Equipment

Callaway redesigns Odyssey R-Ball Prototype using GE’s additive manufacturing

Callaway has announced the company has signed a consultancy agreement with GE Additive’s AddWorks team, with the aim of improving its equipment through the potential of additive manufacturing. According to GE Additive’s website, additive manufacturing is a process that creates a physical object from digital design, enabling the creation of lighter, stronger parts and systems.

What does this mean for Callaway’s equipment?

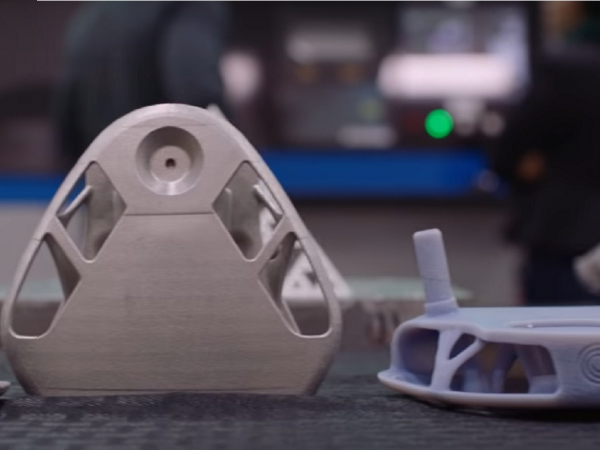

The opening project from the agreement is a redesigned Odyssey R-Ball Prototype putter head. Callaway originally developed the Odyssey R-Ball Prototype as a tour preferred model in Japan, which consisted of removing the front ball from the original 2-ball design. Callaway, through additive manufacturing, has optimized the acoustics of the putter while retaining the preferred shape and performance.

Brad Rice, director – R&D, Advanced Engineering at Callaway, speaking about the process, stressed that the use of additive manufacturing is the future to the production of equipment in the game of golf, stating

“Additive manufacturing is a new tool; which is quickly going beyond the aspirational phase, and into the functionalization phase of the technology. Callaway needs to learn how to use this tool well because it is inevitable that 3D-Printing of production parts is going to happen – it is the production method of the future.”

So just how has Callaway and GE Additive collaborated to create the ideal acoustics on the Odyssey R-Ball Prototype putter head? Well, the answer is by adding geometry that made it difficult for conventional casting methods, which you can get a feel for in this short video.

For the Odyssey Prototype putter to retain its optimal design and shape while altering the acoustic signature of the putter head, Callaway and GE Additive’s AddWorks’ design and engineering teams implemented additive manufacturing through the following process:

- AddWorks provided guidance to Callaway, based on decades of additive design background spanning several industries.

- The team refined existing designs to the build direction to ensure all features were self-supported or easily supported during the build. The AddWorks team designed supports for thermal stresses and overhang constraints.

- Topology optimization was used in conjunction with acoustical mapping to create the optimal design.

According to GE Additive AddWorks general manager, Chris Schuppe, additive manufacturing is a method which we are going to be hearing of a lot down the line, and he is expecting this to be the first of many collaborations with Callaway

“We’re taking away many new learnings from our first project together, especially around aesthetics. We have also used additive technology to create an acoustic map, which is certainly a first for us. We’re looking forward to driving more successful projects with Callaway, as they continue their additive journey.”

What the future holds for Callaway’s products through the use of additive manufacturing remains to be seen. However, the company’s bold stance on the potential of the process enhancing their equipment could be telling.

- LIKE71

- LEGIT3

- WOW7

- LOL6

- IDHT1

- FLOP1

- OB2

- SHANK20

Whats in the Bag

Emiliano Grillo WITB 2024 (May)

- Emiliano Grillo what’s in the bag accurate as of the Wells Fargo Championship. More photos from the event here.

Driver: Callaway Paradym Ai Smoke Triple Diamond (9 degrees @10)

Shaft: Project X Denali Blue 60 TX

3-wood: Callaway Paradym Ai Smoke Triple Diamond (15 degrees)

Shaft: Project X HZRDUS Smoke Blue RDX 70 TX

5-wood: Cobra LTDx Prototype (18.5 degrees)

Shaft: Project X HZRDUS Smoke Blue RDX 70 TX

Irons: Callaway Apex TCB (4-9)

Shafts: Project X 6.5

Wedges: Callaway MD3 Milled (46-08S), Callaway Jaws Raw (50-10S, 54-10S, 60-08T)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: Odyssey White Hot OG #5

Grip: SuperStroke Zenergy Flatso 1.0

Grips: Golf Pride MCC

Check out more in-hand photos of Emiliano Grillo’s clubs here.

