Opinion & Analysis

Hot Metal: The Risks and Rewards of Custom Putter Design

Let’s start off with a basic admission, a dirty little secret most golfers are unwilling to admit to. The putter you’re currently playing with day in and day out is no better or worse than any other.

Grab any putter, new or old, priced dirt cheap or sky-high and see if you can’t get the ball to drop into the bottom of the cup. Between reading the slope of the green, identifying the fault line, analyzing the grain of the grass, judging the pace and making a steady-handed stroke, the putting apparatus in your hands, while certainly not inconsequential to the result, is but a single factor that determines the number of strokes you take to hole out.

So imagine the kind of audacity I had arguing my point of view with Dave Billings, the President of Dogleg Right, better known as the inventor and designer of Machine Golf, one of the most highly respected boutique putter manufacturers in the industry. The conversation could’ve gone sideways in a hurry, but Billings let me off the hook; he’s got a Southern charm that makes you feel at ease. Plus, he’s been around long enough to have heard it all.

Billings has been tinkering with golf equipment since he was a teenager. The self-professed club junkie has been making significant contributions in putter design for the better part of two decades. His innovations have been awarded a dozen patents so far and his Machine putters have been coveted and purchased by die-hard enthusiasts at every conceivable level of the game. So while Billings didn’t agree with my claim that “any old putter will do,” he acknowledged that putters, more so than any other piece of equipment in golf, are judged primarily based on how they look and how they feel in the hands of a golfer standing over his or her ball.

“We’re finally seeing technologies that have come into play that allow us to get into more of the performance than in any time in the past,” says Billings. “It’s a little counterintuitive like a lot of things in golf. People say things like, ‘putting should be simple,’ or ‘I can putt with anything.’ But what we really know now is that a putter has a real impact on how you swing it. We see really remarkable results when we do it right — when we take the time to really get to know the golfer and figure out how to appeal to both the performance aspect and the visual aspect of their wants and needs.”

Machine Golf, while certainly not the only independent company specializing in custom milled putters, has perhaps more than anyone, come to embody the concept of made-to-order, or bespoke design. The company went into business in 1994 with very little seed money, a lot of big dreams and a successful product launch focused around an experimental putter that took the hands out of the equation.

“It started with something that was very innovative, something out of the box, namely the HOG putter,” says Billings. “The first ones were radical in their design. The head was oversized, almost as big as the MacGregor Response [ZT 615] was. The shaft and the grip were equally oversized. That innovative product looked like no other product, performed like no other product and got attention wherever we showed it. We started selling them very quickly in our first year, all around the world in fact.”

Machine putters, if you’re not familiar with them, are anything but run-of-the-mill. Imagine if someone had asked the surrealist painter H.R. Giger to submit a design, the end result might look like something that belongs in the Machine portfolio. A typical Machine putter is modular; the sheer number of customizable options is unmatched. Most Machine putters will incorporate at least some level of innovation, whether it’s adjustable weight and convertible flange technologies, unusual hosel and/or head designs, proprietary milling patterns and grip technologies. In some cases, the innovations lie exposed like a mechanical chassis, in other cases a more refined approach is used.

“We make a broad array of designs from the very classic-looking to those that can be described as being very technology-driven,” says Billings. “With one model we can say it’s more art because it’s Damascus (steel) and it’s a real traditional head. But when you look at the interchangeable flanges and weights, and the internal milling — that’s more about the science. I try to have a balance between those things and it’s a push and pull in different directions for different customers.”

Machine putters aren’t for everyone; perhaps that’s true of customizable putters in general. The sheer number of options that can be adjusted can be overwhelming to comprehend. What Billings, as well as other putter designers were able to impress upon me is that even the slightest change, say for instance the type of hosel used or its offset, can have significant impact on how a putter will swing. So while anything can be used for the purposes of putting, not every putter (certainly not the kind that are randomly chosen off the rack) are a good match for their respective owners, says Billings.

“There’s a lot of pride in being able to buy something that’s handmade as opposed to mass-produced,” he adds. “I think there’s a big draw for that, especially when [a golfer] can become part creator and contribute to what at the very least is a customized product.”

What I’ve come to recognize about the custom milled putter business from speaking to Billings is that it’s a fellowship of gear heads who risk everything in a pursuit to transform metal into art.

