Opinion & Analysis

From idea to reality: Golf club design at major OEMs

Like nearly every modern project of sophisticated design, the club creation process begins with computer-aided design (CAD) software. Ping, an Arizona-based equipment company, primarily drafts using a product design suite called Creo, according to VP of Engineering Paul Wood, although there are several software options that do essentially the same thing.

The ultimate objective in the early design stages, according to Wood? “Essentially using the tools as a sketchbook.”

Everyone on the Ping team is adept using Creo, so moving to another platform would “be like starting over again.” Cleveland golf, for its part, uses Altair’s suite of design applications.

So that G30 in you hand? It began as a digital sketch on Wood’s team’s computer screens.

Wood, who holds a PhD in Applied Mathematics from the University of St. Andrews, said Ping uses different software for different aspects of the design process. Alternatively, specialists have particular preferences, which may not speak to the inherent merits of one software over another, but rather to what a particular person doing a particular job is comfortable with.

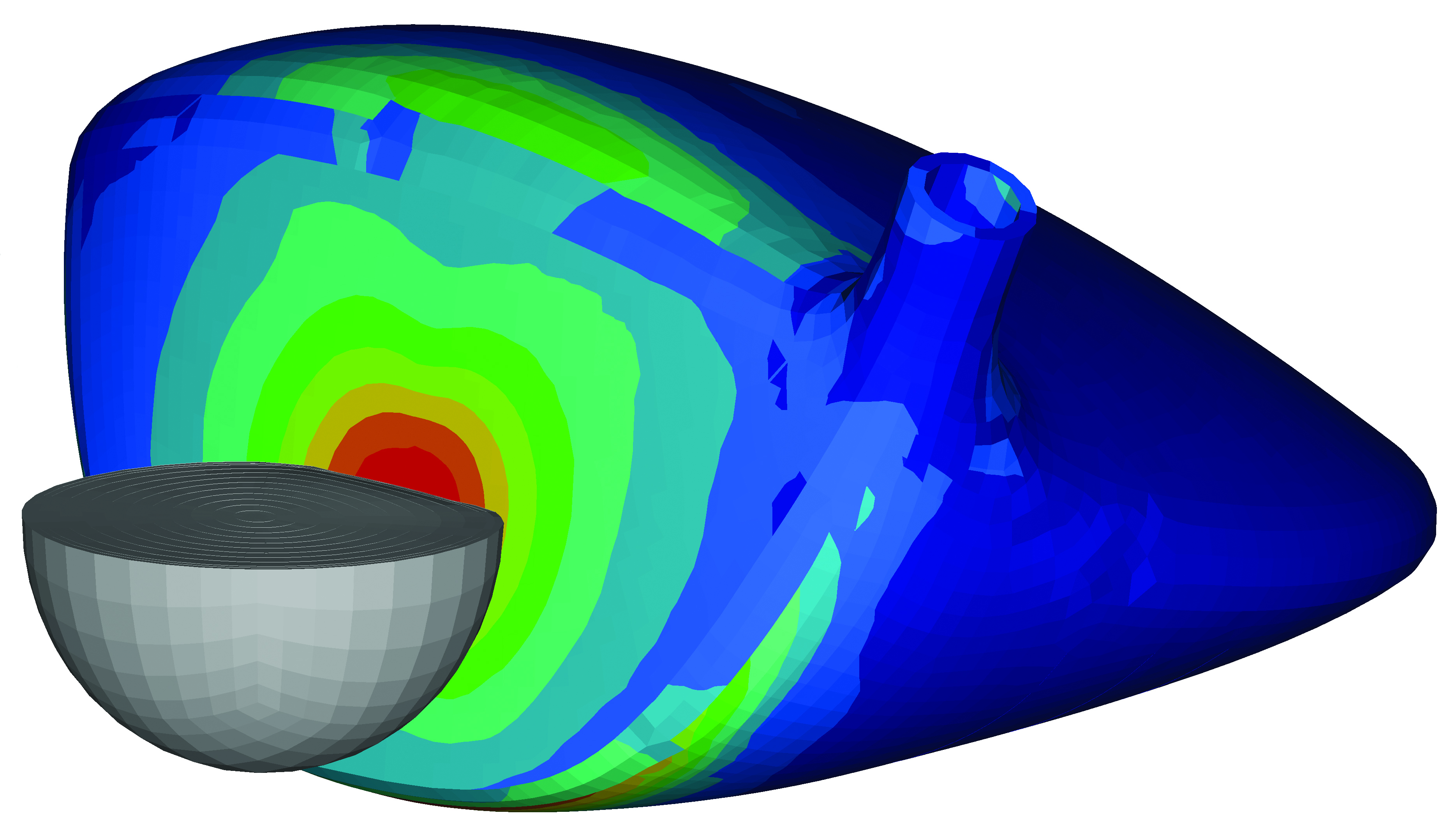

[quote_box_center]”We use some Altair stuff to do our finite element analysis: taking a model … a driver head or whatever, simulating impact, looking at where the stress and strains are … predictions of performance … We have a guy that’s full time,” Wood said. “He’ll work with the design team and pull the design from CREO. We also have aerodynamics packages that will simulate airflow, which is another specialist role.”[/quote_box_center]

I asked Dustin Brekke, Engineering Manager, Research and Development for Cleveland, how the company uses the same Altair software. He said the ultimate objective with the software use is “to evaluate, eliminate, and improve designs prior to spending the time and money to make samples.” The process of evaluating design concepts is different for each club. For woods, the company is assessing the strength of materials and face thickness and simulating impact conditions.

