Equipment

Hooking your hybrid too much? Here’s why the shaft could be the problem

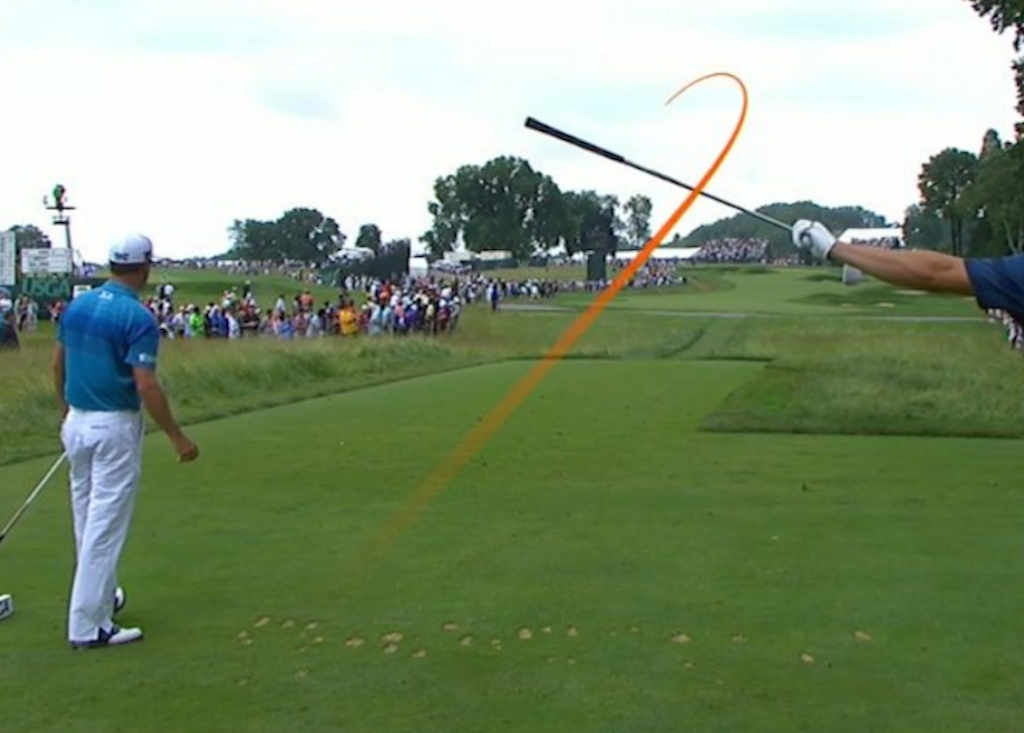

So, I have this recurring nightmare; I smoke one down the par 5 18th hole at my home course. Get to the ball and laser; 222 front, 227 pin. Perfect hybrid distance. I pull off the head cover, do my pre-shot routine and the ball takes off relatively straight. Then, it starts to curve left. Then it’s not just a curve, but a huge hook… and then SPLASH! In the pond short left.

Fed up with this dream, which is all-too-realistic based on my real game, I finally sought out answers while at a recent PGA Tour event. “Hey Kim! How are you sir?” I said.

“Brendan, how are you sir?” responded Kim Braly, my buddy and Director of R&D and Tour Operations at KBS Shafts.

“Well, not very good. As you know I love to play golf but have been struggling with my hybrid; I just seem to have the problem of duck hooking it at the worst times. Drives me crazy!” I responded.

“Look, next week at the Tour stop, why don’t you come spend time with me. It will be great to catch up and I think I might be able to help give you some insight into your problem” said Kim.

Day in the Tour Van? No snap hooks? Sold.