“For anyone who goes into the boutique putter business,” says Billings, “it’s a labor of love. You have to put in the hours, the blood, sweat and tears. There’s not necessarily a pot of gold at the end of the rainbow.”

The kind of hand-crafted putter design that Billings and his contemporaries are engaged in is a fringe business within the putter market, which in itself vies for a tiny fraction of the total dollars spent every year on golf equipment.

So how big, or rather, how small is the pie?

- The two largest golf markets in the world, the United States and Japan, netted a combined $8.8 billion in equipment and apparel sales in 2013 according to a World Golf Market Report released jointly by Golf Datatech and Yano Research Institute.

- Out of the total cited above, only 3.3 percent came from putter sales in the U.S. ($173 million) and 2.6 percent in Japan ($98 million) respectfully.

- If that isn’t sobering enough, putter sales declined by 8 percent in the U.S. in 2013 and 18 percent in Japan. That’s no hiccup. Since 1997, unit sales of putters at big box stores and green grass shops have declined by nearly 42 percent.

Market conditions would appear to suggest that the custom-milled putter is an endangered species. But that hasn’t stopped craftsmen like Machine, Bettinardi, Byron Morgan, Edel and Bobby Grace from competing with the larger OEMs, many of which are producing less expensive cast molded putters.

Joining them within the last few years are a vast number of independent designers; companies such as Low Tide, Piretti, Nead, Bellum Winmore, Carnahan, Carbon, Buzelli and BPutters.

So what convinces these golf enthusiasts to sacrifice time, money and occasionally their common sense to pursue an expensive hobby with no guarantees of success? I looked to Italy for the answers.

Born For The Big Shot

It takes a certain leap of faith to order a putter over the Internet, from a designer overseas, someone just getting started in the golf industry. Sure, I had seen some sample photos online and I had a few terse conversations (over email) with the owner of BPutters, Antonio Biagioli. My hopes were high. Luckily, the model that arrived from Cesena, a town near the eastern coast of Italy and a two-hour drive from Florence, was a real beauty; or as they in Italian, molto bella.

My model, coined the Coyote by Biagioli, was almost too delicate to wield. That is to say, I didn’t want to leave a smudge on the reflective black pearl finish or wrap my hands clumsily around the refined leather pistol grip with raised stitching running across the spine. Biagioli designed the putter to closely match the specs of my Scotty Cameron Del Mar. Four degrees of loft, 34 inches in length and 350 grams of weight in the head. For what it’s worth, the Coyote felt much heavier. Something about it was quintessentially Italian; perhaps it was the clean lines, the feminine-like curves or simply the handcrafted feel.

Italy, as you might imagine, doesn’t have a strong golfing tradition. Biagioli estimates that there might be 80,000 golfers in his country, a number that is actually contracting. Like many Italians, Biagioli grew up playing football and knew nothing about the game until he was dragged to a golf course in Ireland on a business trip almost 20 years ago. He fell in love with golf immediately but his subsequent adventure as a putter designer took a long time to plan and execute.

Biagioli has been working in the automotive industry for most of his life, primarily as an executive manager where he coordinates between suppliers and producers — a boring job as he chooses to put it. Boring though it may have been, the job gave Biagioli a chance to study engineering first hand.

“I started to work closely with the engineers and see the production happen on a daily basis,” says Biagioli. “We work on transmissions and power steering, both hydraulic and mechanical, so we have a lot of work with metals. From that I started to take little pieces at a time and began learning about how suppliers finish metals, how they actually mill metal. It became kind of a second job for me.”

While continuing to work in the automotive industry, Biagioli launched BPutters about year and half ago, combining his love of art, engineering and of course golf.

“I’ve always been intrigued by putters because of the intimacy of their use,” says Biagioli. “I’ve always felt that putters are something so personal compared to a driver or an iron that you carry in your bag.”

He came out with four models initially. One of them, the Hammer, looks like a traditional blade-style putter, the others are adaptations of a mallet design. To come up with these designs, Biagioli says he began sketching on paper.

“I go through at least three or four phases before I can prototype a 3D model of the putter,” he says. “I use a very simple 3D printer to get an initial perspective of the putter itself. It’s a plastic model that ends up becoming a steel prototype.

“That is probably the longest process because you have to program a CNC machine,” he adds. “It’s not that easy and I do have a professional CNC programmer working with me on this project. Once we have a prototype, we test it many times. We make adjustments to the weight distribution, adjust the shape and try to decide which finish can be applied to that model. It’s another three weeks just to test finishes. If we’re talking about carbon steel, it takes more than a month.”

