Equipment

Titleist T-Series irons: Ultimate tour performance

New technology, new name: The Titleist T-Series irons.

The concept behind the T-Series started with one goal: To produce the best performing, most technology packed, playable irons, ever produced by Titleist…simply put: mission accomplished! With the launch of the new T100, T200, and T300s, Titleist is ushering in a new era of forgiveness, speed, and control with Max Impact.

What does that mean? Before diving into Max Impact, let’s start with the control part. With the launch of the new T-Series, Titleist is reminding golfers that fitting is the key to maximizing your set. From wedges to woods, each club should serve a distinct purpose and earn its spot in your bag—never carry a club because you “think” you need it, carry the clubs you know you will use.

Titleist calls this is the 3D Fitting Process

- Distance

- Dispersion

- Descent

Focusing on these factors ensures each iron in your bag is creating the proper parameters to improve scoring. Statistics prove that the closer you hit it to your target (descent and dispersion) the likelihood of getting the next shot closer (or in the hole) goes way up—it’s the strokes gained principle pioneered by Mark Broadie. Each iron in the T-Series has been designed to blend with the other models including the 620 series blades and CBs to make sure regardless of your final set make up it transitions on both looks and performance. With the new T-Series, the larger the number model 100, 200, 300, the faster the ball speeds and the higher the launch. Add the all-new Max Impact Technology, and you have three distinct iron sets designed to help any player find the performance they are looking for.

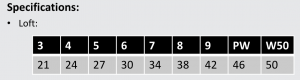

Titleist T100 irons

Built from the ground up with direct input from Titleist’s PGA Tour staff, the mission statement from the design team for the new T100 was to simply create the best performing tour iron ever—NOT “the best AP2.” With a shape that is distinctly Titleist but completely redefined as far as offset, top line, sole width, camber, and blade length, the T100 gives players looking for a tour performance iron more playability than ever before.

Co-forged with large amounts of tungsten (66g on average in the 3-7 irons) in the heel and toe, the T100 looks a lot more like a single-piece forged players cavity back than multi-piece forgiveness monster, but looks can be deceiving. It has the thinnest face they have ever built into a true forged players club, which allows designers to push more mass around the head and create greater ball speed, which is a never a bad thing especially when you consider that it still has a fully supported face.

Just like with club technology, turf conditions are always evolving with new grass types and mower techniques. This means where the club contacts the ground has to evolve too, which is exactly what has happened to the whole T-Series including the T100. Sole width and profiles have been reduced to offer more camber and radius, which through the testing process has lead players to say the same thing over and over: “they feel faster through the turf.” That’s from Marni Ines, Director, Titleist Irons Development. It’s not that they actually go through that much faster but they react through the ground much more efficiently, which means as course conditions vary, whether through the season or thanks to traveling, you are going to great results shot after shot.

(Club fitter thought break for a moment)

I can’t reiterate this enough: In the world of designing golf clubs, the rules set forth by the governing bodies along with mass totals for club heads will always create a unique challenge for engineers. Every single gram saved is valuable in creating higher MOI, better COG placement, and optimizing ball speed. Tweaks that might appear to be small can actually make a big difference for some players, for example; a simple change in sole shape. What we are seeing is the practice of marginal gains, which can be summed up by this practical application: rather than attempt to improve one thing by 10 percent, improve 10 things by 1 percent to equal better results. Now take it further and imagine if you improve 10 measurable factors by 1.5 percent, these are tangible numbers for increased performance.

So why do I bring this up? It’s because this is how engineers work to help you play better golf. All these small changes compounded together make for big improvements to your golf game. It’s about using every technology available in both production and design to create improvement. If you can change three parameters to get angle of decent two percent higher from 43 degrees to 45 degrees that’s greater stopping power to help you get closer to flags, equaling the potential to score better. Something we all want to do.

Speaking to technology jumps, this bring us to…

MAX Impact

Max Impact is a combination of technologies that pairs the thinnest faces Titleist has ever produced with structural support and polymer core behind the geometric center of the face to increase speed, launch, and improve feel.

