Equipment

Blurred Lines: Mizuno launches JPX-900 Tour irons

Mizuno, which has set the golden standard for players irons over the years, is blurring the lines between a blade iron and a forged cavity back with its new JPX-900 Tour irons. The new irons pass the eye-test for a blade, but they’re pumped up with performance features usually reserved for Mizuno’s bulkier JPX irons.

Like Mizuno’s MP iron models, which are designed for the most discerning and skilled golfers, the JPX-900 Tour irons are made from Mizuno’s Grain Flow forged 1025E Mild Carbon Steel to give golfers the familiar soft, solid feel for which Mizuno is known.

“We wanted to make the best Grain Flow Forged iron ever,” says David Llewellyn, Mizuno’s Director of R&D.

What’s different about the JPX-900 Tour irons is the more aggressive styling, which is part form, part function. The addition of Mizuno’s angular “Power Frame” to the cavity increases moment of inertia (MOI), which makes the irons more forgiving. Yet according to Llewellyn, the refined cavity-back irons should be an easy transition for its staff players, Chris Wood and Luke Donald, who currently use the company’s MP-5 blade irons.

Mizuno’s MP-64 irons, a forged cavity-back that many in the Mizuno community believe to be the best-feeling Mizuno iron in recent memory, was used as the benchmark for the acoustics of the JPX-900 Tour irons. By using the company’s HIT (Harmonic Impact Technology) system, which measures and quantifies sound frequencies, Mizuno was able to mimic the acoustics of the MP-64 irons while improving on their construction.

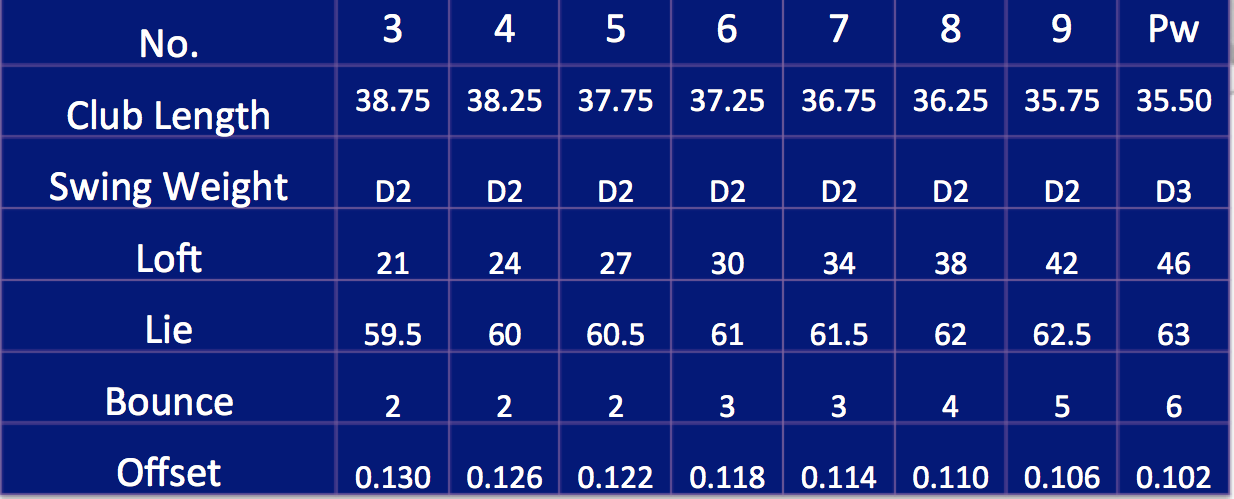

Specs

In terms of looks, the JPX-900 Tour irons are smaller than the MP-25 irons released in 2015, with a lower toe height and a “more modern design” than the MP-25 irons, Llewellyn says. Another note of distinction: the soles of the JPX-900 Tour irons which are thinnest ever used on a JPX model, and feature the same sole geometries Mizuno has been giving its MP irons for several generations. This design will create more versatility than ever from a JPX offering, something better players will surely appreciate.