Aside from his role in designing putters and managing the production line, Biagioli spends his remaining time promoting his brand. If you think it’s difficult for an American putter craftsman to breakthrough in the U.S., try doing it from a far-flung town in Italy. Undaunted, Biagioli has learned how to leverage social media. Many of his posts are tagged with his signature motto — born for the big shot. They feature plenty of product shots of course, but Biagioli has also posted many candid shots of himself, his home in Italy and has made some genuine friendships with golfers over the Internet.

His social media strategy (if you want to call it that) complements the sincere approach he takes to running his small business.

“I don’t want to sell putters in bulk,” Biagioli says. “I just want to sell the right putter to the right person. To establish that sort of a relationship with a customer — I see it as a privilege.”

It’s unclear whether BPutters will have the staying power to succeed. Biagioli tells me that the response from the golf community has been overwhelmingly positive so far. He’s made some in-roads selling to the Asian and Western European markets. Orders from America have also starting trickling in.

“I still have a lot of things to learn,” says Biagioli. “But at the same time I very much enjoy it. Otherwise it would be absolutely impossible for me to do both my job and what will hopefully become my full time activity in the future. I know the entire golf industry is not doing well over the last few years. But I’m taking this as an opportunity to do something that I feel is really important.”

The Scotty Cameron Effect

Unfortunately I can’t take credit for the phrase. That distinction belongs to Golf Digest Equipment Editor, Mike Stachura, who used it to describe how a single putter designer was both able to hold significant market share, while enabling other designers to raise their prices exponentially to keep up in a sort of arms race.

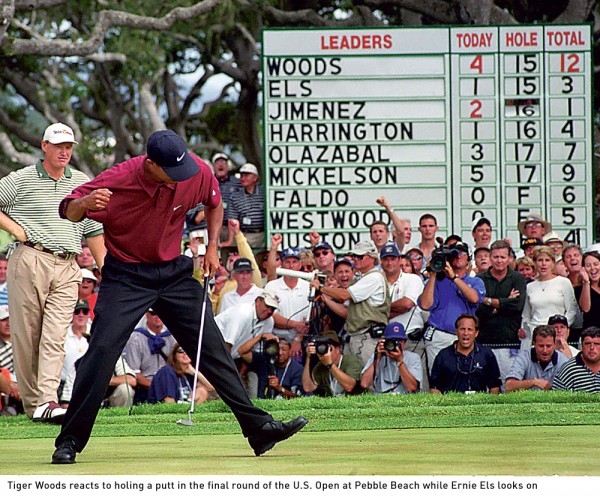

First and foremost, Scotty Cameron deserves his due — he makes fine putters. But it would be hard to deny, even for a casual observer, that Cameron benefited greatly from the many relationships he’s had with PGA Tour superstars over the years, including Tiger Woods who used a Newport 2 prototype for most of his career. Concerning the price of his putters, even Cameron at one time admitted to Golf Digest, “The price points on my putters are relatively high, but you aren’t just buying performance. You’re buying confidence. It’s human nature to have greater faith in something you’ve paid a premium for.”

Tim Shaughnessy, co-owner of Bellum Winmore, a tiny start-up that launched only a year ago, says “Certain manufacturers have pushed that increase. Scotty Cameron has a kind of rockstar status. And at some level Bettinardi has kind of the same thing. I think the more press individual manufacturers receive and as their status increases, it ends up driving the overall cost in the market for putters.”

Shaughnessy and his partner Zac Nicholls, who live on opposite ends of the coast and are lifelong friends and golfers, went into business together with a simple idea: release a quality milled putter at a price everyone can afford.

“We tried not to be in the same realm as say a Byron Morgan who is doing a lot of stamping, Damascus and exotic stuff,” says Shaughnessy. “We weren’t going to be able to compete if we were out there for $350. We don’t have the brand recognition.”

Shaughnessy’s company focuses on three basic things: design, material and process. All Bellum Winmore putters are precision milled from a single block of 303 stainless steel and then bead blasted to a matte finish. There isn’t much variance from model to model, but Bellum Winmore does provide limited finish options, and a wide range of grip weights (10 grams to 100 grams), offering what Shaughnessy feels are the most custom back weighted options of any company out there.

