Equipment

This custom-putter fitting at Bettinardi was more in-depth than you can imagine

When you think of getting a “custom putter,” what do you envision? Length, loft and lie angle measurements, of course, picking your head shape and the grip you want, then maybe put a few stampings on there and be on your way, right?

Well, that’s not the Bettinardi way.

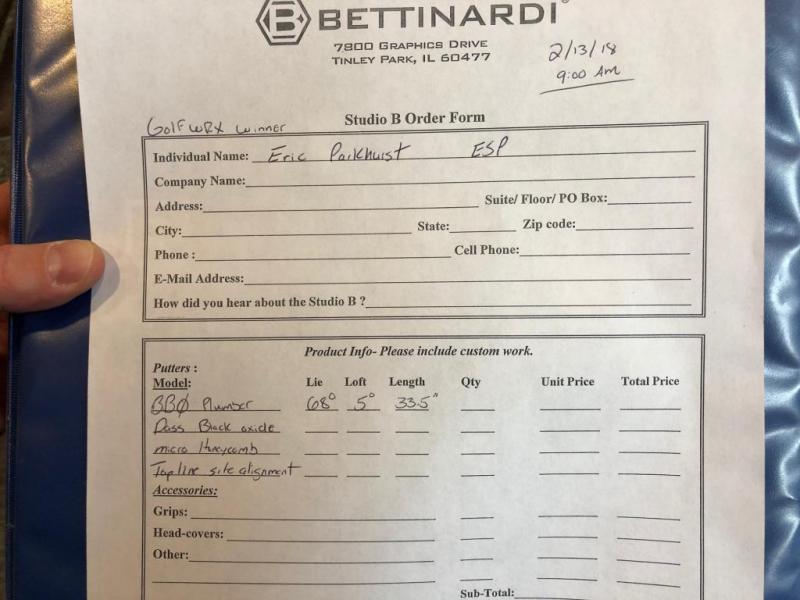

As part of an incredible giveaway, Bettinardi allowed one GolfWRX Member (one of hundreds who entered), to travel to Bettinardi Headquarters to get a “custom putter fitting.” The very-lucky GolfWRX Member “ESP” won the giveaway, but he had no idea what he was actually getting himself into. Hint: He sat down with company founder Bob Bettinardi himself to design his very own putter.

Since Tinley Park, Illinois — where Bettinardi HQ is located — is only a 4-hour drive (or 5-and-a-half with an accident-induced traffic jam, as the case may be), I decided to make the trip and observe exactly what goes into a Bettinardi custom fitting, and how it might be different than what other putter companies may offer.

I’ll explain my observations and what I learned below, but make sure to check out this forum thread where we updated the experience live from Bettinardi HQ with tons of photos. In the thread, member ESP also leaves his full thoughts and answers questions.

First, a Tour of Bettinardi’s manufacturing facility

Bettinardi takes pride in doing all of its milling in house. Actually, it does everything except plating. This allows Bettinardi engineers and Bob Bettinardi himself to walk just steps from his office, directly onto the manufacturing facility floor. That way, he can have his eye on everything from tolerances to welding to paint filling.

“Anything that’s happening, I can walk out there and have my eyes on it,” Bettinardi said. “That’s huge. It’s not China that’s 6,000 miles away, where you put something on a .zip file and hope it’s right, and you gotta wait until it’s in your hands. It’s so much better to be here and see the product being made.”

Bettinardi founded the company in 1998, and he’s been making high-end, precision putters in his facility ever since. You’d be surprised at some of the putters that his company has milled for other companies (i.e. original Scotty Cameron Terylium putters), and he keeps many of his more notable millings in a trophy-like case right in his office.

But, as his son Sam Bettinardi (VP of Sales and Marketing at Bettinardi) says, you won’t see Bob out in the shop welding putters or on the grinding wheel. That’s not what he does. He’s an idea man, and he knows how to get things done.

“I used to keep a notepad [for my ideas],” Bettinardi says. “Now, I use guys like him as my notepad (pointing to engineer Takashi Yoshii).”