The stock shaft for the JPX-900 Tour irons is True Temper’s Dynamic Gold AMT, which uses an ascending weight design to improve performance of each iron. In the X100 flex, for example, the 3-iron shaft weighs roughly 115 grams, while the pitching wedge shafts weighs about 130 grams. The lighter long-iron shafts help golfers hit higher-flying long-iron shots, making it easier to hit and hold greens, while the heavier short iron shafts provide added stability for greater precision.

Mizuno’s JPX-900 Tour irons, available Sept. 16, will sell for $1,199.99 in either steel or graphite. There is no upcharge for custom shafts or grips.

Related

- LIKE741

- LEGIT98

- WOW77

- LOL12

- IDHT13

- FLOP6

- OB7

- SHANK48

Whats in the Bag

Daniel Berger WITB 2024 (April)

- Daniel Berger what’s in the bag accurate as of the Farmers Insurance Open. More photos from the event here.

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

3-wood: TaylorMade Qi10 (15 degrees)

Shaft: Fujikura Ventus Black 7 X

6-wood: TaylorMade Qi10 Tour (21 degrees)

Shaft: Fujikura Ventus Black 8 X

Irons: TaylorMade P770 (3), TaylorMade Tour Preferred MC 2011 (4-PW)

Shafts: Project X Denali Blue 105 TX (3), Project X 6.5 (4-PW)

Wedges: Titleist Vokey Design SM9 (50-12F), Titleist Vokey Design SM10 (56-14F), Callaway Jaws Raw (60-08C)

Shafts: Project X 6.5 (50), True Temper Dynamic Gold Tour Issue S400 (56, 60)

Putter: Odyssey Ai-One Jailbird Mini DB

Grip: SuperStroke Zenergy PistolLock 1.0

Grips: Golf Pride Tour Wrap

Ball: Titleist Pro V1

Check out more in-hand photos of Daniel Berger’s clubs in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Heavy Artillery: A look at drivers in play at the Zurich Classic of New Orleans

What are the driver and shaft combinations of the best golfers in the world? For gearheads, it’s an endlessly interesting question — even if we can only ever aspire to play LS heads and 7 TX shafts.

At this week’s Zurich Classic of New Orleans, GolfWRX got in-hand looks at the driver setups of a wealth of players.

Check out some of the most interesting combos below, then head to the GolfWRX forums for the rest, as well as the rest of our galleries from New Orleans.

Rory McIlroy

Driver: TaylorMade Qi10 (9 degrees @8.25)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride MCC

Alex Fitzpatrick

Driver: Ping G430 LST (10.5 degrees)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride MCC

Daniel Berger

Driver: Ping G430 LST (10.5 degrees @9)

Shaft: Fujikura Ventus Black 6 X

Grip: Golf Pride Tour Wrap

Rasmus Hojgaard

Driver: Callaway Paradym Ai Smoke Triple Diamond (10.5 degrees)

Shaft: Mitsubishi Tensei 1K Blue 60 TX

Grip: Golf Pride MCC

Alejandro Tosti

Driver: Srixon ZX5 Mk II LS (9.5 degrees @10.5)

Shaft: Project X HZRDUS T1100 75 6.5

Grip: Golf Pride MCC Plus4

James Nicholas

Driver: Titleist TSR3 (8 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 7 X

Grip: Golf Pride Tour Velvet

Kevin Streelman

Driver: Titleist TSR3 (10 degrees, D1 SureFit setting)

Shaft: Fujikura Ventus TR Black 6 X

Grip: Golf Pride Tour Velvet

Sang-moon Bae

Driver: Callaway Paradym Triple Diamond (9+ @8)

Shaft: Fujikura Ventus Blue 6 X

Grip: Golf Pride Tour Velvet

Russ Cochran

Driver: Callaway Paradym Ai Smoke (9 degrees)

Shaft: Graphite Design Tour AD TP 6 X

Grip: Golf pride MCC Align

MJ Daffue

Driver: Callaway Paradym Ai Smoke Max (10.5 degrees @9.5)

Shaft: Project X HZRDUS Smoke Green RDX 65 TX

Grip: Golf Pride ZGrip Cord Align

Check our more photos from the Zurich Classic here.

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Rasmus Højgaard WITB 2024 (April)

- Rasmus Højgaard what’s in the bag accurate as of the Zurich Classic.

