Equipment

Wishon: Shaft frequency can be misleading

Numerous times I have read posts on GolfWRX from golfers who persist in selecting a shaft on the basis of a butt frequency measurement. In viewing new shafts that come on the market, many golfers believe as long as the new shaft has the same butt frequency as their current shaft, the shaft’s stiffness design will match their swing.

Unfortunately, there is a lot more to the stiffness design, stiffness performance and the stiffness feel of a shaft than a single butt frequency measurement. In other words, it is quite rare for two shafts with the same butt frequency to be the same stiffness design over the full length of the shaft. And equally, it is quite common for two shafts to have the same exact butt frequency measurement but be completely different in their stiffness design over the rest of the shaft.

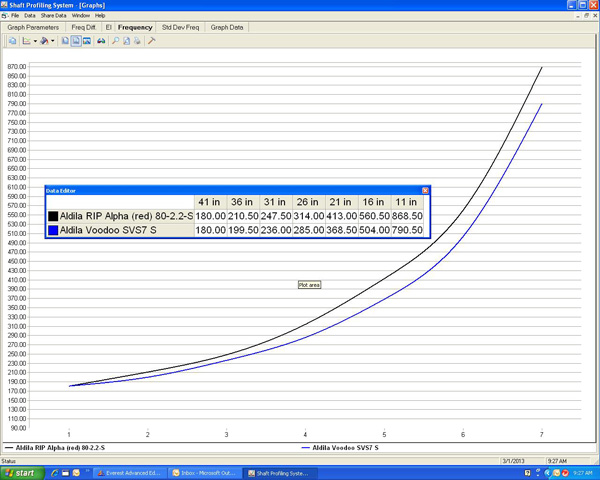

Here’s a couple of examples to illustrate this point. First, let’s take a look at the full-length stiffness design of two shafts for drivers and woods, both made by the same company.

Note: All zone frequency measurements performed for our TWGT Shaft Bend Profile software are taken using a 454-gram tip weight so that we can obtain measurements all the way to the tip section of the shaft. With only a 205-gram tip weight, it would not be possible to obtain the measurements for the lower center to tip section of the shaft. Using a 454-gram tip weight lowers the actual frequency measurement compared to what the measurement would be using a 205-gram tip weight.

The two above shafts with their same 180-cpm butt frequency measurement, if done with a 205-gram tip weight, would both have a frequency measurement of 254 cpm. But the point is the same regardless of the frequency measurement method.

Here are two shafts which if measured only for the butt frequency, would lead a golfer to believe that they have the same flex or same stiffness design. Yet in looking at the full-stiffness design of both shafts, these two shafts may have the same butt frequency measurement, but they could hardly be more different in terms of their overall stiffness design. These two shafts in the hands of the same player would result in a completely different stiffness performance and stiffness feel — yet if the golfer were to look at the shafts by only referencing the single butt frequency measurement, the conclusion would be that they have the same stiffness.

This is not an isolated case. Within the 2,100 different shafts in our Shaft Bend Profile software, there are too many examples to list that are exactly like this — shafts that have the same butt frequency measurement but are completely different in their design, performance and feel.

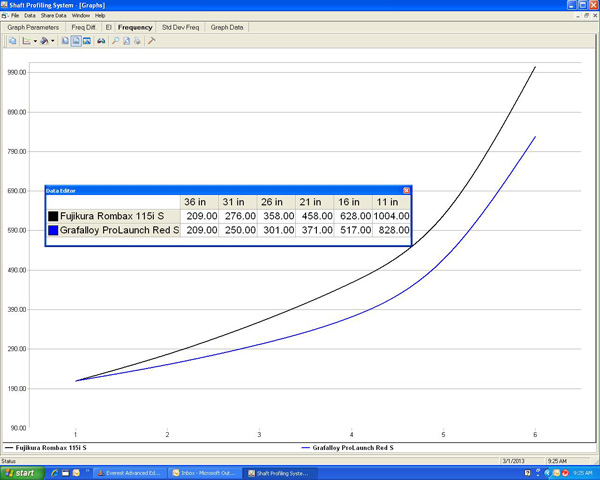

The same thing exists within iron shafts, which is an area in club fitting that many golfers make their shaft selection decision based on comparing the butt frequency measurements. Let’s take a look at an example of two iron shafts with the same butt frequency.

