Equipment

New for 2020, Callaway Jaws MD5 wedges boast more bite

Say hello to the new 2020 Callaway Jaws MD5 wedges from Callaway Golf. Redesigned from the ground up to create ultimate performance on all shots, the new Jaws wedges are being marketed as the most aggressive grooves in golf.

It’s been almost 10 years since we’ve seen the Jaws name used as part of the Callaway wedge lineup, but with the introduction of the new MD5 (Mack Daddy 5) Jaws wedges and their completely rethought-out groove design, Callaway felt that if there was a time to bring it back, it’s now!

Callaway Jaws MD5 wedges: The story

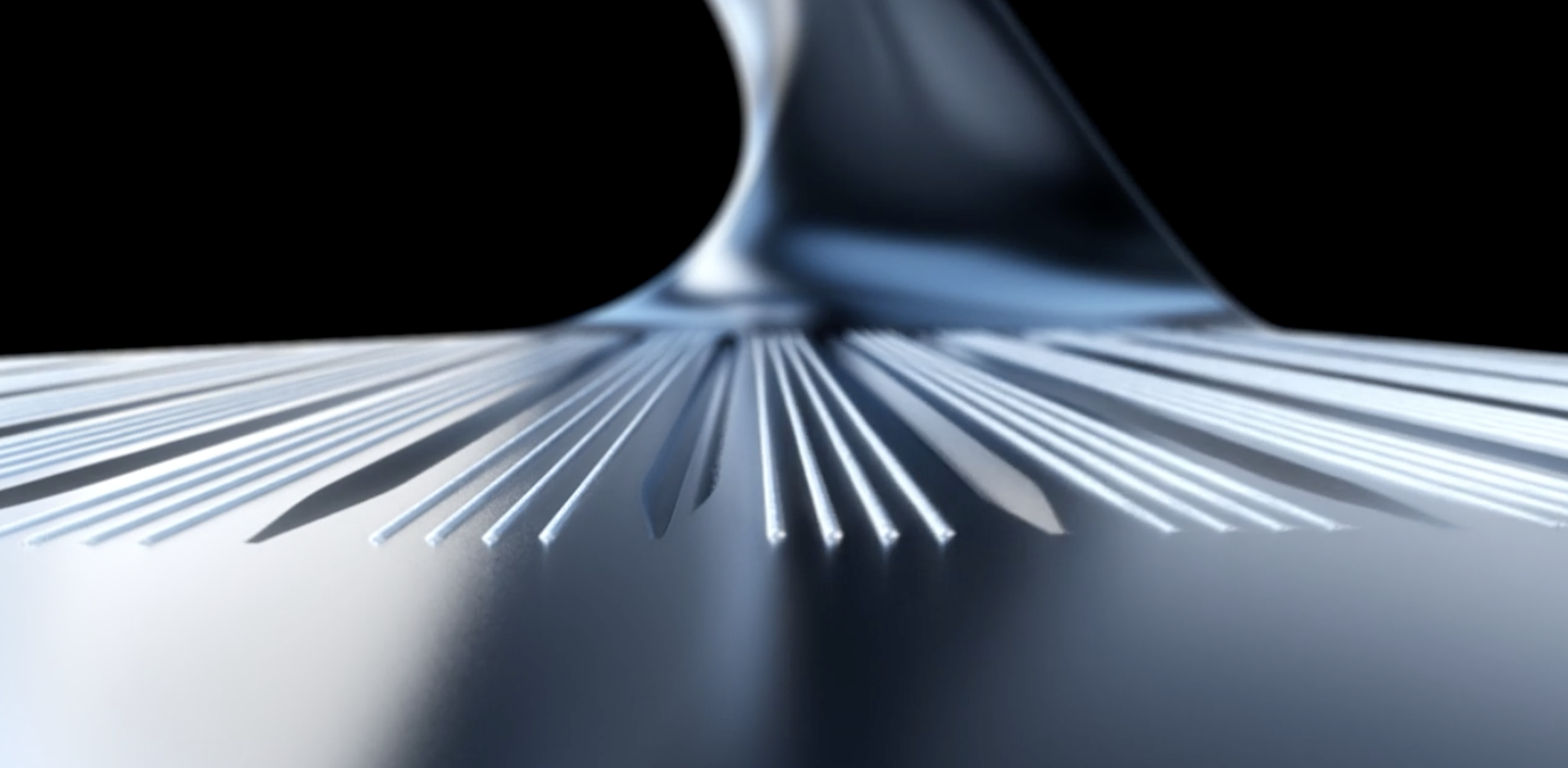

The Rules of Golf have limits set on everything, but when you have a lot of smart people trying to solve problems, those limits just mean you have to get creative with design. That’s exactly what the engineers have done with the new Callaway wedge and its Jaws grooves. By changing the overall shape compared to all previous models, they have increased not just spin but total control. That’s probably the most overlooked part of the wedge equation: creating greater control and consistency. Sure, more spin is great, but if it fluctuates from shot to shot, you are in no way better off.

