Opinion & Analysis

Building Golf Clubs at Home: The Essential Tips, Tricks and Tools

Like so many others I got into club building out of necessity and curiosity. As a kid, I loved to take anything and everything apart — from skateboards to old lawnmowers — so when I starting playing golf clubs were next. It started small, learning how to grip clubs with a Black & Decker workmate with my dad, and then slowly I moved into the more intricate aspects of building clubs. I’ve always joked that I was probably the only 16-year-old who asked for a lie-loft machine for his birthday.

In this article, I’m going to share with you my favorite tips, tricks and tools that I’ve used as a professional golf club builder. I hope to benefit those interested in building their own golf clubs at home, as well as relay valuable information about club building in general to knowledge-hungry GolfWRXers.

Overview

One of the most important things about building clubs is doing it properly with the right tools, and doing it safely. After setting up up multiple build shops over the years, from small hobby shops to large multi-station build shops, having the opportunity to build my own home shop from the ground up was something I always looked forward to. My shop is in my basement, and because of the limited space, it was imperative to find as many space saving-solutions as possible.

Like many people with a hobby they are passionate about, I look forward to one day having a stand-alone garage for all of my tools (and maybe a hitting net), but for now my basement gets the job done. I’m lucky to have access to a much large machine shop where I do wedge grinding, finishing and sand blasting, which are all jobs that make a lot more noise and create a lot more dust. I can’t get away with doing those things in a confined space, but we’ll touch on that later.

Although not a tool, arguably the most important piece of equipment is the work bench. Having a quality workbench is needed because of the amount of abuse that it will take over its lifespan. Also, just like a great kitchen design, you need counter space and a good workbench provides that. Dropping a clubhead (especially a driver or fairway wood with nice paint job) can be costly. The next extension of the workbench is a good vice that has been properly attached to the bench with bolts. Like I’ve said in previous articles, I believe when you do something you should take the time to do it properly. I once saw a vice screwed into a workbench with 1.25-inch screws, and as soon as someone went to use the vice it ripped out and took a club with it.

Not every surface needs to be as stable as a full-scale industrial workbench, but having counter space is important. My personal solution to this was IKEA (honestly, who doesn’t love IKEA?). I recommend checking out Ikea Hacks (just Google it) for space-saving tips. If your space is really limited or needs to be multi-use, flip-up table ends are a perfect solution. As much as I like finding quick solutions to problems, it’s way more satisfying to build things yourself if possible. That way, at the end of the project, you have something that is exactly the way you wanted it.

As seen in the pictures below, I re-purposed two Ikea BEKAN desk bases from the As-Is section into a full workbench after getting a 4-foot by 8-foot piece of 0.75-inch plywood cut to size. This saved me hundreds of dollars and got me close to 30 square feet of counter space to mount other tools including my bench ruler, chop saw, belt sander and frequency machine. And since these desk bases have adjustable heights, I was able to get them to a comfortable workbench height.

There are lots of kits available online to build benches to fit almost any space. Get creative, and customize it to your needs.

One of the other things that’s very important is organization. Having a few small organizational tools can make a difference: think storage bins, trays and component drawers, which are especially useful for ferrules and tip weights. Make sure to put labels on them, too, so it’s always easy to find what you need.

The Tools

Unlike a golf bag where you are limited to 14 clubs, your build shop is only limited to the amount of space you have (and your budget). For me, every trip to the hardware store or to various tool supply shops has me finding another small tool or bit to help make things just a bit easier. Let’s put it this way; I have a lot of LED flashlights and finishing tools lying around.

What I’m trying to say is that what you should really focus on when building a shop from the ground up is quality over quantity. Having the proper tools will make building clubs and doing repairs a lot easier. There are very few things as frustrating as having a club not turn out the way you wanted because you weren’t prepared and didn’t have the right tools for the job.

Cordless Drill

A good cordless drill is a necessity, so make a quality purchase. I’m not an expert on drills, but any of the big name-brand drills that use an 18-20V battery have always done well for me. Make sure the drill has variable torque settings and, if possible, having one that has a built-in flashlight under the chuck makes it super easy to check hosels for debris while drilling. It’s also more ideal to find one in a kit that has two batteries with the charger — that way, if you’re drilling a lot for a single job, you will always have a fresh battery. You should expect to pay $119-$200.

I have seen many shops use a drill press, but personally I never found a real need for one on a day-to-day basis (plus they can take up a bunch of space). Drill presses can be useful for porting wedges, but that’s really not home-shop use.

Metal Drill Bits

Here’s where things get personal for me. I had an inexpensive drill bit break almost instantly and go right into the palm of my left hand (and off to the ER I went). I was not a happy camper, but I did learn a very valuable lesson; don’t buy cheap drill bits and never drill toward another body part. I still have a small scar to remind me of that mistake, and it also serves as a reminder to never take what you may consider a simple repair for granted. Bit sets can often be found on sale, but a small collection of proper bits will run you about $100.

Also, make sure to purchase proper metal drill bits. I’ve lost count of how many times I’ve seen people try and use either masonry or wood drill bits with little success.

