Equipment

Bettinardi launches new Antidote putters in 3 different head shapes

In January of 2017, Bettinardi introduced an Antidote prototype on Tour that used weights on top of a blade-style putter to raise the center of gravity (CG) toward the equator of the golf ball for a faster end-over-end roll. At the 2017 WGC-Bridgestone Invitational in August, we spotted a new Antidote prototype; this time, it was a nearly square-mallet head, also with weights on top for the same purpose… to raise CG for a better roll.

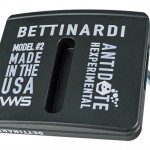

Today, Bettinardi announced that it’s officially launching Antidote putters to retail in three different head shapes — 5 models in total.

The Antidote putters (Model 1, Model 2 and Model 3), like the prototypes that preceded the official launch, use weights on the top half of the putters to raise CG closer to the equator of the golf ball, which Bettinardi says produces a quicker “end-over-end” rotation of the ball. The positioning of the weights also produce higher MOI (moment of forgiveness, a measure of forgiveness), which help offset off-center hits.

The retail versions of the Antidote putters have a carbon matte black finish, and they come with three weights; aluminum (5 grams), stainless steel (10 grams) and copper (15 grams). They are available today, selling for $550 each.

Check out graphic images of each of the models below.

Model 1

Model 2

Model 2 Center-Shafted

Model 2 Left-Handed

Model 3

- LIKE53

- LEGIT7

- WOW4

- LOL13

- IDHT0

- FLOP13

- OB4

- SHANK117

Equipment

Why Rory McIlroy will likely use the new TaylorMade BRNR Mini Driver Copper at the RBC Heritage

Although we spotted Rory McIlroy testing the new TaylorMade BRNR Mini Driver Copper last week during practice rounds at the Masters, he ultimately didn’t decide to use the club in competition.

It seems that will change this week at the 2024 RBC Heritage, played at the short-and-tight Harbour Town Golf Links in Hilton Head.

When asked on Wednesday following his morning Pro-Am if he’d be using the new, nostalgic BRNR Copper this week, McIlroy said, “I think so.”

“I like it,” McIlroy told GolfWRX.com on Tuesday regarding the BRNR. “This would be a good week for it.”

View this post on Instagram

According to Adrian Rietveld, the Senior Manager of Tour at TaylorMade, the BRNR Mini Driver can help McIlroy position himself properly off the tee at the tight layout.

Here’s what Rietveld told GolfWRX.com on Wednesday:

“For someone like Rory, who’s that long at the top end of the bag, and then you put him on a course like Harbour Town, it’s tough off the tee. It’s tight into the greens, and you have to put yourself in position off the tee to have a shot into the green. It kind of reminds me of Valderrama in Spain, where you can be in the fairway and have no shot into the green.

“I’m caddying for Tommy [Fleetwood] this week, so I was walking the course last night and looking at a few things. There’s just such a small margin for error. You can be standing in the fairway at 300 yards and have a shot, but at 320 you don’t. So if you don’t hit a perfect shot, you could be stuck behind a tree. And then if you’re back at 280, it might be a really tough shot into the small greens.

“So for Rory [with the BRNR], it’s a nice course-specific golf club for him. He’s got both shots with it; he can move it right-to-left or left-to-right. And the main thing about this club has been the accuracy and the dispersion with it. I mean, it’s been amazing for Tommy.

“This was the first event Tommy used a BRNR last year, and I remember talking to him about it, and he said he couldn’t wait to play it at Augusta next year. And he just never took it out of the bag because he’s so comfortable with it, and hitting it off the deck.

“So you look at Rory, and you want to have the tools working to your advantage out here, and the driver could hand-cuff him a bit with all of the shots you’d have to manufacture.”

So, although McIlroy might not be making a permanent switch into the new TaylorMade BRNR Mini Driver Copper, he’s likely to switch into it this week.

His version is lofted at 13.5 degrees, and equipped with a Fujikura Ventus Black 7X shaft.

See more photos of Rory testing the BRNR Mini here

- LIKE17

- LEGIT0

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK2

Equipment

Spotted: TaylorMade P-UDI driving iron

It seems like the RBC Heritage is full of new gear to be spotted, and you can add TaylorMade’s P-UDI utility irons to that list.

We spotted a 17-degree P-UDI 2-iron in Nick Dunlap’s bag yesterday, and now have some photos of both the 3- and 4-irons. Nick has his P-UDI 2-iron setup with a Project X HZRDUS Black 4th Gen 105g TX shaft.

From what we can tell, this new P-UDI utility iron looks to have some of the usual TaylorMade technology as we can see the Speed Slot on the sole of the club for additional face flexibility. A toe screw is usually used to close off the hollow body design that will probably be filled with a version of TaylorMade’s Speed Foam that is present in the current iron lineup. This hollow body, foam-filled design should offer additional ball speed, soft feel, and sound, as well as an optimized CG for ball flight.

“Forged” is etched into the hosel, so we can assume that either the face, body, or both are forged for a soft and responsive feel. The club looks good from behind and at address, where we can see just a little offset and a topline that I would consider medium thickness. We don’t have the full details on what is under the hood or how many loft options will be available yet.