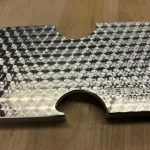

Bettinardi mills putters for retail releases, custom designs and Tour-player-specific needs. But, since Bettinardi is an idea man, the company also mills things such as wallets, phone cases, ash trays, flasks, belt buckles, ball markers and more. Many of which have Bettinardi’s recognizable Honeycomb design. Brief sidenote: The honeycomb milling pattern was birthed because Bettinardi was looking for a way to make the putter face flatter, instead of convex; so he and his engineers came up with eye-catching honeycomb face not for aesthetics, but actually, for function! Who woulda thunk.

Anyway, Bettinardi’s facility houses rows of CNC-milling machines that keep ultra-tight tolerances, a throw-back Bridgeport machine (on which it milled its first putters), and more of what you’d expect in a putter manufacturing facility. But, Bettinardi has something on the manufacturing floor you won’t see anywhere else: the first-ever American made Mori Sieki machine, which was made in California. Bettinardi prides itself on making American-made putters, so this was a point of note.

In another section of the manufacturing floor was where the sexiness happens. Putters get welded, buffed, and made to look pretty with paintfills.

And, of course, a cabinet full of shiny Bettinardi putters that putter enthusiasts could surely stare at all day long.

Now, it was time for ESP to design a putter for himself. Let’s get fit, shall we?

The fitting process

Somewhere toward the end of the Tour, GolfWRX Member and man of the hour “ESP” turned to me and said, “I don’t know what I’m going to do. What should I do?”

After seeing the in-depth process in how a putter gets made, and all of the capabilities Bettinardi has on site, he seemed a bit overwhelmed by the fact he was actually going to design his own putter. I’ll admit, I’d have been overwhelmed too. I mean, how often do you get the opportunity to literally design your own putter? That’s a lot of pressure.

But alas, he started the process.

We walked upstairs to Bettinardi’s private putter fitting studio where we met with Brad Hommes, who would be conducting the fitting. He offered us a beer from Bettinardi’s custom keg, but at 9 a.m. that seemed a bit aggressive, and not terribly conducive to a proper balance during the putter fitting, so we declined.

Then, The Hive gates opened for us, allowing us to go where few golfers have gone before. Sam Bettinardi entered the code for the newly renovated and ultra-exclusive “The Hive,” which houses Bettinardi’s most rare and expensive putters. Inside, ESP selected some putter models that he liked, and drew inspiration from some designs. To get a feel for what he liked from a sound and feel perspective, he hit some putts on the turf golf green. He quickly noticed significant differences between the FIT Face, the honeycomb face, and the micro honeycomb face. It was also clear that ESP, who previously gamed a Scotty Cameron Newport 2, preferred a BB-0 or BB-8 style head, rather than a mallet. He also said he liked the carbon feel, preferred more feedback to less, and stressed he did not want a putter that would rust.

So with four finalists, ESP headed into the fitting section of the putter studio to get some data and really get dialed in. Ultimately, he needed to make a decision on head style, face, material, hosel and grip… not to mention color schemes, stampings and more. With a lot to do and decisions to make, it was time to get to work.

To conduct its fittings, Bettinardi uses a V1, 4-camera system that captures 60 frames per second. According to Hommes, Bettinardi’s fitting philosophy is very much understanding what the player likes, hears and feels, and they do not want to make any corrections to the players stroke; the point is to match a putter to their current stroke so they can make as many putts as possible with it. Like Hommes says, if you fit a player to a stroke that isn’t there’s, then the putter won’t fit when they revert back to their old stroke.

With that in mind, ESP stepped up on the putting mat with V1 analyzing his stroke. Fitter Hommes wanted to determine, as ESP switched putters in and out, which putter head was getting ESP’s stroke on the best plane going back. ESP’s tendency was to take the putter outside the line and cut across the golf ball, so Hommes wanted to find the head that influenced a more inside path.

