Equipment

Is Rory’s Odyssey Putter Coming to Retail?

Rory McIlroy has made more equipment changes than any other top player on the PGA Tour this season, but one club he’s stuck with has been a prototype Odyssey putter. And since the 27-year-old started using the putter early this year, it has has been both literally and figuratively a secret.

As Odyssey does with several of its prototype models, the sole is engraved with question marks to highlight its prototype nature. And out of respect for McIlroy’s current status as an equipment free agent — the No. 2-ranked golfer in the world says he’s playing without an endorsement deal from any equipment manufacturer — neither Odyssey or its parent company Callaway is commenting on what clubs he’s currently using.

That brings us to this week, where we spotted new Odyssey prototype putters on the putting green of the Valero Texas Open, one of which looked almost identical to the prototype putter McIlroy is using. It’s called the 3T, and appears to be a new model in the O Works line Odyssey unveiled earlier this year. While the putter is black, it seems to have the same shape and size as McIlroy’s prototype, and also uses Odyssey’s new Micro-Hinge insert, which the company says helps putts roll more true.

So is Rory’s Odyssey putter coming to retail? A Callaway representative says that the 3T, as well as the other Odyssey putters we spotted in Texas, are just prototypes for now. If it did, however, it’s safe to say that a lot of golfers would buy one.

Related

- LIKE161

- LEGIT11

- WOW5

- LOL2

- IDHT2

- FLOP2

- OB2

- SHANK22

Whats in the Bag

Scottie Scheffler’s winning WITB: 2024 Masters

Driver: TaylorMade Qi10 (8 degrees @8.25) Buy here.

Shaft: Fujikura Ventus Black 7 X (45 inches)

3-wood: TaylorMade Qi10 (15 degrees) Buy here.

Shaft: Fujikura Ventus Black 8 X

Irons: Srixon ZU85 (3, 4) Buy here, TaylorMade P7TW (5-PW) Buy here.

Shafts: Nippon N.S. Pro Modus 3 Hybrid Prototype 10 X (3), True Temper Dynamic Gold Tour Issue X100

Wedges: Titleist Vokey Design SM8 (50-12F, 56-14F) Buy here, Titleist Vokey Design WedgeWorks Proto (60-T) Buy here.

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: TaylorMade Spider Tour X Buy here.

Grip: Golf Pride Pro Only Cord

Grips: Golf Pride Tour Velvet

Ball: Titleist Pro V1 Buy here.

Check out more in-hand photos of Scottie Scheffler’s clubs here.

The winning WITB is presented by 2nd Swing Golf. 2nd Swing has more than 100,000 new and pre-swung golf clubs available in six store locations and online. Check them out here.

- LIKE30

- LEGIT4

- WOW1

- LOL1

- IDHT1

- FLOP1

- OB1

- SHANK2

Whats in the Bag

WITB Time Machine: Danny Willett’s winning WITB, 2016 Masters

Driver: Callaway XR 16 (9 degrees)

Shaft: Mitsubishi Rayon Diamana W-Series 60 X

Length: 45.5 inches

3-wood: Callaway XR 16 (15 degrees)

Shaft: Mitsubishi Rayon Diamana W-Series 70X

5-wood: Callaway XR 16 (19 degrees)

Shaft: Mitsubishi Rayon Diamana W-Series 80X

Irons: Callaway Apex UT (2, 4), Callaway Apex Pro (5-9)

Shaft: True Temper Dynamic Gold X100 Superlite

Wedges: Callaway Mack Daddy 2 (47-11 S-Grind) Callaway Mack Daddy 2 Tour Grind (54-11, 58-9)

Shaft: True Temper Dynamic Gold X100 Superlite

Putter: Odyssey Versa #1 Wide (WBW)

Lie angle: 71 degrees

Ball: Callaway Speed Regime SR-3

Check out more photos of Willett’s equipment from 2016 here.

