When it comes to ferrules, there can be some custom option limitations. If you attempt to install the wrong size, it’s easy to have them break or be damaged beyond repair during the process. This video specifically addresses installing .355″ taper ferrules onto .370″ taper shafts while maintaining a snug fit and preventing creep.

- LIKE25

- LEGIT7

- WOW0

- LOL1

- IDHT1

- FLOP1

- OB1

- SHANK7

Instruction

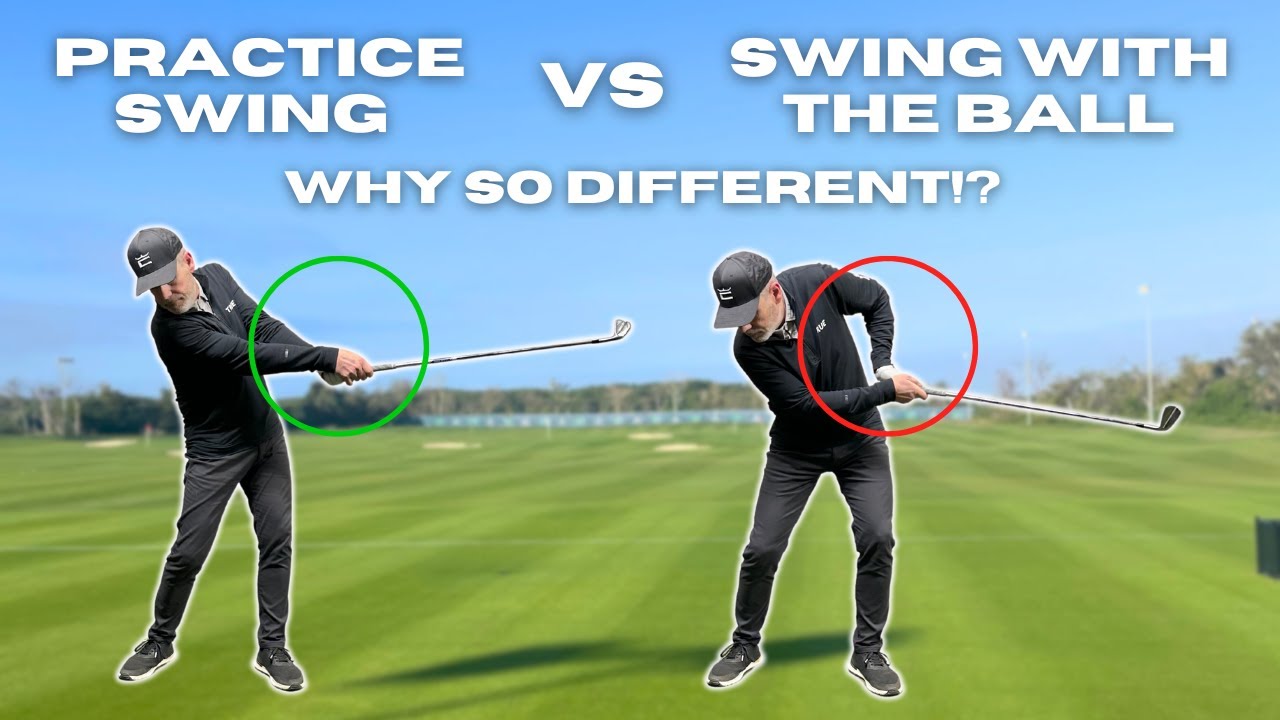

Clement: Why your practice swing never sucks

You hear that one all the time; I wish I could put my practice swing on the ball! We explain the huge importance of what to focus on to allow the ball to be perfectly in the way of your practice swing. Enjoy!

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK2

Equipment

Mitsubishi Diamana WB: Club Junkie takes a technology deep dive

Earlier this week, Mitsubishi announced the return of its iconic Whiteboard profile with the new Diamana WB shaft.

In our launch story, we offered a rundown of the key technology in the new WB — 80-ton Dialead pitch fiber, Aerospace-grade MR70 carbon fiber, Consistent Feel Design, and the Xlink Tech Resin System. To go deeper, however, we enlisted our Resident Club Junkie and bona fide shaft nut, Brian Knudson, to track down someone from Mitsubishi at the PGA Show. Fortunately, Mitsubishi’s Director of Global Aftermarket Sales, Jonathan Alongi, was on hand to answer all of BK’s questions.