For ESP, his job was to just stroke the putts, try to make every putt, and evaluate what head, shape, feel and hosel he liked the most. Surely, that process can get a bit confusing, but ESP was very in-tune with different feels and what he wanted.

“If I like the BB-0 head, but the BB-8 hosel, we can make that right?” ESP asked Hommes.

And that right there is the benefit of having the engineers and the manufacturing facility all under the same roof. Of course Bettinardi can make that happen!

Hommes determined throughout the fitting that ESP needed a lie angle of 68 degrees, as opposed to the standard 71 degrees. However, he wanted to try a BB-0 putter with a length of 33.5 inches and a micro honeycomb face. With none of those lying around, why not build one?

ESP took a liking to the new putter Hommes built, and even liked the grip, too. It wasn’t an absolute winner because the hosel still wasn’t right and it didn’t have the topline ESP wanted, but the putter Hommes built was looking like the winner — and ESP wasn’t missing a putt with it. Here’s what was going through ESP’s brain during that time.

After dialing in the specs we went back to the different millings and head materials to decide which felt the best to me,” ESP said. “I tried everything from a carbon head with F.I.T. Face milling, which was on the softer end of the spectrum, all the way to the Honeycomb DASS with sound slot on firmer end of the spectrum. The FitFace wasn’t for me and neither was the honeycomb with sound slot. I did like the micro honeycomb milling in both the carbon and DASS, which is somewhere in the middle of the feel spectrum feel. One of the hardest decisions was choosing between carbon or DASS. Both felt great, but at the end of the day I went with the DASS for durability and to get the finish I liked.

So, after over two hours in the fitting studio and one of the most in-depth, hands-on putter fittings I’ve ever witnessed, here are the specs for ESP’s putter.

It’s a DASS (Double-aged Stainless Steel) BB-0 with a plumber’s neck, a micro honeycomb face, black oxide finish, 68 degree lie angle and 33.5 inches long.

Now, design time!

Bob Bettinardi helps with the finishing touches

Picture this: You’re sitting around a conference room table, designing your own putter with Bob Bettinardi himself, and his engineer Takashi Toshii. Seems ridiculous, right? Well, that’s exactly what happened…

For this part, I’ll let ESP tell you about it in his own words:

“After we figured out the head and specs, we went off to the conference room to meet Robert Bettinardi and talk design. First, Robert talked about the history of the company and told some great stories about some of the tour players they have worked with over the years. They were excited about the upcoming Genesis Open at Riveria because they have several Bettinardi players in the field. Robert was great and I would have been happy to just sit and listen to him tell stories all day. Sam joined us in the conference room along with Takashi Toshii who would help with the design. We ate lunch and continued to talk all things golf and then Robert, Takashi and I worked on the design. At this point my head was swimming with all of the possibilities and I had a hard time deciding on a design. Ultimately, Robert and Takashi helped me come up with a few design ideas. After we completed the mock up we took a few pictures and Sam took me back to the Hive to look at covers. I could pick anything I wanted, which was another tough decision. Sam told me I should wait because they were receiving a new batch of covers that I could choose from. At the end of the day I picked one that I liked from the Hive to hold back and they will send me pics of the new ones to also choose from. We wrapped things up and I headed out to the airport.

I was back in my office yesterday morning and received an email from Brad with a mock up the putter. I was a little surprised to receive it so quickly! Brad and I traded emails and I had a couple of changes I wanted to make after giving it some thought. They are to send me photos as the putter progresses and I will post them as I get them.”

And there you have it. The day concluded in Tinley Park, Illinois with forum member ESP having designed his very own Bettinardi putter, with design input from Bob Bettinardi himself.

In all, including the tour, the fitting, lunch and the design process, we spent 6 hours at Bettinardi HQ. SIX hours on a custom putter fitting. That’s just the Bettinardi way, I guess.

To follow along in the latest development in ESP’s putter design process, and ultimately, see the final design, click here! And don’t be afraid to ask him a question yourself.

