“Yeah, he ( Mike Taylor ) worked on all these irons. He worked on all my wedges. I talk to him probably every few weeks, giving updates on how I feel, things that I think could be better. He’ll bounce a few ideas off me, what I think, what direction we need to go down the road, how can we make them any better than what they are. And this is the same process I went through all those years when I was working with him at Nike. But now working with him at TaylorMade, it’s a lot more seamless.”

Equipment

Tour issue irons: A look behind the curtain

Thanks to the big win by Francesco Molinari at the Arnold Palmer Invitational recently, I think it’s important to evaluate a few things that are very interesting about his equipment, and the equipment used by other players on tour.

First off, even after a banner year, including a major victory at The Open Championship, Molinari made a full-scale equipment change to a full bag of Callaway clubs, including the Chrome Soft X Ball.

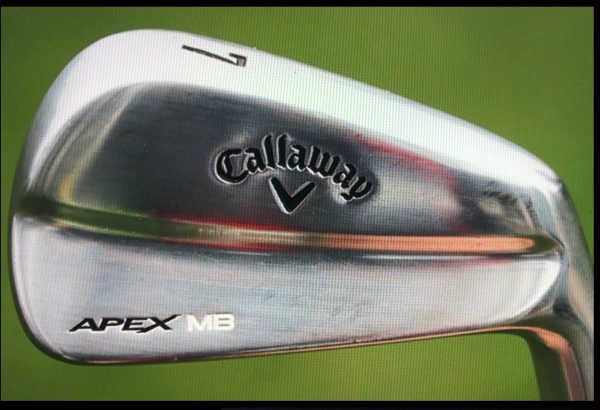

Certainly, this speaks to his confidence in the company’s equipment in general. Specifically, though, the most interesting part of this new full bag of Callaway gear are some interesting prototype blade irons, that when asked about were confirmed to Golf.com‘s Jonathan Wall “These [Apex MB] forged blades are made, I think, in Japan, so they’re slightly different from the standard muscle back.”

As you can see below they are similar but clearly are a different shape from the retail offering below.

I decided to point these prototype irons out on Twitter ( Twitter – Ryan Barath ) not realizing the amount of attention it would get. But none the less, it was intended to educate not to create confusion. The one thing that continues to be true with professional golf is that PGA Tour pros (especially ones with majors on their resumes) have access to essentially anything they want from their sponsors including “made for” prototypes. Let’s be real straight here, this kind of stuff has been going on for a long long time even back to persimmon woods, but thanks to social media and full-time equipment coverage, the consumer has the ability to see what’s really going on behind the curtain.

So what are some famous examples of “tour issue” clubs? Where do they come from? Who’s got them? What do they really offer? Let’s take a look back over the last couple decades and find the real gems.

Tiger Woods: multiple sets

Before amateur Tiger became professional Tiger, he was racking up wins with a combo set of Mizuno MP14 and 29 irons. After that, it was on to Titleist, then the BIG Swoosh. At Titleist, Tiger worked with the legendary builder Larry Bobka, and together they created sets just for him. (Full story on The Gear Dive Chats with Larry Bobka)

Larry Bobka Ground Titleist Blades

When Tiger moved to Nike Golf, he was introduced to Mike Taylor. There’s no need to really go too deep on MT’s impact on the game of golf, since so much has already been said, but a quick refresher: his roots run deep with shaping clubs to perfection, from Hogan, to Impact Golf Technologies (Tom Stites post-Hogan Company, which in essence became Nike Golf overnight), to now Artisan Golf. Together, they worked on a number if irons from the original forged blades to the MM Proto.

On of my top favourite irons of all time PERIOD

With Nike’s departure from the equipment space and now being a part of TaylorMade’s staff, Tiger has the ability to work with their entire R&D team, while also benefiting from Mike Taylor’s work at Artisan Golf in Ft Worth Texas, to create the original masters for what are now the P7TW irons.

There was always speculation about this relationship until recently when it was confirmed by PGA Tour.com’s Equipment Writer, Andrew Tursky, during an interview with Tiger

What makes Tiger’s irons unique is they are very square and have a high muscle, which leads to a higher COG. This is the most apparent with his new TaylorMade irons compared to the other P730 model. The other thing with Tiger is that he famously plays what we now consider weak lofted clubs with a 49 to 50-degree pitching wedge, compared to the modern standard of 45. As one of the best ball strikers the game has EVER seen, and someone that has notoriously been an extremely picky player from an equipment standpoint, it makes sense that Tiger wants to see the ball go through very precise windows and feel a very particular way.

Beyond the irons, there are also the many, many prototype fixed-hosel drivers that he played during his time with Nike golf including: Original Forged, Ignite, SQ Sumo, VR Proto, Vr Dymo Tour (also made famous Mr. Anthony Kim) and then finally the Covert. Only a few of these were ever made available at retail.

