacturing remains to be seen. However, the company’s bold stance on the potential of the process enhancing their equipment could be telling.

- LIKE71

- LEGIT3

- WOW7

- LOL6

- IDHT1

- FLOP1

- OB2

- SHANK20

Whats in the Bag

Matthieu Pavon WITB 2024 (May)

- Pavon’s WITB accurate as of the Wells Fargo Championship. More photos from the event here.

Driver: Ping G430 Max (9 degrees)

Shaft: Fujikura Ventus TR Black 6 X

3-wood: Ping G430 LST (15 degrees)

Shaft: Fujikura Ventus TR Black 7 X

Hybrid: Ping G430 (19 degrees)

Shaft: Fujikura Ventus Black 10 X

Irons: Ping i230 (3-PW)

Shafts: Nippon Modus3 Tour 120 X

Wedges: Ping Si59 (52-12S, 58-8B)

Shafts: Nippon Modus3 Tour 120 X

Putter: Ping Cadence TR Tomcat C

Grip: SuperStroke Claw 1.0P

Grips: Golf Pride MCC Align

Ball: Titleist Pro V1

Check out more in-hand photos of Pavon’s gear here.

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Spotted: Tommy Fleetwood’s TaylorMade Spider Tour X Prototype putter

Tommy Fleetwood has been attached to his Odyssey White Hot Pro #3 putter for years now. However, this week at the Wells Fargo Championship, we did spot him testing a new putter that is very different, yet somewhat similar, to his current gamer.

This new putter is a TaylorMade Spider Tour X head but with a brand new neck we haven’t seen on a Spider before. A flow neck is attached to the Spider head and gives the putter about a 1/2 shaft offset. This style neck will usually increase the toe hang of the putter and we can guess it gets the putter close to his White Hot Pro #3.

Another interesting design is that lack of TaylorMade’s True Path alignment on the top of the putter. Instead of the large white center stripe, Tommy’s Spider just has a very short white site line milled into it. As with his Odyssey, Tommy seems to be a fan of soft inserts and this Spider prototype looks to have the TPU Pure Roll insert with 45° grooves for immediate topspin and less hopping and skidding.

The sole is interesting as well in that the rear weights don’t look to be interchangeable and are recessed deep into the ports. This setup could be used to push the CG forward in the putter for a more blade-like feel during the stroke, like TaylorMade did with the Spider X Proto Scottie Scheffler tested out.

Tommy’s putter is finished off with an older Super Stroke Mid Slim 2.0 grip in blue and white. The Mid Slim was designed to fit in between the Ultra Slim 1.0 and the Slim 3.0 that was a popular grip on tour.

- Check out the rest of our photos from the 2024 Wells Fargo Championship

- LIKE1

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Club Junkie WITB, league night week 4: Some old, some new

We enter week 4 of Thursday night men’s league feeling a little more confident in the game. BK is hoping to go a little lower and reduce the mistakes out there with these clubs in the bag. Watch the video for the full breakdown of why these clubs are getting the starting nod this week!

Driver: Titleist TSR2 (10 degrees, neutral setting)

Shaft: Mitsubishi Diamana WB 63 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: UST Mamiya Lin-Q M40X TSPX Blue 7F5

7-wood: Ping G430 Max (-1 degree, flat Ssetting)

Shaft: Fujikura Ventus TR Blue 8 S

Iron: Mizuno Pro Fli-Hi 4

Shaft: Aerotech Steelfiber hls880 S

Irons: PXG 0317 Tour (5-PW)

Shaft: LA Golf A-Series 105 Low (4)

Wedge: Titleist Vokey SM10 (50-08F)

Shaft: UST Mamiya Dart V 105 F4 Wedge

Wedge: Ping S159 (56-10H)

Shaft: Ping Z-Z115

Wedge: Ping S159 (60-08B)

Shaft: Ping Z-Z115

Putter: PXG Battle Ready II Brandon

Shaft: BGT Stability Tour Spec One

Ball: Callaway Chrome Tour X

- LIKE1

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

-

19th Hole2 weeks ago

19th Hole2 weeks agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoLET pro gives detailed financial breakdown of first week on tour…and the net result may shock you

-

19th Hole2 days ago

19th Hole2 days agoReport: LIV star turns down PGA Championship invite due to ‘personal commitments’