What’s interesting when looking at the full-stiffness measurements of these two S flex iron shafts is that within the world of shafts, these two shafts may have the same butt frequency but they are almost as different in their stiffness measurements for the rest of their lengths as they possibly can be. Were the same golfer to play both these shafts, the Rombax S would feel like a telephone pole compared to the ProLaunch Red S. Yet both are S flex and both have the same exact butt frequency.

This matter of judging shaft stiffness, performance and feel on the basis of the butt frequency only can rise up to mislead golfers in the other direction as well. Let’s take a look at this next pair of shafts, a Cleveland Gold 60 S and the Fujikura Blue 004-R.

Remember that these frequency measurements in the Bend Profile software are done using a 454-gram tip weight. The butt frequency of these two shafts if measured with a 205-gram tip weight would be 254 cpm for the Cleveland Gold 60-S and 244 cpm for the Blur 004-R.

Looking only at the butt frequency measurements, one would think that this 10 cpm difference in butt frequency with a 205-gram tip weight, or 7 cpm difference with a 454-gram tip weight, would most definitely be the reason the Cleveland Gold is an S flex and the Fuji Blur an R flex.

But take a look at all of the rest of the relative stiffness measurements after the butt frequency measurement. The 2- 3-5 differences in frequency for the 26 inch, 21 inch and 16 inch positions on the shaft are so small to be insignificant in terms of a stiffness difference in two shafts. Even the 13 cpm difference in the very tip end of the shaft is extremely small in terms of a performance or feel difference.

For all intents and purposes, beyond that single butt frequency measurement, these two shafts are so close in stiffness design to each other that only a very small number of very feel sensitive players could ever tell the difference in performance or feel between these two shafts.

Another interesting point from this comes to mind when you think about sorting shafts by their butt frequency as a way to make sure all the shafts in a set have the same stiffness. Think about that based on what you have seen in the previous graphs which show shafts of the same butt frequency but totally different over the rest of the shaft, and this above graph which shows two shafts that are completely different for their butt frequency yet so very close to each other over the entire rest of the shaft.

But what about that 7 cpm difference in the butt frequency measurements? Wouldn’t a golfer feel that difference even if the rest of the two shafts are so close to each other in their stiffness design?

Consider this: In the installation of wood shafts into a driver and fairway woods, almost all of that very area where the butt frequency measurement is performed is cut off the shaft when the woods are built to conventional playing lengths. Most shafts for woods are made with a raw uncut length of 45 inches or 46 inches. When installed in most driver heads, to achieve a playing length for the driver of 45 inches, in the area of three inches is cut from the butt end of the raw shaft after installation.

That means the position on the shaft where the butt frequency is measured is now just two inches from the end of the grip. Do you think that last two inches of the butt of the shaft bends very much during the swing? No, it doesn’t, which in turn even further negates the 7 cpm difference in butt frequency between these two shafts in our above example.

Shaft stiffness design selection has to be made not just on the basis of the butt frequency, but on the basis of the stiffness of the full length of the shaft. So the next time you hit shots with a club that you know has the same frequency but the shaft feels or performs different, you now know why. Or the next time you hit shots with two clubs that you are sure have different stiffnesses yet feel and perform the same, you know that reason as well.

Bottom line? If you are serious about your shaft selection, you need to be working with a good, experienced custom club maker who is cognizant of these factors and who is able to show you the actual differences and similarities of the stiffness design of the whole shaft.

Click here for more discussion in the “Clubmaking” forum.

- LIKE40

- LEGIT4

- WOW6

- LOL0

- IDHT0

- FLOP1

- OB1

- SHANK3

Whats in the Bag

Sam Burns WITB 2024 (April)

- Sam Burns’ what’s in the bag accurate as of the RBC Heritage.