Mike Weir: Left-handed R7 forged protos

Canada’s favorite lefty. Before signing his agreement with Taylormade, Mike used to play Hogan irons — if you are familiar with the Hogan brand and some of its designs, there are a few classic telltale design traits, including a higher straight (very square) hosel transition to the top line, a good amount of offset, and an overall square look.

In the era of big money on tour, and with Weir’s status as one of the top-15 players in the world during the 2000s, he was able to work into his contract that he would only play irons if they 100 percent fit his eye. It was this little clause (confirmed and not confirmed) that throughout his best finishes (including his Masters win), Mike played a set of completely one-off TaylorMade prototypes.

Weir’s irons were always branded with the most modern line TaylorMade was producing, but the most famous of these were his original left-handed prototype R7 irons. A standard (and very different) retail version of these came out in limited numbers right-handed, but as far as “tour issue” gear goes, these are still considered one of the rarest sets ever produced.

Danny Lee: Luke Donald Personal Grind MP-32s

Although I did a full breakdown on these a few weeks ago (WRX article here), these irons deserve to be in this conversation, not because of their age and recent usage, but as an example of how some tour only gear is really just a small tweak to an already fantastic design. As a Mizuno fan and gear junkie, although they didn’t last a very long time in Danny’s bag, I’m seriously hoping they make a return sometime this year.

Francesco Molinari’s Callaway Apex MBs

I mentioned these off the top, but what I want to discuss is that, although these are clearly not the retail version of the Apex MB, we as consumers should understand that what we are playing is still 100-percent premium equipment. A set of irons like this is way more about looks than performance. Francesco is one of the premier iron players in the game, and like any player that has a crazy repeatable action (and by the way hits golf balls day in and day out FOR A LIVING), he wanted something that fit his eye with squarer lines compared to the standard Apex MB, and Callaway did its part as his sponsor to deliver an iron to his liking. Don’t forget it took a bag full of woods, hybrids, and wedges to help Francesco get another win under his belt.

Sure, not everyone can go out and fully customize the head shape of an Apex MB, but if you are looking to go that extra mile and get exactly what you are looking for there are options out there including Yoro Craft from Mizuno and National Custom Works irons by Don White. Are they pricey? Yep! BUT if you want something all yours, the option is there.

So what does this mean for the average golfer?

It’s extremely important to get custom fit for your irons and approach the process of getting a new set with an open mind. The reason these tour issue clubs exist in the first place is because OEMs want to make sure that their players under contract are using something that fits them to a tee, along with hoping to have these in the winning bag come Sunday afternoon. It’s way better to have your “guy” playing a prototype that he loves and plays well with, then having him feel like he is compromising and running the risk of not playing his best. We all know confidence in equipment means the same to a tour pro as (if not more than) it does to a 15 handicap.

In their own way, what these OEMs are doing is creating a “branded” brand-agnostic bags so that each player has exactly what they need. These designs are still coming from in-house company designers (in 99 percent of cases ), but as we already know, the difference is these clubs are either extremely small batch or one-off prototypes. Same can be said for metal woods, since we have seen examples of fixed hosel Callaway Epic Flash fairway woods, too. The other thing to consider is, thanks to these prototypes, designs are constantly being tweaked, and the next generation of retail clubs might take these preferences built right in — the Luke Donald grind is the perfect example.

GolfWRX was founded with the idea to share these unique clubs and help people see “behind the curtain” when it comes to equipment from every OEM. Whether it be a $4,000 Scotty Cameron 009 that might work just as well as a $150 putter with identical specs, it’s not really about that for “us.” It’s about having something different and unique. Within every group of hobbyists, there are those that seek out the different and rare. From sneakers, to cars, to golf clubs, I’d be completely dishonest if I said the “cool” factor wasn’t part of the what makes these things so interesting in the first place.

When talking to GolfWRX founder Easyyy recently about the history of the site and some of the crazy gear we have seen over the years, we both agreed that there is “something” about playing either tour issue gear, or a club built just for you. The driver you know the exact specs of, the irons with different bounce or grooves, the wedges with grinds you just can’t buy off the shelf — whether they really are better or not, as golfers we want EVERY single last advantage we can get out of our gear, and getting the chance to play these clubs and feeling like there is a positive impact might just be as good as intrinsically superior equipment.

At the end of the day, for us mortals who are buying our own equipment, it’s vital to get the most out any new clubs by keeping an open mind on everything from brand to shaft flex, and in some cases, seeking out a tour issue component. Regardless of brand, choose the 14 clubs that fit you best and the ones you like the look of. Like I said before, confidence in your gear is something you can’t put a price on.

