Equipment

Review: Titleist 917F2 and 917F3 Fairway Woods

Pros: Dialing in trajectory and spin is more in the hands of the player than ever with SureFit CG adjustability. Feel and sound have improved, and 915 users will likely see a jump in distance.

Cons: If you preferred the black finish, you’re out of luck with the return of silver.

Who they’re for: Everyone who plays a fairway wood should give the Titleist 917F2 and 917F3 fairway woods a shot. They provide everything most golfers want from a fairway wood.

The Review

- Models: 917F2 (13.5, 15, 16.5, 18, 21 degrees), 917F3 (13.5, 15 degrees)

- Release Date: Oct. 21

- Price: $319 (MAP)

Right off the bat, you’ll notice a number of changes to Titleist’s new fairway woods: name, color, center of gravity (CG) adjustability, and if you’re really attentive a change in the Active Recoil Channel. I break down each of the major changes below.

Related: See the results from the Ultimate Titleist Driver Fitting Experience

What’s in a name?

In its most recent fairway wood releases — the 913 and 915 models — Titleist used the F and Fd naming system. “F” was a larger, more forgiving fairway wood that launched higher and spun more, while “Fd” was a smaller, deeper-faced, lower-launching fairway wood that reduced spin. It was a bit confusing, and didn’t mesh well with the D2 and D3 naming system the drivers were using, so Titleist went to F2 and F3, which is what Titleist used in previous models such as the 909.

If you’re confused: F = F2, Fd = F3 (easy to remember since this rhymes).

Now, the F2 (179 cubic centimeters) is the larger, higher-launching and more forgiving model, while the F3 (169 cubic centimeters) is smaller, deeper and more workable. The relationship hasn’t changed, just the names.

Sure thing

As with the 917 drivers, the 917 fairway woods have SureFit CG technology to give golfers the ability to tweak the draw/fade bias of the clubs. In the fairway woods, the SureFit CG system is also positioned slightly crooked, as seen in the driver, which has the same purpose; lower-spinning fades and higher-spinning draws. When in the draw position, the weight system will add spin to keep the ball in the air longer, and will decrease spin in the fade setting to keep shots from ballooning. The design also maintains the moment of inertia (MOI) of the fairway woods, keeping forgiveness high regardless of the weight setting.

In the SureFit CG system, weight is changed using interchangeable weights* or tubes, made of a mixture of different materials. The neutral weights have a uniform weight throughout, while the draw-fade tubes have a heavier side.

When adjusting the system, golfers should look for the “+” sign, which indicates a fade setting, while a “-” sign indicates the draw setting. Note that this is opposite of the 917 drivers, as the entry port is on the opposite side (toe side) of the club head in the 917 fairway woods. A solid red circle indicates a neutral setting. Like the 917 drivers, the 917 fairway woods also have Titleist’s 16-way adjustable SureFit hosel, which offers independent adjust loft and lie settings.

*Note: SureFit CG driver weights cannot be used in fairway woods, and vice versa, due to their different sizes.

Active Recoil Channel 2.0

While the 915 fairway woods had an Active Recoil Channel behind their faces, designed for higher ball speeds on off-center hits, the area was hollow. The channel in the 917 fairway woods is filled with elastomer, helping produce more ball speed across the face and lower spin, according to Titleist. There’s is also a face insert with variable thickness for increased speed on off-center hits.

Another change for the better is the sound and feel of the 917 fairway woods. They have more of a muted sound and softer feel at impact, which is no doubt helped by filling the Active Recoil Channel. Another benefit is that golfers won’t need to frequently clean the dirt out of the channel, as they needed to do with 915 models.

Color

The “liquid slate” finish on the crown is a throwback to Titleist woods of yesteryear, which is something Titleist fans may very much appreciate. Some of the classic Titleist fairway woods, such as the 980F, had a similar gray finish.