“Our overhead is negligible — almost nothing,” says Shaughnessy, when asked about keeping his price points so low. “I handle everything from a design standpoint to the assemblies, the painting, customer service and anything else from New York. Zac focuses on machining and prototyping [in California] and we have an overseas facility that does the production.”

The one common denominator for companies like Bellum Winmore and BPutters is the Internet. While I’m not suggesting that the Web, more specifically social media, has allowed individual putter designers to take on Scotty Cameron and companies of that size directly, it has at least allowed them to co-exist in the industry. Billings, who launched Machine Golf back when dial-up was considered high-tech, believes that entering the marketplace is easier now, but it’s far from a cakewalk.

“The Internet has definitely lowered the barrier,” says Billings. “You don’t have to have sales reps to take your putters to the local golf shops. On the other hand, most people still want to look, feel and try before they buy. So making that switch from over the Internet to traditional retail is a bigger barrier now because there are less golf shops that want to pioneer a new brand.

“Twenty years ago you had great guys like Edwin Watts who always liked to bring in something new and put it in their catalog or over the Internet before any of the smaller companies even knew how to make a good website,” he continues. “We had great guys like that who would get your brand distributed across the country or even around the world. You don’t see much of that anymore; the big companies just don’t want to gamble on smaller brands for a lot of the obvious reasons. It’s kind of sad that it’s gone away because it can be a great shot in the arm for a small company to be able to partner with them and receive a lot of exposure.”

The one thing everyone I spoke to tended to agree upon is that differentiation is the key to survival when operating in a niche market. If your product fails to connect with a core audience, you won’t be in business for very long. And when it comes to golf equipment, putting attracts the most diverse, passionate and opinionated connoisseurs in all of golf.

“On one end of the spectrum, you’ve got the guy who’s so proud to have found a putter out of a barrel that he paid five bucks for and makes everything with it,” says Billings. “On the other end you have someone like Arnold Palmer who’s had 5,000 putters. Let’s just say it — it’s a chase for the next magical wand. It’s part of the fun and adventure of getting a new club and discovering what it might mean to your game.”

- LIKE8

- LEGIT5

- WOW2

- LOL1

- IDHT1

- FLOP3

- OB2

- SHANK4

19th Hole

Vincenzi’s 2024 Zurich Classic of New Orleans betting preview

The PGA TOUR heads to New Orleans to play the 2023 Zurich Classic of New Orleans. In a welcome change from the usual stroke play, the Zurich Classic is a team event. On Thursday and Saturday, the teams play best ball, and on Friday and Sunday the teams play alternate shot.

TPC Louisiana is a par 72 that measures 7,425 yards. The course features some short par 4s and plenty of water and bunkers, which makes for a lot of exciting risk/reward scenarios for competitors. Pete Dye designed the course in 2004 specifically for the Zurich Classic, although the event didn’t make its debut until 2007 because of Hurricane Katrina.

Coming off of the Masters and a signature event in consecutive weeks, the field this week is a step down, and understandably so. Many of the world’s top players will be using this time to rest after a busy stretch.

However, there are some interesting teams this season with some stars making surprise appearances in the team event. Some notable teams include Patrick Cantlay and Xander Schauffele, Rory McIlroy and Shane Lowry, Collin Morikawa and Kurt Kitayama, Will Zalatoris and Sahith Theegala as well as a few Canadian teams, Nick Taylor and Adam Hadwin and Taylor Pendrith and Corey Conners.

Past Winners at TPC Louisiana

- 2023: Riley/Hardy (-30)

- 2022: Cantlay/Schauffele (-29)

- 2021: Leishman/Smith (-20)

- 2019: Palmer/Rahm (-26)

- 2018: Horschel/Piercy (-22)

- 2017: Blixt/Smith (-27)

2024 Zurich Classic of New Orleans Picks

Tom Hoge/Maverick McNealy +2500 (DraftKings)

Tom Hoge is coming off of a solid T18 finish at the RBC Heritage and finished T13 at last year’s Zurich Classic alongside Harris English.

This season, Hoge is having one of his best years on Tour in terms of Strokes Gained: Approach. In his last 24 rounds, the only player to top him on the category is Scottie Scheffler. Hoge has been solid on Pete Dye designs, ranking 28th in the field over his past 36 rounds.

