Opinion & Analysis

Part 1: Taking the guesswork out of selecting shafts

It’s clear that a lot of threads and posts in the GolfWRX forums are from golfers asking all sorts of questions about shafts. In nearly 40 years of golf equipment design and research work, I think it is fair to say that the shaft is the least understood component of the golf club.

I have engaged in serious shaft research since 1990, and from that have learned a lot about shaft design, performance and fitting, I would like to help clear some things up and share some facts about shafts and what you need to know to pick the best shaft for YOUR swing.

I will do my best to make all of this understandable without stressing everyone’s attention span. But there is a lot to explain about this subject so I will separate this into three parts with some time in between each thread to allow you to digest it and ask questions.

How Can Golfers TRULY Compare Shafts to Know their Real Performance Differences?

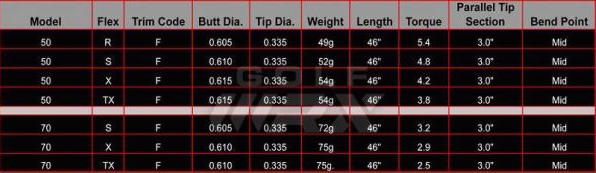

Below is a typical “specification chart” from a major shaft company. I have removed the names because it is not my intent to criticize a specific shaft maker. It is simply my desire to show you how the typical information provided about shafts will not allow golfers to know what they really need to know about shafts to be able to make an informed buying decision.

Plain and simple, the information in this chart cannot tell a golfer how any of these shafts truly perform, much less how they actually compare in stiffness to any other the shaft.

The flex? There are no standards for exactly how stiff any of the flex letter codes are. Charts like this provide no quantitative measurements of exactly how stiff any shaft might be. In fact the ONLY bits of information on a typical chart like this which can be helpful are the WEIGHT and the TORQUE.

The butt and tip diameter? These are fine for knowing what the hosel bore of the clubhead needs to be to easily accept the shaft and to know how to install the grip to obtain a desired size.

The parallel tip section? That simply tells you if you cut more than 2 inches off the tip, it’s not likely to fit all the way into any normal hosel with a 0.335-inch bore.

The bend point? Sorry, but the term bend point is not relevant because with terms like “high,” “mid,” or “low,” it has always been way too generic. WHERE EXACTLY IS a mid bend point? And how does this mid bend point compare to some other company’s mid or low or high bend point?

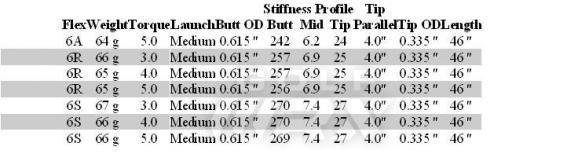

Recently I have seen a couple of other shaft companies begin to offer a form of QUANTITATIVE stiffness measurements for their shafts. Here’s an example:

This shaft company offers a series of stiffness profile measurements for the butt, mid and tip sections of their shafts. That’s a start, but the problem is that this company only offers these stiffness profile measurements for their own shafts. This is somewhat reasonable for comparing the various shaft models and flexes within this one company, but what if you have some other company’s shaft in your driver, or you wish to compare these shafts to some other company’s shafts? And if you have never hit one of these shafts, how stiff or flexible are any of these measurements in the first place? These rudimentary stiffness profile measurements do not allow the depth and scope of stiffness information to allow you to make a valid shaft fitting decision.

You might look at the butt stiffness number and say, “That’s a frequency measurement and I know how stiff a 270 cpm shaft plays.” Yes, that butt stiffness number is a frequency measurement. But the problem is you have no idea how these butt frequency measurements were obtained.

- What length of the butt was clamped?

- How heavy was the tip weight?

- Is this 270 cpm frequency the same as a 270 cpm shaft that you played?

Again, there are no standards in the golf industry for shaft frequency measurement so you have no idea if a measurement of say, 270 cpm from this company is equivalent to a measurement of 255 cpm or 265 cpm or whatever cpm using one of the many other types of shaft frequency measurement.

What makes all this even more “exciting” or I should say, challenging, is the fact the industry is now populated with many shafts that are VERY expensive. Do you really want to GUESS whether that $300 shaft is right for you, or would you like to have a more definitive way to help make that decision?

Is there a Better Way to Compare Shaft Stiffness?

Ever since I began to perform quantitative measurements on shafts, I knew we needed a way to be able to see and compare the stiffness of as many shafts as possible, and do it over their entire length. That way, club makers and golfers could have a tangible way to compare the complete full length stiffness design of shafts to each other. The performance and the bending feel of any shaft are products of its stiffness design over its entire length. Not just the butt, not just the tip, but the whole length of the shaft. There are almost an infinite number of ways the stiffness of a shaft can be created over its entire length.

In 2005, we arrived on a reasonably simple method to perform full length comparative stiffness measurements for golf shafts. From this, we created a software program that would house and display the data from our shaft stiffness comparison methodology. We made the first version of the software available to club makers in 2006. Two times each year we ask the shaft companies to send us multiples of each of their new shaft models and flexes so we can keep adding shafts to the software data base.

At present, we have more than 2,000 different wood, hybrid and iron shafts in the TWGT Shaft Bend Profile software. We charge a one-time fee of $129.50 for the software because the expense to have it programmed and maintained is not insignificant. It also takes us quite a number of hours to acquire, test and input the new shaft data into the software two times each year. You can find more information about this on my site, which is linked in my bio.

As much as we would like, there is no possible way we can include EVERY shaft in the industry in the software’s data base. We have to rely on the shaft companies to send us the multiple samples of each of their shafts to measure because we simply cannot afford to actually buy all of the shafts. We also cannot obtain the OEM stock shafts because the OEM companies will simply not allow anyone to have their raw shafts for any measurement work like this. We do have some OEM stock shafts in the data base, which come from “pulls” from OEM clubs that we can measure. But we do try to put as many shafts as we can into the data base so that clubmakers and golfers can better compare the relative stiffness of shafts.