So about the supporting polymer: It’s not some run of the mill, “Hey that sound like a good idea,” piece of just anything. If there is one thing Titleist knows beyond how to make the number one irons on tour, it’s polymers. With help from the golf ball R&D Team, the Titleist Iron engineers went through a multitude of options before settling on the what was the final variation based on density, rebound properties and finally acoustic enhancement. As they explained,

“Think of the unsupported face like a trampoline, pulled tight with a huge potential for rebound. Now take that trampoline and put an exercise ball underneath it right in the middle. You’re going to bounce higher and increase the rebound not only in the middle but also when you don’t catch the middle of the trampoline – That’s the application of the Max Impact.”

So what do we do about all of this speed? The one thing players often talk about is the inconsistency in distance they see from irons with unsupported faces (“hotspots”) that occur on shots hit around the face. During my discussion with the engineering team, I asked if these “hotspots” still really exist on modern irons and to my surprise I was told in one way or the other “YES…BUT.” These shots that go further don’t actually come from the face being hotter in one area, they come from gear effect from shots usually hit high on the face above the center of percussion…

Center of percussion? Let’s explain that before going any further (Thanks Harvard Natural Sciences Lecture) “The center of percussion (COP) is the place on a bat, racket, or golf club where it may be struck without causing reaction at the point of support. When a ball is hit at this spot, the contact feels good and the ball seems to spring away with its greatest speed and therefore this is often referred to as the sweet spot.”

Just like with a driver, shots hit above that area will launch higher with less spin—that creates parameters for shots to go further. But if you can prevent that from happening or shrink that area, the likelihood of those shots occurring goes WAY down and you get a much more consistent ball flight. That’s part of the genius of Max Impact, not only does it help create greater speed but creates more consistent speed and launch conditions all over the face. Everything you want in an iron built for speed in a players package.

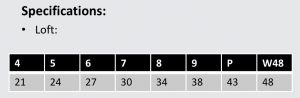

Titleist T200 irons

The first thing you’ll notice that makes the T200 unique from any Titleist iron before it is Max Impact Technology. I realize this sounds very different from any Titleist iron before it and…well…that’s because it is.

Thanks to new materials and manufacturing techniques, along with lessons learned through the introduction of the Concept Series and Speed Project, the T200 has an unsupported (by metal) Forged L-Face that not only feels great but flexes for more ball speed. Thanks to the weight savings of the thinner Forged L-face, more tungsten (average of 90g from the 4-7-irons) can be placed low and on the perimeter of the club to increase forgiveness and overall total stability where players need it.

That’s part of the reason stronger lofts are required—these things really do LAUNCH. Max Impact isn’t found in every T200 though, it has been placed in the 4- 7 irons because Titleist player testing and data crunching proved time after time that as players get away from their scoring clubs distance gapping and dispersion becomes an issue. This is where the 3D fitting process makes sure every club in the set has a purpose and hits a proper flight and distance.

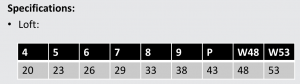

Titleist T300 irons

If you just look at the spec for the T300, I already know what you’re going to say “WOW, these lofts are jacked, no wonder they go so far.” That’s not the full story, and at this point in golf technology, I’m completely over hearing that as an excuse for players to NOT trying a club. This comes from the perspective of a fitter rather than a player—not the other way around.

The T300 is the hottest and most forgiving Titleist iron ever made. Just like its smaller brother, the T200, it uses the same Max Impact Technology to both add rebound and improve overall feel. The unsupported face is stretched across a larger area thanks to the bigger face size, wider sole, and undercut perimeter to push the COG low and away from the face—if the T200 launches, then the T300 REALLY Launches! This deep COG and thin fast face is what makes this club launch so high, it’s also the reason stronger lofts are necessary. If it wasn’t for strong lofts, then with the speed and spin they would create at “standard” lofts, ball flight would end up uncontrollable. Basically the exact opposite of what you want in an iron.

Part of how they were able to make the T300 the most forgiving Titleist iron ever is by actually eliminating a part of the club that was beneficial in previous models (like the AP1)—hollow-body construction. Even with a hollow-body design, there is unnecessary weight placed high along the back of the club.

