Equipment

Inside Titleist’s Golf Ball Facilities

You want to know what a Titleist golf ball plant smells like? Rubber. Want to know what a Titleist golf ball customization plant smells like? Paint.

If you’re wondering anything else — like how Titleist designs and builds its golf balls, how a ball’s core is constructed or what role ball compression really plays — come with me on this journey as I relay my knowledge and experiences from my visit to Titleist’s golf ball facilities.

What’s it like there?

Let’s put it this way, Titleist’s research and design team are possibly the most over-qualified chefs in the world. Biochemists and chemical engineers develop formulas for ingredients with painful precision, and have access to a three-story, factory-style kitchen to cook up golf balls that sell like hot cakes — something to the tune of 240,000 Pro V1 and Pro V1x’s each day.

Ball Plant III (yes, there’s more than one in Massachusetts and another in Thailand) has a rubber mixer that’s taller than three basketball hoops stacked atop one another. It has top-secret rooms that aren’t to be photographed, X-ray machines, automated everything and a terrifying robotic guillotine that slices huge blocks of rubber.

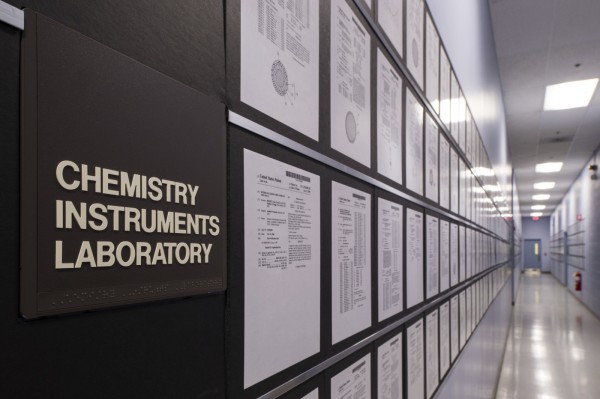

Its R&D facility has a room full of its competitors’ golf balls — pretty much every golf ball ever made, just to keep an eye on the competition — laboratories everywhere and hallways of patent plaques that act as Titleist’s own golf ball hall of fame.

Titleist has over 1,000 patents, the most of any golf ball company, and owns 47 percent of all patents on golf balls.

Just down the road from Titleist’s corporate headquarters in Fairhaven, Mass., is Ball Plant III, where its golf balls are made, as well as Plant C, where Titleist golf balls receive personalized touches.

So what’s it like at Ball Plant III and Plant C? Before I get to that, I’ll start from the beginning.

Chasing perfection

I stood on No. 18 green at New Bedford Country Club, putter and golf ball in-hand, waiting my turn to try the putt that started it all.

The story goes like this.

Acushnet Company founder Phil Young, who was an amateur golfer and owner of a precision molded rubber company at the time, was playing golf one Sunday in the early 1930’s at New Bedford CC. His foursome included Dr. Bonner, head of the x-ray department at St. Luke’s Hospital in New Bedford.

Young was considered a good player, but he was all over the course that day — hitting hooks and slices, struggling mightily to control his ball. On No. 18, however, he had a putt to win the match. Despite a good stroke, the ball rolled offline and missed the hole. While squaring away his bets from the match, Young claimed there was something wrong with his golf ball, not his game.

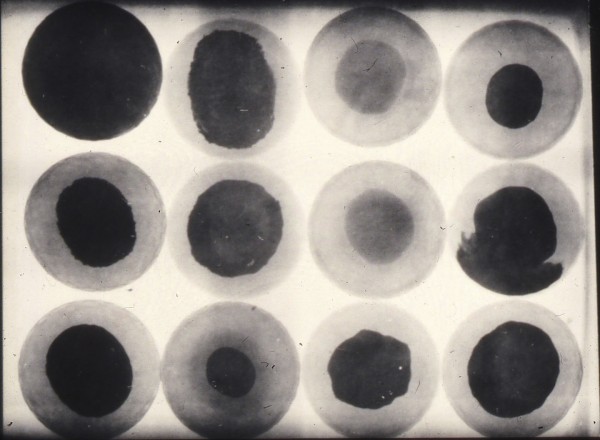

The argument got heated, and Young convinced Dr. Bonner to go to St. Luke’s Hospital and put his golf ball under the X-ray machine. It turned out Young was right — the exterior of the golf ball was round, but the core was way off center.

Young and Bonner returned to the pro shop and convinced the club professional to let them put a dozen balls of every model under the x-ray machine. Sure enough, every ball had an unbalanced core, some worse than others.

This discovery set a fire under Young, who set his mind to developing a truly balanced golf ball. It took nearly three years — in the midst of the Great Depression, mind you — to get a ball that was ready for the golf course. But when he did, he had built golf’s first, perfectly balanced golf ball.

