Equipment

Phase 1 vs. P7TW: An inside look at Tiger Woods’ TaylorMade irons

At this point, the story of the development of Tiger Woods’ TaylorMade irons has been told and told again. There have been numerous articles, YouTube videos, and even a TV documentary on how they were made—and even a Tour Championship and a Sunday Masters telecast to validate both models.

But I wanted to know the differences and similarities of the two TaylorMade iron models Woods has played since signing with the company in January of 2017: the Phase 1, and the final masterpiece the, P7TW.

Fortunately, in this job, you become friends with a good number of R&D people, so I went to my buddies and TaylorMade Lead Engineers Paul Demkowski and Matt Bovee to fill in some blanks.

This is what they had to say.

Matt Bovee Sr. Manager Product Creation

JW: The Phase 1 iron was based on what previous iron of TW? What inspired it?

MB: The PH1 iron was based off of the set he was playing just prior, the TGR set. Inspiration for the P7TW is really founded in all the years of TW’s career. From the numerous victories, countless hours grinding, and all his majors… the P7TW is really a culmination of what he specifically wants in an iron design after years and years of being the best ball striker in the game.

JW: What was the testing process like going from his TGR into the Phase 1?

MB: The PH1 set was a collaboration between TaylorMade and Mike Taylor with a new cosmetic design we created. We didn’t want to change any significant performance attributes because the immediate goal was to get TW into a TM iron. We partnered with Mike Taylor to help with the creation of PH1 as well as the learning process required for the development of P7TW. For us, it was a learning experience as TW went through his testing protocol for a new set. Making sure everything was dialed in and felt right.

JW: What are the similarities of the two irons, PH1 and P7TW?

MB: There are a lot of similarities between the PH1 and P7TW from a performance perspective. It’s been said before, and I’ll say it again, TW is very, very specific in what he wants. Launch, spin, carry, look, feel…he has every attribute for each iron defined in his head. Nothing more, nothing less. They use the same lofts, lie, scorelines, essentially the same CG, etc.

JW: What kept PH1 from being the “Tiger Iron”?

MB: The PH1 irons were built from an existing forging profile. By using an existing forging he was familiar with it allowed us to minimize variables as we learned and dissected what works best for him. Even after the PH1 iron performance matched what he was looking for, TW requested the MG sole technology for his irons so he could replace them more frequently with much less testing from set to set. We needed to take this into account with a new TM forging design.

*The milled grind sole was designed specifically for this benefit. It has allowed TM to duplicate the sole of irons and wedges which in turn eliminates a number of steps during testing and/or mid season replacement.

JW: The name Phase 1 suggests a new version was to come, was that always a bridge iron into the current?

MB: Yes, we knew designing a TaylorMade iron for him from the ground up would take some time and we needed a “bridge” of sorts while the new design was in development.

JW: When TW began testing irons in the beginning, (knowing the challenge which is well documented) what was the original process like? Who was involved?

MB:

- Participants: Tiger, Tomo Bystedt, Brian Bazzel, Keith Sbarbaro, Paul Demkowski, Mike Taylor, and Matt Bovee.

- The development process was a longer road than we anticipated. Much back and forth between TM and Mike Taylor to start. We needed to unpack years of learning as to what works best for the Big Cat and what he likes. From that point, it was a lot of back and forth testing of individual sticks. Starting with the 6i and not moving on from that until we got it perfect. It actually took 7 different CNCs prototypes before we nailed the 6i. From there we added in the 3i and the 9i to serves as bookends for design. After these three SKUs got TW’s blessing we filled out the rest of the set.

JW: How many PH1 sets were made?

MB: As far as we know just the 1 set. Mike Taylor would be the only person who would know differently

JW: What are the differences between P1 and P7TW?

MB: The largest differences are:

- Built from different forgings

- Addition of MG sole—when Tiger needs replacements due to wear, the Milled Grind soles are exactly the geometry that he needs and so any opportunity for slight variations has been removed. That’s why the P7TW is ultimately Tiger’s gamer irons.

- Milled channel along the back bar of the iron. Cosmetic was designed to fit with the PSeries.

- Cosmetic design is different, the back bar geometry is slightly different the milled channel was used in 730 to reposition mass, TWs is a much smaller version of that

JW: Does TW only have input (R&D) on his irons or all the TM irons (forgings of course)

MB: TW’s R&D input on irons has been limited to his P7TWs up to this point…which was extensive. All the way down to a modified font for the sole number making it easier from him to read and therefore more confident he had the right stick. He has provided some input in other categories however, wedges most specifically.