The new proprietary groove design of the Jaws wedge is a change to the whole shape, including a different way to get the contact radius right to the limit, and when we say right to the limit, we mean it. In fact, when initially prototyped and brought to Callaway’s manufacturing partners for scaled-up manufacturing, the initial response from the factory after test runs was “sorry, we just can’t do this.” The reason? Fail rate was close to 50 percent becoming nonconforming which is a big no-go in the world of manufacturing. Such a situation would drive cost (because of losses) through the proverbial roof, especially when you consider each wedge’s face takes 10 minutes of machine time—not including the microgrooves.

The solution for Callaway? Changing the cutting tool every 15 wedges. Sure, you could attempt to get more life out of each tool, but when you have everyone from recreational players to the world’s best putting them in play, you can’t make sacrifices.

The end result is the MD5 Jaws spins over 10 percent more on shots hit around the green compared to the Callaway MD4 and launches lower by one degree (for those wondering if one degree matters: yes it does). Lower launch might not seem like something you want with a wedge, but if you talk to any short game coach with a launch monitor, or Roger Cleveland in Callaway’s case, you will quickly realize that being able to control launch with a wedge is just as important and is it with a driver. A lower-launching wedge means the coefficient of friction is higher since the ball isn’t riding/sliding up the face—and boom, you have a greater ability to hit the better-player-preferred “low checker.”

Now beyond the grooves, Callaway and the wedge team re-evaluated the whole shape and profile of the MD5 Jaws, along with the grind options. As the trend of more players swapping their stock pitching wedges for wedges that match the lower end of the bag (up to 45-46 degrees). Callaway designers decided to reshape the lower lofted wedges from the 46-56 degrees to have a smaller profile and flow better from the lowest to highest loft in the wedge set. Don’t think this is just for looks either—smaller heads allow for more concentrated mass and with a smaller shape comes better workability. There is no sense in trying to replace your stock set pitching wedge with a less versatile option.

The other reason for this change in the MD5 Jaws wedges is that data and player testing shows the 46- 56-degree clubs are used a lot more often for full shots compared to the higher lofted wedges, which are more likely than not to be hit with a more open face. This creates the ability to flight and control the ball better with the “full swing” clubs, yet still gives more face surface area to hit when the higher lofted “around the green” clubs and opened up. It’s a “best of both worlds” design philosophy. Instead of committing to a single size and shape for the whole line—which from a manufacturing perspective is less expensive—Callaway pulled out all the stops in making the Jaws wedges better, not just newer.

With all the talk of reshaping, the last part of this puzzle are the sole grinds. From the C Grind to the W (wide) sole wedges, everything has been tweaked. One of the best examples of this tweaking is the new lower bounce W (Wide) sole wedge. Mr. Roger Cleveland himself was doing a lot of customizing for tour players to tweak the stock MD4 W Grinds to reduce bounce and width of the soles, and after seeing this trend, the most popular tweak has now become a stock option on the MD5 Jaws.

There is even additional heel relief to help those players that want to open the face up for shots around the green. The opposite could be said about the new C Grind; with more effective bounce thanks to a wider center of the sole—but more playability with aggressive heel and toe relief. What seem like small changes are really a commitment to continued improvement by the wedge team at Callaway Golf, and I think with the MD5 Jaws wedges they have a winner destined to take a BITE out of the wedge market (Give me credit for taking this long to make a shark pun).

Customs

With the new MD5 Jaws, Callaway is upping its Customs game with 10 different “zones” to choose from, including the paint fill on the sole, the hosel, new medallion options (including emojis), and the back of the club. More ways to customize your wedge than ever before!