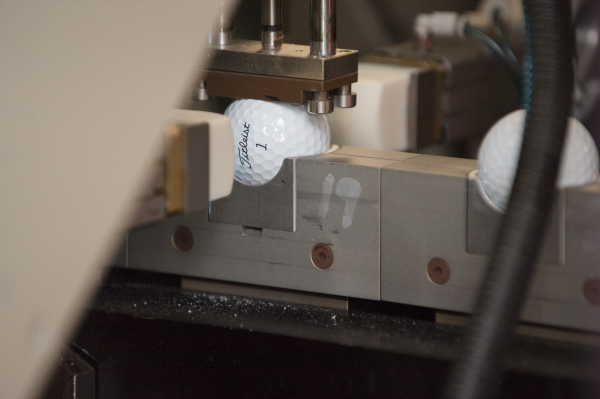

Today, more than 80 years later, quality standards are still paramount with Titleist golf balls. Each Pro V1 goes through more than 90 quality checks, and each Pro V1x, because of its dual core, undergoes over 120 quality checks. And, sticking to it’s roots, every Titleist ball passes through an X-ray machine before it’s retail-ready.

With that said, I did miss my 6-foot putt on No. 18 at New Bedford CC with a new Pro V1x. Titleist balls have been much improved in the 80 years since Phil Young missed the putt that started it all, but it still takes a good stroke to knock a 6-footer in the hole.

Ball Plant III: The Mecca

Now for the fun stuff. Join me on a tour of Ball Plant III, where I saw Pro V1 and Pro V1x golf balls get built from scratch.

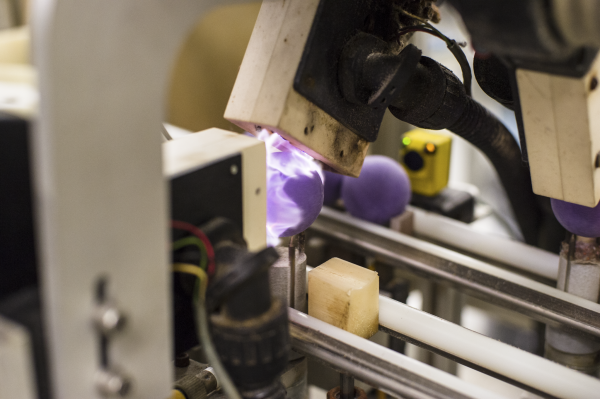

Core’s for Titleist Pro V1 golf balls being automatically transported to undergo the next step in the process.

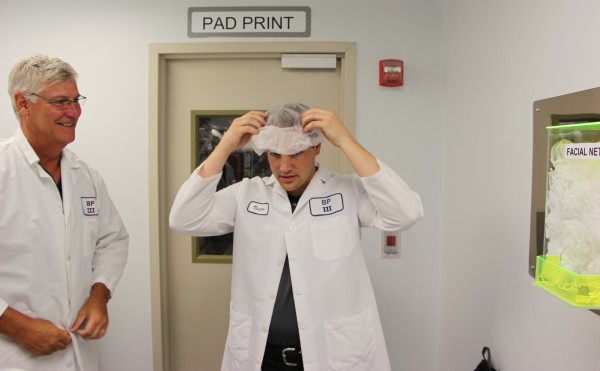

Managing Editor Zak Kozuchowski preparing to enter the PAD Print room. It gets messy, plus Titleist didn’t want our hair to get in the paint!

Before adding print onto the balls, employees use a magnifying glass to manually ensure there’s no imperfections.

Sticking to its roots, Titleist puts every ball through an X-ray before it gets ready for packaging.

The Custom Plant

At the custom plant, employees sit at golf ball stamping machines and exhibit ninja-like hand-eye coordination. You can see below just how fast one of the factory workers moves her hands, changing golf balls in and out to get fresh stampings.

Golf balls with logos, sports teams, organizations, names and sayings lay around the custom plant by the hundreds of thousands. This batch of Titleist Pro V1X No. 7’s read “Junkyard Dog.”

5 Minutes, Max

That concludes our tour of Titleist’s golf ball facilities. If you’re like me, you now have a new appreciation of what it takes to make a premium golf ball. Remember, the rules of golf only permit you to search for 5 minutes before a ball is deemed “lost” — even if it’s a Pro V1.

Complete Photo Gallery

- LIKE280

- LEGIT65

- WOW56

- LOL3

- IDHT4

- FLOP5

- OB4

- SHANK8

Whats in the Bag

Daniel Berger WITB 2024 (April)

- Daniel Berger what’s in the bag accurate as of the Farmers Insurance Open. More photos from the event here.

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Fujikura Ventus Black 7 X

6-wood: TaylorMade Qi10 Tour (21 degrees)

Shaft: Fujikura Ventus Black 8 X

Irons: TaylorMade P770 (3), TaylorMade Tour Preferred MC 2011 (4-PW)

Shafts: Project X Denali Blue 105 TX (3), Project X 6.5 (4-PW)

Wedges: Titleist Vokey Design SM9 (50-12F), Titleist Vokey Design SM10 (56-14F), Callaway Jaws Raw (60-08C)

Shafts: Project X 6.5 (50), True Temper Dynamic Gold Tour Issue S400 (56, 60)

Putter: Odyssey Ai-One Jailbird Mini DB

Grip: SuperStroke Zenergy PistolLock 1.0

Grips: Golf Pride Tour Wrap

Ball: Titleist Pro V1

Check out more in-hand photos of Daniel Berger’s clubs in the forums.