Driver: Callaway Ai Smoke Triple Diamond (10.5 degrees)

Shaft: Mitsubishi Tensei 1K Blue 60 TX

3-wood: Callaway Ai Smoke Triple Diamond Prototype (16.5 degrees)

Shaft: Mitsubishi Tensei 1K White 80 TX

Utility: Callaway Apex UW (21 degrees)

Shaft: Mitsubishi Tensei AV Raw White 85 TX

Irons: Callaway Apex Pro (3), Callaway X Forged (4-PW)

Shafts: KBS $-Taper 130

Wedges: Callaway Jaws Raw (52-10S, 56-10S, 60-06C)

Shafts: KBS Tour 130 X

Putter: Odyssey Ai One Milled Eight T DB

Grips: Golf Pride MCC

Check out more in-hand photos of Hojgaard in the forums.

- LIKE3

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 days ago

19th Hole2 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 days ago

19th Hole2 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

Ufourix

Aug 22, 2016 at 7:34 am

Will they be offered in Left Handed??

TWShoot67

Aug 16, 2016 at 3:52 pm

I use to play Mizuno blades for the longest time 14’s, 29’s and even the 33’s. Didn’t like the 32’s, but these look like they might be that perfect go between blade and cb. If they feel like my old time dizzy blades with a little extra punch Mizuno may have me back. But for now I’m sticking with my King Cobra pro mb/cb’s. Definitely can’t wait to demo. Love the minimal offset, one thing I din’t like about the 29’s in the scoring clubs was the huge amount of offset thus the Tiger combo of 29’s in long irons and 14’s in scoring clubs.

tonks

Aug 15, 2016 at 7:26 am

I am using Mizuno TP9s with DG S400 shafts for the last four years (designed in 1986). I bought them from someone who had only used them four times from new (they were still in the original Mizuno box!). I find them well balanced and accurate and they look fantastic. The loft of the 7 iron is 37 degrees. Does anyone have any thoughts as to how they compare with MPs and JPXs should I want to change to a modern club?

Tim

Aug 12, 2016 at 7:50 pm

Does anyone else see the Ping s55 when you look at these irons? The toe portion of the cavity is identical as well as the general shape of the cavity. Overall design goal is exactly what the s55 achieved: smaller, players cavity back iron. Good news for all the fans of Ping’s S line who have being asking Ping to forge their clubs.

KK

Aug 13, 2016 at 9:47 pm

Just the high toe weighting. Everything else is very different, including the unseen tech.

Double Mocha Man

Mar 17, 2017 at 11:04 am

Does anyone else see the Titleist AP1 and AP2 irons when they look at the back of these clubs?

Dane

Aug 12, 2016 at 3:56 pm

To bad Mizuno doesn’t offer the Dynamic Gold Tour Issue shafts in custom. That’s my favorite iron shaft. These irons would be awesome paired with those shafts. Most of the club manufacturers carry that shaft but for some reason Mizuno does not.

L

Aug 12, 2016 at 4:30 pm

Not this again.

There is no need for those shafts. Mizuno can build their clubs to precise spec with the standard ones. No need to spend the extra money for labels

Dane

Aug 14, 2016 at 1:51 am

It’s not just labels. The Tour Issue model has a tighter tolerance and are more consistent compared to the standard shafts. I can feel the difference between the two and others can agree with me. It’s the #1 shaft model on Tour. Titleist, TaylorMade, Callaway and Ping offer that shaft but not Mizuno. That’s unfortunate in my honest opinion.

Also, Go to TrueTemper.com where they have a video explaining the differences between the two shafts. Your not paying more for a label, your paying more for a better, tighter tolerance and more consistent shaft.

Jim

Aug 14, 2016 at 11:39 pm

….and everyone on tour was ALSO SST Pured….every shaft can be found to have a most stable plane to install in the head for optimum feel & performance.

while it’s been illegal to manufacture a shaft specifically with a ‘spine’ to be inserted in a specific orientation, It’s not illegal to ‘find’ it in a shaft and reinstall it so it lies on a better axis…

I’m diggin KBS now after being an original Brunswick Rifle defector from DG X100’s

Christopher

Aug 15, 2016 at 11:05 am

From what I remember originally they’re the same shaft, just cherry-picked. There wouldn’t be any difference in feel or performance between two shafts weighted the same, with the same playing characteristics. The only difference would be the label and the upcharge.