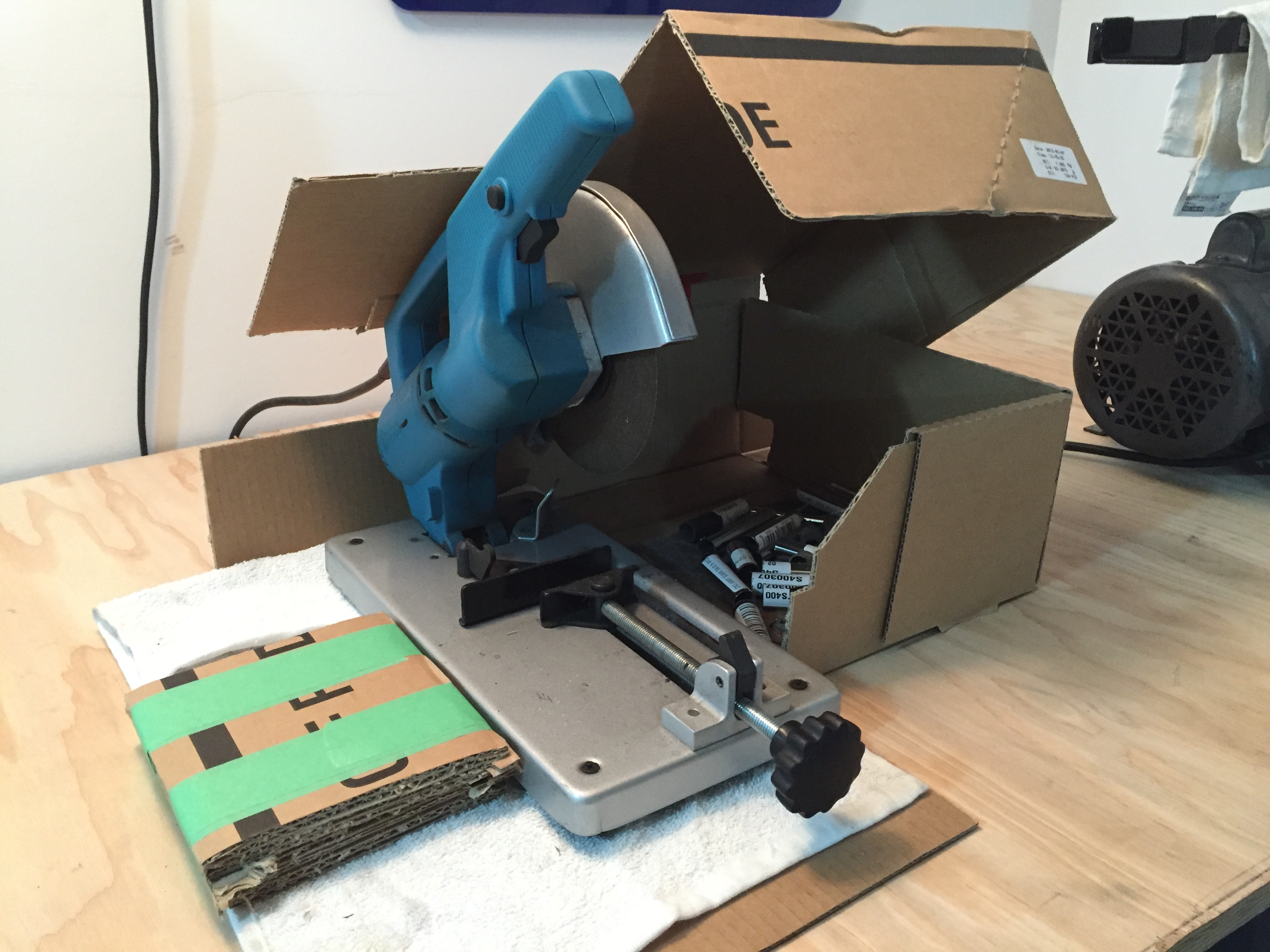

Chop Saw

A good chop saw is worth every penny. There’s nothing worse than using a crappy saw and having it splinter the butt section of an expensive driver shaft. My personal favorite, and the favorite of many professionals, is the Gryphon Miter Saw. Almost any video in a tour van features one of these saws… and for good reason. They are compact, durable, use relatively inexpensive blades,and also make very precise cuts at high RPM. The better the blades and higher the RPM, the better the cut.

I don’t do that much volume in my basement, so I went with a more basic chop saw from GolfWorks that uses 6-inch blades. I did my research. It is still a good quality saw and worked with my budget, but compared to the Gryphon that I used in the past it is louder. The Gryphon is $260 direct from Gryphon, while mine was in the $80 range from GolfWorks. I’ve had my saw from almost eight years, and although is doesn’t see anything close to an industrial workload it performs great.

Side Note: Just like with drill bits, be sure to buy quality cutting wheels made for steel and other fibers. The thinner the better, because they will help keep dust down and reduce noise.