- LIKE3

- LEGIT0

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB1

- SHANK0

Equipment

Heavy Artillery: A look at drivers in play at the Zurich Classic of New Orleans

What are the driver and shaft combinations of the best golfers in the world? For gearheads, it’s an endlessly interesting question — even if we can only ever aspire to play LS heads and 7 TX shafts.

At this week’s Zurich Classic of New Orleans, GolfWRX got in-hand looks at the driver setups of a wealth of players.

Check out some of the most interesting combos below, then head to the GolfWRX forums for the rest, as well as the rest of our galleries from New Orleans.

Rory McIlroy

Driver: TaylorMade Qi10 (9 degrees @8.25)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride MCC

Alex Fitzpatrick

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride MCC

Daniel Berger

Driver: Ping G430 LST (10.5 degrees @9)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride Tour Wrap

Rasmus Hojgaard

Driver: Callaway Paradym Ai Smoke Triple Diamond (10.5 degrees)

Shaft: Mitsubishi Tensei 1K Blue 60 TX

Grip: Golf Pride MCC

Alejandro Tosti

Driver: Srixon ZX5 Mk II LS (9.5 degrees @10.5)

Shaft: Project X HZRDUS T1100 75 6.5

Grip: Golf Pride MCC Plus4

James Nicholas

Driver: Titleist TSR3 (8 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 7 X

Grip: Golf Pride Tour Velvet

Kevin Streelman

Driver: Titleist TSR3 (10 degrees, D1 SureFit setting)

Shaft: Fujikura Ventus TR Black 6 X

Grip: Golf Pride Tour Velvet

Sang-moon Bae

Driver: Callaway Paradym Triple Diamond (9+ @8)

Shaft: Fujikura Ventus Blue 6 X

Grip: Golf Pride Tour Velvet

Russ Cochran

Driver: Callaway Paradym Ai Smoke (9 degrees)

Shaft: Graphite Design Tour AD TP 6 X

Grip: Golf pride MCC Align

MJ Daffue

Driver: Callaway Paradym Ai Smoke Max (10.5 degrees @9.5)

Shaft: Project X HZRDUS Smoke Green RDX 65 TX

Grip: Golf Pride ZGrip Cord Align

Check our more photos from the Zurich Classic here.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

Whats in the Bag

Rasmus Højgaard WITB 2024 (April)

- Rasmus Højgaard what’s in the bag accurate as of the Zurich Classic.

Driver: Callaway Ai Smoke Triple Diamond (10.5 degrees)

Shaft: Mitsubishi Tensei 1K Blue 60 TX

3-wood: Callaway Ai Smoke Triple Diamond Prototype (16.5 degrees)

Shaft: Mitsubishi Tensei 1K White 80 TX

Utility: Callaway Apex UW (21 degrees)

Shaft: Mitsubishi Tensei AV Raw White 85 TX

Irons: Callaway Apex Pro (3), Callaway X Forged (4-PW)

Shafts: KBS $-Taper 130

Wedges: Callaway Jaws Raw (52-10S, 56-10S, 60-06C)

Shafts: KBS Tour 130 X

Putter: Odyssey Ai One Milled Eight T DB

Grips: Golf Pride MCC

Check out more in-hand photos of Hojgaard in the forums.

- LIKE3

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole3 days ago

19th Hole3 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 days ago

19th Hole2 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

Pingback: ?? ???????? ????????? ??? Google ?? ???????????? ????????. ????? ???????? ?? ??????; - ?? ??? ????;

Pingback: Best Babel » Google’s Toughest Interview Questions. Can You Answer Them?

bob

Jan 19, 2015 at 10:13 am

I was hoping for more, something similar to the “How its made” series on discovery.

This turned out to be just pictures of ball forms with no detail as to how they really got that way.

FTWPhil

Jan 16, 2015 at 1:17 pm

And they will still think more of themselves than you ever will.

Jim

Jan 16, 2015 at 12:17 pm

Terrific article and great photos. I knew someone that worked at the facility and he said the amount fuel required to run the facility is pretty incredible too – it apparently takes a a great deal of resources to make the balls. Nice to know that they are made in my backyard too. And the photo of the static electricity is awesome.

kev

Jan 16, 2015 at 4:07 am

think about this x-ray next time you want to purchase any x-outs.

Jon

Jan 15, 2015 at 9:36 pm

As expensive as Titlest balls are, they should be made 100% in the USA. Bring back our jobs please.

Seth

Dec 8, 2015 at 10:46 am

Thank you Jon. No reason for Titleist to build a golf ball plant in Thailand “to meet international demand.”

Mats B

Jan 15, 2015 at 7:56 pm

Looking forward to test the New 2015 series of Pro V1:s both the regular and the X…. 🙂

TR1PTIK

Jan 15, 2015 at 3:50 pm

Very good read!

Johnny

Jan 15, 2015 at 3:35 pm

I’m surprised they even let him in the facility. A big chunk of patent applications come from Golf ball manufacturers and they’re very secretive how they make their golf ammo..

slider

Jan 15, 2015 at 3:09 pm

best ball on the market