- LIKE7

- LEGIT0

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

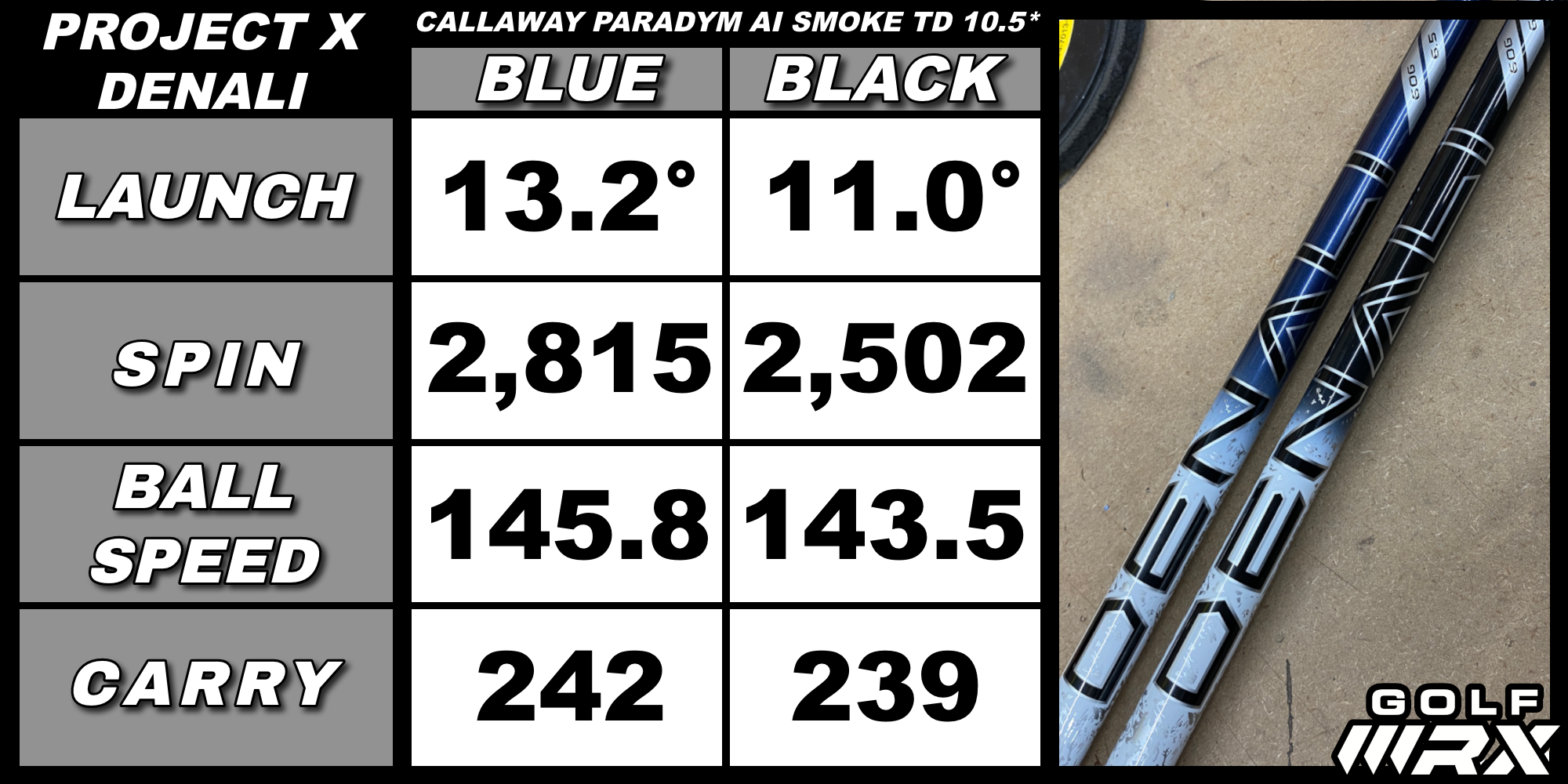

Project X Denali Blue, Black shaft Review – Club Junkie Review

Originally, Project X was known for low-spin steel iron shafts. However, the company might now be known for wood shafts. Denali is the newest line of graphite shafts from Project X. With the Denali line, the company focuses on feel as well as performance.

There are two profiles in the Denali line, Blue and Black, to fit different launch windows. Denali Blue is the mid-launch and mid-spin profile for players who are looking for a little added launch and Denali Black is designed for low-launch and low-spin. Both models are going to offer you a smooth feel and accuracy.

For a full in-depth review check out the Club Junkie podcast on all podcast streaming platforms and on YouTube.

Project X Denali Blue

I typically fit better into mid-launch shafts, as I don’t hit a very high ball so the Denali Blue was the model I was more excited to try. Out of the box, the shaft looks great and from a distance, it is almost hard to tell the dark blue from the Denali Black. With a logo down install of the shaft, you don’t have anything to distract your eyes, just a clean look with the transition from the white and silver handle section to the dark navy mid and tip.