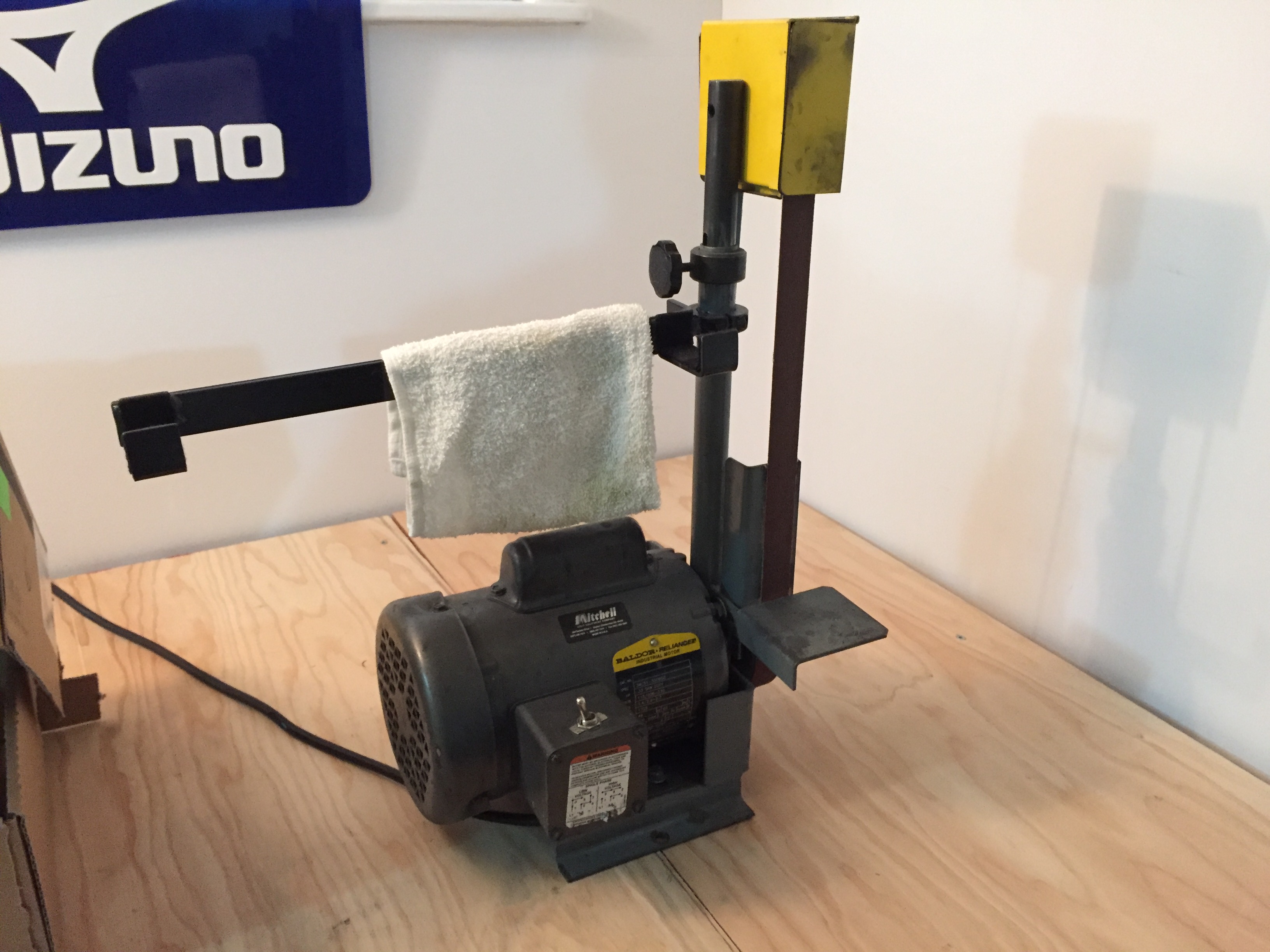

Belt Sander

Who doesn’t love the look of a properly turned-down ferrule that has just been shined with acetone? To me, this is one of the most important aspects of finishing a club. It seems simple, but it took me a long time to get really good at it.

To properly turn down a ferrule you need a belt sander, and don’t skimp on a cheap one. The best ones use 42-inch belts, and I prefer the DuraBrite Felt belts since they don’t take too much material off the ferrule at once. This makes them more forgiving, especially for beginners, and I find them much cleaner, which makes final finishing easier. You can use a belt sander with a inexpensive motor for around or under $100, but you can’t go cheap on the attachments. The attachment shown here is the most widely used and reliable one that I’ve found and costs around $200 from most suppliers. Some of the most reliable tools found in shops have Baldor Motors that alone start around $350. Since grinders are very common tools, you can often get a good deal on a used one if you stay patient.

Dust Collector

You can’t cut or sand at any volume without creating dust. I don’t know what the long-term effects of breathing in graphite and steel dust are, but I’m not ready to be a test subject either. You may have noticed the ugly looking box around my chop saw. It’s not only a catch basin for shaft ends, but is also used in conjunction with a shop vac to keep airborne dust to a minimum in my basement. I designed it to act as a mini-negative air system.

Most tool shops like Harbour Freight (or Princess Auto/Busy Bee Tools in Canada) have some type of inexpensive dust collector, and even a shop vac can do the trick. When purchasing a dust collection system, look out for CFM, or cubic feet per minute, which explains how much air/dust the system can collect as once. The more air that the system can pull through the filter the more dust it can pull out of the air. A simple cyclone system is about $100, but you can find mini 1HP systems (lots of power for a saw or small sander) for about $175 on sale or between $200-$250 full price.