Overall performance

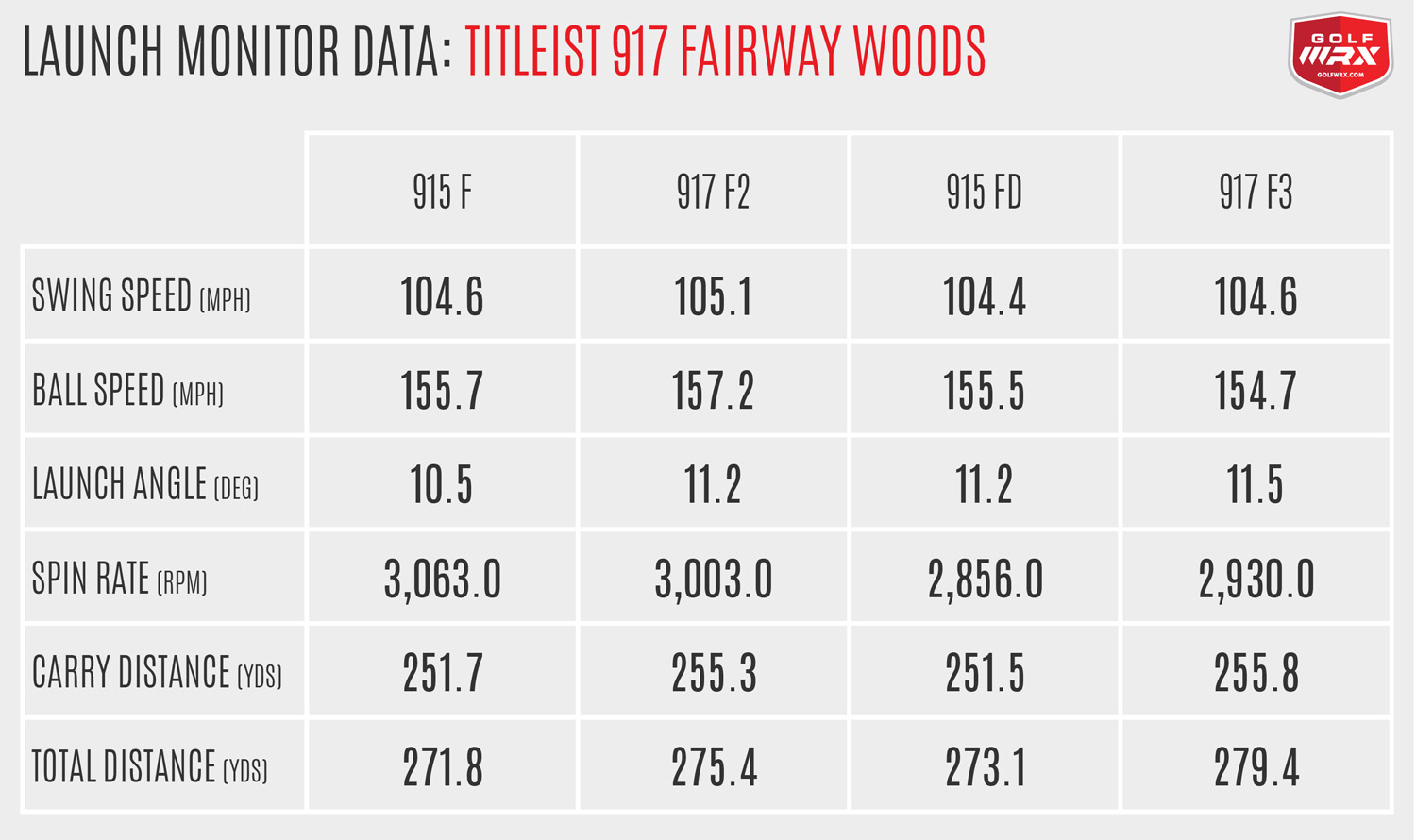

So what’s to be expected of the 917F2 and 917F3 in terms of performance? According to Titleist, golfers hitting the 917 versus a 915 should expect higher ball speeds, a higher launch, slightly lower spin and 4-7 yards in increased distance. It just so happens I hit the 917F2 and 917F3 versus the 915F and 915Fd, and you can see the numbers below.

The Numbers

I took the 917F2 and 917F3 fairway woods to the Launch Pad at Carl’s Golfland in Bloomfield Hills, Mich., where I tested them against Titleist’s 915F and 915Fd models on Trackman with premium golf balls. The fairway woods were set to my specifications (C2 hosel setting, neutral weight setting in the 917 models) with the same Mitsubishi Rayon Diamana Limited D+ 80X shaft. Shots were hit with each club — order was constantly rotated, and outliers deleted — until 10 shots with each club had been recorded.

917F2 v. 915F:

- The 917F2 generated slightly less spin (-60 rpm) and a slightly higher launch angle (+0.7 degrees) than the 915F.