Out on the course, the Blue offers a very smooth feel that gives you a good kick at impact. The shaft loads easily and you can feel the slightly softer handle section compared to the HZRDUS lineup. This gives the shaft a really good feel of it loading on the transition to the downswing, and as your hands get to impact, the Denali Blue keeps going for a nice, strong kick.

Denali Blue is easy to square up at impact and even turn over to hit it straight or just little draws and most of the flex of the shaft feels like it happens right around where the paint changes from silver to blue. The Blue launches easily and produces what I consider a true mid-flight with the driver. While it is listed as mid-spin, I never noticed any type of rise in my drives. Drives that I didn’t hit perfectly were met with good stability and a ball that stayed online well.

Project X Denali Black

When you hold the Denali Black in your hands you can tell it is a more stout shaft compared to its Blue sibling by just trying to bend it. While the handle feels close to the Blue in terms of stiffness, you can tell the tip is much stiffer when you swing it.

Denali Black definitely takes a little more power to load it but the shaft is still smooth and doesn’t give you any harsh vibrations. Where the Blue kicks hard at impact, the Black holds on a little and feels like keeps you in control even on swings that you try and put a little extra effort into. The stiff tip section also makes it a little harder to square up at impact and for some players could take away a little of the draw from their shot.

Launch is lower and more penetrating compared to the Blue and produces a boring, flat trajectory. Shots into the wind don’t rise or spin up, proving that the spin stays down. Like its mid-launch sibling, the Black is very stable and mishits and keeps the ball on a straighter line. Shots low off the face don’t get very high up in the air, but the low spin properties get the ball out there farther than you would expect. For being such a stout shaft, the feel is very good, and the Denali Black does keep harsh vibrations from your hands.

Overall the Project X Denali Blue and Black are great additions to the line of popular wood shafts. If you are looking for good feel and solid performance the Denali line is worth trying out with your swing. Choose Blue for mid-launch and mid-spin or Black for lower launch and low spin.

- LIKE4

- LEGIT4

- WOW2

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole5 days ago

19th Hole5 days agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

-

19th Hole6 days ago

19th Hole6 days agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 weeks ago

19th Hole2 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoAddiction, spinal fusion, and scam artists – Everything Anthony Kim revealed in candid interview with David Feherty

-

19th Hole1 week ago

19th Hole1 week agoAnthony Kim says doctors told him that he ‘may not have much time left’ ahead of LIV return

-

19th Hole7 days ago

19th Hole7 days agoBrooks Koepka and Sergio Garcia make significant equipment changes as 2024 Masters looms

-

19th Hole13 hours ago

19th Hole13 hours agoTwo star names reportedly blanked Jon Rahm all week at the Masters

Darryl

Apr 20, 2017 at 7:53 am

Things you should use Rory to advertise in golf: Drivers, Fairway Woods, Blade Irons, Tight shirts that make your odd shaped pecs look more defined.

Things you shouldn’t use Rory to advertise in golf: Putters

Tried the Micro-hinge at the recent Scottish golf show, didn’t really notice any difference to my old DFX 2 Ball, if I’m honest. Maybe a bit heavier, but I think that’s a general design trend.

Gozer

Jun 13, 2017 at 12:30 pm

When it comes to putters, Rory does more damage to who he dumps than who he picks up. What he chooses next may not make him a great putter (and thus is no reason for us to leap to that one yet), but he clearly thinks it is better than the old one (based on a lot of his comparison testing), which is at least somewhat damning.

Golf Traditionalist

Apr 20, 2017 at 1:42 am

If the USGA and R&A had any principles to protect the game they would ban the dubious Odyssey Micro-hinge face insert… but we know they are in the pockets of the OEMs to keep the industry scams alive. Golf on it’s last legs.

Chuck

Apr 20, 2017 at 11:31 am

Hey, I’m okay with that. Then, 460cc driver heads, composite shafts, and a re-regulation of multilayer urethane balls.

But seriously (well, I was being serious above); do you think that the Microhinge is a huge/unfair advantage? If so, why?

Mike

Apr 19, 2017 at 7:43 pm

Why does the retail model have the black ferrule and Roy’s doesn’t? Is the ferrule even needed never understood why odyssey put’s them on all of these style putter.

gunmetal

Apr 19, 2017 at 12:24 pm

I love that there is a small dent on the bottom of the shaft of the darker finish one from bending. Some of my clients cry when they see a small ding from club alterations. I tell them to think of it like a badge of honor – no “standard” for you – type a thing. It’s refreshing to see arguably the best player in our game with imperfections on his clubs!