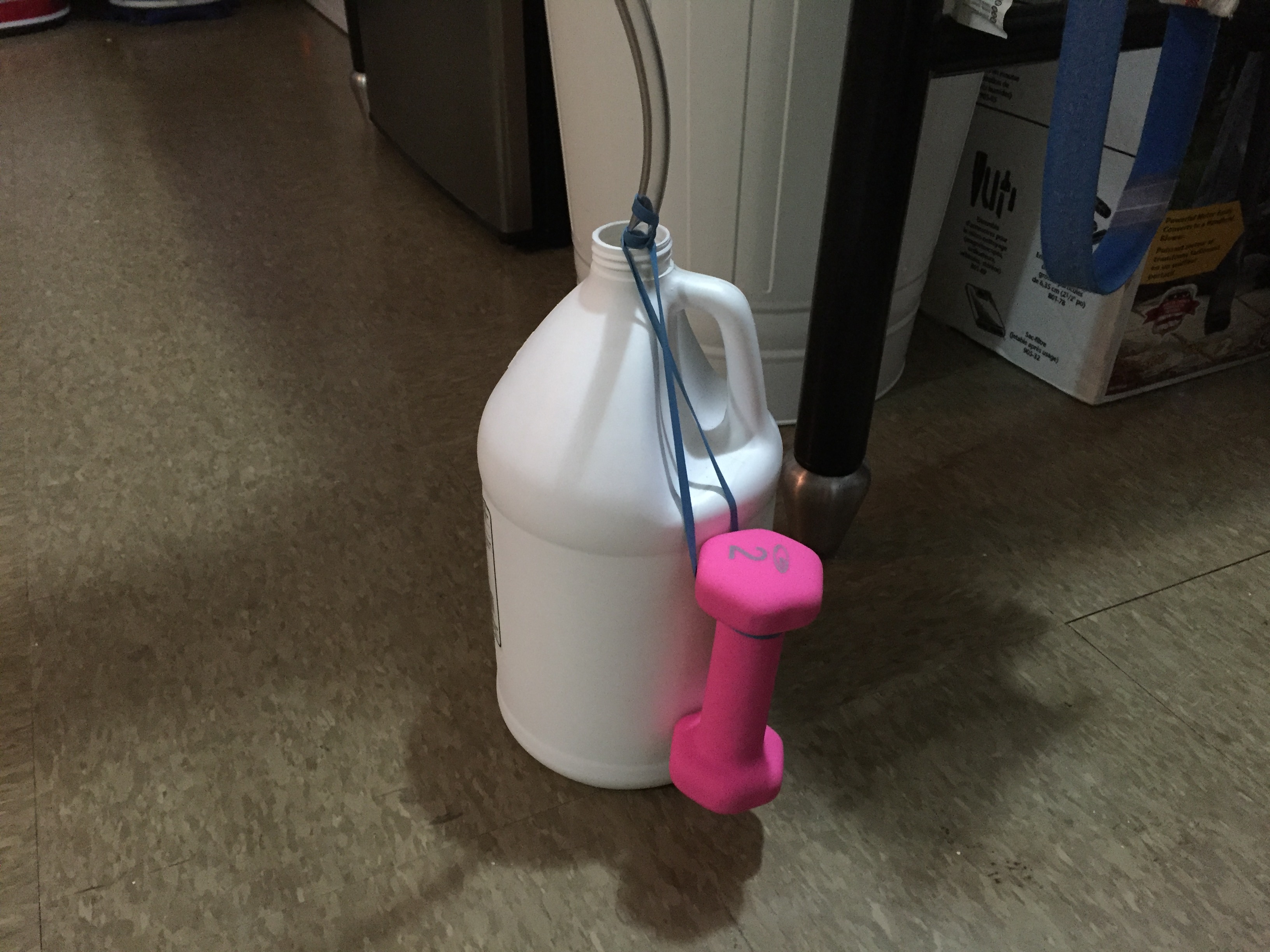

Gripping Station

When it comes to gripping clubs, the best solution is a proper gripping station that will collect and recycle grip solvent and safely hold a club “square.” The nicest shop I ever worked in had foot-activated pneumatic clamps that automatically adjusted pressure, just like a tour van. Starting with solvent, it’s never good to run that stuff into a drain or have it sitting in an open container, especially with children or pets kicking around. My setup, although not perfect, is very effective at not wasting solvent and allowing me to get grips on in a timely fashion. The picture shows exactly how I recycle my solvent. Like I said, it’s not fancy, but it is very effective. This exact system from GolfMechanix is $185 before the cost of solvent or tape.

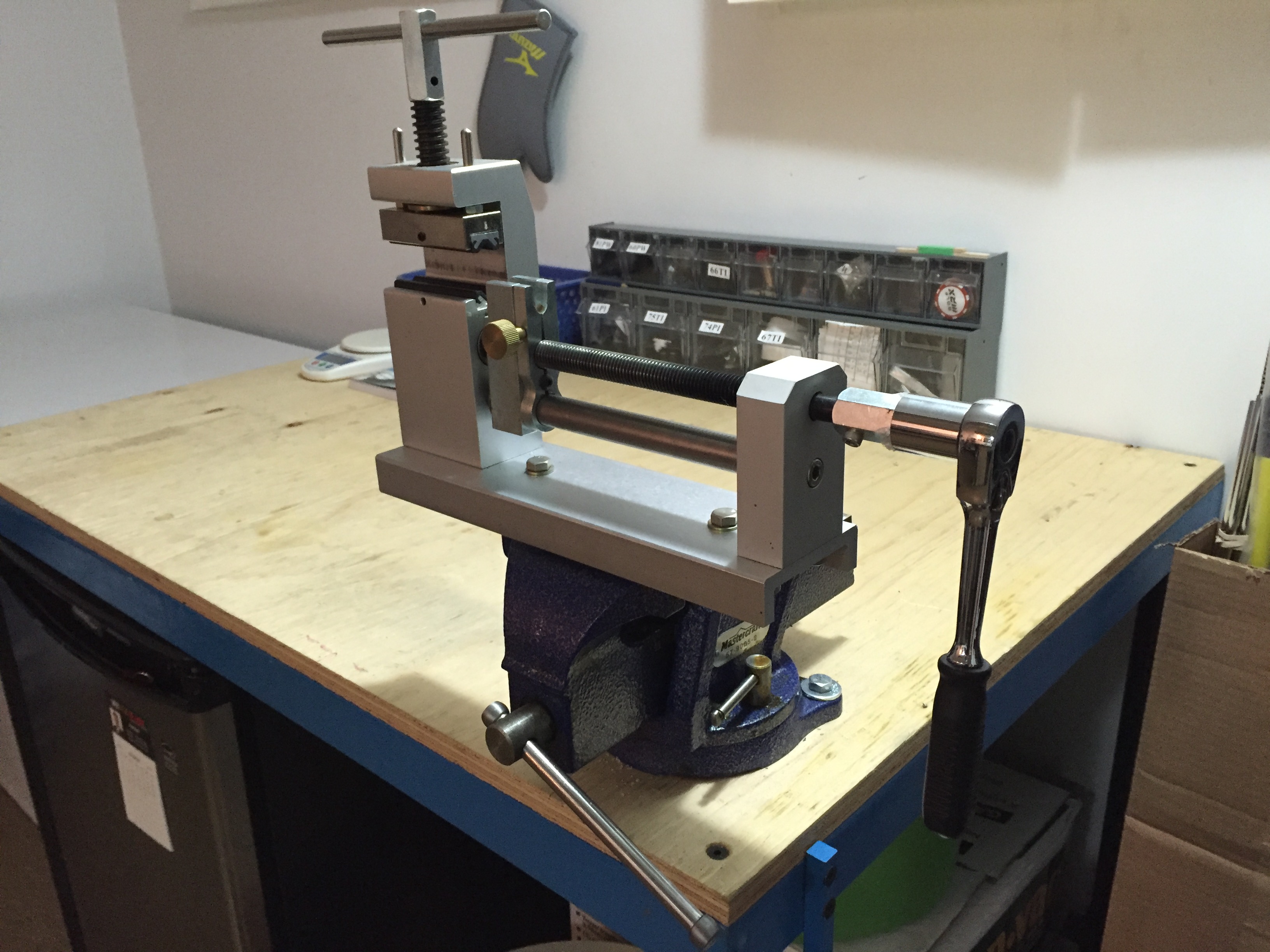

Graphite Shaft Puller

So you want to pull a graphite shaft? Like I mentioned in my last article, Avoid These 5 Club Building Disasters, there is a right way and a wrong a way to do it. Using a proper shaft extractor is necessary for graphite because of the fibers and the way the graphite sheets are wrapped. If you plan on doing a bit more than just the occasional shaft pull, I ALWAYS recommend using one with either a spring or hydraulic mechanism. Maltby makes a few really nice ones, as does GolfMechanix. I’ve had my Golf Mechanix shaft puller for more than 10 years now with no problems and hundreds of shafts pulled. The model in the photo retails for $350.

Loft-Lie Machine

Loft-lie machines are pricey, but just like a belt sander a good one is very much worth it. If you’re entrepreneurial, loft-lie machines can be a good little money maker, too, since the golf shops that have them can be few and far between, depending on where you live. Do good work on a few clubs for friends and word will spread. Believe me.