- LIKE145

- LEGIT20

- WOW15

- LOL5

- IDHT2

- FLOP2

- OB1

- SHANK12

Whats in the Bag

Michael S. Kim WITB 2024 (April)

- Michael S. Kim what’s in the bag accurate as of the Valero Texas Open.

Driver: Titleist TSR3 (10 degrees, B1 SureFit setting)

Shaft: Graphite Design Tour AD DI 8 X

3-wood: Ping G430 Max (15 degrees)

Shaft: Graphite Design Tour AD UB 8 TX

Irons: Titleist T200 (3, 4), Titleist T100 (5-PW)

Shafts: Graphite Design Tour AD IZ 95 X (3), Nippon N.S. Pro Modus3 Tour 120 S

Wedges: Titleist Vokey Design SM9 (52-12F), SM10 (56-14F), WedgeWorks Proto (60-L)

Shafts: True Temper Dynamic Gold Tour Issue S300

Check out more in-hand photos of Michael Kim’s clubs here.

Putter: L.A.B. Link.1

Grip: SuperStroke Zenergy Tour 1.0P 17

Grips: Golf Pride MCC

Ball: Titleist Pro V1x

Check out more in-hand photos of Michael Kim’s clubs here.

- LIKE0

- LEGIT0

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

TaylorMade BRNR Mini Driver Copper: Leveraging 90s nostalgia

TaylorMade is leaning in even further to the retro vibes with the 2024 edition of its BRNR Mini Driver.

Patterned after the Carlsbad-based company’s iconic late 1990s Burner driver design, the 2024 BRNR Mini features similar copper styling and a retro version of the TaylorMade logo.

Featuring the same technology as its 2023 BRNR Mini Driver, the 2024 edition continues to play the hits that saw the unique club land in the bag of tour pros, such as Tommy Fleetwood and Jake Knapp.

- Check out details on the technology in our 2023 BRNR launch story.

- See more in-hand photos and read what GolfWRXers are saying in the forums.

Why play a mini driver?

In general, TaylorMade finds two types of golfers gravitate toward a mini driver. In the first case, it’s an addition to a standard driver: Players looking for a “fairway finder” driver without giving up too much distance that can also be hit off the deck. Second, TaylorMade recommends giving a mini a go to golfers who struggle to hit 460 cc drivers, particularly choppers. It’s a better alternative than a 3-wood off the tee.

Tommy Fleetwood’s endorsement of playing a mini driver

“For me, if I HAD to hit a fairway, I’m more comfortable hitting a driver than a 3-wood. I would tee the driver down, and I would hit a little cut, or a neck-y cut in the fairway. The 3-wood isn’t for that. The 3-wood, generally, is a pretty hot club that I’ll hit from 270 or 280 in the fairway on a par 5. You get some courses where a 3-wood is not always necessary. [With the BRNR] you put a normal swing on it, and I’m more comfortable hitting it straight. It’s a replacement for a 3-wood, basically.”

Pricing, specs, availability

TaylorMade’s new BRNR Mini Driver Copper clubs will sell for $449.99 in 11.5 (RH/LH) and 13.5 (RH) degree options, and they will be available for custom orders.

- LIKE76

- LEGIT5

- WOW10

- LOL5

- IDHT0

- FLOP1

- OB0

- SHANK6

Equipment

Coolest thing for sale in the GolfWRX Classifieds (4/5/24): I think I ‘Blacked Out’ trying to love these irons

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a set of blacked out P770 irons

From the seller: (@hammertime1515): “Just one single iron set up for grabs today. Got these right before they quote selling them at the end of February. Only played 3 full rounds with them and a couple short range sessions. 7 iron shows the most wear and 8 iron has a sandy mark on the toe (ball striking out of winter wasn’t the strong suit) Just not right for me no matter how much I wanted them to be. Price is shipped and OBO……

