Equipment

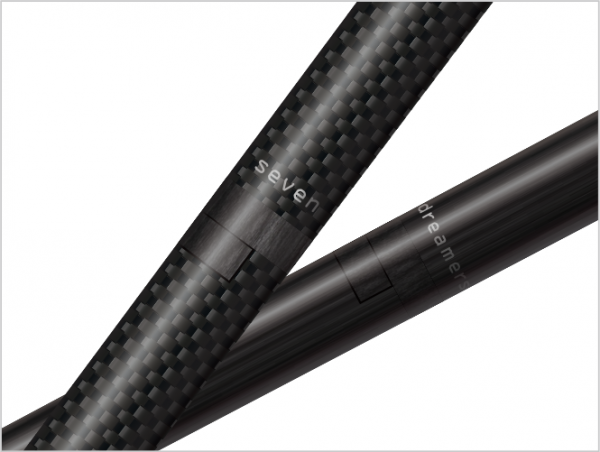

A Q&A with Seven Dreamers about its $1,200 shafts

We spotted Seven Dreamers at Demo Day at the PGA Show last year and were impressed by GolfWRX member chiromikey’s fitting experience in Japan. With the company expanding to the U.S. market, we wanted to dig a little deeper.

The Japanese company says that once you demo one of the its $1,200 shafts, you’ll see and feel its superiority to your current gamer. Fortunately for those interested, you’ll soon be able to do so at select fitters and green grass locations in the U.S.

Seven Dreamers is rooted in the aerospace industry. An interesting note: In 1998, the company was involved in the development of Japan’s “Hayabusa” spacecraft, the first and only unmanned craft to land on an asteroid and return to earth with a sample from the surface. The shafts are made in Tokyo by a team of craftsmen and scientists who collaborate to custom build each shaft. A point of differentiation: Seven Dreamers uses an autoclave pressure chamber in its manufacturing process. Other manufacturers cure their shafts in ovens. The company says this process produces superior quality carbon fibers, reduced resin, and eliminated the need for grinding, polishing, or painting.

For the U.S. and Canadian market, the company offers 33 different bend profiles, identified from thousands of fittings.

We spoke with Mike Rossi, Vice President of Sales and Marketing at Seven Dreamers.

GolfWRX: Tell us a little bit about the history of the company, as our readers likely aren’t too familiar with Seven Dreamers.

Mike Rossi: The company started back in 1957 under the name Super Resin. At that time they were into fiber-reinforced plastics…as time moved on, they got into composites (composite design, composite products). That led into aerospace involvement. So, there’s always been a precision, high-end focus. If you fast-forward to today, the company has three divisions. They launched the golf division in Japan in 2014. There’s also a medical division, which designed a disposable sleep apnea device…that’s been on sale in Europe and Japan for the past couple of years and is under FDA review here. And then there’s a third division: electronics…they’ve developed and patented the only fully automatic laundry folding robot.

The name came from…the chairman at the time, he envisioned seven centers of excellence throughout the world.

GolfWRX: Why a golf shaft?

MR: The company wants to leverage its expertise in composite material. They’re using a variety of specialty materials…the quality of which is fit for satellites. The premium-grade materials required prompted the interest in golf.

GolfWRX: What sets Seven Dreamers apart?

MR: What really sets us apart is the process. Every shaft is made on a mandrel, and our mandels are absolutely pristine. The material is placed by hand on the mandrel. It’s then inserted into a mold. Then we autoclave cure it. The beauty of autoclave curing is it’s done under pressure…which gives us outstanding compaction. It squeezes out all the unnecessary resin, so we get an optimal ratio of carbon fiber to resin, which improves both feel and energy transfer in the shaft. But the best part of the process is, once we remove the shaft from the mold, we literally trim it to length and wipe it down. The surface condition is perfect. So, we have no unbroken fibers. We have no fiber tears. We have no fiber bullets. All that contributes to incongruities and inconsistencies in the shaft.

Virtually every other manufacturer, they put their material on the mandrel, and then they use shrink tape. Then the shrink tape is removed after curing, and you’ve got the inconsistencies–the rough edges of the tape–so then everybody else grinds the profile. I’m not saying that’s a terrible way to do it, but I’m saying I believe our way is better, and there’s no one else that’s doing it the way we do.

GolfWRX: Talk a little bit about the company’s positioning in the shaft market…

MR: Our company decided we wanted to focus on the ultra-high-end. What they did in Japan to start out, they went out and obtained several hundred clubs that were on the market–primarily driver heads. They measured the inertial properties and the physical properties of all these heads just to understand how they performed, then they worked to develop shafts that were optimized for certain heads.

This really morphed into two what I’ll call “studios” in Tokyo where consumers can come in and hit balls on the simulator and try different shafts. The one they like best, whether it’s their gamer or ours, we place sensors on the shaft. Using our proprietary 3D system, we then measure their particular loading and how they deliver the clubhead…how the shaft performs during the swing. Then all those measurements are recorded, and we design them a shaft 100 percent custom. The process takes three to four weeks. It’s designed for the golfer and the particular head he chooses to play. So, it’s truly custom.

We’ve done thousands of those over the past few years, and the ticket on that is $2,500. So yes, it’s premium. It’s high-end. We believe the premium end is the last frontier in the golf space. We’re not trying to sell to everybody. We’re trying to identify high-end fitters. We’re looking at aspirational clientele who wants the best, highest-quality stuff out there.

GolfWRX: Tell us about the range of shafts…

MR: We go from the mid-to-low 40s in weight all the way up to the 80s with three different bend profiles, which are basically low-, mid-, and high-launch. Our U.S. product offering will contain 28 driver shafts to start. We have iron shafts in development, hybrid shafts too, which we’ll be adding. Our wood shaft’s MSRP is $1,200. Our main objective with the launch is to be able to fit a wide range of players: from amateurs to tour professionals.