An expert clubmaker could cherry pick the same exact Dynamic Gold shafts off the rack and there would be no difference, apart from the price. You’re only paying more for True Temper to sort the shafts correctly, which is arguably something they should do in the first place.

Scooter McGavin

Aug 15, 2016 at 4:52 pm

No, you can’t feel the difference.

Eric

Aug 16, 2016 at 8:55 pm

Some players won’t feel the difference between the standard shafts versus Tour Issue shafts but good players will. Plus the Tour Issue shafts look better with the Tour Issue shaft band.

Christopher

Aug 17, 2016 at 4:10 pm

They’re the same shaft, so they’re imagining a difference. The only difference is that each shaft will match your other shafts in your irons to a tighter margin, but you could cherry pick the standard Dynamic Gold shafts to achieve the same result. Imagine if you bought new pool balls for your 9-ball table, one or two balls are slightly heavier or lighter than the others, that would be your Dynamic Gold set, and the Tour Issue’s would all be same weight. They’re the same balls, they just have tighter quality control with the Tour Issues.

MP-4

Aug 12, 2016 at 1:17 pm

“…should be an easy transition for its staff players.” Highly doubt LD would move from the MP-5 to a JPX iron. Going to be awhile before anything surpasses the MP-5. Looking forward to the JPX 900 driver though, which I think is the most interesting club of the new JPX line.

bogeypro

Aug 12, 2016 at 9:34 am

What is your beef with Mizuno? Did they touch you inappropriately or something? They make great equipment. Don’t get mad at them if you can’t play it…

smizzletroll

Aug 12, 2016 at 11:58 am

no, they didn’t touch him, thats his beef. professional troll of golf message boards, ridiculously sad…

KK

Aug 11, 2016 at 10:51 pm

Beautiful but these don’t look very forgiving– basically an MB. Tour is a good name.

Dat

Aug 11, 2016 at 8:53 pm

I think they look very different for Mizuno in a good way. Really looks like the engineers spent their time on this one. A true leap in the generation of their products. I don’t care what they call them as long as they perform.

Double Mocha Man

Aug 11, 2016 at 6:54 pm

They look like a streamlined version of the Titleist AP-2 irons.

Tom Duckworth

Aug 11, 2016 at 5:11 pm

I have never owned a set of Mizuno irons but have always wanted to . Just never got around to it. I have some Wilson FG Tour V2s with some Nippon shafts that I just can’t kick out of the bag. These look really nice I never liked the looks of the 800 series and didn’t think the MPs were right for me. The MP-64s are beautiful and I was thinking about getting a used set for fun and to try them out. Maybe I’ll have to look into these. This is the first series of JPX irons that look good to me funny I always thought MPs were some of the best looking irons out there and JPX the worst . Hope to see some reviews soon. Maybe Mizuno will want some WRX testers.

Brian

Aug 11, 2016 at 4:10 pm

You should stick with your Callaways and their 29 degree 7 iron.

Bill

Aug 14, 2016 at 4:04 pm

You can’t hit a 7 iron?

Jay

Aug 11, 2016 at 2:57 pm

While the “no upcharge” is nice, if you prefer a more stock shaft – DG S300 – kind of have to feel you are getting hosed.

DJ

Aug 11, 2016 at 5:24 pm

Why would anyone take a chevy when the caddilac is the same price? They are not targeting the cheap end with these irons.

Jim

Aug 14, 2016 at 11:30 pm

Actually, it was a huge, smart move from Callaway…First year of Apex irons, they knew they were so good – and 1099 – $100 more than other big OEM’s ‘BEST’ they offered whichever shaft you needed for no upcharge. That helped make them a huge successs.

When Rocketblades died a painful death after only 8 months and Speedblades (the next ‘greatest iron ever made’) came out with the same POS $9.00 shaft as Rocketblades for $899, getting into Apex (a FAR better head) w/KBS C-Tapers or Project X’s for 200 more wasn’t that big a stretch for shoppers.

it’s a smart move for every OEM. Cripes – even Adams put CTapers in that funky black head a couple years ago, and they came to market for 699. It destroyed that dog Speedblade head…

DG’s are reliable shafts – the standard we judge from – kinda like an IBM Mainframe – but if for no extra charge, you can

definitely get a better feeling better performing stick.

it always goes back to getting fit by an expert – with outdoor ball flight & proper launch monitor… Steel shaft tech has been blowin’ up big time in last 5 years. Take advantage of it!