To date more than 600 different club makers now use the TWGT Shaft Bend Profile software in their shaft fitting. This use by the club makers has also provided “in the field” verification that the measurements of the shafts do indeed provide a valid representation of the performance and even the bending feel of the shafts in the data base. The shaft fitting comparisons made with the data in the TWGT Shaft Bend Profile software is most definitely valid for predicting the performance and feel of a shaft.

How Does the Bend Profile Data Explain the Performance and Differences Between Shafts?

Some of you have seen graphs from the TWGT Bend Profile software that I have posted to answer a question here and there about shafts. For those of you who have not seen this, the following is a basic screen image from the software showing a comparison of the relative stiffness design of two shafts. I just randomly chose to use the Mitsubishi Rayon’s Diamana White 83 X5CT S flex and the UST ProForce V2 HL65 S flex to start the explanation.

You see seven columns in the data box. These show WHERE on the shafts we do the stiffness measurements. Starting at 11 inches up from the tip, the measurements then are made at 5-inch spaced positions up from the tip end of each shaft, ending at 41 inches up from the tip. Because iron and hybrid shafts are shorter in raw length, their measurements run from 11 inches up to 36 inches up from the tip end of the shafts.

Measurements are done with a 454 gram weight attached to the tip of the shaft using a specially designed frequency analyzer that measures the shaft oscillations using two separate load cells and two separate strain gauges. Each shaft is tested at the same exact place on the shaft, using the same exact test methodology. This ensures the data is comparable from shaft to shaft to shaft in the data base of the software.

Let’s take a look at an example graph and data chart

The 41-inch, 36-inch and 31-inch measurements represent the butt section, the 31-inch, 26-inch and 21-inch measurements represent the center section and the 21-inch, 16-inch and 11-inch measurements represent the tip section of the shaft (yes, there is an overlap).

When companies design different flexes of a shaft, each different letter flex version is ordained chiefly by the stiffness measurements of the 41-inch to 21-inch positions of the shaft (butt, to center, to upper tip). Tip section differences on shafts do not play as significant of a role in the overall flex design (swing speed rating) of a shaft as do the butt to center to upper tip sections. The tip section design of a shaft is chiefly designed to create differences in the launch angle, trajectory and spin rate among shafts within the same flex.

After significant research and study of the shaft data, we can make conclusions about how much of a difference in the stiffness measurements is significant or not. With so many shafts in the data base, we can also identify a basic relationship between a golfer’s clubhead speed, the average bending force generated by that clubhead speed, and the overall stiffness design of a shaft. This is very important for being able to tell a golfer which shaft may be better suited to his clubhead speed. Therefore, we can use the stiffness measurements of the 41-inch to 21-inch positions on the shaft to determine the swing speed rating of any shaft.

We can also determine how much of a measurement difference is significant or not with respect to stiffness in the butt, center and tip sections of the shafts.

- For example, at the start of the butt section, as represented by the 41-inch measurement, a measurement difference of 8-to-10 cpm is approximately equivalent to one full letter flex difference.

- At the middle of the center section, as represented by the 26-inch measurements, a difference of 12-to-15 cpm is equivalent to one full letter flex difference.

- In the middle of the tip section, as represented by the 16-inch measurement, a difference of 30-to-40 cpm usually accounts for a visible difference in the launch angle, trajectory and spin rate of the shot.

There are no standards for how stiff any of the letter flex designations of shafts may be. How stiff IS an R flex, an S flex (or any of the other letter flexes)? How much variation is there among shafts of the same letter flex?

Below is data to show the low-to-high range in stiffness for all shafts for drivers and fairway woods in our data base that are marked as being a letter R flex shafts. These are listed from softest to stiffest, but all of these are made and marked by their respective companies to be an R flex shaft.

Based on the measurements of the 41-inch and 36-inch sections for the butt section, you are looking at a range of FOUR FULL FLEXES. That means the R flex shafts in the golf industry actually exist within a range of four full flexes. The same is true for S flex shafts, as well.

Because there are far fewer L, A and X flex shafts, the range in stiffness within these letter flex codes is not quite as wide as it is within the R and S flex shafts. Here is the Bend Profile graph and data chart to illustrate the range in R flex shafts for woods that exist today.

Based on all of our research to associate a driver clubhead speed with the measurements for the 41-inch, 36-inch, 31-inch, 26-inch positions of the butt and center of the shaft, here are the appropriate driver clubhead speed ratings for each of these above five different R flex shafts:

- Miyazaki C.Kua 39 R: For a golfer with a driver clubhead speed of 55-to-65 mph

- UST ProForce V2 HL-55 R: For a golfer with a driver clubhead speed of 65-to-75 mph

- Aldila RIP’d NV65 R: For a golfer with a driver clubhead speed of 75-to-85 mph

- Fujikura Blue 004 R: For a golfer with a driver clubhead speed of 85-to-95 mph

- Rapport Blue Velvet R: For a golfer with a driver clubhead speed of 95-to-105 mph

Therefore, you are looking at shafts in the golf industry that match up to a range in swing speed of 50 mph, yet ALL are marked and sold as R flex shafts.

You may be prompted to comment, “This has to be the exception rather than the rule.” If we take a look at the data base to search where the majority of R-flex shafts lie with respect to their 41-inch, 36-inch and 31-inch butt section measurements, we find that the majority of R-flex shafts exist within a range that represents a 20-to-30 mph difference in the clubhead speed rating for the shafts.

This is precisely why golfers sometimes buy a new club and its shaft doesn’t feel as stiff or feels stiffer than their previous shaft with the same letter flex.

Do all shafts of the same letter flex have the same butt-to-center section stiffness (same swing speed rating) within the same shaft company or the same golf club company?

Let’s take a look at the R-flex version of a number of different shaft models from one shaft manufacturing company. All are selected on the basis of being very close to the same shaft weight so they potentially could be considered for purchase by the same golfer.