JW: In your opinion is the P7TW the best muscleback TM has ever developed?

MB: “Best” is such a relative term that lies in the eyes of the beholder… It is certainly the most prestigious with the most design iterations and R&D development.

JW: If you could project into the future, what improvements if any could be made to a TW iron?

MB: Because that iron is specific to him and what he wants, there really isn’t any way we could make it better unless his swing or style of play changes. The P7TW is dialed in for TW’s game as it exists today.

Paul Demkowski, Sr. Product Engineer was the person that worked the closest with Mike Taylor in the development of both models and this is what he had to say

JW: Are you still in close contact with Mike Taylor at Artisan? and if so is it more just to verify info or is it also for future R&D?

PD: Yes, I’m still in close contact with Mike T. He continues to build the irons for TW. He verifies all the specs as they are built and records the data.

JW: In regards to the CG placements between P1 and P7TW what is the difference?

PD: CG locations are very close. Couldn’t deviate too much as he would feel the difference and would see it in his ball flight.

JW: Random question but had to ask, did you ever attempt to make TW a specific driving iron?

PD: No, never made a specific TW driving iron. Only thing I did once make a slower P790 UDI for him. He said the standard one went too far. LOL.

It’s also noteworthy that TW’s specs don’t change much but as you can see current set up, the only real shift in his irons is lie angle which will go up one depending on his swing at the time.

Tiger Woods’ Current Iron Specs

All with True Temper Dynamic Gold Tour Issue X100. Irons tipped 1/4 inch, w/wooden dowels and SST Pure (Scott Garrison on Tour) at exactly 130 grams.

All lengths without grips. (Loft. Lie. Length. Swing Weight)

- 3-iron: 22.5, 59.5, 38 13/16, D4

- 4-iron: 25.5, 60, 38 5/16, D4

- 5-iron: 29, 60.5, 37 13/16, D4

- 6-iron: 32.5, 61, 37 5/16, D4

- 7-iron: 36, 61.5, 36 7/8, D4

- 8-iron: 40.5, 62, 36 5/16, D4

- 9-iron: 45, 62.5, 35 11/16, D4

- PW: 49, 63, 35 11/16, D4

Another cool aspect of Tiger’s irons (rarely spoken of) are his shafts. The shafts are True Temper Dynamic Gold Tour Issue X100 with no labels, and they are sorted to exact weights (130 grams) and sent to Scott Garrison (@ScottEGgolf) to SST Pure, then over to David “DR” Richey at Artisan Golf to be built. Lots of cooks in the kitchen, but it’s Tiger, so no doubt totally worth it for all involved!

.

- LIKE341

- LEGIT49

- WOW43

- LOL8

- IDHT3

- FLOP4

- OB4

- SHANK14

Whats in the Bag

Max Homa WITB 2024 (April)

- Max Homa what’s in the bag accurate as of the Masters.

Driver: Titleist TSR3 (9 degrees, D1 SureFit setting)

Shaft: Fujikura Ventus TR Black 6 X

3-wood: Titleist TSR2+ (14.5 degrees, A1 SureFit setting)

Shaft: Mitsubishi Tensei 1K Red 80 TX

5-wood: Titleist TSR2 (21 degrees @19.25, D1 SureFit setting)

Shaft: Fujikura Ventus Blue 9 TX

Irons: Titleist T100S (4), Titleist T100 (5), Titleist 620 (6-9)

Shafts: KBS $ Taper 130 (4-9)

Wedges: Titleist Vokey Design SM10 (46-10F, 50-12F, 56-14F), WedgeWorks (60)

Shafts: KBS $ Taper 130 (46) KBS Hi-Rev 2.0 135 X (50, 56), KBS Hi-Rev 2.0 125 X (60)

Putter: Scotty Cameron T-5.5 Proto

Grips: Golf Pride Tour Velvet Cord

Ball: Titleist Pro V1

More photos of Max Homa’s WITB in the forums.

- LIKE7

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

Whats in the Bag

Bryson DeChambeau WITB 2024 (April)

Driver: Krank Formula Fire Pro (6 degrees)

Shaft: Project X HZRDUS T1100 75g 6.5

Mini driver: TaylorMade BRNR Mini Driver (11.5 degrees @10)

Shaft: Project X HZRDUS T1100 75g 6.5

- Unconfirmed. We are working to gather details.

5-wood: Krank Formula Fire

- Unconfirmed. We are working to gather details.