Arriving early, I was greeted at the Tour Van by Kim Braly and John Weber of KBS. “Welcome! Welcome, Brendan! Great to see you,” said Kim as I made my way up the stairs and entered the van. As we shook hands and greeted everyone, I handed Kim my hybrid for his thoughts and inspection. He quickly set it aside and said, “Brendan, what you have is a widespread problem with graphite because of the process of making the shaft. Unlike steel, which is a consistent material and easy to work with, graphite is complex. Graphite shafts are made through a process, which usually involves two or three sheets being cut and then woven together electronically to fit manufactures specifications. Although we have consistently gotten better at the process, graphite has limitations and it is very hard to make it stiff, light and consistent.”

I nodded and stopped, “Why is it so hard?” I questioned.

“When working with steel, you have almost perfect consistency and durability but have few options with weight (that’s why the lightest steel shafts are approximately 95 grams). With graphite you have greater problems with consistency; people want lighter, but it becomes hard to make stiff. As a result, many graphite hybrid shafts have large windows of frequency and they tend to be weak or soft. The result? Often that miss left you are struggling with!” explained Kim.

“So, does that mean that I need to change to steel? I will do anything to stop those quakers!” I responded.

“No. Most graphite companies are used to making wood shafts, not iron shafts. We have a ton of data to understand what players need in a hybrid shaft,” said Kim as he picked up my hybrid and walked towards the work bench. “The shaft we are going to test is our KBS Tour Hybrid Proto. It has very close to the same stiffness profile as our KBS Tour, which is what you play in your irons.”

“Oh, awesome! I love my iron shafts and honestly a lot of times I choose to hit 4-iron instead of my hybrid because I have a lot more confidence it will not go left!” I responded.

With meticulous precision, Kim worked on my hybrid. First, he applied heat and removed the head. He then cleaned the inside of the head and started the process of re-shafting the club. “We are going to ‘Pure’ this hybrid shaft, using this machine,” said Kim as he took the shaft and inserted it into one of the space-aged looking contraptions on the Van. He hit a button, the shaft spun and done. “That machine helped us to understand where the shaft should be placed to optimize performance. Now we need to get a ferrule, glue the club and have you pick a grip” he said as he opened Pandora’s box of grips.

My eyes went wide, and I started to look through the grips, finally settling on one, “how about this?” I said as I handed it to Kim.

“Perfect,” he said. “Let me put it on and we will be ready.” After about 15 minutes of letting everything dry, Kim presented me with my new weapon; it was beautiful! I thanked him and took off to the car, excited to test the club at my local club.

As I got into the car, I called my best friend Julian: “Bro, can you get an emergency 9 in? I just got a new KBS Proto shaft in my hybrid and I am feeling muy confident!”

“KBS Proto! Whaaaa? That’s a killer shaft. Phil Mickelson used one this year when he won. I’ve wanted one soooooo bad. Ya, I’m on the putting green. Let’s play!” responded Julian.

Of course, we headed off the back and on the 18th hole I smoked one leaving 216 yards to the pin. It was the moment of truth; hybrid time. Pulled the club, went through my routine and SMASH. “Pure!” said Julian as I smiled and watched the ball sail straight towards the green.

- LIKE61

- LEGIT9

- WOW2

- LOL11

- IDHT4

- FLOP10

- OB8

- SHANK212

Whats in the Bag

Taylor Montgomery WITB 2024 (March)

- Taylor Montgomery what’s in the bag accurate as of the Cognizant Classic. Check out more photos from the event here.

Driver: TaylorMade Qi10 (9 degrees)

Shaft: Graphite Design Tour AD VF 7 TX

3-wood: TaylorMade Qi10 Tour (15 degrees)

Shaft: Graphite Design Tour AD VF 8 TX

Hybrid: TaylorMade Qi10 Tour (19.5 degrees)

Shaft: Mitsubishi MMT HY 100 TX

Irons: TaylorMade P7TW (4-PW)

Shafts: True Temper Dynamic Gold Tour Issue X100

Wedges: TaylorMade MG4 (52-09SB, 56-12SB), Vokey Design WedgeWorks Proto (60-T)

Shafts: True Temper Dynamic Gold Tour Issue X100

Putter: TaylorMade Spider Ghost S

Grip: Elite

Grips: Golf Pride MCC

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

WITB Time Machine: Paul Casey’s winning WITB, 2019 Valspar Championship

At the 2019 Valspar Championship, Englishman Paul Casey took the trophy at the Copperhead Course for the second year in a row. On a difficult Sunday, Casey’s 1-over 72 was good enough for a one-stroke victory over Louis Oosthuizen and Jason Kokrak as Dustin Johnson faltered.