- LIKE218

- LEGIT24

- WOW7

- LOL146

- IDHT2

- FLOP151

- OB147

- SHANK209

Whats in the Bag

Rasmus Højgaard WITB 2024 (April)

- Rasmus Højgaard what’s in the bag accurate as of the Zurich Classic.

Driver: Callaway Ai Smoke Triple Diamond (10.5 degrees)

Shaft: Mitsubishi Tensei 1K Blue 60 TX

3-wood: Callaway Ai Smoke Triple Diamond Prototype (16.5 degrees)

Shaft: Mitsubishi Tensei 1K White 80 TX

Utility: Callaway Apex UW (21 degrees)

Shaft: Mitsubishi Tensei AV Raw White 85 TX

Irons: Callaway Apex Pro (3), Callaway X Forged (4-PW)

Shafts: KBS $-Taper 130

Wedges: Callaway Jaws Raw (52-10S, 56-10S, 60-06C)

Shafts: KBS Tour 130 X

Putter: Odyssey Ai One Milled Eight T DB

Grips: Golf Pride MCC

Check out more in-hand photos of Hojgaard in the forums.

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Rory McIlroy WITB 2024 (April)

- Rory McIlroy what’s in the bag accurate as of the Zurich Classic.

Driver: TaylorMade Qi10 (9 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Fujikura Ventus Black 8 X

5-wood: TaylorMade Qi10 (18 degrees)

Shaft: Fujikura Ventus Black 9 X

Irons: TaylorMade Proto (4), TaylorMade Rors Proto (5-9)

Shaft: Project X 7.0 (4-9)

Wedges: TaylorMade MG4 (46-09SB, 50-09SB, 54-11SB), Titleist Vokey Design WedgeWorks (58-K @59)

Shafts: Project X 6.5 (46-54), Project X 6.5 Wedge (60)

Putter: TaylorMade Spider Tour X3

Grip: SuperStroke Zenergy Pistol Tour

Ball: 2024 TaylorMade TP5x

Grips: Golf Pride MCC

Check out more in-hand photos of Rory McIlroy’s WITB in the forums.

- LIKE3

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

Equipment

Spotted: Nate Lashley’s Ping PLD “Wolverine” putter

Ping PLD putters have been a very common site on profesional tours. Pros seem to gravitate toward the PLD line’s custom options and precision milling. We have seen the PLD line expanded over the years, but we haven’t seen too many, if any, large mallets.

This week we spotted a PLD putter in Nate Lashley’s bag that has a similar look to the old Ping Wolverine head shape. This putter is a large mallet with the famous “claws” on the outside and oval center that housed the alignment aid.

Nick’s putter has the PLD logo on the back but also looks like it might have an insert installed on the face. It is hard to tell but at the address picture, it looks like the face is a lighter material than the rest of the putters. The putter is center-shafted and should be face-balanced with a high MOI for stability and forgiveness on mishits. The sole is completely milled and has no markings of name or technologies that might be present in the head. A single white site line is on the top of the putter for alignment.

Nick’s putter is finished off with a chrome steel shaft and a Super Stroke Zenergy Flatso 2.0 grip in black and white.

- Check out the rest of our photos from the 2024 Zurich Classic

- LIKE4

- LEGIT3

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB2

- SHANK2

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 days ago

19th Hole2 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 days ago

19th Hole2 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

youraway

Apr 14, 2019 at 8:53 pm

All USGA Conforming

DAVID LAUF

Apr 9, 2019 at 2:25 pm

I read above about the Miura comment but was told by a Lynx Tour rep. that the Lynx Irons Fred Couples used were actually forged by Miura and stamped Lynx.

Rich Douglas

Apr 7, 2019 at 9:01 pm

I “Liked” the article, but I never, ever read WITB pieces. They don’t matter for two important reasons.

First, WITB should be re-named “WITC” (What’s in the Contract). There are almost no choices being made by these players; they play what they’re being paid to play. Why should the reader care about that? The only time the concept is at all interesting is when a player signs a deal and has to play clubs that mess up his game. Payne Stewart comes to mind.

Second, it doesn’t matter WITB because it doesn’t apply to “WIYB” (What’s in YOUR Bag). As this article demonstrates, you can’t get what your favorite pro plays because his/her gear is custom-made, fitted, and ground. Even if it is marked the same, the clubs usually aren’t. Also, you can’t play that club anyway. You can’t play ANY of the clubs in the player’s bag–even the driver is different (and probably has a lot more swing weight and a much lower CG).

That’s why people go nuts over putters. They’re the one club Joe Average can wield just like his favorite pro. Remember when Nicklaus won the Master’s in ’86 using that giant brick on a fishing rod? They sold a huge number of those in the ensuing weeks!

WITB? Who cares? I don’t care what kind of shocks are on Kyle Busch’s car and I don’t care what irons Tiger Woods is gaming. I can’t use either one.