I want to be sure to first make something clear. I am NOT saying it is wrong for a company to make the same letter flex version of each different shaft model to be of a different stiffness design. That is their right as a company to determine the exact design of each flex for each shaft they make.

What I am saying is that it is very difficult for consumer golfers to know how to choose the shaft that might best match their swing when the companies provide no empirical information like this to use for making quantitative comparisons of the different shafts.

The swing speed range for all these R-flex shafts from Aldila ranges by 25 mph. At one end, the NVS 65-R is a shaft that would be rated for use by a golfer with a driver clubhead speed of 70-to-80mph. At the other end, the RIP Gamma 60-3.6-R is a shaft that would be rated for use by a golfer with a driver clubhead speed of 85-to-95 mph. That means within all the R-Flex shafts from Aldila, the clubhead speed rating for possible selection by a golfer can range by 25 mph – yet all are marked as being an R-Flex shaft.

On top of this are definite differences in the TIP SECTION design of all these different R-flex shafts. Within all the R-Flex shafts from Aldila, we see shafts with a tip section design that ranges from the very tip-soft (Habanero 60-R) all the way up to the moderately tip stiff design of the RIP Gamma 60-3.6-R. If both these R-flex shafts were hit by the same golfer, the Habanero would launch the ball approximately 3-degrees higher and with an estimated 750 rpm more backspin than the RIP Gamma 60-3.6-R. Yet again, both are marked as R-flex shafts.

Again, each company is free to design their shafts as they see fit, for whichever golfer swing types they designate. But how can any golfer really know the difference in the overall stiffness design of any of these shafts and from that, know anything about the performance difference between these shafts of the same flex without clear, quantitative comparative information?

Please understand that variation between the same letter flex of different shaft models goes on INTENTIONALLY with every shaft company in the golf industry. It is not specific to Aldila. I simply use them to illustrate that this does happen within each shaft manufacturing company. Without a clear, quantitative means to compare the stiffness design of shafts, consumer golfers are in the dark with respect to making accurate shaft buying and shaft fitting decisions.

For those of you who made it this far, CONGRATULATIONS! You ARE indeed interested in shafts. For those of you who didn’t… well, true shaft knowledge can be a little beyond a normal realm of interest, I do admit that. I hope you all got something out of this, and there is more to come to help you know much more about how to determine the differences between shafts and how to turn that information into better shaft buying decisions.

By the way, there are many custom clubmakers out there who can help you find the right shaft FAR more accurately than the ways you have been trying to pick the right shaft in the past. These club makers who study this stuff are worth knowing and can help you. Again, to find a good club fitter, check out these sources:

- The AGCP (Association of Golf Clubfitting Professionals)

- The ICG (International Clubmakers’ Guild)

- The TWGT Clubmaker Locator

Related

- Part 1 — Taking the guesswork out of selecting shafts

- Part 2 — Taking shaft fitting from guessing to specifics

- Part 3 — Facts about shafts, and what they do

- LIKE277

- LEGIT20

- WOW36

- LOL6

- IDHT2

- FLOP3

- OB3

- SHANK17

Instruction

The Wedge Guy: The easiest-to-learn golf basic

My golf learning began with this simple fact – if you don’t have a fundamentally sound hold on the golf club, it is practically impossible for your body to execute a fundamentally sound golf swing. I’m still a big believer that the golf swing is much easier to execute if you begin with the proper hold on the club.

As you might imagine, I come into contact with hundreds of golfers of all skill levels. And it is very rare to see a good player with a bad hold on the golf club. There are some exceptions, for sure, but they are very few and very far between, and they typically have beat so many balls with their poor grip that they’ve found a way to work around it.

The reality of biophysics is that the body moves only in certain ways – and the particulars of the way you hold the golf club can totally prevent a sound swing motion that allows the club to release properly through the impact zone. The wonderful thing is that anyone can learn how to put a fundamentally sound hold on the golf club, and you can practice it anywhere your hands are not otherwise engaged, like watching TV or just sitting and relaxing.

Whether you prefer an overlap, interlock or full-finger (not baseball!) grip on the club, the same fundamentals apply. Here are the major grip faults I see most often, in the order of the frequency:

Mis-aligned hands

By this I mean that the palms of the two hands are not parallel to each other. Too many golfers have a weak left hand and strong right, or vice versa. The easiest way to learn how to hold the club with your palms aligned properly is to grip a plain wooden ruler or yardstick. It forces the hands to align properly and shows you how that feels. If you grip and re-grip a yardstick several times, then grip a club, you’ll see that the learning curve is almost immediate.