Generally for many designs this is fine because the wall thickness is minimal, and thanks to smarter people than me, this allows for more flexing of the body of the club to enhance ball speeds. But if given the option between the two, a fully undercut iron would have a higher MOI and help create that same trampoline when engineered properly and free up more discretionary mass. For the T300, Max Impact is found in the 4-7 irons to again help with launch and speed and create proper set gapping.

Stock Shafts & Availability

Titleist has one of the largest available shaft matrices available through custom order, but the stock shafts for each model are as follows.

Steel

T100 – True Temper AMT Tour White AMT White

T200- True Temper AMT Black AMT Black

T300- True Temper AMT Red AMT Red

Graphite

This is a new one for Titleist. Just like with the original True Temper AMT, they will be the first to offer the Mitsubishi MCA Tensei AM2 (stands for ascending mass) shafts that will come in versions White, Blue, & Red.

T100 – Mitsubishi MCA Tensei White AM2 | Low launch, low spin | 94-108g (2g per club)

T200- Mitsubishi MCA Tensei Blue AM2 | Mid launch, mid spin | 74-88g (2g per club)

T300- Mitsubishi MCA Tensei Red AM2 | High launch, mid-high spin | 54-68g (2g per club)

T-SERIES AVAILABILITY: New Titleist T-Series irons will be available in golf shops worldwide beginning Aug. 30, with fittings beginning Aug. 8. With Pricing of the T100 and 200 set at $175 per club with steel ($1,399/set of 8) and $187.50 per club ($1,499 /set of 8) graphite

T300 will be $125 per club ($999/set of 8) Steel & $137.50 per club ($1,099/set of 8) graphite

- More photos of Titleist T100 irons in the forums.

- More photos of Titleist T200 irons in the forums.

- More photos of Titleist T300 irons in the forums.

- More photos (including cutaways) in the forums.

- LIKE141

- LEGIT12

- WOW7

- LOL9

- IDHT3

- FLOP7

- OB6

- SHANK63

Equipment

Coolest thing for sale in the GolfWRX Classifieds (4/23/24): TaylorMade Qi10 Driver Ruby Red

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a TaylorMade Qi10 Driver Ruby Red.

From the seller: (@Gehly): “TaylorMade Qi10 Driver 9.0 Designer Series Ruby Red. Custom Mitsubishi Kai’li Red 60s (stiff) shaft, plays 46”. Great condition, head near mint (see pics). w/ Red/Black Golf Pride NDMC Midsize grip. No headcover for it. $545“

To check out the full listing in our BST forum, head through the link: TaylorMade Qi10 Driver Ruby Red

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE0

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Sam Burns WITB 2024 (April)

- Sam Burns’ what’s in the bag accurate as of the RBC Heritage.

Driver: Callaway Paradym Triple Diamond S (9 degrees @10)

Shaft: Fujikura Ventus Blue 7 TX

3-wood: Callaway Paradym Ai Smoke Triple Diamond T (15 degrees @16)

Shaft: Fujikura Ventus Blue 8 X

Hybrid: Callaway Apex UW (21 degrees)

Shaft: Fujikura Ventus Blue 8 X

Irons: Callaway Apex TCB ’24 (4-AW)

Shafts: Project X 6.5 (4-PW), True Temper Dynamic Gold X100 Tour Issue (AW)

Wedges: Titleist Vokey Design SM10 (56-14F @55), WedgeWorks Proto (60-T)

Shafts: True Temper Dynamic Gold S400 Tour Issue (56, 60)

Putter: Odyssey Ai-One #7S

Grips: Golf Pride Tour Velvet Align

Ball: Callaway Chrome Tour X

Check out more in-hand photos of Sam Burns’ WITB in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Will Zalatoris WITB 2024 (April)

- Will Zalatoris’ what’s in the bag accurate as of the RBC Heritage.

Driver: Titleist TSR2 (9 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Black 7 X (44.5 inches)

3-wood: Titleist TSi2 (15 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 8 X

Irons: Titleist T350 (3), Titleist T150 (4-PW)

Shafts: Nippon N.S. Pro Prototype G.O.S.T. 10 ST X (3), True Temper Dynamic Gold Tour Issue X100 (4-PW)

Wedges: Titleist Vokey Design SM10 (50-08F, 54-10S @55, 60-04T)

Shafts: True Temper Dynamic Gold Tour Issue X100

Putter: L.A.B. Golf Mezz.1 Max

Grips: Golf Pride Z-Grip Cord

See more photos of Will Zalatoris’ WITB in the forums.