Irons: Avoda Prototype (5-PW)

Shafts: LA Golf Prototype

Wedges: Ping Glide 4.0 (46-12S @45, 50-12S, 56, 60)

Shafts: LA Golf Prototype

Putter: SIK Pro C-Series Armlock/LA Golf Proto

Shaft: LA Golf C2L-180

Grip: JumboMax JumboFlat 17

Grips: JumboMax UltraLight XL

Ball: Titleist Pro V1x Left Dash

- LIKE8

- LEGIT2

- WOW2

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

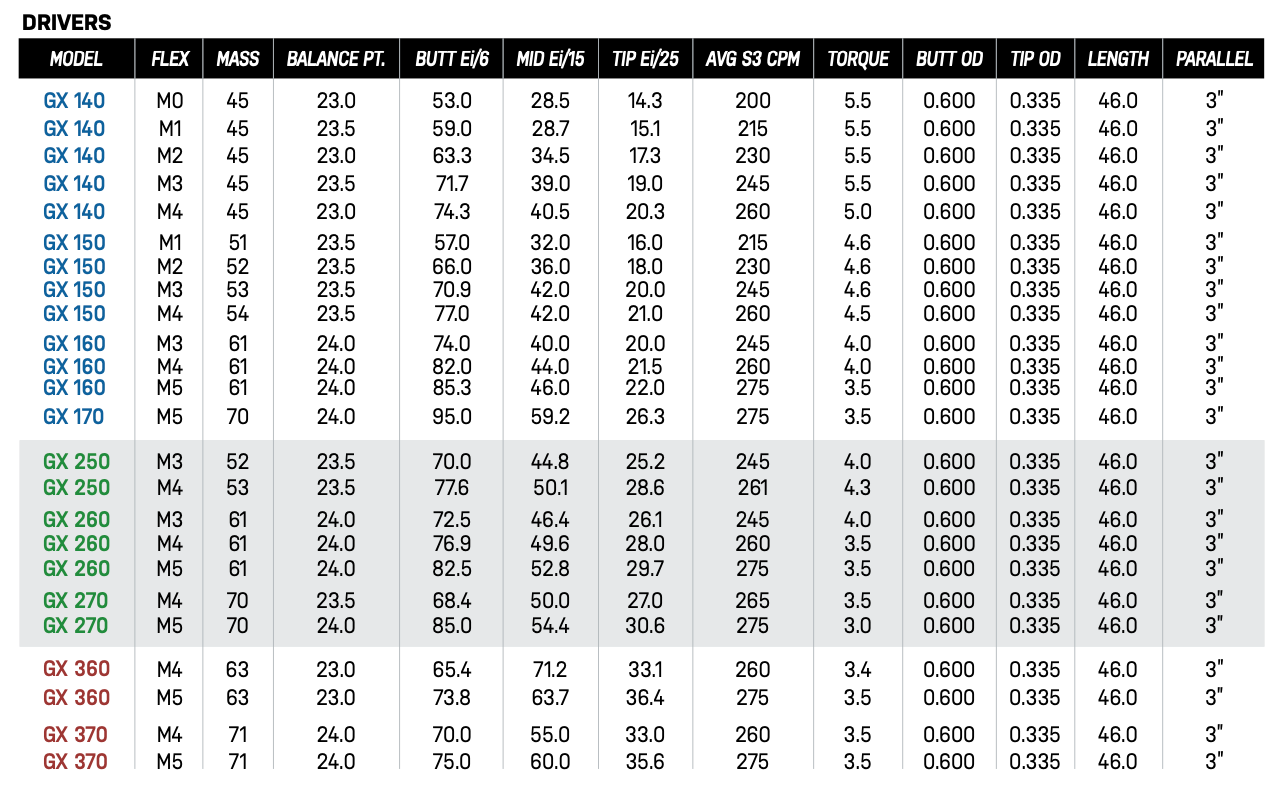

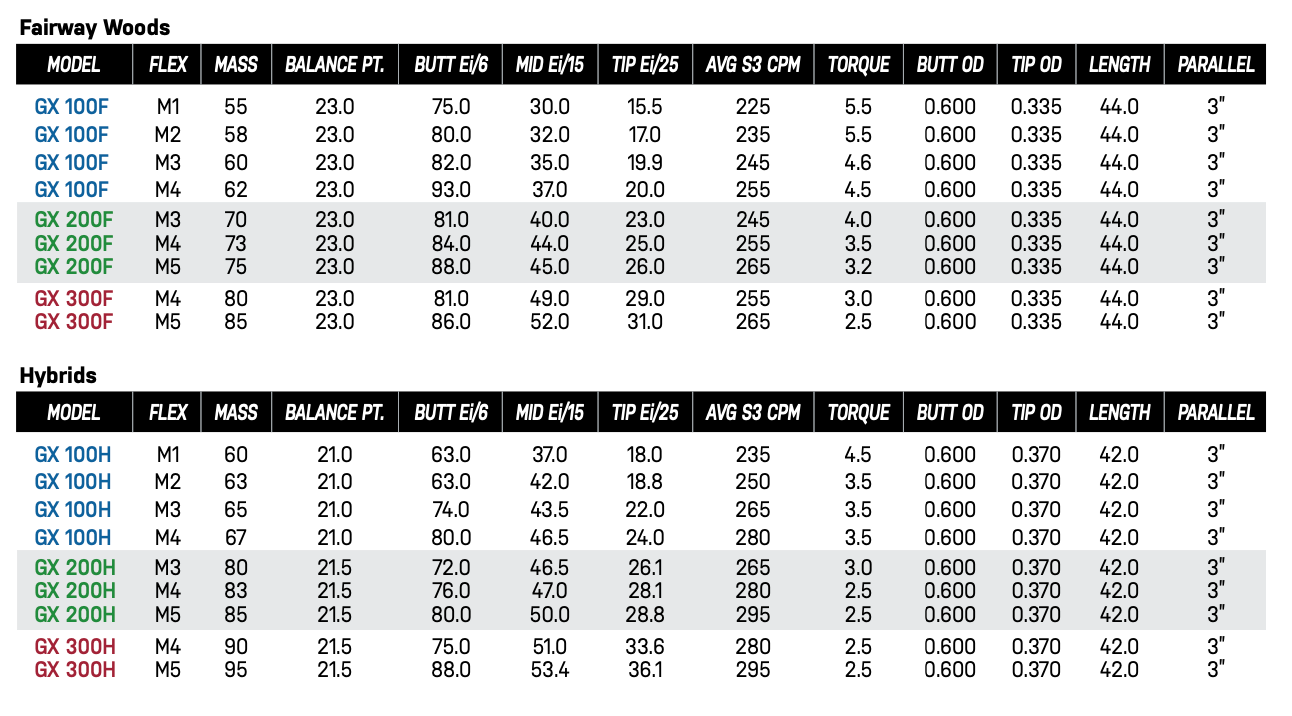

Accra launches new GX wood and hybrid shafts

Accra Golf shafts have long been synonymous with fitting, and the new GX line of driver, fairway, and hybrid shafts continues that legacy.

Since 2004, Accra has been making high-end performance golf shafts that use the latest in materials and design philosophy. Their group of around 350 fitters are some of the best and most highly ranked in the world. While you might see other brands on professional tours more often, there are plenty of touring pros using Accra products and winning.

Accra’s new GX line of shafts is designed to offer a consistent and accurate shaft to a wide range of players. The GX line consists of 3 different shafts in driver, fairway, and hybrid designs.

The Accra GX shafts are designed for fitters to dial in golfers to the perfect shaft for their swing. Accra included a ton of technology into the GX line including their S3 profiling, DyMatch, and Constant Flex technology. DyMatch has been Accra’s quest to ensure that all shafts in a family feel and perform similar from driver to hybrid or iron shaft. Typically shafts get stiffer as they go up in weight, but Accra’s Constant Flex keeps the flex of the shafts consistent so fitters and golfers can dial in the weight that the golfer need without have to work around a stiffer or softer flex. Accra worked with Cool Clubs to build out its S3 Shaft Profiling system that not only allows a quick and easy EI profile of any shaft, it helps with quality control to ensure shafts come out of production exactly as they were designed.

Accra GX Red 300 Series

GX Red is lowest launching and spinning option in the GX line. Driver shafts have fewer options with just the 360 and 370 models that come in at 63 and 71 grams. The GX Red is made for faster swinging, or stronger, players who require a stiff (M4) or x-stiff (M5) shaft for their swing. Fairway and hybrid models are also on the higher weight side with the fairway clocking in at 80g and 90g for the hybrid. Accra designed this series with one of the stiffest tip sections of any Accra shaft in the current line, and while it is built to control launch and spin, the Red 300 Series will still offer that smooth feel.