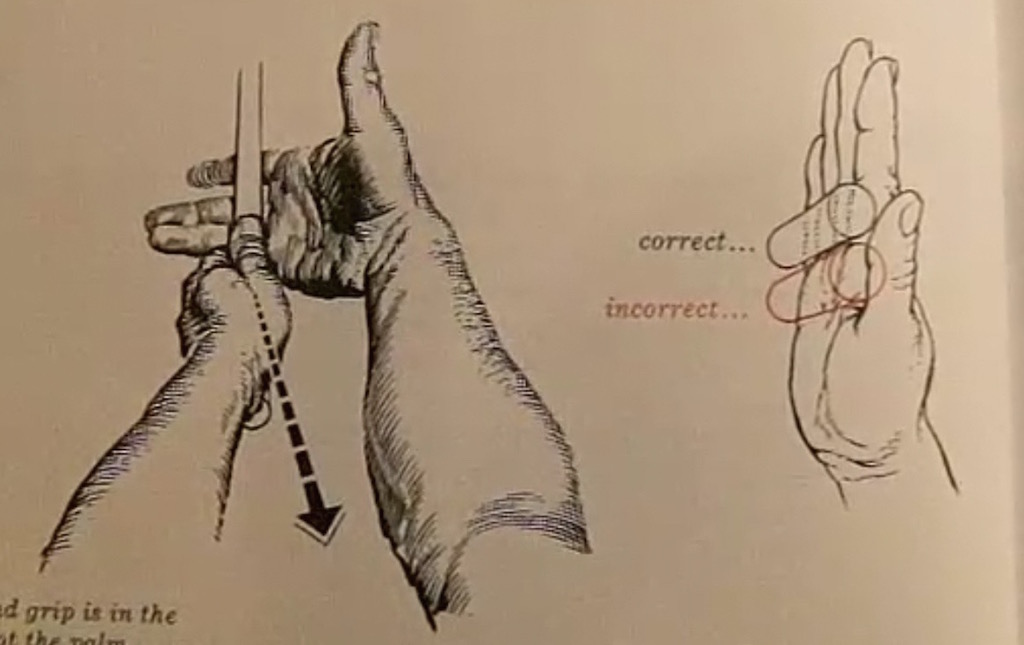

The position of the grip in the upper/left hand

I also observe many golfers who have the butt of the grip too far into the heel pad of the upper hand (the left hand for right-handed players). It’s amazing how much easier it is to release the club through the ball if even 1/4-1/2″ of the butt is beyond the left heel pad. Try this yourself to see what I mean. Swing the club freely with just your left hand and notice the difference in its release from when you hold it at the end of the grip, versus gripping down even a half inch.

To help you really understand how this works, go to the range and hit shots with your five-iron gripped down a full inch to make the club the same length as your seven-iron. You will probably see an amazing shot shape difference, and likely not see as much distance loss as you would expect.

Too much lower (right) hand on the club

It seems like almost all golfers of 8-10 handicap or higher have the club too far into the palm of the lower hand, because that feels “good” if you are trying to control the path of the clubhead to the ball. But the golf swing is not an effort to hit at the ball – it is a swing of the club. The proper hold on the club has the grip underneath the pad at the base of the fingers. This will likely feel “weak” to you — like you cannot control the club like that. EXACTLY. You should not be trying to control the club with your lower/master hand.

Gripping too tightly

Nearly all golfers hold the club too tightly, which tenses up the forearms and prevents a proper release of the club through impact. In order for the club to move back and through properly, you must feel that the club is controlled by the last three fingers of the upper hand, and the middle two fingers of the lower hand. If you engage your thumbs and forefingers in “holding” the club, the result will almost always be a grip that is too tight. Try this for yourself. Hold the club in your upper hand only, and squeeze firmly with just the last three fingers, with the forefinger and thumb off the club entirely. You have good control, but your forearms are not tense. Then begin to squeeze down with your thumb and forefinger and observe the tensing of the entire forearm. This is the way we are made, so the key to preventing tenseness in the arms is to hold the club very lightly with the “pinchers” — the thumbs and forefingers.

So, those are what I believe are the four fundamentals of a good grip. Anyone can learn them in their home or office very quickly. There is no easier way to improve your ball striking consistency and add distance than giving more attention to the way you hold the golf club.

More from the Wedge Guy

- The Wedge Guy: Golf mastery begins with your wedge game

- The Wedge Guy: Why golf is 20 times harder than brain surgery

- The Wedge Guy: Musings on the golf ball rollback

- LIKE83

- LEGIT13

- WOW4

- LOL1

- IDHT0

- FLOP4

- OB1

- SHANK8

19th Hole

Vincenzi’s 2024 Texas Children’s Houston Open betting preview

As the Florida swing comes to an end, the PGA Tour makes its way to Houston to play the Texas Children’s Houston Open at Memorial Park Golf Course.

This will be the fourth year that Memorial Park Golf Course will serve as the tournament host. The event did not take place in 2023, but the course hosted the event in 2020, 2021 and 2022.

Memorial Park is a par-70 layout measuring 7,432 yards and features Bermudagrass greens. Historically, the main defense for the course has been thick rough along the fairways and tightly mown runoff areas around the greens. Memorial Park has a unique setup that features three Par 5’s and five Par 3’s.

The field will consist of 132 players, with the top 65 and ties making the cut. There are some big names making the trip to Houston, including Scottie Scheffler, Wyndham Clark, Tony Finau, Will Zalatoris and Sahith Theegala.

Past Winners at Memorial Park

- 2022: Tony Finau (-16)

- 2021: Jason Kokrak (-10)

- 2020: Carlos Ortiz (-13)

In this article and going forward, I’ll be using the Rabbit Hole by Betsperts Golf data engine to develop my custom model. If you want to build your own model or check out all of the detailed stats, you can sign up using promo code: MATTVIN for 25% off any subscription package (yearly is best value).

Key Stats For Memorial Park

Let’s take a look at several metrics for Memorial Park to determine which golfers boast top marks in each category over their last 24 rounds:

Strokes Gained: Approach

Memorial Park is a pretty tough golf course. Golfers are penalized for missing greens and face some difficult up and downs to save par. Approach will be key.

Total Strokes Gained: Approach per round in past 24 rounds:

- Tom Hoge (+1.30)

- Scottie Scheffler (+1.26)

- Keith Mitchell (+0.97)

- Tony Finau (+0.92)

- Jake Knapp (+0.84)

Strokes Gained: Off the Tee

Memorial Park is a long golf course with rough that can be penal. Therefore, a combination of distance and accuracy is the best metric.

Total Strokes Gained: Off the Tee per round in past 24 rounds:

- Scottie Scheffler (+0.94)

- Kevin Dougherty (+0.93)

- Cameron Champ (+0.86)

- Rafael Campos (+0.84)

- Si Woo Kim (+0.70)

Strokes Gained Putting: Bermudagrass + Fast

The Bermudagrass greens played fairly fast the past few years in Houston. Jason Kokrak gained 8.7 strokes putting on his way to victory in 2021 and Tony Finau gained in 7.8 in 2022.

Total Strokes Gained Putting (Bermudagrass) per round past 24 rounds (min. 8 rounds):

- Adam Svensson (+1.27)

- Harry Hall (+1.01)

- Martin Trainer (+0.94)

- Taylor Montgomery (+0.88)

- S.H. Kim (+0.86)

Strokes Gained: Around the Green

With firm and undulating putting surfaces, holding the green on approach shots may prove to be a challenge. Memorial Park has many tightly mowed runoff areas, so golfers will have challenging up-and-down’s around the greens. Carlos Ortiz gained 5.7 strokes around the green on the way to victory in 2020.