Check out Casey’s clubs from five years ago below.

Driver: TaylorMade M4 (10.5 degrees)

Shaft: Mitsubishi Diamana D+ Limited 70 TX (tipped 1 inch)

3-wood: TaylorMade M1 (15 degrees)

Shaft: Mitsubishi Diamana D+ 80 TX Limited (tipped 1.75 inches)

Irons: Mizuno MP-25 (3), Mizuno JPX 919 Hot Metal Pro (4), Mizuno MP-5 (5-PW)

Shafts: Nippon N.S. Pro Modus3 Tour 120 TX

Wedges: Titleist Vokey Design SM7 (52-08F, 56-10S), Vokey Proto (60)

Shaft: Nippon N.S. Pro Modus3 Tour 120 X

Putter: Scotty Cameron Circle T 350-SSS

Grip: Scotty Cameron Matador

Grips: Golf Pride ZGrip Cord Midsize

Golf Ball: Titleist Pro V1

Mizuno’s Senior Club Engineer, Chris Voshall told us Casey’s somewhat surprising setup in his long irons is simply the product of Casey hitting the windows he wants to with the particular clubs in question.

“It’s all based on the height of the ball flight,” Voshall said. The MP-25 3-iron was more penetrating and better for him off the tee, so he kept it in there.”

- LIKE2

- LEGIT2

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Coolest thing for sale in the GolfWRX Classifieds (3/22/24): Nike Vapor Pro Combo 4-A iron heads

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a set of Nike Vapor Pro Combo 4-A iron heads.

From the seller: (@DrCoFo): “Nike Vapor Pro Combo 4-A heads in really nice shape. Just bought these recently- thought I would be the cool kid on the block with the Nikes. Was going to do a custom look, but I was way too ambitious and would rather just have a new set of irons. So here we are. Heads are already pulled from the shafts. Ready for your project needs. $550 shipped.”

To check out the full listing in our BST forum, head through the link: Nike Vapor Pro Combo 4-A iron heads

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE5

- LEGIT0

- WOW1

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK1

-

Whats in the Bag3 weeks ago

Whats in the Bag3 weeks agoScottie Scheffler WITB 2024 (March)

-

Tour Photo Galleries3 weeks ago

Tour Photo Galleries3 weeks agoPhotos from the 2024 Arnold Palmer Invitational

-

19th Hole3 weeks ago

19th Hole3 weeks agoJoaquin Niemann names 3 PGA Tour events he’d love to play each year ‘in a perfect world’

-

19th Hole3 weeks ago

19th Hole3 weeks ago‘Seems suspect’ – PGA Tour pro hits out at decision to hand Adam Scott and Webb Simpson Bay Hill sponsor exemptions

-

Equipment3 weeks ago

Equipment3 weeks agoSpotted: Bettinardi irons at the Arnold Palmer Invitational

-

19th Hole3 weeks ago

19th Hole3 weeks agoPaulina Gretzky opens up on receiving death threats following DJ’s move to LIV Golf

-

19th Hole3 weeks ago

19th Hole3 weeks agoVincenzi’s 2024 Arnold Palmer Invitational betting preview: Big names ready to pounce at Bay Hill

-

19th Hole3 weeks ago

19th Hole3 weeks agoVincenzi’s LIV Golf Hong Kong betting preview: Trio of major champs primed for big week

Pooter

Aug 29, 2018 at 2:03 am

We are all dumber for having read this. I award you no points and may god have mercy on your soul.