Driver: Callaway Paradym Triple Diamond S (9 degrees @10)

Shaft: Fujikura Ventus Blue 7 TX

3-wood: Callaway Paradym Ai Smoke Triple Diamond T (15 degrees @16)

Shaft: Fujikura Ventus Blue 8 X

Hybrid: Callaway Apex UW (21 degrees)

Shaft: Fujikura Ventus Blue 8 X

Irons: Callaway Apex TCB ’24 (4-AW)

Shafts: Project X 6.5 (4-PW), True Temper Dynamic Gold X100 Tour Issue (AW)

Wedges: Titleist Vokey Design SM10 (56-14F @55), WedgeWorks Proto (60-T)

Shafts: True Temper Dynamic Gold S400 Tour Issue (56, 60)

Putter: Odyssey Ai-One #7S

Grips: Golf Pride Tour Velvet Align

Ball: Callaway Chrome Tour X

Check out more in-hand photos of Sam Burns’ WITB in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Will Zalatoris WITB 2024 (April)

- Will Zalatoris’ what’s in the bag accurate as of the RBC Heritage.

Driver: Titleist TSR2 (9 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Black 7 X (44.5 inches)

3-wood: Titleist TSi2 (15 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 8 X

Irons: Titleist T350 (3), Titleist T150 (4-PW)

Shafts: Nippon N.S. Pro Prototype G.O.S.T. 10 ST X (3), True Temper Dynamic Gold Tour Issue X100 (4-PW)

Wedges: Titleist Vokey Design SM10 (50-08F, 54-10S @55, 60-04T)

Shafts: True Temper Dynamic Gold Tour Issue X100

Putter: L.A.B. Golf Mezz.1 Max

Grips: Golf Pride Z-Grip Cord

See more photos of Will Zalatoris’ WITB in the forums.

- LIKE3

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

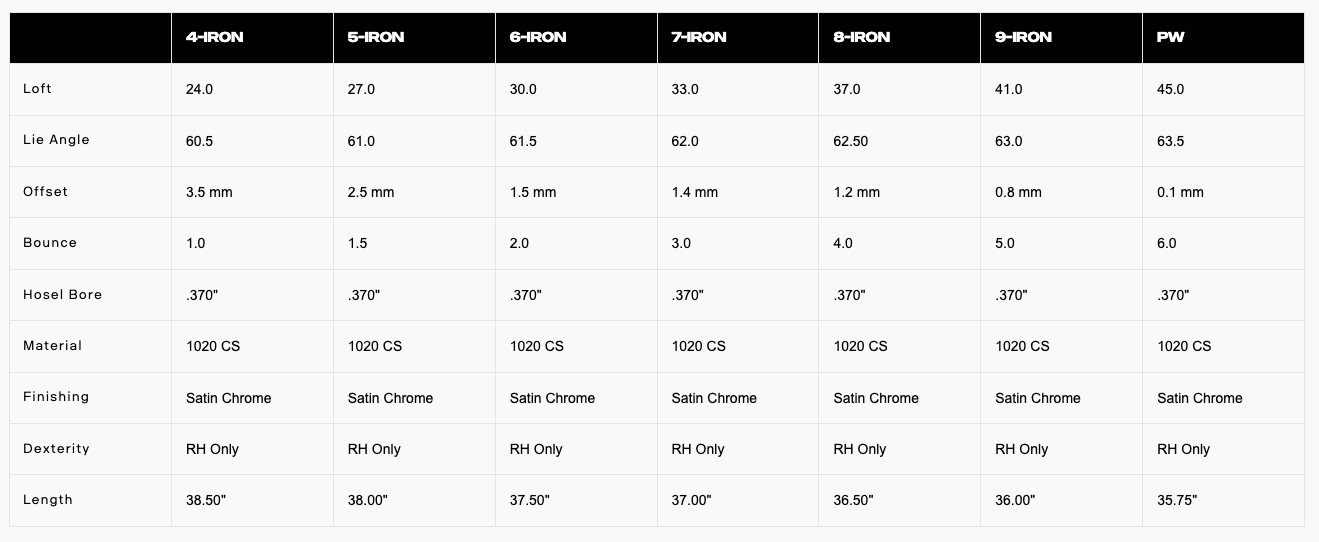

New Level launches new 480-DB irons, blending performance and forgiveness

New Level has been making some really good golf equipment since the company started up in 2018. Offering irons that are more geared towards the better player, precision has been a fundamental philosophy for New Level in creating irons and wedges.