Total Strokes Gained: Around the Green per round in past 24 rounds:

- Mackenzie Hughes (+0.76)

- S.H. Kim (+0.68)

- Scottie Scheffler (+0.64)

- Jorge Campillo (+0.62)

- Jason Day (+0.60)

Strokes Gained: Long and Difficult

Memorial Park is a long and difficult golf course. This statistic will incorporate players who’ve had success on these types of tracks in the past.

Total Strokes Gained: Long and Difficult in past 24 rounds:

- Scottie Scheffler (+2.45)

- Ben Griffin (+1.75)

- Will Zalatoris (+1.73)

- Ben Taylor (+1.53)

- Tony Finau (+1.42)

Course History

Here are the players who have performed the most consistently at Memorial Park.

Strokes Gained Total at Memorial Park past 12 rounds:

- Tyson Alexander (+3.65)

- Ben Taylor (+3.40)

- Tony Finau (+2.37)

- Joel Dahmen (+2.25)

- Patton Kizzire (+2.16)

Statistical Model

Below, I’ve reported overall model rankings using a combination of the five key statistical categories previously discussed.

These rankings are comprised of SG: App (24%) SG: OTT (24%); SG: Putting Bermudagrass/Fast (13%); SG: Long and Difficult (13%); SG: ARG (13%) and Course History (13%)

- Scottie Scheffler

- Wyndham Clark

- Tony Finau

- Joel Dahmen

- Stephan Jaeger

- Aaron Rai

- Sahith Theegala

- Keith Mitchell

- Jhonnatan Vegas

- Jason Day

- Kurt Kitayama

- Alex Noren

- Will Zalatoris

- Si Woo Kim

- Adam Long

2024 Texas Children’s Houston Open Picks

Will Zalatoris +2000 (Caesars)

Scottie Scheffler will undoubtedly be difficult to beat this week, so I’m starting my card with someone who I believe has the talent to beat him if he doesn’t have his best stuff.

Will Zalatoris missed the cut at the PLAYERS, but still managed to gain strokes on approach while doing so. In an unpredictable event with extreme variance, I don’t believe it would be wise to discount Zalatoris based on that performance. Prior to The PLAYERS, the 27-year-old finished T13, T2 and T4 in his previous three starts.

Zalatoris plays his best golf on long and difficult golf courses. In his past 24 rounds, he ranks 3rd in the category, but the eye test also tells a similar story. He’s contended at major championships and elevated events in the best of fields with tough scoring conditions. The Texas resident should be a perfect fit at Memorial Park Golf Club.

Alex Noren +4500 (FanDuel)

Alex Noren has been quietly playing some of his best golf of the last half decade this season. The 41-year-old is coming off back-to-back top-20 finishes in Florida including a T9 at The PLAYERS in his most recent start.

In his past 24 rounds, Noren ranks 21st in the field in Strokes Gained: Off the Tee, 30th in Strokes Gained: Around the Green, 25th in Strokes Gained: Total on long and difficult courses and 21st in Strokes Gained: Putting on fast Bermudagrass greens.

In addition to his strong recent play, the Swede also has played well at Memorial Park. In 2022, Noren finished T4 at the event, gaining 2.2 strokes off the tee and 7.0 strokes on approach for the week. In his two starts at the course, he’s gained an average of .6 strokes per round on the field, indicating he is comfortable on these greens.

Noren has been due for a win for what feels like an eternity, but Memorial Park may be the course that suits him well enough for him to finally get his elusive first PGA Tour victory.

Mackenzie Hughes +8000 (FanDuel)

Mackenzie Hughes found himself deep into contention at last week’s Valspar Championship before faltering late and finishing in a tie for 3rd place. While he would have loved to win the event, it’s hard to see the performance as anything other than an overwhelming positive sign for the Canadian.

Hughes has played great golf at Memorial Park in the past. He finished T7 in 2020, T29 in 2021 and T16 in 2022. The course fit seems to be quite strong for Hughes. He’s added distance off the tee in the past year or and ranks 8th in the field for apex height, which will be a key factor when hitting into Memorial Park’s elevated greens with steep run-off areas.

In his past 24 rounds, Hughes is the best player in the field in Strokes Gained: Around the Greens. The ability to scramble at this course will be extremely important. I believe Hughes can build off of his strong finish last week and contend once again to cement himself as a President’s Cup consideration.

Akshay Bhatia +8000 (FanDuel)

Akshay Bhatia played well last week at the Valspar and seemed to be in total control of his golf ball. He finished in a tie for 17th and shot an impressive -3 on a difficult Sunday. After struggling Thursday, Akshay shot 68-70-68 in his next three rounds.

Thus far, Bhatia has played better at easier courses, but his success at Copperhead may be due to his game maturing. The 22-year-old has enormous potential and the raw talent to be one of the best players in the world when he figures it all out.

Bhatia is a high upside play with superstar qualities and may just take the leap forward to the next stage of his career in the coming months.

Cameron Champ +12000 (FanDuel)

Cameron Champ is a player I often target in the outright betting market due to his “boom-or-bust” nature. It’s hard to think of a player in recent history with three PGA Tour wins who’s been as inconsistent as Champ has over the course of his career.

Despite the erratic play, Cam Champ simply knows how to win. He’s won in 2018, 2019 and 2021, so I feel he’s due for a win at some point this season. The former Texas A&M product should be comfortable in Texas and last week he showed us that his game is in a pretty decent spot.

Over his past 24 rounds, Champ ranks 3rd in Strokes Gained: Off the Tee and 30th in Strokes Gained: Total on long and difficult courses. Given his ability to spike at any given time, Memorial Park is a good golf course to target Champ on at triple digit odds.