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Product Reviews

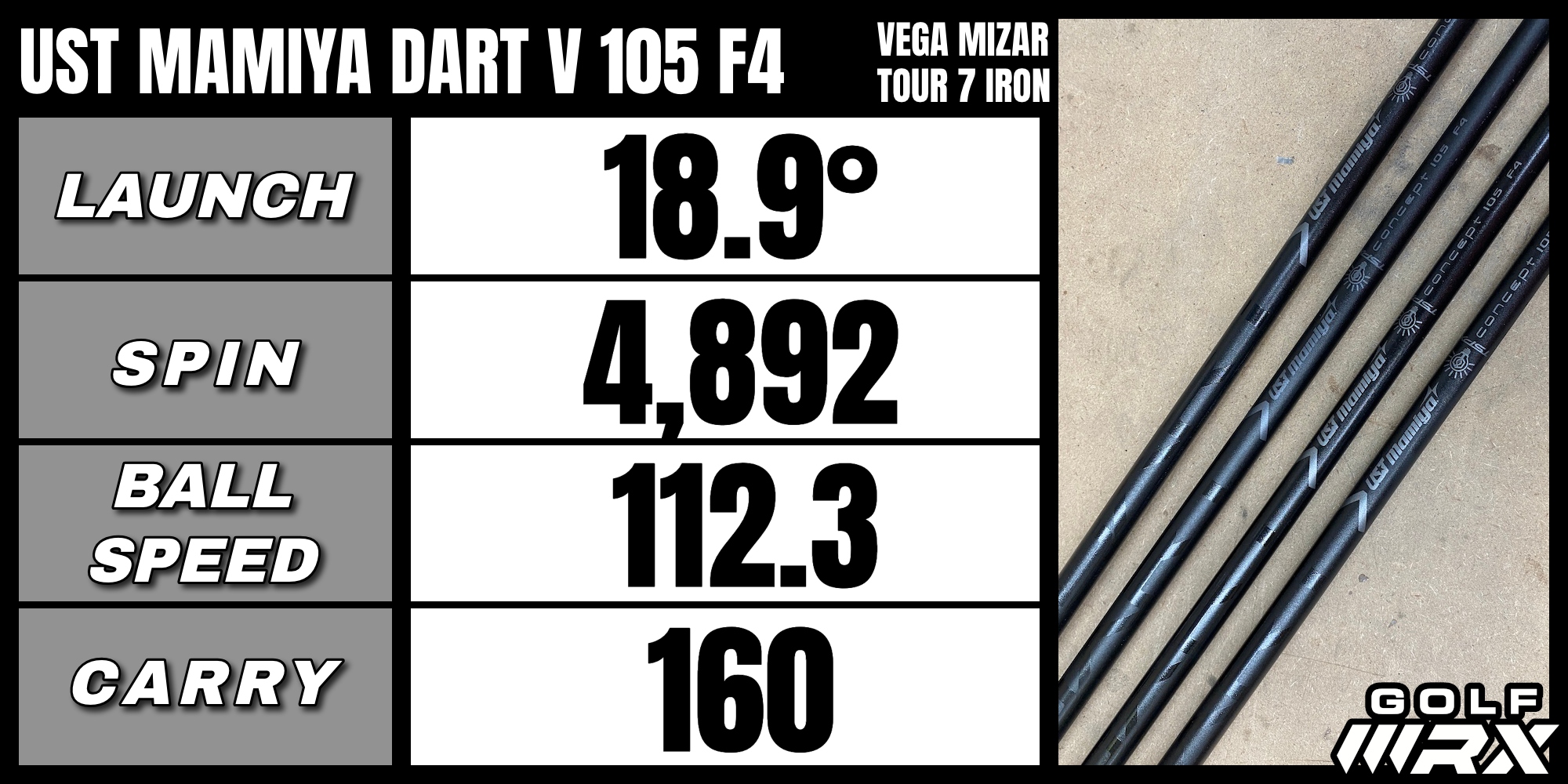

UST Mamiya Dart V iron shaft review – Club Junkie Reviews

Recently, graphite iron shafts have grown in popularity as technology has taken giant leaps forward. The old thoughts of graphite being too soft, too high launching, or too inconsistent have gone by the wayside. This new batch of graphite iron shafts has been played by all levels of golfers, from players who do need help with launch and spin to professionals who are looking for added control.

