Equipment

Cleveland releases limited-edition Tour Rack wedges

Cleveland Golf has announced the release of its Tour Rack wedges, which are very limited-edition prototypes. How limited are we talking? Only 300 of each model were produced and they are only available at limited locations.

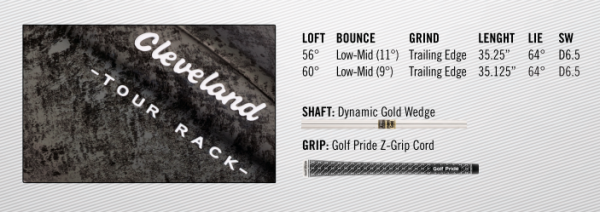

Aesthetically, the design takes “cool” to the next level, with an icy back flange that looks frosted over. The wedges, which carry an MAP of $249.99, come available in two lofts (56 degrees with 11 degrees of bounce and 60 degrees with 9 degrees of bounce), a trailing edge grind, a True Temper Dynamic Gold Wedge Shaft and a Golf Pride Z-Cord Grip. See below for additional specs.

Call Cleveland Golf at 800-999-6263 or send an email to customerservice@

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Steve Stricker WITB 2024 (April)

- Steve Stricker WITB accurate as of the Zurich Classic. More photos from the event here.

Driver: Titleist TSR3 (9 degrees, C4 SureFit setting)

Shaft: Fujikura Motore Speeder VC 7.2 X

3-wood: Titleist 915F (13.5 degrees)

Shaft: Mitsubishi Tensei CK Pro White 80 TX

Hybrid: Titleist 816 H1 (17 degrees)

Shaft: Fujikura Motore Speeder VC 9.2 X

Irons: Titleist T200 (3, 4), Titleist T100 (5-9)

Shafts: Project X 6.5

Wedges: Titleist Vokey SM8 (46-10F @55), Titleist Vokey SM10 (54-10S @53), Titleist Vokey SM4 (60 @59)

Shafts: True Temper Dynamic Gold X100 w/Sensicore

Putter: Odyssey White Hot No. 2

Ball: Titleist Pro V1x

Grips: Golf Pride Tour Velvet Grip Rite

Check out more in-hand photos of Steve Stricker’s clubs here.

- LIKE12

- LEGIT2

- WOW0

- LOL0

- IDHT1

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Alex Fitzpatrick WITB 2024 (April)

- Alex Fitzpatrick what’s in the bag accurate as of the Zurich Classic.

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Fujikura Ventus TR Black 7 X

Hybrid: Ping G430 (19 degrees)

Shaft: Fujikura Ventus Black HB 10 TX

Irons: Ping iCrossover (2), Titleist T100 (4-PW)

Shafts: Fujikura Ventus Black HB 9 TX (2), Nippon N.S. Pro Modus 3 Tour 120 X (4-9)

Wedges: Titleist Vokey Design SM10 (50-12F, 56-12D, 60-08M)

Shafts: Nippon N.S. Pro Modus 3 Tour 120 X

Putter: Bettinardi SS16 Dass

Grips: Golf Pride MCC

Check out more in-hand photos of Alex Fitzpatrick’s clubs here.

- LIKE4

- LEGIT0

- WOW0

- LOL0

- IDHT1

- FLOP0

- OB0

- SHANK0

Equipment

What’s the perfect mini-driver/shaft combo? – GolfWRXers discuss

In our forums, our members have been discussing Mini-Drivers and accompanying shafts. WRXer ‘JamesFisher1990’ is about to purchase a BRNR Mini and is torn on what shaft weight to use, and our members have been sharing their thoughts and set ups in our forum.

Here are a few posts from the thread, but make sure to check out the entire discussion and have your say at the link below.

- PARETO: “New BRNR at 13.5. Took it over to TXG (Club Champ but TXG will always rule) in Calgary for a fit. Took the head down to 12, stuck in a Graphite Design AD at 3 wood length and 60g. Presto- numbers that rivaled my G430Max but with waaaaay tighter dispersion. Win.”

- driveandputtmachine: “Still playing a MIni 300. The head was only 208, so I ordered a heavier weight and play it at 3 wood length. I am playing a Ventus Red 70. I play 70 grams in my fairways. I use it mainly to hit draws off the tee. When I combine me, a driver, and trying to hit a draw it does not work out well most of the time. So the MIni is for that. As an aside, I have not hit the newest BRNR, but the previous model wasn’t great off the deck. The 300 Mini is very good off the deck.”

- JAM01: “Ok, just put the BRNR in the bag along side a QI10 max and a QI10 3 wood. A load of top end redundancy. But, I have several holes at my two home courses where the flight and accuracy of the mini driver helps immensely. Mine is stock Proforce 65 at 13.5, I could see a heavier shaft, but to normal flex, as a nice alternative.”

Entire Thread: “What’s the perfect Mini-Driver/Shaft combo? – GolfWRXers discuss”

- LIKE4

- LEGIT1

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK4

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole5 days ago

19th Hole5 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole3 weeks ago

19th Hole3 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole4 days ago

19th Hole4 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole2 weeks ago

19th Hole2 weeks agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole1 week ago

19th Hole1 week agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

RAT

Jul 28, 2014 at 11:40 am

Cleveland is a better weighted and balanced club than any other.

nikkyd

Jul 25, 2014 at 5:01 pm

I wonder if the hosels break as easily as the regular retail versions.

RMB3

Jul 25, 2014 at 7:54 pm

Only reason you would break a Cleveland hosel is if you don’t know what your doing. I remember my first time bending clubs.

Cleveland Golf

Jul 24, 2014 at 1:10 pm

Yes, they are forged from 1025 Carbon Steel.

KK

Jul 24, 2014 at 10:07 am

Customized, this could make an awesome gift for a Cleveland wedge fan.

dunn2500

Jul 24, 2014 at 12:25 am

And these are different from retail wedge how?…lol, $250 for same wedge I can get for under $100….no thanks

Love cleveland wedges but just don’t see where extra money is going….you can keep em

Or buy em in 6 months on closeout

Cleveland Golf

Jul 24, 2014 at 1:11 pm

Dunn2500, these will NEVER go on closeout because there are only 300 pieces in the world.

Tom

Aug 1, 2014 at 11:21 am

I guess you are paying for the limited finish and rarity of the model. All the golf companies seem to be pushing cool finishes for a higher price since you really should replace your wedge every 2 or so years. It is the only club I would regularly replace.

Jason P.

Jul 23, 2014 at 8:38 pm

Stupid crazy price but somebody will fork over the money to show how little brain power they have. I’ll just keep my Mizuno MP T-11 Wedges until the head cracks in half which will never happen.

joro

Jul 23, 2014 at 8:18 pm

250 a bit steep? Downright over the hill.

Kev Jones

Jul 23, 2014 at 2:09 am

Cleveland wedges,,,,,,,,,,,,,,,,,most played wedge on tour for a reason ,,Awsome .

Sm5

Jul 23, 2014 at 5:32 pm

I would think vokeys are the most played wedge on tour.

RG

Jul 27, 2014 at 5:47 am

and you would think wrong

Christian

Jul 22, 2014 at 8:00 pm

Forged?

D

Jul 22, 2014 at 5:56 pm

$250 is steep but man these wedges look sweet!