Robert MacIntyre +12000 (FanDuel)

The challenge this week is finding players who can possibly beat Scottie Scheffler while also not dumping an enormous amount of money into an event that has a player at the top that looks extremely dangerous. Enter McIntyre, who’s another boom-or-bust type player who has the ceiling to compete with anyone when his game is clicking on all cylinders.

In his past 24 rounds, MacIntyre ranks 16th in the field in Strokes Gained: Off the Tee, 17th in Strokes Gained: Around the Green and 10th in Strokes Gained: Total on long and difficult courses.

MacIntyre’s PGA Tour season has gotten off to a slow start, but he finished T6 in Mexico, which is a course where players will hit driver on the majority of their tee shots, which is what we will see at Memorial Park. Texas can also get quite windy, which should suit MacIntyre. Last July, the Scot went toe to toe with Rory McIlroy at the Scottish Open before a narrow defeat. It would take a similar heroic effort to compete with Scheffler this year in Houston.

Ryan Moore +15000 (FanDuel)

Ryan Moore’s iron play has been absolutely unconscious over his past few starts. At The PLAYERS Championship in a loaded field, he gained 6.1 strokes on approach and last week at Copperhead, he gained 9.0 strokes on approach.

It’s been a rough handful of years on Tour for the 41-year-old, but he is still a five-time winner on the PGA Tour who’s young enough for a career resurgence. Moore has chronic deterioration in a costovertebral joint that connects the rib to the spine, but has been getting more consistent of late, which is hopefully a sign that he is getting healthy.

Veterans have been contending in 2024 and I believe taking a flier on a proven Tour play who’s shown signs of life is a wise move at Memorial Park.

- LIKE15

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK2

Opinion & Analysis

Ryan: Why the race to get better at golf might be doing more harm than good

B.F. Skinner was one of the most important psychologists of the 20th century, developing the foundation of the development of reinforcement, and in doing so, creating the concept of behaviorism. In simple terms, this means that we are conditioned by our habits. In practical terms, it explains the divide between the few and far between elite instructors and college coaches.

To understand the application, let’s quickly review one of B.F. Skinner’s most important experiments; superstitions in the formation of behavior by pigeons. In this experiment, food was dispensed to pigeons at random intervals. Soon, according to Skinner, the pigeons began to associate whatever action they were doing at the time of the food being dispensed. According to Skinner, this conditioned that response and soon, they simply haphazardly repeated the action, failing to distinguish between cause and correlation (and in the meantime, looking really funny!).

Now, this is simply the best way to describe the actions of most every women’s college golf coach and too many instructors in America. They see something work, get positive feedback and then become conditioned to give the feedback, more and more, regardless of if it works (this is also why tips from your buddies never work!).

Go to a college event, particularly a women’s one, and you will see coaches running all over the place. Like the pigeons in the experiment, they have been conditioned into a codependent relationship with their players in which they believe their words and actions, can transform a round of golf. It is simply hilarious while being equally perturbing

In junior golf, it’s everywhere. Junior golf academies make a living selling parents that a hysterical coach and over-coaching are essential ingredients in your child’s success.

Let’s be clear, no one of any intellect has any real interest in golf — because it’s not that interesting. The people left, including most coaches and instructors, carve out a small fiefdom, usually on the corner of the range, where they use the illusion of competency to pray on people. In simple terms, they baffle people with the bullshit of pseudo-science that they can make you better, after just one more lesson.

The reality is that life is an impromptu game. The world of golf, business, and school have a message that the goal is being right. This, of course, is bad advice, being right in your own mind is easy, trying to push your ideas on others is hard. As a result, it is not surprising that the divorce rate among golf professionals and their instructors is 100 percent. The transfer rate among college players continues to soar, and too many courses have a guy peddling nefarious science to good people. In fact, we do at my course!

The question is, what impact does all this have on college-age and younger kids? At this point, we honestly don’t know. However, I am going to go out on a limb and say it isn’t good.

Soren Kierkegaard once quipped “I saw it for what it is, and I laughed.” The actions of most coaches and instructors in America are laughable. The problem is that I am not laughing because they are doing damage to kids, as well as driving good people away from this game.

The fact is that golfers don’t need more tips, secrets, or lessons. They need to be presented with a better understanding of the key elements of golf. With this understanding, they can then start to frame which information makes sense and what doesn’t. This will emancipate them and allow them to take charge of their own development.

- LIKE14

- LEGIT4

- WOW1

- LOL2

- IDHT0

- FLOP1

- OB0

- SHANK11

-

19th Hole2 weeks ago

19th Hole2 weeks agoJohn Daly stuns fans into silence with brutal opening tee shot on PGA Tour Champions

-

19th Hole4 days ago

19th Hole4 days agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

-

19th Hole20 hours ago

19th Hole20 hours agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks ago2-time major champ announces shock retirement from the sport at age of 33

-

19th Hole2 weeks ago

19th Hole2 weeks agoCharlie Woods finds it tough going on American Junior Golf Association debut

-

19th Hole2 weeks ago

19th Hole2 weeks agoEdoardo Molinari reveals the latest PGA Tour golfer to turn down ‘good offer’ from LIV Golf

-

19th Hole3 weeks ago

19th Hole3 weeks agoScottie Scheffler had an interesting response when asked how he ‘quiets the noise’ following Players victory

-

19th Hole2 weeks ago

19th Hole2 weeks agoJon Rahm dealt fresh blow to hopes of qualifying for 2025 Ryder Cup

Pingback: Best 13 swing speed shaft flex chart - lindaadvisors.com

Graham Davis

Dec 10, 2016 at 10:00 pm

One more point. I am 5 fòot 7 inches and 11 stone, so not a power house. 7 is my highest handicap and I hit my driver about 240 yards with mý 88 to 90mph swing speed. 220 yards carry.

Graham Davis

Dec 10, 2016 at 9:15 pm

I should add to my previous mail that I have put together at least ten different shaft combos ranging from 45.5 inch fujikura 44gm regular to 44.25 inch black tie regular. I have tried senior, regular and stiff flex, and high , mid and low bend points At 85 to 90mph, why does a long heavy shaft give me the best results?