McNealy is also having a solid season. He’s finished T6 at the Waste Management Phoenix Open and T9 at the PLAYERS Championship. He recently started working with world renowned swing coach, Butch Harmon, and its seemingly paid dividends in 2024.

Keith Mitchell/Joel Dahmen +4000 (DraftKings)

Keith Mitchell is having a fantastic season, finishing in the top-20 of five of his past seven starts on Tour. Most recently, Mitchell finished T14 at the Valero Texas Open and gained a whopping 6.0 strokes off the tee. He finished 6th at last year’s Zurich Classic.

Joel Dahmen is having a resurgent year and has been dialed in with his irons. He also has a T11 finish at the PLAYERS Championship at TPC Sawgrass which is another Pete Dye track. With Mitchell’s length and Dahmen’s ability to put it close with his short irons, the Mitchell/Dahmen combination will be dangerous this week.

Taylor Moore/Matt NeSmith +6500 (DraftKings)

Taylor Moore has quickly developed into one of the more consistent players on Tour. He’s finished in the top-20 in three of his past four starts, including a very impressive showing at The Masters, finishing T20. He’s also finished T4 at this event in consecutive seasons alongside Matt NeSmith.

NeSmith isn’t having a great 2024, but has seemed to elevate his game in this format. He finished T26 at Pete Dye’s TPC Sawgrass, which gives the 30-year-old something to build off of. NeSmith is also a great putter on Bermudagrass, which could help elevate Moore’s ball striking prowess.

- LIKE6

- LEGIT2

- WOW1

- LOL0

- IDHT0

- FLOP3

- OB1

- SHANK1

19th Hole

Vincenzi’s 2024 LIV Adelaide betting preview: Cam Smith ready for big week down under

After having four of the top twelve players on the leaderboard at The Masters, LIV Golf is set for their fifth event of the season: LIV Adelaide.

For both LIV fans and golf fans in Australia, LIV Adelaide is one of the most anticipated events of the year. With 35,000 people expected to attend each day of the tournament, the Grange Golf Club will be crawling with fans who are passionate about the sport of golf. The 12th hole, better known as “the watering hole”, is sure to have the rowdiest of the fans cheering after a long day of drinking some Leishman Lager.

The Grange Golf Club is a par-72 that measures 6,946 yards. The course features minimal resistance, as golfers went extremely low last season. In 2023, Talor Gooch shot consecutive rounds of 62 on Thursday and Friday, giving himself a gigantic cushion heading into championship Sunday. Things got tight for a while, but in the end, the Oklahoma State product was able to hold off The Crushers’ Anirban Lahiri for a three-shot victory.

The Four Aces won the team competition with the Range Goats finishing second.

*All Images Courtesy of LIV Golf*

Past Winners at LIV Adelaide

- 2023: Talor Gooch (-19)

Stat Leaders Through LIV Miami

Green in Regulation

- Richard Bland

- Jon Rahm

- Paul Casey

Fairways Hit

- Abraham Ancer

- Graeme McDowell

- Henrik Stenson

Driving Distance

- Bryson DeChambeau

- Joaquin Niemann

- Dean Burmester

Putting

- Cameron Smith

- Louis Oosthuizen

- Matt Jones

2024 LIV Adelaide Picks

Cameron Smith +1400 (DraftKings)

When I pulled up the odds for LIV Adelaide, I was more than a little surprised to see multiple golfers listed ahead of Cameron Smith on the betting board. A few starts ago, Cam finished runner-up at LIV Hong Kong, which is a golf course that absolutely suits his eye. Augusta National in another course that Smith could roll out of bed and finish in the top-ten at, and he did so two weeks ago at The Masters, finishing T6.

At Augusta, he gained strokes on the field on approach, off the tee (slightly), and of course, around the green and putting. Smith able to get in the mix at a major championship despite coming into the week feeling under the weather tells me that his game is once again rounding into form.

The Grange Golf Club is another course that undoubtedly suits the Australian. Smith is obviously incredibly comfortable playing in front of the Aussie faithful and has won three Australian PGA Championship’s. The course is very short and will allow Smith to play conservative off the tee, mitigating his most glaring weakness. With birdies available all over the golf course, there’s a chance the event turns into a putting contest, and there’s no one on the planet I’d rather have in one of those than Cam Smith.