Check out their discussion about the new WB, as well as the 20th anniversary of the original design, in the video above — time stamps of key points below, including a definitive answer as to how the surfboard graphic ended up on the original Whiteboard in 2004!

- :40 – Mitsubishi Japan expands to the U.S. in 2004

- :50 – “The shaft that set the standard”

- 1:12 – “The ‘board is back”

- 1:45 – WB or Whiteboard? Or both?

- 1:55 – The first iteration of the sixth generation of Diamana

- 2:10 – Incorporating key technology from a 20-year journey

- 3:10 – Modifying the tip section for more ball speed

- 3:50 – Delivering ball speed in a low-launch, low-spin shaft

- 4:20 – Drilling down on the shaft profile compared to the original Whiteboard

- 5:00 – The most impressive element of the new WB

- 5:30 – Butt, mid, tip specifications

- 6:00 – WB’s iconic graphics and the Diamana legacy — flowers, surfboard, numbering system

- 8:15 – An abundance of available weights and flexes

- 8:55 – More players going lightweight

Check out more photos and see what GolfWRXers are saying about Mitsubishi WB in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL1

- IDHT1

- FLOP0

- OB0

- SHANK0

Equipment

2024 Vokey SM10 wedges: Club Junkie’s full fitting video

Our Resident Club Junkie, Brian Knudson, goes through a wedge fitting with Chris Baingo, Titleist’s Club Fitting Analyst.

Get the full story on new SM10 wedges in our launch piece.

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP1

- OB0

- SHANK0

-

19th Hole6 days ago

19th Hole6 days agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

-

19th Hole7 days ago

19th Hole7 days agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 weeks ago

19th Hole2 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 day ago

19th Hole1 day agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoAddiction, spinal fusion, and scam artists – Everything Anthony Kim revealed in candid interview with David Feherty

-

19th Hole2 weeks ago

19th Hole2 weeks agoAnthony Kim says doctors told him that he ‘may not have much time left’ ahead of LIV return

-

19th Hole1 week ago

19th Hole1 week agoBrooks Koepka and Sergio Garcia make significant equipment changes as 2024 Masters looms

Andrew G

Jan 6, 2019 at 12:59 am

Wow – reached a new low. Unsafe and not even scratching the surface on the topic of preventing creep. Time for WRX to replace the so called ‘equipment experts’ with people who actually know about the topics and have extensive experience.

Mark Doel

Jan 3, 2019 at 6:06 pm

Show us how you turn down a furrule…

john curry

Jan 2, 2019 at 12:52 pm

Get a basic 3/8ths (.375) course rat tail file. Lock the file horizontally in a vice. Run the inside of the ferrule up and down on the file.

joro

Jan 2, 2019 at 12:16 pm

Or, you can just buy some proper size ferrules. The vast amount of ferrules are 370 irons and 335 woods.. This guy is tragic.

Scheiss

Jan 2, 2019 at 11:52 am

Just use proper fitting ferrules. Instead of lopping off the skin or my fingers like this. Got it.

I like having my fingers and the skin and beautiful nails on them.

Thanks

JuannyBravo

Jan 2, 2019 at 10:44 am

Really? Not even a glove while you handle a ferrule that has a reamer bit in it?

Just use some acetone and q-tips to “ream” out the ferrule and slide it onto the shaft. 2-3 passes and a .335 ferrule is now a .370. far safer than what you just did.

Tony

Jan 1, 2019 at 11:32 pm

That might have been the most unsafe thing I’ve ever seen advocated on WRX. Reaming out the ferrule with a high speed reamer – freehand. Can’t believe you would advocate doing something like that without protection. There was absolutely nothing between you and the drill bit. I ream out ferrules all the time, but you’ve got to protect your hands and fingers. One little slip off the ferrule and you could severely damage your fingers. Do what you like off camera, but some dolt is going to watch this, try it and end up missing his skin.

stan

Dec 31, 2018 at 3:22 pm

Just what I always wanted to know… happy new year, ferrule fitters

2putttom

Jan 1, 2019 at 4:31 pm

and happy new year to you