Graham Davis

Dec 10, 2016 at 9:02 pm

I am a 7 handicap 61 year old with driver swing speed of 88 to 90 mph. You often say current drivers are too long and to use more loft but my stats on trackman say 45.5 inch shaft at 9° gives my best launch and carry with least spin. Why is this? I use grafalloy prolaunch blue and swing weight is about D5. This is a 68gm shaft. I have the same shaft at 44.5 inches but don’t hit it as far. Consistency is not a compromised with the longer shaft. My smash factor is just as good. I can see 10 to 20 yards more carry. Do I simply have good tempo?

Montree

Mar 23, 2016 at 11:34 pm

May I share my story to choose golf swing analyser

A common mistake made by amateur golfers is choosing golf clubs that are not suited to their swing speed. If you do not match your clubs to your abilities to swing them, it can have an adverse effect on your game. Club factors that should be adjusted based on how fast you swing a club include the shaft flex, torque and the type of shaft. By taking the time to find the right clubs for your game, you can best leverage your golf equipment to improve your game.

Step 1

Determine your swing speed. Many golf retail stores and pro shops can take this measurement. Otherwise, the speed can be estimated based on the club that you hit from a distance of 150 yards. If you use a 3-iron or wood, your swing speed is probably less than 60 mph; a 4-iron is 60-75 mph; a 5-iron is 75-84 mph; a 6- or 7-iron is 84-93 mph; and an 8- or 9-iron is over 93 mph.

Step 2

Determine the shaft flex of your clubs based on your swing speed. The shaft flex is representative of how much force is required for the shaft to transfer energy to the golf ball during your swing. Ladies flex should be used for a swing speed of less than 60 mph, senior flex for 60-75 mph, regular flex for 75-84 mph, stiff flex for 84-93 mph, and extra-stiff flex for speeds above 93 mph. Choosing the wrong shaft flex can lead to hooked, sliced or generally inaccurate shots.

Step 3

Pick a material for the shafts of your irons. The two most common options are graphite and steel. Players with a slow swing speed normally will choose a graphite shaft to maximize the distance the ball travels, while those with a fast swing will choose steel for greater consistency. If your swing speed is moderate, test clubs of each type to determine which feels the best. The majority of modern fairway woods and drivers are sold with graphite shafts and should be chosen based on the information provided in Step 2.

Step 4

Choose the clubhead for your irons. Low-handicap players will prefer half-cavity or blade clubheads for greater consistency and control, while high-handicap players should opt for full-cavity clubs to aid in getting the ball in the air consistently. A half- or full-cavity golf clubhead has a hollowed-out area toward the back to distribute weight around the clubhead, creating a larger “sweet spot.” Blade clubheads have more weight around the face of the club.

Step 5

Test the clubs you have chosen before purchasing them. If you do not like the feel of the clubs, pick a different manufacturer with the same configuration options before changing the shaft flex, material or clubhead variant.

Read More : http://www.golfswinganalysers.com/best-golf-swing-analyzer-2016/

Pingback: How to Hit More Fairways with a Custom Golf Shaft

Rob Campbell

May 8, 2015 at 6:45 pm

Dear Mr. Wishon,

How about if I clamp the grip to a work bench with the shaft cantilevered, hang a weight (maybe 454 g) onto the head (hosel) and measure the deflection along the shaft, once with just the head, once with the added weight? A lot more time consuming than clamping a bare shaft in an expensive oscillator but way easier for us at home. A profile of the shaft bend could be drawn and different shafts could be compared without messing with the club.

I just found out I hit my cousin’s driver 30 yards further than mine. He’s got an R Fujikara and I have an A Project X. His would have way more deflection.

Could such a profile convert to yours?

Pingback: Does the golf shaft really effect your shots? | golfblogaustralia

Adrian Hubert

Mar 31, 2013 at 11:20 am

Hi,

I have some good knowledge of shafts, please can someone confirm that there is a difference between buying a shaft from say Golfsmith and having the same branded shaft from the tour. ?

Tom

Mar 11, 2013 at 5:38 pm

Great article Tom. Just wondering, how did you determine that 454 grams was the best weight to use?

tlmck

Oct 8, 2012 at 10:09 pm

lol. Just thinking of the guy who tried to sell me a C.Kua 39 R for my 92mph clubhead speed.

I can say for certainty, with only my swing as evidence, that a C.Kua 39 stiff is equivalent to a Diamana Red 44L stiff. I have the C.Kua in my identical head backup driver as the Diamana is apparently no longer made, and was nowhere to be found. It’s also nice that the C.Kua does nor require a special grip.

Nathan

Oct 2, 2012 at 3:56 am

This article looked promising untill i got to the part ( you really want to know it will cost you!!) good work

Chris

Oct 1, 2012 at 9:39 pm

When can we expect part 2?

Tom Wishon

Sep 26, 2012 at 5:25 pm

to JEFF who asked about shaft swing speed ratings for golfers with different levels of transition/tempo force in their swing.

Most definitely you are sniffing at a lot of what is going to be in Part 2 of this series. This is precisely why we teach clubmakers to do a basic 1, 2, 3 rating of each golfer’s transition force and downswing tempo to go along with their swing speed.

For example, three golfers all with a 90mph swing speed. But Golfer #1 has a very forceful transition and aggressive tempo. Golfer 2 has an average force/aggressiveness in transition/tempo and Golfer 3 has a smooth, more passive “swinger” type of transition and tempo.

For golfer 2, you can choose from shafts rated to be 85-95mph because his bending force is average for a 90mph swing. For golfer 1, you’d pick from shafts rated at 90-100 because these would be slightly stiffer shafts his swing speed is at the low end of the shaft’s rating – more stiff to better match with the fact that for his 90mph swing speed, his strong/forceful transition/tempo puts more bending force on the shaft so he needs a little stiffer shaft than what his swing speed indicates on its own.

And then finally the 90mph smooth swinger should pick from shafts with a swing speed rating of 80-90mph because he is NOT putting as much bending force on the shaft for his 90mph swing.