Nathan

Aug 2, 2018 at 7:32 pm

Why not just get your Driver shaft pured with a new KBS Tour Shaft? That way, you’ll hit it 30 yards further, leaving yourself only 190 in to the flag, where you can stiff your 6 iron (with KBS shaft)? Seems like a much better solution to me.

Poot

Aug 2, 2018 at 2:16 am

This is why KBS is overrated, and I will never use their shafts as they all feel like cr!p

JARED BRANT

Aug 2, 2018 at 1:10 am

Hate to say that I actually feel dumber now that I read and reread this article multiple times. I thought I missed a paragraph that may have explained something about the loft, grip size, stiffness, length or anything that would cause the ball to go left. I think it ultimately just said that I should buy a shaft made of “Pure Steel”?!

Offcho

Aug 1, 2018 at 8:14 pm

This might be the worst article/click bait ever on GolfWRX. I want my wasted time back reading this garbage.

woof

Aug 1, 2018 at 7:18 pm

lol look at all the true temper kids getting mad online

Ron Swanson

Aug 1, 2018 at 4:48 pm

This story is awful, misleading and the statements being made by Kim Braly are embarrassing for someone in the golf industry whose business is shafts. Also, he knocks graphite, but yet their “proto” shaft is made of graphite, a material they have NO expertise in? First of all, his statements about graphite are grossly untrue. And also, if graphite is so inconsistent then why is it used in driver shafts for players with swing speeds upwards of 125 mph? Hybrids go left because they are almost always too upright from the factory, period. It aint the shaft. This article should be deleted as it is reciting false quotes and misleading your readers. This is embarrassing for GolfWRX to have on their website.

Pete O'Tube

Aug 1, 2018 at 4:37 pm

Dreadful, overexcited journalism.

PT

Aug 1, 2018 at 4:29 pm

What hybrid are you using? What loft?

Terrible advertorial for KBS, this.

JD

Aug 1, 2018 at 4:24 pm

I sure hope KBS didn’t pay very much for this article.

stevez

Aug 1, 2018 at 3:33 pm

most hybrids are 1.5″ longer than the similar # iron, think Wishon has said the hybrid length should be similar to iron.

DB

Aug 1, 2018 at 2:59 pm

Interesting info, just don’t know why you wrote the article as if your audience was 13 year-old girls.

Acemandrake

Sep 1, 2018 at 6:53 pm

That’s funny (& true).

Max

Aug 1, 2018 at 1:33 pm

Hooking hybrids off the planet? Here are some reasons:

-ball too far forward in stance

-standing too far away from the ball, promoting an in to out path

-club is too upright

-club is too light

-club is draw biased

-stock shaft is a wet noodle piece of garbage

larrybud

Aug 1, 2018 at 3:13 pm

Bingo on all fronts. My main issue is too upright. I play 3 flat irons, and with the 3/4 hybrid they don’t get too hooky, but with the 5 the face is aiming left unless I open it up a bit.

David

Aug 1, 2018 at 1:00 pm

Light, weak, high-torque shafts in hybrids (especially higher lofted hybrids) are what pretty much all OEM’s install in their hybrids. They want the ball to go “high and far” with hybrids. It’s a recipe for disaster.

You want to hit your hybrids rock-solid? Get heavier, stiffer shafts in your hybrids than the OEM wants to put in them and you will be on your way to much, much better shots with your hybrids, and they will more faithfully replace the iron they are supposed to replace that way also. Just look out for lofts. a 23 degree hybrid is a 5-hybrid??? WTF?? You will hit that every bit as far (or farther) than a typical 4-iron.

SMH at OEM’s….

carl

Aug 1, 2018 at 12:24 pm

Yep you hooked your hybrid cause the shaft wasnt pured. HaHaHa

Also calling people ‘Bro’ after you get your new $200 KBS hybrid shaft is a must