Benjamin

May 5, 2019 at 6:45 am

…yeah…go get em’ brother…

chip75

Mar 29, 2019 at 6:30 pm

“I mentioned these off the top, but what I want to discuss is that, although these are clearly not the retail version of the Apex MB, we as consumers should understand that what we are playing is still 100-percent premium equipment.”

I think this has always been up for debate. In their heyday tour issue clubs weren’t just more desirable for their uniqueness, they were desirable because of their quality, look and feel. Our store bought equipment just wasn’t the same, the difference between the place of manufacturer was noticeable.

jl

Mar 29, 2019 at 4:43 pm

In my time with Adams Golf, we had dozens of “tour issue” hybrids that you couldn’t buy on the shelves that were in the bags of tour players. From the 9031sf and 9031df hybrids to the highly sought after “PNT” hybrids, each hybrid was basically an “in betweener” that made it easier for us as reps to get a hybrid into a particular players bag because it gave us more shots for the players to be able to hit. The stock offerings were great, but Tour players often needed the flight to be a little higher or lower to fit their eye, or a face angle or paint line to be a little lower on the crown to have a certain look. We even had every loft from 14* to 28* in some models of the hybrids available to the players so we could hit a certain yardage gap, and we bent every hybrid we made to loft, and lie spec.

Every player was different and had a different idea of how they needed that club to perform, and we were able to deliver because we had the ability to fill gaps. As far as the “tour issue” clubs being hotter, or more or less forgiving, etc….. not true. Faces on tour were more closely monitored to ensure that they were conforming to USGA specs and were often “slower” off the face than retail models to ensure that there was no chance of structural failure during play. The last thing you wanted as a rep was to have a “gamer” crack. You lost your chance to get a second one in play.

Kade Patterson

Mar 29, 2019 at 12:50 pm

Weirs irons are absolutely hideous!

Harry H Adam

Apr 29, 2019 at 6:11 pm

Weird?

Mario

Mar 29, 2019 at 10:30 am

Most of these are Muiras

Bob

Mar 30, 2019 at 10:14 pm

Please…..stop……with the “they’re all Muiras” bullshit line….

J

Mar 29, 2019 at 10:26 am

234 negative reactions in the first hour? Why?

Shallowface

Mar 29, 2019 at 7:31 am

An interesting read. I’d like to see something similar on the golf balls currently used on Tour, as we’ve heard in the past that a lot of custom designs and even past models are in play.

Q

Mar 29, 2019 at 10:54 am

I’ve heard their is 6 models of Pro V1/V1x in play on tour not including older models. Most are lower or high spin versions.

Simms

Mar 29, 2019 at 7:23 pm

For sure you can bet Ricky has special balls from Taylormade… grew up with an uncle in the golf ball business…(past in 2010) he told me many players have special little needs that could be taken care of in their supply of golf balls..but he said they were not major differences from the standard and some just got balls that were considered the best of a bunch….

MCoz

Mar 30, 2019 at 11:37 am

No Ricky played the commercial ball. Years ago Sergio played a ball with a different dimple pattern, (bigger and fewer). Rose went to it also. That went on for 2-3 years but it worked as a prototype that helped development of later commercial models. Tiger at Nike usually played a special ball for himself. Most of the tour ballspice today are either the commercial ball or a prototype for the next model. Titleist has typically been the one to have the most different balls. But they have tried to stem the tide in recent years. They stopped shipping every model to each tour stop and forced those who wanted the oldest models to receive like 100 dozen at a time and bring their own balls to each event.

Benny

Mar 30, 2019 at 4:04 pm

Not only is Titliest a customer of mine but I know a couple who works at Titliest – ProV line. So while they have Prototype runs they Pros are playing the cream of the crop production balls. Ones that meet a much deeper check list than what hits the shelves. Ones that don’t hit the shelves sell as defects or range Premium balls. Pros can certainly request more of the prototype balls but if they aren’t production models that Pro will not have them very long.

The changes made in release is so small and there is no way Titliest could cater to each swing.

Simms

Apr 15, 2019 at 12:01 am

That sounds just what a Taylormade rep told me….tour players get the ones with fastest cores and get the best of of the best of any lot.

Benjamin

May 5, 2019 at 6:48 am

…that…would be on eye opener…

B

Mar 29, 2019 at 3:08 am

Yeah that Apex MB is actually a Mizuno lol

What a load of bull

Mower

Mar 29, 2019 at 10:21 am

Strange, it looks exactly like the MP-33!

Mizuno ftw!

Ed

Mar 29, 2019 at 4:28 pm

Not hardly ????

The dude

Mar 30, 2019 at 9:49 pm

It’s closer to a Miz than it is to a Cally….

…what?….WHAT!?!?!