Louis Oosthuizen +2200 (DraftKings)

Louis Oosthuizen has simply been one of the best players on LIV in the 2024 seas0n. The South African has finished in the top-10 on the LIV leaderboard in three of his five starts, with his best coming in Jeddah, where he finished T2. Perhaps more impressively, Oosthuizen finished T7 at LIV Miami, which took place at Doral’s “Blue Monster”, an absolutely massive golf course. Given that Louis is on the shorter side in terms of distance off the tee, his ability to play well in Miami shows how dialed he is with the irons this season.

In addition to the LIV finishes, Oosthuizen won back-to-back starts on the DP World Tour in December at the Alfred Dunhill Championship and the Mauritus Open. He also finished runner-up at the end of February in the International Series Oman. The 41-year-old has been one of the most consistent performers of 2024, regardless of tour.

For the season, Louis ranks 4th on LIV in birdies made, T9 in fairways hit and first in putting. He ranks 32nd in driving distance, but that won’t be an issue at this short course. Last season, he finished T11 at the event, but was in decent position going into the final round but fell back after shooting 70 while the rest of the field went low. This season, Oosthuizen comes into the event in peak form, and the course should be a perfect fit for his smooth swing and hot putter this week.

- LIKE10

- LEGIT3

- WOW0

- LOL1

- IDHT0

- FLOP1

- OB1

- SHANK1

Opinion & Analysis

The Wedge Guy: What really makes a wedge work? Part 1

Of all the clubs in our bags, wedges are almost always the simplest in construction and, therefore, the easiest to analyze what might make one work differently from another if you know what to look for.

Wedges are a lot less mysterious than drivers, of course, as the major brands are working with a lot of “pixie dust” inside these modern marvels. That’s carrying over more to irons now, with so many new models featuring internal multi-material technologies, and almost all of them having a “badge” or insert in the back to allow more complex graphics while hiding the actual distribution of mass.

But when it comes to wedges, most on the market today are still single pieces of molded steel, either cast or forged into that shape. So, if you look closely at where the mass is distributed, it’s pretty clear how that wedge is going to perform.

To start, because of their wider soles, the majority of the mass of almost any wedge is along the bottom third of the clubhead. So, the best wedge shots are always those hit between the 2nd and 5th grooves so that more mass is directly behind that impact. Elite tour professionals practice incessantly to learn to do that consistently, wearing out a spot about the size of a penny right there. If impact moves higher than that, the face is dramatically thinner, so smash factor is compromised significantly, which reduces the overall distance the ball will fly.

Every one of us, tour players included, knows that maddening shot that we feel a bit high on the face and it doesn’t go anywhere, it’s not your fault.

If your wedges show a wear pattern the size of a silver dollar, and centered above the 3rd or 4th groove, you are not getting anywhere near the same performance from shot to shot. Robot testing proves impact even two to three grooves higher in the face can cause distance loss of up to 35 to 55 feet with modern ‘tour design’ wedges.

In addition, as impact moves above the center of mass, the golf club principle of gear effect causes the ball to fly higher with less spin. Think of modern drivers for a minute. The “holy grail” of driving is high launch and low spin, and the driver engineers are pulling out all stops to get the mass as low in the clubhead as possible to optimize this combination.

Where is all the mass in your wedges? Low. So, disregarding the higher lofts, wedges “want” to launch the ball high with low spin – exactly the opposite of what good wedge play requires penetrating ball flight with high spin.

While almost all major brand wedges have begun putting a tiny bit more thickness in the top portion of the clubhead, conventional and modern ‘tour design’ wedges perform pretty much like they always have. Elite players learn to hit those crisp, spinny penetrating wedge shots by spending lots of practice time learning to consistently make contact low in the face.

So, what about grooves and face texture?

Grooves on any club can only do so much, and no one has any material advantage here. The USGA tightly defines what we manufacturers can do with grooves and face texture, and modern manufacturing techniques allow all of us to push those limits ever closer. And we all do. End of story.

Then there’s the topic of bounce and grinds, the most complex and confusing part of the wedge formula. Many top brands offer a complex array of sole configurations, all of them admittedly specialized to a particular kind of lie or turf conditions, and/or a particular divot pattern.

But if you don’t play the same turf all the time, and make the same size divot on every swing, how would you ever figure this out?

The only way is to take any wedge you are considering and play it a few rounds, hitting all the shots you face and observing the results. There’s simply no other way.