- LIKE4

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole1 day ago

19th Hole1 day ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole6 days ago

19th Hole6 days agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

Pingback: Best irons in golf of 2022: Easiest to launch – GolfWRX

B LANEY

Aug 19, 2019 at 4:24 pm

Do you guys have an editor? If not, please hire one. The spelling and grammar errors across the site are sloppy very unprofessional.

bill

Aug 19, 2019 at 3:20 pm

whats the offset?

Nate

Aug 19, 2019 at 2:06 pm

You negate the question, but then don’t answer it – WHY does Titleist use these ridiculous loft angles!? PSA to anyone at Titleist – I was actually getting into the idea of getting these T200s, but when I see these loft angles, I just think that you guys are trying to fool us into thinking our X iron goes further than the competition and that makes me really not want to get these. Is there a reasonable explanation why??

Aztec

Aug 17, 2019 at 1:55 am

These are UGLY…

s

Aug 8, 2019 at 5:10 pm

Now that PW is a 150yd club, we will need to buy 5-6 Vokey wedges to fill the gap. Way to go, Titleist!

Pelling

Aug 8, 2019 at 6:31 am

Junk.

Bing Hogan

Aug 8, 2019 at 10:20 am

Yep, and embarrassing to have in the bag.

Bobby

Aug 7, 2019 at 8:32 pm

The T300 will be in my bag ASAP. AP1s were great. If these are better, sign me up.

Bing Hogan

Aug 7, 2019 at 9:43 am

Time to have a PW distance contest

Robstercsi

Aug 7, 2019 at 5:16 am

See you’ve changed the spelling of ‘descent’ now – no thanks needed, and best wishes, Rob

Mark

Aug 7, 2019 at 2:05 am

Dear Mr. Barath,

I have an interest in golf club technology but possess limited knowledge. Given your extensive knowledge, please would you be so kind as to explain what the terms “tour performance” and “tour iron” mean.

Yours appreciatively,

Mark B.

Kansaslefty

Aug 7, 2019 at 12:25 am

No thanks

Spyy

Aug 6, 2019 at 11:03 pm

One ugly set of irons, a huge glob stuck in cavity’s…….pitiful loony

Chuckies In love

Aug 6, 2019 at 10:41 pm

Oh look!! Fashion irons, the penny loafer and tie bar on a stick!

Brent

Aug 6, 2019 at 10:38 pm

I’d be interested in AP1 irons this fall, but not the new T300s. Ryan, any idea if both sets will be available for custom orders for a few more months, or only the new irons?

DJ

Aug 6, 2019 at 8:54 pm

I want the T300 11* one iron

dat

Aug 6, 2019 at 8:47 pm

Hideous

Curt

Aug 6, 2019 at 8:29 pm

Cool clubs. To much technology. Should be banned on tour. I’ll never understand why pros are so spoiled. Be like the MLB finally allowing metal bats. Just making the sport easier and easier every day. Personally do not believe modern pros are any better and every record breaker needs an asterisk *****.

Scott

Aug 6, 2019 at 5:57 pm

Mizuno MP 20 release is 9/5

Cc Shop

Aug 6, 2019 at 5:04 pm

Much better look in person. Plus I couldn’t argue with results. Current 718 Ap2 are two degrees strong loft and I was getting nearly identical distance and spin numbers out of the T100 at its stock loft. If your an AP2 player give the New CB a strong look. A little higher spin for me but feel and forgiveness was outstanding.

JCGolf

Aug 6, 2019 at 2:15 pm

Changing descent angle from 43 degrees to 45 degrees is a 4.6% difference. Not a 2% difference.

BettiBoop

Aug 6, 2019 at 1:50 pm

Those have to be the ugliest irons I’ve seen in a long time. All of them are just plain ugly.

duke

Aug 6, 2019 at 11:39 am

Beautiful clubs and T100 for me. Wow 43* PW. OEM’s are on a “pw loft” competition.