Today, we’re taking a look at one of these “new graphite iron shafts.” UST Mamiya Dart V irons shafts come out of the company’s TSPX Lab that creates the most cutting-edge designs and uses the latest materials.

Check out the full review on YouTube below or on any podcast platform.

UST Mamiya’s Dart V shafts are designed around Dual Action Recoil Technology that makes sure the entire shaft flexes consistently for much tighter shot dispersion. The Dart V shafts are offered in 90, 105, and 120-gram weight options to fit a wide range of golfers. UST Mamiya also has very tight tolerances and quality control to ensure that every shaft is the same in the set. Utilizing Torray M40X carbon fiber gives the engineers a material that is 30% better tensile strength and gives the shafts better feel with less harsh vibration.

I went with the Dart V 105 F4 (stiff) shafts as I have found more success with lighter shafts as I have gotten older. Building these shafts up with a set of Vega Mizar Tour heads was very easy and didn’t take a lot of tip weights. I think the 7-iron needed a small 2g tip weight and the rest were installed without any weight at my desired D1 swing weight at standard length with standard size grips.

Out on the course, the first thing I noticed was how tight the Dart V 105 feels. Every swing feels like the shaft is under complete control, no matter if you take a partial or went after it. Stout is a great term for the shafts as they definitely play true to flex, but they aren’t harsh feeling. While the Dart V plays stiff, it still does a good job of reducing vibration and keeping joints or injured body parts free from additional shock.

You can feel the shaft load during the transition to the downswing, but it has a stiffer feel of less flex than some other graphite shafts. Some players like this boardier feel and will get it with the Dart V. Feel at impact is similar to the loading where you are going to feel some kick at the bottom of the swing, but it won’t be as aggressive as other shafts. On center strikes the Dart V offers a very solid feel with great, soft feedback. When you mishit shots with these shafts you get immediate feedback with some additional vibration that feel players will really like. The mishits aren’t too harsh on the hands but still let the head give you the louder click that your ears will want.

Ball flight for me was lower than I expected with UST Mamiya listing the shaft as more mid-launch. I would consider my launch with the Dart V mid-low launch with a more penetrating flight. Better players will like the ability to flight shots, with any club, higher or lower in order to get the ball close to the hole. The penetrating flight helps in windy conditions as it offers a stable trajectory that doesn’t waver from your aiming point.

Shots that you mishit off the toe or heel go pretty straight and you don’t see big curvature that causes you to really miss the green. Most of those misses come off the face fairly straight and leave you with a fairly easy chip or pitch shot to the green. Distance control is consistent and repeatable as I found on the range that well-struck shots have a very tight carry distance window and I have yet to see some wildly long or short shots show up.

Overall, the UST Mamiya Dart V iron shafts are solid options for players who are very particular about performance. Like other shafts among the new breed of graphite iron shafts, the Dart V delivers the type of shots you need when you need them.

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Coolest thing for sale in the GolfWRX Classifieds (5/8/24): Scotty Cameron Art of Putting Laguna putter

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a Scotty Cameron Art of Putting Laguna putter.

From the seller: (@kcsf): “Scotty Cameron Art of Putting Laguna. -I will regret this one selling for sure. It does have one small nick on the face near the toe as shown, otherwise in amazing new condition. -BOS reconditioned and received last month. Oil can finish as done new by BOS when this putter was released many moons ago. -Head cover is authentic SC and shows age. Velcro is worthless of course, but does stay closed. -Length is 34.25 inches, original shaft. -Grip is old and needs replacing. I can have my pro do it prior to shipping at an additional cost of the grip only. -$475.”