Bl

Aug 11, 2016 at 12:51 pm

Looks cool. Smaller than the MP-25? Even better.

Chuck

Aug 11, 2016 at 12:10 pm

1. So no tungsten in the soles or the toes? Do they accomplish most of what is going on with the tungsten inserts in other brands, with just the shape of the perimeter weighting? I’d be fine with that. My gripe with the tungsten-weighted Titleists was that the head was just a shade too compact for my own tastes.

2. Are these the strongest lofts that Mizuno has ever offered?

3. I would want a lot more information on the sole grinds. Does Mizuno offer anything custom in that regard? Can you order a blunted leading edge?

4. So is this the prelude to a new MP model?

Brian

Aug 11, 2016 at 12:55 pm

1. Mizuno has never used tungsten inserts in their irons and these do not depart from that standard.

2. These have the same loft specs as the MP-25, MP-15, and MP-5; so no, these aren’t lofted strong.

3. You would likely have to order custom sole grinds from Mizuno’s Yoro arm and should expect to pay a premium to do so.

4. No idea

tl

Aug 11, 2016 at 4:30 pm

And, they are also still 1/4″ shorter than Titleist

kloyd0306

Aug 12, 2016 at 8:57 pm

Don’t you mean that Titleist are 1/4 inch longer than Mizuno?

There is no industry standard for length. Who is to say that Titleist’s lengths are the correct length? Besides, stock lengths are only for stock clubs and if you are buying stock clubs from anyone, you may as well drive a car that does not have an adjustable seat, an adjustable steering wheel or adjustable mirrors.

Mizuno measures length WITHOUT the grip. Titleist measures length WITH the grip. There is still a small difference but not a 1/4 inch when both are finished.

Justin

Aug 11, 2016 at 11:34 am

If they are in fact smaller than the MP25s then I’ll be salivating over these. May have to work up a combo set with MP25 4 and 5 irons

Dj

Aug 11, 2016 at 10:59 am

Look like 716 ap2

Scooter McGavin

Aug 11, 2016 at 1:38 pm

Yeah, except that they don’t.

Dj

Aug 11, 2016 at 5:49 pm

Talking design of cavity only. So yes, they design is identical.

Scooter McGavin

Aug 15, 2016 at 4:53 pm

No, not really.

GetRichorTyTryon

Aug 19, 2016 at 8:09 pm

LOL!!

Brian

Aug 11, 2016 at 4:08 pm

They look like the club that the Ap2 aspires to be.

Dj

Aug 11, 2016 at 5:50 pm

Except ap2 will outsell by 20 times

Brian

Aug 12, 2016 at 8:39 am

I’m not a Mizuno shareholder, so their sales aren’t a concern of mine.

rpm300

Aug 11, 2016 at 10:52 am

They look nice, but as usual for Mizuno, they have way too muck offset in the short irons.

Alex

Aug 11, 2016 at 10:23 am

My gosh, those look incredible. However, am I the only person who thinks those grooves seem like they’re extending too far on the toe?

sumsum

Aug 11, 2016 at 10:21 am

I hear they will be offering Recoil now with no upcharge, might make this a mean set!

Mat

Aug 11, 2016 at 4:31 pm

That would be killer.

Marty Moose

Aug 11, 2016 at 10:06 am

Mizuno makes very nice clubs. If I were one of the current Nike staffers, I’d be talking to Mizuno. Even if that means a pay cut. Prob turn out to to be the same $ if they continue to wear Nike clothing.

Nolanski

Aug 11, 2016 at 10:01 am

Pretty

LabraeGolfer

Aug 11, 2016 at 9:56 am

Best selling irons of 2016-2017…. Well should be anyway at least for better players. They look fantastic and they are Mizuno’s so I know they will perform.

Mikec

Aug 12, 2016 at 9:12 am

So you are making a predication that these will lead iron sales??