The 480 line of irons has been the flagship of the brand, and the newest member of that team is the 480-DB iron that is now open to pre-orders. A new cavity design is what the whole 480 line is about, and the 480-DB takes advantage of that with added ball speed and a larger sweet spot.

For players who require their irons to offer the best feel, rest assured the DB is a fully forged (from 1020 carbon steel) one-piece golf club. No multi-piece, hollow design with this iron.

While the 480-DB is the next generation of the popular 902-OS, New Level didn’t follow the current trend in golf by chasing distance with the new iron. They actually weakened the lofts on the 480-DB with the spec sheet showing a 33-degree 7-iron and 45-degree pitching wedge. These lofts allow the DB to have less offset while still offering consistent distance off the face.

A traditional design was also at the forefront of the new irons to make sure that golfers with an eye for detail can look down at them with confidence that they will perform under any condition.

A weight low in the back cavity will allow their master club builders to dial in the perfect weight for the golfer, no matter the length or shaft being used. New Level believes that the new 480-DB is one of the most forgiving one-piece forged irons on the market today. A pre-worn leading edge on the sole should get through the turf quickly and with reduced digging for better turf interaction.

You can pre-order the New Level 480-DB right now on the New Level website.

Pricing specs availability

- Irons: 4-PW

- Price: $149/oron

- Availability: Pre-order

- LIKE20

- LEGIT3

- WOW2

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole20 hours ago

19th Hole20 hours ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole7 days ago

19th Hole7 days agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole6 days ago

19th Hole6 days agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

Sam Grogg

Feb 18, 2014 at 4:01 pm

If I wanted to do the complete profile on different shafts installed in the exact same model head, would the results be of any use to me?

Tom Wishon

Feb 19, 2014 at 11:40 am

Sure. Doing bend profile measurements like this on DIFFERENT shafts that are installed in the same head gives you the chance to see why you may like certain shafts over others because it eliminates the variable that different heads bring about.

The biggest way that different driver heads affect a shaft’s feel and performance is through the differences you see from model to model in the “bottom of bore to ground” (BBTG) dimension. Not all driver heads are made to have the same distance from where the tip end of the shaft ends in the hosel to the ground. Some are 2″, some 2.5″, some 3″ – there is no standard for this in a driver head or any head’s design.

So if you put the same shaft into two heads, one with a 2″ BBTG and the other with a 3″ BBTG, the same shaft in the head with the 3″ BBTG measurement is going to play softer because that greater BBTG causes the shaft tip to be farther off the ground. BUt what you are talking about, to test hit different shafts all installed in the same exact head, and then doing bend profile measurements on the shafts, that will tell you why you like some shafts and not others.

One other thing on this all golfers have to be aware of. You can have two of the same exact shaft in the same head and have them feel and perform differently. When this happens it is almost always because the +/- tolerances in production of the shafts rose up and bit you. Try as they like, shaft companies simply cannot make all shafts of the same model as tight to each other in all specs. Some certainly do a better job of this than others. And by no means does a higher priced shaft mean that you are buying more shaft to shaft consistency. Some expensive shafts ARE very close to each other in tolerances, while some are not. Just as some cheaper shafts are very close to each other in tolerances and some are not.

Thus this bend profile measurement system is a very good way to know all these things for sure.

TOM

steve

Mar 4, 2013 at 9:37 pm

its always interesting to read Mr.Wishon`s articles but everytime i get more knowledge about golf clubs and shafts. it makes me very uncomportable because i know that it would take hard work/time/money to get the golf club right for myself. moreover, more i read Mr.Wishon `s articles, I know that i’ve been fitted WRONG! and knowing that my equipments can be optimized to fit my swing better. and my IDEAL CLUB HEAD AND SHAFTS are out there to be found with hard work/time/money. sometimes i wish i didn`t know the stuff that i know now. the more i know it gets more complex! i wish i could just swing without worrying too much on the equipment side.

purkjason

Mar 5, 2013 at 11:46 am

@steve … I’m at the point also of not wanting to know anymore about ideal clubs ,shafts, etc. The game is just about going out and having fun. Whether a good round or bad I just enjoy being out there away from the real world for a little bit. I just went to the driving range and tried different swing angles and choking up on the club etc. and did all the modifications myself at home. Works for my recreational play haha.