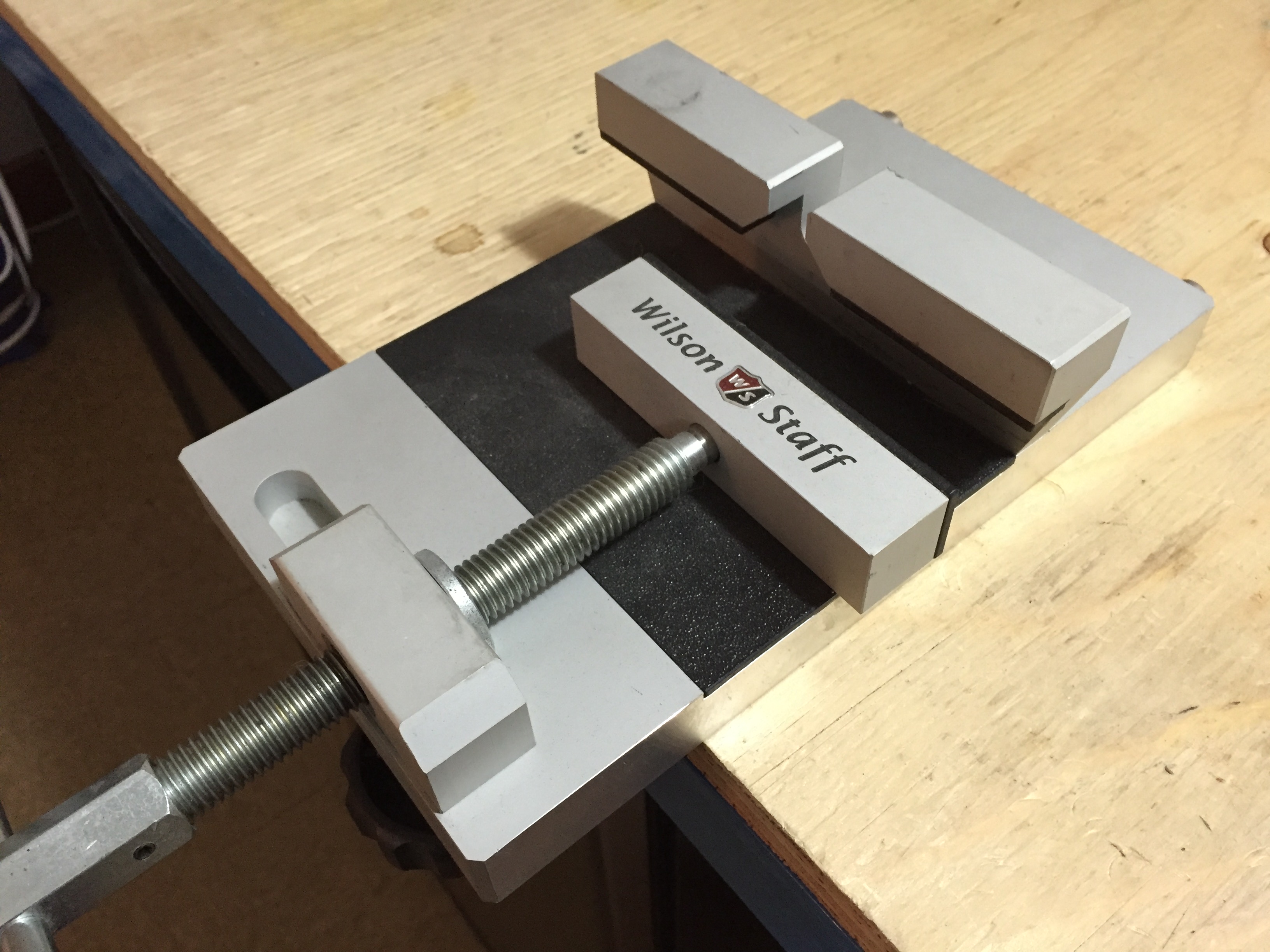

The cream of the crop loft-lie machines are digital. I wish I had one, but know that a well-machined loft-lie machine can be just as effective. Just like with the shaft puller, a great one can be had from Maltby and Golf Mechanix. On top of a loft-lie machine for irons, a separate loft-lie machine for putters is a really nice thing to have. Mine is from an older Wilson Staff unit dating back to when Kirk Currie was still making putters. It’s most effective with blade style putters, but can be used with most styles. Again, you don’t need to completely break the bank to have an effective shop with the right tools.

Don’t forget to make sure to get a good, non-maring bending bar tool, too. Bending marks are almost unavoidable for certain iron heads, but to make as few marks as possible a good bending bar is key.

A professional-quality loft/lie machine starts at around $550, but prices can get into the thousands. On top of that, a proper base usually add about $100-$200 to the cost. Putter machines are about $300 to start, but remember, bend a few putters for friends with great results and you will start getting phone calls.

Frequency Machine

This is a tool that certainly falls under the category of a luxury build shop item. My personal machine is a older model that was built and designed by Fujikura, which has a pneumatic pressure controlled clamping system to ensure consistent results. The age or model of the frequency machine has little impact on the reading that are put out (as long as it’s a quality, properly calibrated machine). The other specification to pay attention to is clamp length. You will get vastly different readings depending on the clamp length used, and if you’re using a computer-based formula your entire set could be off because of the clamp length.

Some newer machines have clamps that can be adjusted from 3-5 inches. I wouldn’t build a set of irons without it, but then again, club building was my livelihood and I’ve gotten used to the luxury. A frequency machine is by no means a necessary tool when it comes to doing home builds and repairs, as they start at about $550. A nice one from Maltby goes for $650, and a top-of-the-line model from GolfMechanix will set you back $750.

Air Compressor

An air compressor is a tool that falls under the category of “not just useful for a custom shop.” An air compressor has an abundance of uses including blowing on grips, cleaning out hosels and powering a plethora of pneumatic tools. I always charge mine up when building iron sets for use with my frequency machine, as well as making sure clubhead hosels are clean and ready to go for gluing. I selected mine based on three things:

- Size. This was important, because it needed to fit in my smaller shop.

- Volume. It needed have a tank big enough that it didn’t have to charge every time I used a tool. Also, pay attention to CFM (cubic feet per minute), which is how efficient the compressor is at filling the tanking and keeping up with demand.

- Noise. Most small compressors have a decibel rating. Try and find one that’s not too loud. Some are even advertised as being more quiet. It’s not always a big deal, especially if you’re working in a larger space, but can be key in a smaller shop.

A nice, simple compressor will go for around $150.

So what am I missing?

I realize that I haven’t even begun to cover cover all the small tools that can be very important when building clubs. In attempt to offer a complete list, I have compiled the items below.

- Bench ruler designed to measure golf clubs.

- Swing weight scale. Digital is best, but conventional is still very good.

- Digital scale that reads to +/-0.1 grams.

- Wire brushes for cleaning out hosels.

- Ram rod for removing old stuck tip weights and epoxy.