To check out the full listing in our BST forum, head through the link: Scotty Cameron Art of Putting Laguna putter

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoLET pro gives detailed financial breakdown of first week on tour…and the net result may shock you

-

19th Hole7 days ago

19th Hole7 days agoGary Player claims this is what ‘completely ruined’ Tiger Woods’ career

-

19th Hole22 hours ago

19th Hole22 hours agoReport: LIV star turns down PGA Championship invite due to ‘personal commitments’

-

Whats in the Bag1 week ago

Whats in the Bag1 week agoTeam McIlowry (Rory McIlroy, Shane Lowry) winning WITBs: 2024 Zurich Classic

-

19th Hole3 weeks ago

19th Hole3 weeks agoTaylorMade signs 15-year-old AJGA Rolex Junior Player of the Year to an NIL contract

-

Equipment1 week ago

Equipment1 week agoGolf fans left surprised by LIV’s choice of course for its 2024 individual championship event

aga

Nov 18, 2018 at 7:41 pm

Can’t wait to get my hands on one of those tour tested R-Ball prototype putters… and price is no deterrent !!!!

Tom

Nov 17, 2018 at 11:53 pm

Equipment manufacturers have run out of new product ideas….now just blowing smoke and mirrors…..sellers be sellin!

gunmetal

Dec 5, 2018 at 2:00 pm

Yep.

Callaway is King of this. Boeing, Lamborghini, now GE. They partner with companies that can add credibility to their marketing story.

engineer bob

Nov 17, 2018 at 1:05 am

GE will attempt to “engineer out” the unnecessary material and make it ring like a bell… how low can you go using high tech capability?!! Pa thetic US technology usage.

Engineer Swede

Nov 20, 2018 at 8:35 am

EBM or Electronic Beam Manufacturing is for the most part a bought up technology from a Swedish company called Arcam, that is now a part of GE. It’s actually fun to see 3D-printing technologies getting a wider audience. Rapid prototyping might soon become rapid(and local) production! Now wouldn’t that be a thing Bob? Where all you’re golfclubs is not produced in Taiwan but in the neighbouring town? Supporting local business and less shipping?

JP

Nov 16, 2018 at 10:28 pm

Has anyone ever complained about the sound the putter makes? If the sound sucks, the design probably sucks. Start over.

ogo

Nov 17, 2018 at 1:07 am

Geerhead duffers want a good sounding putter because that’s all they look forward to… a ding sound…!

Tiger Noods

Nov 16, 2018 at 7:30 pm

So, the short story is they couldn’t figure out how to do this in-house, called a contractor, and they’re spinning it as competence.

Nice story, bros.

Maybe they will start making clubs that don’t have high failure rates. That’d be nice.

Jamie

Nov 16, 2018 at 10:24 pm

That’s called patent infringement, libtard. You don’t just get to take another’s ideas and processes and make them your own.

Libtard

Nov 18, 2018 at 3:44 am

First, Libtard? Grow up.

Second, patent infringement? I’m guessing that your use of “libtard” probably precludes a college degree, so maybe, just maybe, leave the litigation to those qualified.

Third, you clearly weren’t replying to the above, so I suggest you brush up on your interwebbing, Señor AOL…

Finally, I don’t get the American fascination with insults and someone’s political views. I thought America was “land of the free” and such… you really are an intolerant bunch.

Hogenben

Nov 16, 2018 at 5:25 pm

All they are doing is working on acoustics…..just bs marketing hype.

bj

Nov 16, 2018 at 2:46 pm

Callaway AND many other manufacturers of ALL kinds of products should have ALREADY been using 3D printing!!! The EXTREME amount of savings in designing ANY proto type is and the ability refine their products is very flexible AND inexpensive!!

Its about time, they are FAR behind in using this tech that is HAS BEEN WELL PROVEN!!

ac

Nov 16, 2018 at 5:34 pm

whats the deal with the random all caps? is it code? AND ALL ALREADY EXTREME ANY AND FAR HAS BEEN WELL PROVEN..guess not.

DB

Nov 16, 2018 at 1:57 pm

Cool story. I do think additive, 3-D, multi-material, etc. will be the future for some golf clubs. Article would have been better if Callaway had released some pictures of the final product or some information about how they can actually apply this to a product.

Jamie

Nov 16, 2018 at 1:52 pm

GE will be bankrupt in a few weeks. Callaway would be smart to buy this unit now.

Benny

Nov 18, 2018 at 6:20 pm

I certainly hope not. Would love to put a wager on this. Now is a great time to buy!