- The 917F2 offered more ball speed (+1.5 mph), more carry distance (+1.6 yards), and more total distance (+3.6 yards) than the 915F.

917F3 v. 915Fd:

- The 917F3 offered slightly less ball speed (-0.8 mph), a slightly higher launch (+0.3 degrees), and a little more spin (+74 rpm) than the 915Fd.

- The 917F3 increase carry distance (+4.3 yards) and offered more total distance (+6.3 yards) than the 915Fd.

Specs, pricing, availability

Titleist 917F2 and 917F3 fairway woods ($319 MAP) will be available on Oct. 21 with the following stock shafts: Aldila Rogue M-AX, Fujikura Speeder Pro Tour Spec and Mitsubishi Rayon Diamana Limited D+, S+ and M+.

With the purchase, consumers will receive either a 10, 12, 14, 16 and 18-gram neutral weight (the 12-gram is stock) and a matching draw-fade weight. Additional weights can be purchased for $40, or SureFit weight kits are available for $180 with every weight.

The Takeaway

Any golfer with an older version of a Titleist fairway wood, especially one with a silver finish, will find the switch to a 917 fairway wood an easy and valuable transition.

Not only do the fairway woods offer CG adjustability for fine tuning trajectory, but they also have a softer feel and more muted sound than the 915 versions while providing more carry distance and more total distance. You’d be hard pressed to show me an all-around better fairway wood in the current market.

Related

- See what GolfWRXers are saying about the 917 fairway woods in our forum.

- Our review of Titleist’s 917D2 and 917D3 drivers.

- LIKE239

- LEGIT17

- WOW9

- LOL4

- IDHT5

- FLOP4

- OB6

- SHANK30

19th Hole

Callaway issues statement after report claimed company is for sale

According to South Korea’s Chosun Daily, Topgolf Callaway Brands Corp. is considering selling its Callaway Golf business, which is based in California. The report indicates the brand has a $3 billion valuation.

“The current rumored sale price for Callaway Golf is around $2.98 billion (4 trillion won). The price is considered to be reasonable by industry players given its significantly low market capitalization of $2.554 billion (about 3.4 trillion won), compared to that of rival Acushnet Holdings (Titleist) of $3.902 billion, and an accompanied management premium,” the report says.

It appears as if Topgolf would not be a part of the sale and would remain separate from the Callaway Golf brand.

After the news got out, the Callaway stock price (MODG) was up around 10% for Wednesday.

However, since the report has surfaced, Topgolf Callaway Brands Corp have stated that they are “unaware” of these discussions.

“While it is our long-standing practice not to respond to market rumors and speculation, in light of today’s unusual market activity, coupled with a recent media report originating in Korea regarding discussions of a potential sale of the Company or its golf equipment business, we confirm that we are not aware of any such discussions,” the company wrote in an emailed comment. “We do not intend to comment further on this topic, and we assume no obligation to make any further announcement or disclosure should circumstances change.”

More from the 19th Hole

- Rory McIlroy urges Ryder Cup eligibility rules to be re-written following Rahm’s LIV move

- Report: Former World Number 1 not joining LIV despite speculation

- Brooks Koepka’s Smash GC side and prominent golf journalist trade insults over latest LIV trade

New here?

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

David Ford WITB 2024 (March)

- David Ford WITB accurate as of the Arnold Palmer Invitational.

Driver: Titleist TSR2 (9 degrees, C4 SureFit setting)

Shaft: Project X HZRDUS Smoke Blue RDX 60 TX

3-wood: Titleist TSR2 (13.5 degrees, C1 SureFit setting)

Shaft: Project X HZRDUS Smoke Blue RDX 80 TX

Irons: Titleist T150 (3), Titleist 620 CB (4-6), Titleist 620 MB (7-PW)

Shafts: Graphite Design Tour AD DI 105 X (3), Project X 6.0 (4-PW)

Wedges: Titleist Vokey Design SM9 (50-12F), SM10 (54-10S, 60)

Putter: Scotty Cameron Timeless

Grips: Lamkin Crossline

- LIKE4

- LEGIT0

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Carl Yuan WITB 2024 (March)

- Carl Yuan what’s in the bag accurate as of the Cognizant Classic.