- Ferrules of all sizes, shims and tip weights.

- Sanding belts for prepping shafts (80 or 120 grit works well).

- SHARPIES! You can never have enough.

- Small pliers and clips.

- Acetone.

- Sand paper of varying grits.

- Gloves for using acetone. It can be nasty on the skin.

- Safety glasses. I can’t stress this enough.

- Calipers (digital are best, but analog can do the trick).

- Grip tape.

- Sharp hook knife and straight blade.

- Butane torch with extra fuel.

- Flash lights.

- Scissors

- Metal trash bin

Questions, concerns or comments? Let me know in the comments section below. I’ll do my best to answer all I can.

- LIKE449

- LEGIT60

- WOW18

- LOL9

- IDHT3

- FLOP0

- OB1

- SHANK11

19th Hole

Vincenzi’s 2024 Zurich Classic of New Orleans betting preview

The PGA TOUR heads to New Orleans to play the 2023 Zurich Classic of New Orleans. In a welcome change from the usual stroke play, the Zurich Classic is a team event. On Thursday and Saturday, the teams play best ball, and on Friday and Sunday the teams play alternate shot.

TPC Louisiana is a par 72 that measures 7,425 yards. The course features some short par 4s and plenty of water and bunkers, which makes for a lot of exciting risk/reward scenarios for competitors. Pete Dye designed the course in 2004 specifically for the Zurich Classic, although the event didn’t make its debut until 2007 because of Hurricane Katrina.

Coming off of the Masters and a signature event in consecutive weeks, the field this week is a step down, and understandably so. Many of the world’s top players will be using this time to rest after a busy stretch.

However, there are some interesting teams this season with some stars making surprise appearances in the team event. Some notable teams include Patrick Cantlay and Xander Schauffele, Rory McIlroy and Shane Lowry, Collin Morikawa and Kurt Kitayama, Will Zalatoris and Sahith Theegala as well as a few Canadian teams, Nick Taylor and Adam Hadwin and Taylor Pendrith and Corey Conners.

Past Winners at TPC Louisiana

- 2023: Riley/Hardy (-30)

- 2022: Cantlay/Schauffele (-29)

- 2021: Leishman/Smith (-20)

- 2019: Palmer/Rahm (-26)

- 2018: Horschel/Piercy (-22)

- 2017: Blixt/Smith (-27)

2024 Zurich Classic of New Orleans Picks

Tom Hoge/Maverick McNealy +2500 (DraftKings)

Tom Hoge is coming off of a solid T18 finish at the RBC Heritage and finished T13 at last year’s Zurich Classic alongside Harris English.

This season, Hoge is having one of his best years on Tour in terms of Strokes Gained: Approach. In his last 24 rounds, the only player to top him on the category is Scottie Scheffler. Hoge has been solid on Pete Dye designs, ranking 28th in the field over his past 36 rounds.

McNealy is also having a solid season. He’s finished T6 at the Waste Management Phoenix Open and T9 at the PLAYERS Championship. He recently started working with world renowned swing coach, Butch Harmon, and its seemingly paid dividends in 2024.

Keith Mitchell/Joel Dahmen +4000 (DraftKings)

Keith Mitchell is having a fantastic season, finishing in the top-20 of five of his past seven starts on Tour. Most recently, Mitchell finished T14 at the Valero Texas Open and gained a whopping 6.0 strokes off the tee. He finished 6th at last year’s Zurich Classic.

Joel Dahmen is having a resurgent year and has been dialed in with his irons. He also has a T11 finish at the PLAYERS Championship at TPC Sawgrass which is another Pete Dye track. With Mitchell’s length and Dahmen’s ability to put it close with his short irons, the Mitchell/Dahmen combination will be dangerous this week.

Taylor Moore/Matt NeSmith +6500 (DraftKings)

Taylor Moore has quickly developed into one of the more consistent players on Tour. He’s finished in the top-20 in three of his past four starts, including a very impressive showing at The Masters, finishing T20. He’s also finished T4 at this event in consecutive seasons alongside Matt NeSmith.

NeSmith isn’t having a great 2024, but has seemed to elevate his game in this format. He finished T26 at Pete Dye’s TPC Sawgrass, which gives the 30-year-old something to build off of. NeSmith is also a great putter on Bermudagrass, which could help elevate Moore’s ball striking prowess.

- LIKE6

- LEGIT3

- WOW1

- LOL1

- IDHT0

- FLOP3

- OB1

- SHANK1

19th Hole

Vincenzi’s 2024 LIV Adelaide betting preview: Cam Smith ready for big week down under

After having four of the top twelve players on the leaderboard at The Masters, LIV Golf is set for their fifth event of the season: LIV Adelaide.

For both LIV fans and golf fans in Australia, LIV Adelaide is one of the most anticipated events of the year. With 35,000 people expected to attend each day of the tournament, the Grange Golf Club will be crawling with fans who are passionate about the sport of golf. The 12th hole, better known as “the watering hole”, is sure to have the rowdiest of the fans cheering after a long day of drinking some Leishman Lager.

The Grange Golf Club is a par-72 that measures 6,946 yards. The course features minimal resistance, as golfers went extremely low last season. In 2023, Talor Gooch shot consecutive rounds of 62 on Thursday and Friday, giving himself a gigantic cushion heading into championship Sunday. Things got tight for a while, but in the end, the Oklahoma State product was able to hold off The Crushers’ Anirban Lahiri for a three-shot victory.

The Four Aces won the team competition with the Range Goats finishing second.

*All Images Courtesy of LIV Golf*

Past Winners at LIV Adelaide

- 2023: Talor Gooch (-19)

Stat Leaders Through LIV Miami

Green in Regulation

- Richard Bland

- Jon Rahm

- Paul Casey

Fairways Hit

- Abraham Ancer

- Graeme McDowell

- Henrik Stenson

Driving Distance

- Bryson DeChambeau

- Joaquin Niemann

- Dean Burmester

Putting

- Cameron Smith

- Louis Oosthuizen

- Matt Jones

2024 LIV Adelaide Picks

Cameron Smith +1400 (DraftKings)

When I pulled up the odds for LIV Adelaide, I was more than a little surprised to see multiple golfers listed ahead of Cameron Smith on the betting board. A few starts ago, Cam finished runner-up at LIV Hong Kong, which is a golf course that absolutely suits his eye. Augusta National in another course that Smith could roll out of bed and finish in the top-ten at, and he did so two weeks ago at The Masters, finishing T6.