TaylorMade P-UDI 3-iron – 20°

TaylorMade P-UDI 4-iron – 22°

- Check out the rest of our photos from the 2024 RBC Heritage

- LIKE12

- LEGIT1

- WOW2

- LOL0

- IDHT0

- FLOP1

- OB0

- SHANK1

Whats in the Bag

Collin Morikawa WITB 2024 (April)

- Collin Morikawa what’s in the bag accurate as of the RBC Heritage. More photos from the event here.

Driver: TaylorMade Qi10 LS (9 degrees)

Shaft: Mitsubishi Diamana D+ Limited 60 TX (45 inches)

3-wood: TaylorMade Qi10 (13.5 degrees)

Shaft: Mitsubishi Diamana D+ Limited 80 TX

5-wood: TaylorMade Qi10 (18 degrees)

Shaft: Mitsubishi Diamana D+ Limited 80 TX

Irons: TaylorMade P770 (4), P7MC (5-6), P730 (7-PW)

Shafts: True Temper Dynamic Gold Tour Issue Mid 115 X100 (4-6), True Temper Dynamic Gold Tour Issue X100 (7-PW)

Wedges: TaylorMade MG4 (50-SB09, 56-LB08), TaylorMade MG4 TW (60-TW11)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: TaylorMade TP Soto

Grip: SuperStroke Zenergy Tour 2.0

Grips: Golf Pride Z-Grip Cord

Ball: TaylorMade TP5x

- LIKE4

- LEGIT0

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

-

19th Hole1 week ago

19th Hole1 week agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

-

19th Hole1 week ago

19th Hole1 week agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 weeks ago

19th Hole2 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole3 days ago

19th Hole3 days agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole3 days ago

19th Hole3 days agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole2 weeks ago

19th Hole2 weeks agoAddiction, spinal fusion, and scam artists – Everything Anthony Kim revealed in candid interview with David Feherty

-

19th Hole2 weeks ago

19th Hole2 weeks agoAnthony Kim says doctors told him that he ‘may not have much time left’ ahead of LIV return

BN

Oct 18, 2017 at 12:04 pm

BRING BACK THE BB32

Larry Cooper

Oct 13, 2017 at 9:47 am

I’d rather stay sick with the plague that take this Antidote. I love my BB1 and Betti blade. These are terrible. Please don’t do this again Bob.

1,2,3 are Bad, Terrible, the worst.

DB

Oct 12, 2017 at 12:53 pm

Hey, the Model 3 looks pretty nice. Clean and simple aside from the weights. But the website says it is 1/4 toe hang? Is that right? If you’re going to make a classic shape why not do the classic 1/2 toe hang?

M. Vegas

Oct 11, 2017 at 6:25 pm

If these were any uglier….

They’d be Brian’s mom

MB

Oct 11, 2017 at 5:40 pm

I like the Number 2. That giant fly swatter works for me. I wish there was one with a flow neck

BB

Oct 11, 2017 at 1:23 pm

If you like the square don’t sleep on the BB55. Been gaming mine for 3 years now and love it. Feel is there too, unlike many larger mallet style putters.

Shawn K

Oct 11, 2017 at 10:57 am

Been trying to replace my Bobby Grace V-foil but nothing can touch it. Maybe the square one here as the Betti feel is as close to it as I have felt. We’ll see. Actually, I changed my mind. If it ain’t broke!

cosmos411

Oct 11, 2017 at 10:05 am

For $550 I better be able to pick up my ball with the back of the putter!

Jeffrey

Oct 12, 2017 at 2:20 am

You should be picking it out of the hole.

Robert Parsons

Oct 12, 2017 at 3:28 pm

Maybe he wants it to come with the suction cup at the end of the grip? Hahaha

Nobody makes suction cups like we do. Period.

Jeffrey

Oct 13, 2017 at 5:48 am

Your line up of rollers looks awesome. Is the suction cup an optional extra? LOL.

Jon

Oct 10, 2017 at 5:22 pm

It looks like they beat PGX to the punch on this group, minus the excessive amount of screws.

alvin

Oct 10, 2017 at 9:43 pm

Plenty of ‘screws’ here, particularly for $550…..

Steve I

Oct 10, 2017 at 4:57 pm

I’m amazed, amazed, at all the fantastic engineering that has gone into all three models.

The square mallet headed putter has got to be the final solution to putting, not to mention the fantastic metallurgy and machining that has gone into the head.

I love the markings on the putter soul and the pride of bagging a Made in USA putter…. and only $550 plus sales tax …. which can be amortized over the next 10 year for ~$60+ per year cost.

It’s a steal and worth every penny for what must be a guided missile putter.

MB

Oct 11, 2017 at 5:40 pm

Were you trying to be funny or summin?

Tider992010

Oct 10, 2017 at 4:29 pm

too much money. too much square. too much everything. Sad thing is, I love Bettinardi’s.

etc.

Oct 10, 2017 at 6:50 pm

How deep is your love for Bettinardi’s?…. share your feeelings.

Milo

Oct 10, 2017 at 3:22 pm

Mmm, that model 2 center shafted putter looks delicious too bad I’m not spending 550 bucks on a putter.

etc.

Oct 10, 2017 at 6:51 pm

…. and they don’t even provide instructions on how to use this Antidotal putter… not really a bargain, is it?!!

Milo

Oct 10, 2017 at 9:42 pm

I’ve been gaming an OG Futura since release but switched it up this year, bought a Callaway The Tuttle for 10 bucks and sold the Futura, kinda miss the big spaceship.