Steven Safran

Mar 3, 2013 at 5:41 pm

Interesting and explains what I found today. I have 2 3 woods….one with an UST Axivcore 79 red and the other with an AD Di7. The AD Di7 feels and plays more stiff to me but today when I had them frequency checked the UST shaft has a significantly higher frequency. Gotta go buy feel over one parameter that doesn’t tell the whole picture.

K

Mar 3, 2013 at 10:32 pm

That’s not what this article is saying.

If they are already-installed shafts in the heads, they have been cut and glued with heads that weight differently, so of course they are going to read differently. Not only that, your two shafts have different torque as well as kick points, so your point is null and void.

Mr. Wishon is talking about the shafts BEFORE they are installed, so that you get fitted properly to the right shaft.

Pingback: “What’s the frequency Kenneth” – Golfbloggen

Jesse

Mar 3, 2013 at 12:30 am

Wow cool article. It is getting so complicated to choose shafts as everything is getting more technical and measurable. I am beginning to think that just trying shafts till I find what I like based on feel and ball flight. I do that with lies and lofts on irons some bent stronger or weaker based on distances, and some upright and flatter based on left right. I dont even know what they measure just go to a guy and say move it 2 degrees upright from whatever it is now.

Jessesbane

Mar 5, 2013 at 1:55 am

@Jesse: In the most laughter-provoking way you have just trashed Tom Wishon’s article. ROFL

Walt

Mar 2, 2013 at 8:59 pm

Too bad there still isn’t some uniform way for the manufacturers to agree upon in which to measure the shafts.

If they all agreed to use the method you are, then every shaft would have a visible graph like you have shown that would immediately help the buyer move into any companies shaft he wanted too.

What a novel concept.

Rob

Mar 4, 2013 at 2:01 pm

Every shaft is visible on a graph like that, but it’s not available to consumers or the monkeys working at golftown/golfsmith. Expeienced custom club fitters have that information, which is why they always say to go to them to get properly fitted.

What would be nicer is if industry standards on flex ratings were implememnted so that way all stiff/regular/x-stiff shafts are the same frequency, regardless of what company makes them.

John

Jul 10, 2013 at 5:10 pm

Actually ROB we have them printed out and are in just about every golfsmith proshop…in the interest of time and our main customer base we choose not to even mention it because we can’t have guys hitting in our bays for hours (I could see you being that guy)…golfsmith is a retail store, not a custom fitting studio, we exist to make money and fatheads like yourself and Tom Wishon (who left golfsmith) just don’t seem to get that simple concept…spend your money where ever you want but don’t bash a store because they won’t spend 2 hours of payroll flicking 15 different shafts on a frequency meter for you, get real buddy

Tom Wishon

Feb 18, 2014 at 3:37 pm

The guy calls you a monkey and this is what you say in response? Sounds fair. Oh, hey, wait a minute – I didn’t call you a monkey yet you still called me a fathead!! I guess you don’t win a star from the school of diplomacy.

RanchoBob

Feb 21, 2014 at 4:16 pm

Tom, I’m thinking maybe he’s not in their PR department. That’s probably just as well.

Your reasons for leaving them were your own and, based on what I know and what I’ve seen from Golfsmith of late, were spot on. It’s a great place to go to buy an off the rack club or to buy glue or grips or clothing. Fitting? Not so much.

Now then. When can I demo the 939 AHT? 😀

John D

Feb 21, 2014 at 10:50 am

Rob

There are clubfitters that have the shaft data and in the past it wasn’t published. But now a lot of this data is being made available to the average golfer. Go to http://www.golfshaftreviews.info to see the wealth of information that is becoming more available on the performance of golf shafts. I doubt that there will every be standards but if all shafts are measured in the same way you can compare different shafts to see how they should perform.

Hunterdog

Mar 2, 2013 at 8:37 pm

@tom – great article as always. Finding the knowledgable club maker is the trick.