GolfWRX: What can you tell us about any comparison testing you’ve done?

MR: As odd as this sounds, we don’t compare to existing shafts in the marketplace. Our history and experience is based on our analysis and the fittings we’ve done with players at all levels, and we’ve seen appreciable gains and improvements both in distance and dispersion. But we’re not out there to denigrate any of our competitors. That’s not what we’re about.

Back to the decision to enter the ultra-premium space more about a market opportunity or did it necessarily follow from the sophistication of the manufacturing process and materials?

It’s a combination of both. Certainly, we saw that niche. But with our costs and our structure, we’re not a commodity supplier…we selected a niche where we can succeed. So it’s high-end fitters and high-end facilities, but we’re also seeking OEM partners that want to enter that ultra-premium space.

GolfWRX: Are there any thoughts toward a presence on Tour?

MR: We will have a face of the brand. It will be a recognized, credible player. A proper driver of the golf ball…that search is underway, but we’re not going to do it the way it’s currently being done [tour van, large professional staff].

- LIKE34

- LEGIT1

- WOW5

- LOL3

- IDHT0

- FLOP0

- OB1

- SHANK22

Equipment

Coolest thing for sale in the GolfWRX Classifieds (4/23/24): TaylorMade Qi10 Driver Ruby Red

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a TaylorMade Qi10 Driver Ruby Red.

From the seller: (@Gehly): “TaylorMade Qi10 Driver 9.0 Designer Series Ruby Red. Custom Mitsubishi Kai’li Red 60s (stiff) shaft, plays 46”. Great condition, head near mint (see pics). w/ Red/Black Golf Pride NDMC Midsize grip. No headcover for it. $545“

To check out the full listing in our BST forum, head through the link: TaylorMade Qi10 Driver Ruby Red

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Sam Burns WITB 2024 (April)

- Sam Burns’ what’s in the bag accurate as of the RBC Heritage.

Driver: Callaway Paradym Triple Diamond S (9 degrees @10)

Shaft: Fujikura Ventus Blue 7 TX

3-wood: Callaway Paradym Ai Smoke Triple Diamond T (15 degrees @16)

Shaft: Fujikura Ventus Blue 8 X

Hybrid: Callaway Apex UW (21 degrees)

Shaft: Fujikura Ventus Blue 8 X

Irons: Callaway Apex TCB ’24 (4-AW)

Shafts: Project X 6.5 (4-PW), True Temper Dynamic Gold X100 Tour Issue (AW)

Wedges: Titleist Vokey Design SM10 (56-14F @55), WedgeWorks Proto (60-T)

Shafts: True Temper Dynamic Gold S400 Tour Issue (56, 60)

Putter: Odyssey Ai-One #7S

Grips: Golf Pride Tour Velvet Align

Ball: Callaway Chrome Tour X

Check out more in-hand photos of Sam Burns’ WITB in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Will Zalatoris WITB 2024 (April)

- Will Zalatoris’ what’s in the bag accurate as of the RBC Heritage.

Driver: Titleist TSR2 (9 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Black 7 X (44.5 inches)

3-wood: Titleist TSi2 (15 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 8 X

Irons: Titleist T350 (3), Titleist T150 (4-PW)

Shafts: Nippon N.S. Pro Prototype G.O.S.T. 10 ST X (3), True Temper Dynamic Gold Tour Issue X100 (4-PW)

Wedges: Titleist Vokey Design SM10 (50-08F, 54-10S @55, 60-04T)

Shafts: True Temper Dynamic Gold Tour Issue X100

Putter: L.A.B. Golf Mezz.1 Max

Grips: Golf Pride Z-Grip Cord

See more photos of Will Zalatoris’ WITB in the forums.

- LIKE3

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole21 hours ago

19th Hole21 hours ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole6 days ago

19th Hole6 days agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

ogo

Jul 21, 2018 at 1:42 am

****FANTASTICO****

Ed

Jan 31, 2018 at 1:14 pm

There you have it fellow gearheads…. oven-baked graphite shafts are inferior to autoclave cured shafts because there is too much ‘plastic’ resin in the inferior shafts. Carbon graphite is a metal and has the dynamic properties of steel shafts less the weight.

Cheap graphite shafts have inconsistent dynamic properties, particularly in the tip section during final release when the shaft is whip-snapping… drooping, torquing and recovering. One graphite manufacturer blends steel strands into their shafts. Steel is the gold standard and graphite shafts are soggy and floppy going through impact.

That’s why tour pros prefer heavier weight shafts because the very low weight shafts were like spaghetti at high swing speeds.

You can get away with heavy graphite shafts for irons but not light weight shafts for drivers. Light weight graphite shafts are adequate for slower swing speed recreational golfers, not for pros.

OB

Feb 1, 2018 at 11:12 am

Does that mean gearhead’s clubs are fitted with inferior epoxy-filled shafts that are unstable and ruin their swing release action? Pros use heavier weighted graphite shafts to compensate for shaft inconsistencies; shafts over 100 grams like Sadlowski using the 104 gram Nunchuk shaft mentioned in another WRX article.

Ed

Feb 3, 2018 at 2:41 am

Off your meds much. Conspiracy theory posts on almost every article and you reply to your own comments. Sad

OB

Feb 5, 2018 at 11:41 am

Where, oh where

Have the gear heads gone?

Where, oh where can they be?

With shirts cut long

And pants cut short

Where, oh where can they be?

I last saw them by the putting green

Playing and puttering around

But I just can’t see them anymore

They just can’t seem to be found

Perhaps the club pro over there will know

He may have seen them go by

But who knows where

They might have decided to go away

But we’ve got to give it a try