P770 Black Out irons. 4-PW. —New Tour Velvet Align Midsize Grips —1/2” over TM standard —2 degrees upright —Standard Lofts —Dynamic Gold 105 X100 shafts —PW has never been hit, most of them have been hit sparingly. Tried to capture the wear on the 7 iron and the toe mark on the 8 iron the best I could. Soles have virtually no scratching from use and no bag chatter. -If more pics are needed just ask ——PRICE: $1000 OBO” & Shipped

To check out the full listing in our BST forum, head through the link: Blacked out P770 irons

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

-

19th Hole2 weeks ago

19th Hole2 weeks agoJohn Daly stuns fans into silence with brutal opening tee shot on PGA Tour Champions

-

19th Hole5 days ago

19th Hole5 days agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

-

19th Hole2 days ago

19th Hole2 days agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks ago2-time major champ announces shock retirement from the sport at age of 33

-

19th Hole2 weeks ago

19th Hole2 weeks agoEdoardo Molinari reveals the latest PGA Tour golfer to turn down ‘good offer’ from LIV Golf

-

19th Hole2 weeks ago

19th Hole2 weeks agoCharlie Woods finds it tough going on American Junior Golf Association debut

-

19th Hole3 weeks ago

19th Hole3 weeks agoScottie Scheffler had an interesting response when asked how he ‘quiets the noise’ following Players victory

-

19th Hole4 days ago

19th Hole4 days agoAddiction, spinal fusion, and scam artists – Everything Anthony Kim revealed in candid interview with David Feherty

Pingback: P?ekvapivý putter JR Smith se objevuje na pro-am BMW - Flores

Ro

Mar 9, 2018 at 2:47 am

You better be making less than 24 putts every round from now on, otherwise you will prove to the whole world that all this is completely meaningless and that a good, skilled player can putt with a $1 putter from the local salvation army shop. Oh can somebody tell me the time? I forgot to wear my Rolex today lmao

Steve S

Mar 8, 2018 at 8:44 am

My comment was removed because I stated facts. This article is a nice ad for “betty’s” and they must not have liked my statement of fact.

dela

Mar 8, 2018 at 2:04 pm

Repeat your comment and keep the word count down to a minimum otherwise it will trip the word count bot and push it into the ‘moderation’ category.

Steve S

Mar 9, 2018 at 9:54 am

Dela, wrong. I shortened it to less words than your post and it was bounced

Steve S

Mar 9, 2018 at 12:46 pm

Try again……

Your comment is awaiting moderation.

M* G*lf Sp* tests “Betty’s and “Scotty” in their putter tests and they always finish at the bottom.

Rob

Mar 7, 2018 at 10:28 pm

Great story! Very cool!

Jim Southcomb

Mar 7, 2018 at 3:48 pm

I have a bettinardi for close to15+ years and love it!, I believe it’s rhe BB1 .i

Would love to have it refinished. Is it possible to have this done. There was supposed

To be a bettinardi rep come to our CC but he/she never showed up. Please advise if this

Is feasible and the cost

Thank you

Jim

Boo Strongly

Mar 7, 2018 at 4:46 pm

They refinish them. Just call Bettinardi directly.

Ogo

Mar 7, 2018 at 11:26 pm

Next to ‘feel’, ‘love’ is everything because without ‘love’ you can’t have ‘feel’.

A man and his putter shall never be parted. A good putter is like a good dog, both faithful.

CrashTestDummy

Mar 7, 2018 at 3:07 pm

I think swingweight is going to start to be a metric for putting fitting and selling putters. It does make a difference.

ESP

Mar 7, 2018 at 2:08 pm

ESP here,

Head weight during testing was right around 354 to 355. I haven’t received word on the actual weight of my putter after finishing, but I expect it to be in the 353 to 354 range. I don’t recall the actual toe hang but it was a factor in our fitting to help get the putter head on path. Initially, I wanted to shorten the neck a little, as the BB0 neck is a little longer than I am used to looking at. However, we felt the toe hang was right for my stroke and we didn’t want to change the toe hang by shortening the neck. All milling options were available, including the fly milling. Ultimately, I liked the feel and sound of the micro honeycomb face, plus I like the way it looks. There were no restrictions on the build, I was able to get everything I wanted and asked for.