So, hopefully this will inspire a lively conversation in our comments section, and I’ll chime in to answer any questions you might have.

And next week, I’ll dive into the rest of the wedge formula. Yes, shafts, grips and specifications are essential, too.

- LIKE32

- LEGIT7

- WOW1

- LOL1

- IDHT2

- FLOP3

- OB1

- SHANK3

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole1 day ago

19th Hole1 day ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole6 days ago

19th Hole6 days agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

Pingback: The Risks and Rewards of Putter Design | Rusty Cage | Writer and Golfer

Pingback: The Risks and Rewards of Custom Putter Design | Rusty Cage | Writer and Golfer

Preston

Jan 11, 2015 at 11:30 am

Excuse my ignorance, but couldn’t someone that has access to CAD and a milling machine make their own putter? Just dial up the design and feed it to the computer. It then runs the program.

Kyle

Jan 21, 2015 at 7:23 pm

Preston,

The short answer is: Yes, it is possible for someone with CAD and a CNC machine to be able to mill out their own putter.

*However* It is that it is much more complicated than you are probably imagining. You need to have expertise in CAD design, CNC programming, as well as machining in order to produce a retail-ready product. It is definitely much more difficult than just feeding your CAD model to your CNC machine to cut out for you.

Joey

Jan 9, 2015 at 11:14 pm

Sounds like he’s trying to talk out of it all the little guys, start-ups, dreamers that are popping up more and more now.

Lancebp

Jan 9, 2015 at 7:05 pm

I’d bet serious money that if every golfer were required to pick a putter the first week he starts playing and then prohibited under penalty of death from ever changing that putter again, 99.8% of golfers would now be better putters than they are. For that matter, require every golfer on the planet to use an original Ping Anser, and 99.8% would be better putters than they are.

dr bloor

Jan 9, 2015 at 3:54 pm

The putters are gorgeous and the ability to produce so many variations is impressive, but I’d be interested in reading more about how the fitting process for the respective companies is carried out without actually seeing the client putt. I don’t think you can actually call a putter “custom made” if the specs are dependent on something equivalent to static fitting for a driver or set of irons.

rymail00

Jan 9, 2015 at 2:24 pm

Good article Rusty Cage. It’s unfortunate that a few members always try to tear down just about every article that’s written. Usually the people that do try that usually really have no idea WTF they talking about.

JEFF

Jan 9, 2015 at 1:14 pm

The tool author was charmed by a man?

david

Jan 9, 2015 at 12:01 pm

PT Barnum: sucker born every minute! Most of the best putters were from yesteryear, (Ben Crenshaw, Jack, Bob Locke, Loren Roberts, Stockton; all using old technology and 10 dollar putters. Putting is after green reading, confidence. I laugh when people spend 300 bucks on a putter. Having said that, if that’s waht it takes for you to get confidence that lasts, then spend the 350, it’s worth it. My 5 dollar garage sale special is my friend and I’m an awesome putter.

DMR

Jan 9, 2015 at 4:24 pm

Cool story, bro. Clearly Rusty covered that not everyone needs a custom milled putter. I’m sure that even you would benefit from purchasing a new putter but I do envy you confidence in your putting game.

DaveT

Jan 9, 2015 at 11:46 am

“Identifying the fault line”?!? Do you expect an earthquake to affect your putt?

Rusty Cage

Jan 9, 2015 at 12:09 pm

More about the fault line:

http://golfclubatlas.com/forum/index.php?topic=16149.10;wap2

Hopefully you got something more out of the article than simply picking apart a single obscure reference that you don’t know much about.

DaveT

Jan 9, 2015 at 5:59 pm

Oh, I understand it just fine. I didn’t recognize the mistaken reference. In the link in your reply, DMoriarty gets it right. You meant “fall line”.

sgniwder99

Jan 9, 2015 at 8:21 pm

So…that would be a no, then.

Tom

Jan 9, 2015 at 10:36 am

I own a Bellum Winmore. The company really is awesome. One thing I really liked about them was how important it was to Tim to make sure that my putter was perfect for me and had what I wanted on it rather than it just be an off the rack kind of putter.

Jason

Jan 9, 2015 at 3:44 pm

I also have a Winmore and love it. Great people to deal with and Tim worked with me for 2 hrs finding the perfect fit for me. Great look, feel, and performance of anything out there.