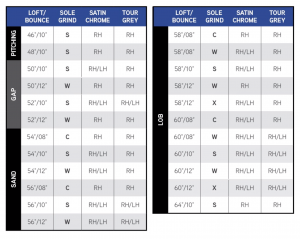

Callaway Jaws MD5 wedges: Availability and options

Shafts

Steel: True Temper Tour Issue 115 with a blue and silver shaft band

Graphite: Project X Catalyst 80g

Grip: Lamkin UTX Blue

Price: $159.99

- LIKE156

- LEGIT21

- WOW7

- LOL10

- IDHT1

- FLOP8

- OB9

- SHANK25

Equipment

A shocking Backstryke putter appearance + 7 interesting gear photos from the Zurich Classic

Welcome to New Orleans, where TPC Louisiana plays host to the 2024 Zurich Classic. In between breakfast beignets and nightly Creole feasts, PGA Tour players are also competing in the unique two-man format at the Zurich this week.

Although the vibes in Nawlins are a bit lighter-fare than the recent back-to-back competitions the Masters and the RBC Heritage signature event), the gear news was no less serious this week.

We spotted some recent changes from Rory McIlroy, a very rare Odyssey Backstryke putter, dove into the bag of legendary New Orleans Saints quarterback Drew Brees, and spotted Patrick Cantlay continuing to test new equipment.

Get your beads out and crack your crawfish, because it’s time for an equipment rundown from The Big Easy (meaning New Orleans, of course, not Ernie Els).

See all of our photos from the Zurich Classic here

Rory’s on-and-off lob wedge

Since the end of 2023, Rory McIlroy has had an on-again, off-again relationship with a Titleist Vokey K-Grind lob wedge. In his last start, it was on, and the wedge is back in the bag again this week. We got a great look at the complicated grind that McIlroy uses.

View this post on Instagram

A full look into McIlroy’s bag above also shows that he switched out of the TaylorMade BRNR Mini Copper that he used at the RBC Heritage, and he’s back into the Qi10 core 3-wood. As we discussed last week, McIlroy will likely keep the BRNR around as a course-specific club, trading it in and out for the 3-wood.

See Rory McIlroy’s full 2024 WITB from the Zurich here

Turning Back the clock

Unless Tommy Gainey is in the field, it’s unlikely you’ll ever see Odyssey’s Backstryke technology make an appearance on the PGA Tour.

But then, when you least expect it, Russ Cochran shows up.

For more than a decade – since the 2013 Sony Open in Hawai’i – Cochran has been stuck on 599 PGA Tour starts. This week will be his 600th.

Cochran is in the field at the Zurich this week playing alongside Eric Cole, whose regular caddie is Reed Cochran, Russ’s son.

The Backstryke putter was first released back in 2010, and its unique design helps shift the axis point of the putter closer to the CG of the head. And, the putter is getting a nod this week at the Zurich Classic, thanks to Cochran’s 600th career PGA Tour start.

The putter is certainly awesome, but don’t forget to check out Cochran’s full WITB from this week.

Drew Brees with a Super Bowl winning Scotty Cameron putter

Drew Brees, a legendary retired quarterback for the hometown New Orleans Saints, made an appearance at the Zurich’s Wednesday Pro-Am, playing alongside Zach Johnson, Ryan Palmer, and current Saints QB Derek Carr.

Brees’ bag included a TaylorMade Stealth2 Plus driver, a BRNR Mini 13.5-degree, a Stealth 5-wood, a mixed set of P-790 and P-760 irons, Milled Grind Hi-Toe wedges, and a custom Scotty Cameron “New Orleans Saints” putter, which Scotty made for Brees following his Super Bowl MVP-winning performance in 2010.

View this post on Instagram

It should also be noted that Brees has his Venmo QR code as a bag tag.

If you’re gambling with Brees on the course, just know that not having cash won’t work as an excuse.

Brilliant.

See Drew Brees’ full WITB from the Zurich here

Stricker’s unrecognizable putter

Steve Stricker has made numerous upgrades to his bag recently, including a new TSR3 driver and T100 irons, but his longtime Odyssey White Hot No. 2 putter is still going strong. It’s the most recognizable unrecognizable putter ever.

Here’s a better look at Stricker’s flatstick, which he started using back in 2007.

View this post on Instagram

Patrick Cantlay has opened the equipment-switching floodgates

Over on the PGA Tour’s Equipment Report this week, we covered Cantlay’s recent switch into Ping Blueprint S irons, and a Titleist TSR2 driver.

Cantlay hadn’t switched irons for about seven years, so the iron switch he made at The 2024 Masters came as a shock to the norm. He simply isn’t one to change gear very often, so anytime Cantlay makes a switch, it’s news.