Accra GX Green 100 Series

If your swing usually works best with mid-launch and spin, then the GX Green 200 series might be the right shaft for you. Offered in more weight and flex options, you can get a GX Green in 52 grams and all the way up to 70 grams in regular, stiff, and x-stiff flexes. GX Green will give the player a smooth feel and transition from the handle down to the tip section while still providing great stability and consistency. Accra also focused on the energy transfer of this shaft, and golfers can see some increased ball speed compared to other shafts.

Accra GX Blue 200 Series

While the GX Blue 100 Series is the highest launching and spinning option in the GX lineup, it will still give golfers the control and consistency they need. Starting off at 40g, the GX Blue series puts an emphasis on lighter weight to allow players to swing the club faster, promoting more distance. Accra touts the stability of the GX 140 Blue driver shaft by stating that some long driver competitors have put it in play to try and gain every MPH they can. Matching fairway and hybrid shafts are both on the lighter side at around 60g for the fairway and 65g for the hybrid depending on the flex.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP1

- OB0

- SHANK0

-

19th Hole6 days ago

19th Hole6 days agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

-

19th Hole7 days ago

19th Hole7 days agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 weeks ago

19th Hole2 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 day ago

19th Hole1 day agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoAddiction, spinal fusion, and scam artists – Everything Anthony Kim revealed in candid interview with David Feherty

-

19th Hole2 weeks ago

19th Hole2 weeks agoAnthony Kim says doctors told him that he ‘may not have much time left’ ahead of LIV return

-

19th Hole1 week ago

19th Hole1 week agoBrooks Koepka and Sergio Garcia make significant equipment changes as 2024 Masters looms

gticlay

Aug 5, 2020 at 4:57 pm

I know what the TW is, but why are they called P7?

Can we have any more details on the X100 dowels? I’ve never liked how the X100 feels and maybe the dowels make a big difference in feel.

Benny

Jul 15, 2020 at 5:27 pm

Aweeome read and great comments guys!

Mower

Mar 31, 2020 at 2:54 pm

Alright, going to Home Depot for some wooden dowels.

😛

RayDon

Mar 31, 2020 at 6:17 am

Where are the wood dowels positioned?

Tiger Fan

Mar 31, 2020 at 10:21 am

Wooden dowels would be in the shaft tip like his old Titleist PT fairway woods.

Craig McMahon

Mar 31, 2020 at 1:13 pm

Down near the tip

Cody

Mar 30, 2020 at 5:54 pm

Good article.

There is some good info here. These irons are great for Tiger, specific to him. That does not make them magical or better than anything else. Still a great iron for someone that wants it.

Brandon

Mar 30, 2020 at 3:54 pm

What do the wooden dowels do?

Craig McMahon

Mar 30, 2020 at 4:35 pm

Supposed to just be a dampener I think

Jarnio Bubly

Mar 30, 2020 at 2:56 pm

In other words Mike Taylor and TW told Taylormade to get out of the way and we’ll let you know when we’re ready for logo stamping.

15th Club

Mar 30, 2020 at 1:05 pm

If his X100’s are “tipped 1/4 inch” does that mean that they are parallel tip shaft blanks?!? If so, his irons are all hosel-drilled at .350″ right? That would sure explain the custom build (as if a “custom build” for Tiger Woods would even require explanation).

I guess I just never imagined Tiger playing PT iron shafts. Gotta make Ralph Maltby and Tom Wishon smile.

TG

Mar 30, 2020 at 6:48 pm

No they are still taper tip shafts (0.355) by tipping them a quarter inch it is reducing the taper at the hosel making them play just a touch stiffer then a “standard” straight in X100. They just take the tour issue tag to another level and make sure that they are exactly 130 grams. Standard TI Dynamic Golds are +- 2 grams i believe. It may be +- 1 gram but either way its just making sure they are perfect.

Mike T

Mar 30, 2020 at 7:12 pm

No I think the standard DG tour issue x100 with 1/4″ tipping will still fit into the hosel as is

15th Club

Mar 31, 2020 at 4:01 pm

I typed.350, but PT iron shafts would actually be .370. Minor self-correction.

btw, I also accept the notion that a small bit of tipping like 1/4” is something you could get away with in a taper tip. Appreciate the replies.

stephen hall

Mar 30, 2020 at 12:29 pm

GREAT…

Jordan

Mar 30, 2020 at 10:50 am

Well looks like I’m ripping all the labels off my shafts now since the boss man does it

Tiger Fan

Mar 31, 2020 at 10:23 am

YES!

Ryan

Mar 30, 2020 at 10:12 am

Wish the retail release would have been to his actual specs, would have been cool.