NoName

Apr 20, 2017 at 12:33 am

The crimp on the hosel is “tour only”

Brad T

Apr 18, 2017 at 1:00 pm

how long before rory has a spider in his bag ?

gg

Apr 19, 2017 at 1:09 am

As he s probably signing/signed a deal with callaway, it doesn t appear to be soon…

Chuck

Apr 18, 2017 at 12:55 pm

So I wanted to tell you guys about a silly little anecdotal-and-not-quantitative “study” I did at my local Golf Galaxy the other day.

First, I grabbed about four or five Pro V1’s on their indoor putting green, which is a carpet and which feels like about 9.5-10.0 Stimpmeter speed.

Next, I grabbed two new putters, and one used putter. Each was 34.” The first putter was one of the new Microhinge O-works Odysseys, a 1W. (My favorite model.) Next, was my favorite current Scotty Cameron, the Newport M2. Similar head shapes. Third and last was my previous favorite Odyssey, an older model Versa BWB 1W. Again, nearly identical head shape.

So the experiment was to hit 4-5 putts with each one, just listening to the sound of the ball on the carpet-y putting green surface. There was a scuffing sound as the ball started to roll in the first 2 feet of the putt, before it started its true roll. The sound of the ball skidding along the top of the surface instead of rolling silently.

The putter that felt the best in my hands, was the Scotty. But it produced the noisiest roll. The putter that produced less noise in the first two feet of roll was the old Versa (which had the softest feel, I must say). The putter that produced NO sound as the ball started to roll was the O-works Microhinge. And it was freaky, what the difference was. There was nothing else like it in the shop. And it seemed as though every O-works Microhinge putter produced the same result. It also seemed like the Microhinge was effectively “faster” too. That is, putts got rolling so fast that it was easy to hit it too far.

This was a completely subjective, unscientific, unquantifiable test. I’m not trying to kid myself or anybody else. But I worked at it for a while. And what I saw/heard was real.

Johnnylongballz

Apr 18, 2017 at 11:50 pm

Cool story bro

Joe

Apr 18, 2017 at 10:41 am

Not funny.

Dat

Apr 18, 2017 at 9:39 am

Funny, it was released years ago as a PING.

Bob Chipeska

Apr 18, 2017 at 9:32 am

You can now own one for the low, low price of $600.

Tony

Apr 18, 2017 at 8:56 am

You can wait for this to come to retail or you can go find a Scotty Cameron Fastback. Exact same shape

rebfan73

Apr 18, 2017 at 12:10 pm

That’s exactly what I thought……

Tyler

Apr 18, 2017 at 1:34 pm

Ditto

Chuck

Apr 18, 2017 at 1:56 pm

No; it’s not the shape. It’s the face insert. And no; a Scotty Cameron Fastback doesn’t have that insert. Nobody else does.

Some people might not like the insert; some people might like it. So far, I see Rory McIlroy, Phil Mickelson, about ten LPGA players (using amazingly stock-looking models) all gravitating to the Microhinge.

Tim

Apr 18, 2017 at 9:20 pm

Except if you hit the hinge just right it goes off line…

Chuck

Apr 19, 2017 at 2:33 pm

See, you are arguing that the Microhinge is a bad idea. You can make that argument if you want. But no matter what, this O-Works putter is not a Cameron with a different name on it. You just sort of admitted to the point; the Microhinge makes it different. That was my point.

I don’t know if what you are saying is true, by the way. I didn’t hit any putts that I thought jumped off the face off-line. And I have a hard time imagining lots of Tour-level players using Microhinge technology if it were actually suspect, in getting putts started on-line. Just guessing here, that Phil Mickelson knows more about putting, and has more money riding on his making putts, than I do.

NoName

Apr 20, 2017 at 12:35 am

But it doesn’t have the micro hinge technology

Dj

Apr 18, 2017 at 8:46 am

Of course they’re going to release it. They release so many putters per year I’d be incredibly surprised if they don’t sell this at retail.

Tyler

Apr 18, 2017 at 1:35 pm

There are so many Odyssey makes and models out at any given time its confusing.

Dj

Apr 18, 2017 at 9:28 pm

Agreed. Impossible to keep track

Tod

Apr 19, 2017 at 1:10 am

+1