At Augusta, he gained strokes on the field on approach, off the tee (slightly), and of course, around the green and putting. Smith able to get in the mix at a major championship despite coming into the week feeling under the weather tells me that his game is once again rounding into form.

The Grange Golf Club is another course that undoubtedly suits the Australian. Smith is obviously incredibly comfortable playing in front of the Aussie faithful and has won three Australian PGA Championship’s. The course is very short and will allow Smith to play conservative off the tee, mitigating his most glaring weakness. With birdies available all over the golf course, there’s a chance the event turns into a putting contest, and there’s no one on the planet I’d rather have in one of those than Cam Smith.

Louis Oosthuizen +2200 (DraftKings)

Louis Oosthuizen has simply been one of the best players on LIV in the 2024 seas0n. The South African has finished in the top-10 on the LIV leaderboard in three of his five starts, with his best coming in Jeddah, where he finished T2. Perhaps more impressively, Oosthuizen finished T7 at LIV Miami, which took place at Doral’s “Blue Monster”, an absolutely massive golf course. Given that Louis is on the shorter side in terms of distance off the tee, his ability to play well in Miami shows how dialed he is with the irons this season.

In addition to the LIV finishes, Oosthuizen won back-to-back starts on the DP World Tour in December at the Alfred Dunhill Championship and the Mauritus Open. He also finished runner-up at the end of February in the International Series Oman. The 41-year-old has been one of the most consistent performers of 2024, regardless of tour.

For the season, Louis ranks 4th on LIV in birdies made, T9 in fairways hit and first in putting. He ranks 32nd in driving distance, but that won’t be an issue at this short course. Last season, he finished T11 at the event, but was in decent position going into the final round but fell back after shooting 70 while the rest of the field went low. This season, Oosthuizen comes into the event in peak form, and the course should be a perfect fit for his smooth swing and hot putter this week.

- LIKE12

- LEGIT3

- WOW0

- LOL1

- IDHT0

- FLOP1

- OB1

- SHANK1

Opinion & Analysis

The Wedge Guy: What really makes a wedge work? Part 1

Of all the clubs in our bags, wedges are almost always the simplest in construction and, therefore, the easiest to analyze what might make one work differently from another if you know what to look for.

Wedges are a lot less mysterious than drivers, of course, as the major brands are working with a lot of “pixie dust” inside these modern marvels. That’s carrying over more to irons now, with so many new models featuring internal multi-material technologies, and almost all of them having a “badge” or insert in the back to allow more complex graphics while hiding the actual distribution of mass.

But when it comes to wedges, most on the market today are still single pieces of molded steel, either cast or forged into that shape. So, if you look closely at where the mass is distributed, it’s pretty clear how that wedge is going to perform.

To start, because of their wider soles, the majority of the mass of almost any wedge is along the bottom third of the clubhead. So, the best wedge shots are always those hit between the 2nd and 5th grooves so that more mass is directly behind that impact. Elite tour professionals practice incessantly to learn to do that consistently, wearing out a spot about the size of a penny right there. If impact moves higher than that, the face is dramatically thinner, so smash factor is compromised significantly, which reduces the overall distance the ball will fly.

Every one of us, tour players included, knows that maddening shot that we feel a bit high on the face and it doesn’t go anywhere, it’s not your fault.

If your wedges show a wear pattern the size of a silver dollar, and centered above the 3rd or 4th groove, you are not getting anywhere near the same performance from shot to shot. Robot testing proves impact even two to three grooves higher in the face can cause distance loss of up to 35 to 55 feet with modern ‘tour design’ wedges.

In addition, as impact moves above the center of mass, the golf club principle of gear effect causes the ball to fly higher with less spin. Think of modern drivers for a minute. The “holy grail” of driving is high launch and low spin, and the driver engineers are pulling out all stops to get the mass as low in the clubhead as possible to optimize this combination.

Where is all the mass in your wedges? Low. So, disregarding the higher lofts, wedges “want” to launch the ball high with low spin – exactly the opposite of what good wedge play requires penetrating ball flight with high spin.

While almost all major brand wedges have begun putting a tiny bit more thickness in the top portion of the clubhead, conventional and modern ‘tour design’ wedges perform pretty much like they always have. Elite players learn to hit those crisp, spinny penetrating wedge shots by spending lots of practice time learning to consistently make contact low in the face.

So, what about grooves and face texture?

Grooves on any club can only do so much, and no one has any material advantage here. The USGA tightly defines what we manufacturers can do with grooves and face texture, and modern manufacturing techniques allow all of us to push those limits ever closer. And we all do. End of story.

Then there’s the topic of bounce and grinds, the most complex and confusing part of the wedge formula. Many top brands offer a complex array of sole configurations, all of them admittedly specialized to a particular kind of lie or turf conditions, and/or a particular divot pattern.

But if you don’t play the same turf all the time, and make the same size divot on every swing, how would you ever figure this out?

The only way is to take any wedge you are considering and play it a few rounds, hitting all the shots you face and observing the results. There’s simply no other way.

So, hopefully this will inspire a lively conversation in our comments section, and I’ll chime in to answer any questions you might have.

And next week, I’ll dive into the rest of the wedge formula. Yes, shafts, grips and specifications are essential, too.

- LIKE32

- LEGIT7

- WOW1

- LOL1

- IDHT2

- FLOP3

- OB1

- SHANK3

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole1 day ago

19th Hole1 day ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole2 days ago

19th Hole2 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

KENS CUSTOM CLUBS. PXG DEALER

Apr 30, 2019 at 6:04 pm

Chop saw is a no no, to much dust a good wet saw with proper blade and also a complete bench collection system, throw in a good launch monitor and 25 years experience also club fitting schools and club building schools and you might be getting close also a moment of inertia machine to ho beyond swingweight and make every iron feel the same could go on with more list never ends if you want to keep up with technology.

geohogan

Mar 4, 2019 at 1:19 pm

Please, where is the fire extinguisher?

Grinding sparks ignited on the bench after I finished grinding.

I almost lost my home to a fire on my work bench.

There is wood and flammable chemicals. Have to have a working fire extinguisher and know how to use it. cheers

Tom D

Oct 17, 2016 at 3:22 pm

Heck, I’d love to get a loft/lie machine and I’m closer to 60 that to 16!