It seems the floodgates of equipment testing have opened up a bit for Cantlay, who was also spotted testing a custom Scotty Cameron blade putter on Tuesday this week. By Wednesday, Cantlay was back practicing with his familiar Scotty Cameron T5 Proto mallet, but it’s certainly something to keep an eye on going forward.

Daniel Berger’s custom Jailbird site lines

Berger, who’s currently using Odyssey’s Ai-One Mini Jailbird mallet putter, has a unique 3-dot, 2-line alignment on the crown of his navy-white-navy-white mallet putter. Looking down at the putter, it’s easy to see why this alignment system would help; it just seems impossible to set up to the ball off-center, or misaligned to the target.

Also, for anyone worried, you can rest easy. Yes, he’s still playing the 2013 TaylorMade TP MC irons, which we highlighted in our recent “Modern Classics: Old vs. New” video testing series.

FitzMagic teams back up

Brothers Matthew and Alex Fitzpatrick are teaming up once again at the Zurich this year, and Bettinardi Golf hooked them up with some festive “FitzMagic” headcovers to match this week.

See what else is in Alex Fitzpatrick’s WITB here

And, with that, we say goodbye to the Zurich Classic in New Orleans. Don’t forget to check out all of our photos from this week, including 30 unique photo galleries full of equipment photos.

We’ll see you next week in Texas for the 2024 CJ Cup Byron Nelson!

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Alejandro Tosti WITB 2024 (April)

- Alejandro Tosti what’s in the bag accurate as of the Zurich Classic.

Driver: Srixon ZX5 Mk II LS (9.5 degrees @10.5)

Shaft: Project X HZRDUS T1100 75 6.5

3-wood: TaylorMade Qi10 Tour

Shaft: Project X HZRDUS Black 80 TX

Hybrid: TaylorMade Qi10 Tour Rescue (22 degrees)

Shaft: Project X HZRDUS Smoke Black RDX 6.5 100

Irons: Srixon ZX7 Mk II (4-PW)

Shafts: True Temper Dynamic Gold Mid Tour Issue X100

Wedges: Cleveland RTX6 ZipCore Tour Rack (50-10 MID, 54-10 MID, 58-10 MID, 60-06 LOW)

Shafts: True Temper Dynamic Gold Mid Tour Issue X100, S400

Putter: Scotty Cameron

Grips: Golf Pride MCC Plus4

Check out more in-hand photos of Alejandro Tosti’s WITB in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Drew Brees WITB 2024 (April)

View this post on Instagram

Driver: TaylorMade Stealth 2 Plus (10.5 degrees)

Mini driver: TaylorMade BRNR Mini Copper (13.5 degrees)

5-wood: TaylorMade Stealth Plus (19 degrees)

Irons: TaylorMade P790 (4-8, PW), TaylorMade P760 (9)

Wedges: TaylorMade MG Hi-Toe (52-09, 56-10, 60)

Putter: Scotty Cameron Select Newport 2 Prototype

Check out more in-hand photos of Drew Brees’ clubs here.

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole3 days ago

19th Hole3 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole3 days ago

19th Hole3 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole1 week ago

19th Hole1 week agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

Pingback: Ein genauerer Blick auf die neuen Callaway Jaws Raw Wedges - Nach Welt

Pingback: GolfWRX Spotted: Prototype Callaway Jaws wedge – GolfWRX

Pingback: Best wedges of 2021: Traditional – GolfWRX

Sean

Oct 9, 2019 at 6:14 am

Great wedges. Well worth the investment.

chadj

Sep 10, 2019 at 8:13 pm

No LH 46 degree or 64 degree, but 5 different LH options for a 60 degree. Seems fair callaway….idiots

Milo

Sep 10, 2019 at 7:07 pm

Why are wedges so damn expensive?

gwelfgulfer

Sep 11, 2019 at 9:00 am

Because people continue to pay the prices. Lemmings will always lemming.

DB

Sep 10, 2019 at 3:10 pm

They look good, forged or cast?

Greg

Sep 10, 2019 at 12:31 pm

The steel shaft offering sucks.

Travisty

Sep 10, 2019 at 9:26 am

These are actually a nice step forward from MD4 (and MD3 before that). Callaway is doing great things in their wedge department. The black finish here IMO is much better than before too.

Off-Centre ChromeSoft

Sep 10, 2019 at 8:05 am

Find it, cut it.

Bradley

Sep 10, 2019 at 7:46 am

I wonder if Callaway clubs are off like there golf balls?