As far as the loft, their “standard” is 3* but the high speed cameras show that I have a slight forward press that is maintained through impact resulting in less dynamic loft. Adjusting the loft up to 5* helped to get the ball rolling sooner off the face.

steve

Mar 7, 2018 at 3:11 pm

Did the 5º face loft increase skid distance? I would think it would.

ESP

Mar 7, 2018 at 4:36 pm

The opposite. Because I was delofting the putter at impact I was creating skid at 3*. Adjusting the loft to 5* reduced the skid.

steve

Mar 7, 2018 at 11:33 pm

At 3º delofted you must be hitting down and digging the ball into the ground thus reducing skid and causing bouncing. With greater loft of 5º you must be lifting the ball and thus increasing skid distance because you are now hitting the ball further.

ted

Mar 7, 2018 at 1:33 pm

So how much do these vanity putters cost? $1000? I hope they come with an instruction manual!

Boo Strongly

Mar 7, 2018 at 4:47 pm

It depends on what you get. I’ve spent anything from $450 there to just under $1000. If you end up with something close to stock it won’t cost you much but if you can a stainless tour head it’ll probably be around $1000.

steve

Mar 7, 2018 at 11:37 pm

So what do you get that is extra for a $1000+ stainless tour head… other than the “tour only” engraving on the sole? Do they reserve the best putter designs and materials for the tour pros and we get the stock junk?

Boo Strongly

Mar 7, 2018 at 12:37 pm

You experienced a bit of a dog and pony show most likely because they knew you would be writing a review. I live an hour from Tinley Park so I’ve been in for several fittings in the past and my experience wasn’t even close to yours. I’ve been in and out of there in 20 minutes or so on average and it’s basically hit a few putts, put the putter together and get you on your way.

Dan G.

Mar 7, 2018 at 12:17 pm

What about head weight and toe hang. I have built several putters with some amazing builders and head weight is one of the most important pieces to a fitting besides the look. Essentially top line, plumbers, etc. is more of look, yes the stroke plays into that but a flow neck to plumber is also appeal. There is no mention of weight. I have dialed into my specs and will not have a head weight under 350. They also didnt mention Superfly Mill Face, this is their best face yet. I wonder if the custom build was a bit restricted.

DB

Mar 7, 2018 at 11:52 am

So many snarky comments. Haha

Here’s an actual question – Do they commonly fit people into 5 degrees of loft? Or does ESP have lots of forward shaft lean?

Ell

Mar 7, 2018 at 10:38 am

No putter is worth the amount that you have to pay for this putter. It isn’t the putter, its the golfer using it.

The Law Professor

Mar 7, 2018 at 10:28 am

Am so sick of the juvenile overuse of the world “incredible”. “Incredible” is a real word with an actual meaning, it means beyond all belief, something so amazing that no one could believe it.

Willie Wonka giving away his corporation to a boy is incredible (but of course, that’s fiction); a golf manufacturer involved in a promotion that of maybe a couple thousand dollars is most decidedly not.

Will

Mar 7, 2018 at 10:37 am

You are and angry elf!

The Law Professor

Mar 7, 2018 at 3:57 pm

Fool! It’s “an”, not “and”. Learn the English language!

Not The Law Professor

Mar 7, 2018 at 10:40 am

you must be fun at parties

The Law Professor

Mar 7, 2018 at 3:56 pm

You imbecile–you didn’t capitalize “You”!

SC Pilgrim

Mar 7, 2018 at 11:27 pm

Should it not be up to each individual to decide what is “incredible”?

Example: Some people would find your fine command of the English language and desire to correct people, quite “incredible”; however, I find it to be a total distraction when I have to read comments not directly related to the content of the article. Therefore, I do not find it “incredible”…

Please stick to law or grammar sites, professor.

dela

Mar 8, 2018 at 2:02 pm

Perhaps the use of “incredible” was wrong and it should have been “incredulous” ….(read the difference in your Dictionary).