Driver: Callaway Paradym Ai Smoke Max (9 degrees)

Shaft: Graphite Design Tour AD VF 6 TX

3-wood: Callaway Paradym Ai Smoke Max (15 degrees)

Shaft: Graphite Design Tour AD DI 6 X

Hybrid: Callaway Apex UW (19 degrees)

Shaft: Fujikura Ventus Blue 9 X

Irons: Callaway Apex Pro (4), Callaway Apex TCB (5-11)

Shafts: Project X LZ 6.5

Wedges: Titleist Vokey Design SM10 (56-10S, 60-K)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: Odyssey Tri-Hot 5K Seven long

Grip: SuperStroke Split

Grips: Golf Pride MCC Align

- LIKE4

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

Whats in the Bag3 weeks ago

Whats in the Bag3 weeks agoAnthony Kim WITB 2024 (February)

-

Whats in the Bag2 weeks ago

Whats in the Bag2 weeks agoScottie Scheffler WITB 2024 (March)

-

Tour Photo Galleries2 weeks ago

Tour Photo Galleries2 weeks agoPhotos from the 2024 Arnold Palmer Invitational

-

19th Hole3 weeks ago

19th Hole3 weeks agoThe total sum that Sergio Garcia needs to pay in fines if he wants to return to DP World Tour revealed

-

19th Hole2 weeks ago

19th Hole2 weeks agoJoaquin Niemann names 3 PGA Tour events he’d love to play each year ‘in a perfect world’

-

19th Hole2 weeks ago

19th Hole2 weeks ago‘Seems suspect’ – PGA Tour pro hits out at decision to hand Adam Scott and Webb Simpson Bay Hill sponsor exemptions

-

Equipment2 weeks ago

Equipment2 weeks agoSpotted: Bettinardi irons at the Arnold Palmer Invitational

-

19th Hole2 weeks ago

19th Hole2 weeks agoPaulina Gretzky opens up on receiving death threats following DJ’s move to LIV Golf

Alex

Sep 21, 2016 at 1:52 am

correction: in the 913 series the Fd was LARGER than the 913f, correct?

rymail00

Sep 10, 2016 at 5:48 pm

Whoops meant the head size of 915F/FD?

rymail00

Sep 10, 2016 at 5:46 pm

Anyone know the head sizes of 916 F/FD?

kdunn

Sep 10, 2016 at 12:51 am

I love titleist but their really isn’t anything over previous generations…….you can alter those numbers easily by just where you hit it on face……pretty clubs for sure but to redo my woods for over 1k, not a chance…….I understand that it’s tough being in their shoes trying to sell new product without being able to really do anything significant as per USGA rules…….I have all titleist woods now but not gna change to newer stuff….

COGolfer

Sep 10, 2016 at 11:46 pm

Agree with you on that. I love the 915F, but don’t see a reason to upgrade. Especially at that price point.

kdunn

Sep 10, 2016 at 12:49 am

And $180 for weight kit is ridiculous……..truly insane, almost half cost of top tier driver…..you have to be kidding me

kdunn

Sep 10, 2016 at 12:47 am

I love titleist but their really isn’t anything over previous generations…….you can alter those numbers easily by just where you hit it on face……pretty clubs for sure but to redo my woods for over 1k, not a chance…….I understand that it’s tough being in their shoes trying to sell new product without being able to really do anything significant as per USGA rules…….I have all titleist woods now but not gna change to newer stuff……….and you be pretty hardpressed to find any fairway wood that doesn’t perform these days……they all have same tech that does same thing……gna be a tough sell to current 915 users, I had a 910,913 and think my 915 sounds and feels fine…….couple of rpms, and couple of yds isn’t gonna change someone’s game and would be unoticeable on course…..

Sake

Sep 8, 2016 at 11:51 pm

Looks good but I still prefer my 913 FD 13.5*

Jeffrey Purtell

Sep 9, 2016 at 4:30 am

I have the 13.5* too. Love it. Ive nicknamed it my mini driver.

Uncle Buck

Sep 8, 2016 at 2:16 pm

$180 for whaaaat?!! I’ll stick with me $5.99 packet of lead tape!

Dj

Sep 8, 2016 at 11:10 am

Bahahaha $180 for a weight kit. Also, please keep that horrid color in the 90s. Losing more and more respect for titleist nowadays

OH

Sep 8, 2016 at 9:59 am

Looks fantastic and I love that Titleist continues to fine tune a quality product rather than market their stuff with ridiculous claims and gimmicks.