Andrew Nielsen

Oct 9, 2016 at 10:30 pm

Great article and appreciate the tip on the Gryphon Mitre Saw. Been looking for a small chop saw just for shafts and the Gryphon is perfect. Any recommendations on Bench top drill presses?

Skip VanB

Oct 7, 2016 at 3:19 pm

Ryan,

Great fun article! That’s a nice shop you have. Where did the base for your work bench, the one with your vice come from?

Ryan Barath

Oct 7, 2016 at 9:48 pm

Hi Skip,

I’m gonna be straight up, I am a very lucky guy to not only be married to a great lady, but to also have a very talented brother-in-law. He’s is not only a welder, but also a great designer of all things metal. This base was completely custom built to the space that I had and specs that I gave him ( although I installed the vice on my own after the bench was built )

But for most, there are a bunch of bench kit system that very easily allow you to build to your spec at a very reasonable cost. You just need to buy the metal or plastic fibre brackets and then have the base pieces cut to length.

Really hope this helps.

Ryan

alan

Oct 6, 2016 at 7:53 am

nice article thanks. i tinker around in my garage and get by.

my wife is canadian. we head up to muskoka usually once a year. when we are on the 403 bridge i look over at hamilton and wonder who would wanna live in hamilton. now i know!

Wesley

Oct 5, 2016 at 10:57 pm

Great article Ryan. I have all these tools but some are less costly like club scout. Folks don’t forget there are plenty of places like harbor freight to get tools that will perform same function for significantly less cost than golf specific suppliers.

Ryan Barath

Oct 6, 2016 at 1:08 am

Exactly!

I really tried to stress that you can stretch your dollar by purchasing either used or more cost effective options with certain tools. This is also very effective since most people are only going to go as far as using the tools irregularly and because of that lighter duty machines can be just as effective.

Travis S

Oct 5, 2016 at 10:55 pm

If you had to guess how much would everything cost for this complete setup? Just the necessities tools and machines not the extra parts like ferrules, tape and etc?

Ryan Barath

Oct 6, 2016 at 1:10 am

from new you’re looking at probably close to $5000 but if going used like I did and if you are willing to invest some time in building a few things yourself you can do it for less than half.

Travis S

Oct 5, 2016 at 10:52 pm

What a great story I just started tinkering this year and installed a vice. I would kill for all that and appreciate your enthusiasm and modest cost effective setup. Keep up the good work!

Grizz01

Oct 5, 2016 at 10:17 pm

If you are building your own clubs and tinkering around. You don’t need all that crap.

KK

Oct 5, 2016 at 7:02 pm

Missing hotmelt setup. Otherwise absolutely fantastic.

Ryan Barath

Oct 5, 2016 at 9:25 pm

100%

I have used them many times before, but just like with the chop saw, I don’t want to buy a cheap one at the moment and I’m waiting to buy the champ model used on tour vans.

DJ

Oct 5, 2016 at 4:15 pm

Regarding dust collection systems. A really good club fitter I went too never had a vacuum system to control dust, specifically when cutting graphite shafts. He had to quit his business since all those years of breathing graphite led to him losing 40% lung capacity. Reason enough to invest in a high quality system if you are going to make this more than a hobby.

Ryan Barath

Oct 5, 2016 at 8:57 pm

Exactly!

Breathing in any sort of small particles for a long period of time is never good. Its the exact reason I do all of my finishing work and grind work in a proper metal shop, and with a dust mask.

John G

Oct 5, 2016 at 3:15 pm

Nice article for beginner but we know that when one starts repairing/rebuilding/building clubs from everywhere, tools and parts really-really add up fast.

When I started many years ago, most all my tools came from Mitchell and this or that special tool or part is always on going.

Steven

Oct 5, 2016 at 2:25 pm

Wow, that is an impressive setup. I don’t know if I want to build or alter clubs, but looking at the setup makes me want to try.

Blade Junkie

Oct 5, 2016 at 1:02 pm

You don’t know how lucky you are in the USA having big houses, basements and huge garages to put all this stuff. Many of us in the UK are making do with a 6′ x 3′ garden shed LOL.

Jason Thompson

Oct 5, 2016 at 10:58 am

I’m curious what large scale workshops you have built? I know the guys who did Modern Golf’s and you weren’t even employed there.

NFG

Oct 5, 2016 at 10:49 am

I want to be like this guy, sweet set up!! My work shop is small but I can do what I need to do.

alexdub

Oct 5, 2016 at 10:43 am

Great write-up! This is one of the better features from GolfWRX in a while. Who doesn’t love repair shop man caves>?

Ryan Barath

Oct 5, 2016 at 8:59 pm

Thanks!

This really was a subject I wanted to cover and share. I’m glad you like it.

Christopher

Oct 5, 2016 at 10:20 am

Can you share your plans you used for that bench ruler. I like that setup!

Ryan Barath

Oct 5, 2016 at 9:04 pm

Here’s the Link to my GolfWRX post from last year where I posted exactly how I made it.

http://www.golfwrx.com/forums/topic/1197824-my-very-easy-diy-bench-ruler-plans-why-spend-when-you-can-spend-and-be-accurate-home-shop-pics-incd/page__p__11807904__hl__+build%20+bench%20+ruler#entry11807904

RAT

Oct 5, 2016 at 10:02 am

Interesting , gone from just a little to making it a vocation. Start up – pick 3 of the most important, forget the small hand tools and etc.

Jim

Oct 5, 2016 at 9:59 am

Drill Press is a must for accurate, straight/tight hosel bores.

Tom

Oct 5, 2016 at 12:04 pm

amen to that

Tom

Oct 5, 2016 at 9:05 am

Great hobby to get involved in if your a serious golfer. I do it so that I can buy inexpensive sets of irons. Take measurements, make adjustments for junior player just starting he game.

David W.

Oct 5, 2016 at 8:23 am

Good stuff! Not going to build anything myself, but a great read.

Charlie

Oct 5, 2016 at 7:54 am

Were you seeing just how much you could bend a Mizuno MP T11 wedge before it snaps?

Ryan Barath

Oct 5, 2016 at 9:08 pm

I wasn’t sure someone would catch that or not.

It was a Mizuno wedge I bent completely flat: 0 LIE, 0 LOFT. I thought it was going to break when i did it but it just kept going. I actually have two, 1 is a paper weight (pictured) and the other is an assembled club that’s around 14″ long. It looks hilarious and is fun to try and hit a ball with.