-

19th Hole1 week ago

19th Hole1 week agoGary Player claims this is what ‘completely ruined’ Tiger Woods’ career

-

Whats in the Bag2 weeks ago

Whats in the Bag2 weeks agoTeam McIlowry (Rory McIlroy, Shane Lowry) winning WITBs: 2024 Zurich Classic

-

19th Hole3 weeks ago

19th Hole3 weeks agoTaylorMade signs 15-year-old AJGA Rolex Junior Player of the Year to an NIL contract

-

Equipment1 week ago

Equipment1 week agoGolf fans left surprised by LIV’s choice of course for its 2024 individual championship event

aga

Nov 18, 2018 at 7:41 pm

Can’t wait to get my hands on one of those tour tested R-Ball prototype putters… and price is no deterrent !!!!

Tom

Nov 17, 2018 at 11:53 pm

Equipment manufacturers have run out of new product ideas….now just blowing smoke and mirrors…..sellers be sellin!

gunmetal

Dec 5, 2018 at 2:00 pm

Yep.

Callaway is King of this. Boeing, Lamborghini, now GE. They partner with companies that can add credibility to their marketing story.

engineer bob

Nov 17, 2018 at 1:05 am

GE will attempt to “engineer out” the unnecessary material and make it ring like a bell… how low can you go using high tech capability?!! Pa thetic US technology usage.

Engineer Swede

Nov 20, 2018 at 8:35 am

EBM or Electronic Beam Manufacturing is for the most part a bought up technology from a Swedish company called Arcam, that is now a part of GE. It’s actually fun to see 3D-printing technologies getting a wider audience. Rapid prototyping might soon become rapid(and local) production! Now wouldn’t that be a thing Bob? Where all you’re golfclubs is not produced in Taiwan but in the neighbouring town? Supporting local business and less shipping?

JP

Nov 16, 2018 at 10:28 pm

Has anyone ever complained about the sound the putter makes? If the sound sucks, the design probably sucks. Start over.

ogo

Nov 17, 2018 at 1:07 am

Geerhead duffers want a good sounding putter because that’s all they look forward to… a ding sound…!

Tiger Noods

Nov 16, 2018 at 7:30 pm

So, the short story is they couldn’t figure out how to do this in-house, called a contractor, and they’re spinning it as competence.

Nice story, bros.

Maybe they will start making clubs that don’t have high failure rates. That’d be nice.

Jamie

Nov 16, 2018 at 10:24 pm

That’s called patent infringement, libtard. You don’t just get to take another’s ideas and processes and make them your own.

Libtard

Nov 18, 2018 at 3:44 am

First, Libtard? Grow up.

Second, patent infringement? I’m guessing that your use of “libtard” probably precludes a college degree, so maybe, just maybe, leave the litigation to those qualified.

Third, you clearly weren’t replying to the above, so I suggest you brush up on your interwebbing, Señor AOL…

Finally, I don’t get the American fascination with insults and someone’s political views. I thought America was “land of the free” and such… you really are an intolerant bunch.

Hogenben

Nov 16, 2018 at 5:25 pm

All they are doing is working on acoustics…..just bs marketing hype.

bj

Nov 16, 2018 at 2:46 pm

Callaway AND many other manufacturers of ALL kinds of products should have ALREADY been using 3D printing!!! The EXTREME amount of savings in designing ANY proto type is and the ability refine their products is very flexible AND inexpensive!!

Its about time, they are FAR behind in using this tech that is HAS BEEN WELL PROVEN!!

ac

Nov 16, 2018 at 5:34 pm

whats the deal with the random all caps? is it code? AND ALL ALREADY EXTREME ANY AND FAR HAS BEEN WELL PROVEN..guess not.

DB

Nov 16, 2018 at 1:57 pm

Cool story. I do think additive, 3-D, multi-material, etc. will be the future for some golf clubs. Article would have been better if Callaway had released some pictures of the final product or some information about how they can actually apply this to a product.

Jamie

Nov 16, 2018 at 1:52 pm

GE will be bankrupt in a few weeks. Callaway would be smart to buy this unit now.

Benny

Nov 18, 2018 at 6:20 pm

I certainly hope not. Would love to put a wager on this. Now is a great time to buy!