But you have the big basic point of shaft flex fitting down – amount of bending force is not always related to the golfer’s swing speed, but is heavily influenced by their transition and downswing tempo.

Tom Wishon

Sep 26, 2012 at 5:04 pm

To John who asked about OEM stock shaft stiffness:

There’s no nice way to say this. You can’t and won’t know how stiff an OEM stock shaft is. The OEMs do not provide any quantitative information on the stiffness/bend profile design of their stock shafts. Test hitting is the only way unless you buy the club, take it apart and then send me the shaft so I can measure it and include it in the data base of the software we created.

We’d love to include them in the data base of this software program but they will not send us their stock shafts to measure, nor will they allow their shaft mfg vendor to do that either. So the few OEM stock shafts we have in the software come from clubmakers who pull these shafts intact from stock clubs and send them to us to measure.

This again is one more good reason to be working with a GOOD, experienced clubmaker who has this software when you want to nail down what works/performs best for your swing and sense of feel.

Ian Mikutel

Apr 22, 2013 at 4:18 am

Why not use some of the $129.50 you charge for database access to purchase OEM shafts each year? It seems to me like the most valuable data for most golfers out there would be that of the OEM shafts, not super expensive, custom shafts? Unfortunate that the OEMs won’t send clubs for this testing, or just standardize this testing across all OEMs.

Pingback: GolfWRX.com – Taking the guesswork out of selecting shafts (Part 1) | Golf Products Reviews

Pingback: Light VS heaver shafts or clubs??? - Page 2 - Golf Forum - Golf Rewound is the Family Friendly Golf Forum and Discussion Group

Justin

Sep 24, 2012 at 11:36 pm

@Eric:

Yes, the more flexible the shaft, the more you can “feel”.

Davy

Mar 29, 2015 at 2:40 pm

The more ‘what’ you can feel?

The answer should be interesting.

Ryan

Sep 22, 2012 at 4:17 pm

Great write up. This definitely confirms what a lot of us already thought we knew which was every OEM even within there own shafts has no tangible way of discerning flex even within their own shafts that to me is CRAZY but soo glad Tom gave us real eveidence to prove this and I cannot wait for part 2

Davy

Mar 29, 2015 at 2:50 pm

You seem to have missed the point. Each manufacturer arbitrarily decides by their own measurement and priorities what they will market as an ‘R’ flex for example. One practice is to offer an ostensible ‘R’ flex with an ‘S’ shaft band on it to capture the vastly misinformed share of the market that believes they require a stiff shaft. But, you are correct about Tom’s authoritative expertise.

Ryan

Sep 22, 2012 at 4:14 pm

Great write up. This definitely confirms what a lot of us already thought we knew which was every OEM even within there own shafts has no tangible way of discerning flex even within their own shafts that to me is CRAZY but soo glad Tom gave us real eveidence to prove th

Jeff

Sep 21, 2012 at 8:24 pm

Terrific article. Does the data about stiffness profiles lend itself to discerning which shafts are more suitable based on an individual’s loading characteristics at a given swing speed? Does this matter? Looking forward to reading your next article.

Eric

Sep 21, 2012 at 5:17 pm

Tom:

I play hickory clubs with a group. One thing I’ve noticed is one can truly feel the weight of the club, and I believe that significantly affects how the club is swung – particularly as you begin the forwardswing, and your subconscious changes the path of the swing.

As a result, I wonder if the whippier shafts improve feel of the clubhead – OR – is there a way to get great clubhead feel without giving up the control of a stiffer shaft?

Mark

Sep 21, 2012 at 3:06 pm

Thanks Tom.

As always, a well thought out and informative article. I’ll be getting the software, and look forward to part 2.

ACGOLFWRX

Sep 21, 2012 at 8:42 am

Excellent information for the masses, well written and above all, very informative.

John

Sep 21, 2012 at 6:16 am

Very well written Tom – thanks. The only problem remains, how do I know what level of stiffness I should be purchasing through the OEM’s at retail stores? Hope that’s covered in Part II.

Al

Oct 16, 2012 at 11:47 pm

Not speaking for Tom by any means, but his philosophy is that, rather than relying on the OEM’s, you should be custom fitted for your clubs rather than buying off the shelf.

Davy

Mar 29, 2015 at 2:54 pm

Well, you might try hitting before buying. Would you buy shoes without trying them on?

Matt

Sep 20, 2012 at 10:50 pm

As an engineer I am fascinated by this and am always on the search for the right fit as a scratch golfer, to maximize my game. This is revolutionary stuff. Thanks!

Davy

Mar 29, 2015 at 3:18 pm

It probably seems revolutionary, but Tom has been doing this since back in the 1980s when he was at Dynacraft and wrote his first Complete Guide to Golf Shaft Fitting. While there are no generalities, many tour players over the years have opted for heavier dynamic and static weighting with flatter lie angles than off the shelf mass-produced clubs. As an engineer, you probably enjoyed reading Homer Kelley’s The Golfing Machine. Bob Tway, Bobby Clampett, and a litany of others found it interesting all the way to their demise in a vortex of paralysis by analysis. But, it is interesting and has one salient bit of advice you can look up at 6B-1D in the book.

Bill B

Sep 20, 2012 at 8:54 pm

Tom,

Without a doubt this is the best information on shafts I have seen in one place. You have created my dream of the “golf shaft genome project”. The golf shaft is the heart of the club and you are making quantative information available that provides options to professional fitters and club junkies alike. We have all made our own personal golf shaft assments on various shafts via real life play, launch monitor results, and feel, but this speeds up the process and opens the door to choices across various manufactures.

Thanks and keep up the good work

Bill Baitinger

Mike D.

Sep 20, 2012 at 12:50 pm

Thanks for the write-up Tom. Verifies what I’ve thought about shaft manufacturing. Can’t wait to see part two!

Chris

Sep 20, 2012 at 12:35 pm

This is absolutely fantastic information. Many thanks!.