So, regardless of the particular software and its specific applications, the objective is the same: model initial concepts in CAD software and test them prior to production.

How CAD software was a game changer

Todd Beach, VP Product Development, TaylorMade Golf Company, laid out the differences between the pre-1990s method of club design and CAD-based design.

Before the 1990s, Beach said, clubmakers hand-shaped master designs “based on external cosmetics.” Companies would then use the masters to make the tools for the casting process. Adjustments and improvements would then be made.

[quote_box_center]

“Now clubs are designed with high powered CAD systems, which model all of the complex internal features and adjustability features,” Beach said. “The mass properties can be optimized on the computer before ever launching a prototype.

“The sound/feel, durability, aerodynamics and launch performance can also be simulated using sophisticated finite element methods [virtual prototyping]. Using these tools, it is possible to iterate multiple times to optimize performance before launching the first test prototype.”

[/quote_box_center]

Cleveland’s Brekke highlighted the speed of the CAD-based design process. In the case of creating a “master” design prior to CAD software, not only was the process significantly more time consuming, a company was left with just one design to test, rather than multiple variations.

[quote_box_center]”That is how the industry has changed so much in the last few decades,” Brekke said. “With all the advances in modeling, simulation, and rapid prototyping exponentially more design concepts can be evaluated and therefore new discoveries are constantly within reach.”[/quote_box_center]

So from process, innovation, and speed-to-market standpoints, CAD suites like Creo and Altair have changed the game.

Working outside the product cycle

There are two modes of operation in the engineering world of major OEMs: inside and outside the product cycle. The companies try to do as much as they can outside of the product cycle, which isn’t surprising, given the innovation imperative in golf equipment and the need to produce game-improving, marketable products.

Rather than thinking about next year’s driver or specific clubs, outside the product cycle, the engineers are more concerned with concepts and technologies. As Wood says, outside the product cycle, “we try to do things generally,” saying, “this would apply to any driver,” rather than worrying about specific constraints or what was on the shelf last year.

However, at Ping at least, there’s a team that is perpetually working outside of specific product cycles whose only imperative is innovation.

[quote_box_center]”We have a dedicated innovation team that is much more outside of the specific product cycle, aiming at technology development, knowledge development, things that the design team can kind of plug into the next club they have.”[/quote_box_center]

The end goal, of course, is a market-beating offering. However, to deliver, say, the next great driver, said driver needs to be loaded with innovative components. It’s to this end that Wood says, “we want to know as much as we can about technology and materials and the specifics of what’s going on and what the customer needs.”

TaylorMade’s Todd Beach echoed Wood’s sentiments about the market and customer needs as well as the ongoing pursuit of innovation.

[quote_box_center]“We have several teams working on … concepts, which are more breakthrough, next-generation stuff. Stuff where you don’t know if it’s going to work, so you don’t have a specific time frame on it. And our product marketing group is constantly looking at the marketplace and seeing what products are resonating in the marketplace.”[/quote_box_center]

Interestingly, Beach added, R&D may continue to work on a concept for a long time, even in excess of 10 years if the marketing team feels a technology is truly groundbreaking.

Within the product cycle

Inside the product cycle, as you’d expect, things are more systematized, coordinated and deadline driven.

How long is the product cycle? Anywhere from one year to three years.

And rather than seeking to reinvent the wheel, companies often begin with the most recent design for, say a driver, and seek to improve upon it/implement technologies they’ve been working on.

[quote_box_center]“You’re taking ideas you might want to incorporate into the next model,” Wood said. “So for some of that, you can take an existing prototype … For example, we can take the G30 iron and mess around with it.”[/quote_box_center]

After the club in question has been sufficiently “messed around with” to create something worth investigating further, the company will produce a few prototypes for initial testing.

Alternatively, as Wood indicated, designers may want to build a few prototypes merely to test a new technology to arrive at a point called “concept validation,” which determines the viability of a technology for inclusion in a future club offering.

Beach said TaylorMade often begins a product cycle with the question: “What’s the best fit given the technologies the Phase I group has been working on?”

Beyond messing around to see what works and prototype creation, the rubber meets the road once a company enters into product development and firmer decisions must be made.

[quote_box_center]“Once you start to get into product development … we’ll start to make decisions like ‘this is going to be a cast iron,’” Wood says. “You start worrying about every little detail and that’s when maybe you’d start working with a supplier.”[/quote_box_center]

And an interesting note about product development, particularly iron development. Ping will often start with a 7-iron then build backward (6, 5, 4) and forward (8, 9) until they have a whole set, tweaking the initial 7-iron design. Likewise, driver design often begins with the 9-degree, right-handed model.

A component of club production, of course, is tool creation. For example, producing the metal blocks used in the iron casting process. And a big part of scaling up production is getting overseas manufacturers the appropriate tools with the appropriate tolerances to create quality products.

During this time, TaylorMade moves between durability, player and consumer testing as a lead-up to mass production.

Following these preliminaries, a company will usually initiate a pilot run to work out the details of production, costs (including scrap rates) and tolerances. At this point, a U.S.-based club company can authorize its overseas production facility to manufacture a run of five of 10,000 units.

Assuming the above goes off without a hitch, “ownership” of the project transfers from the design team to what Wood referred to as the “quality group.”

“Once you’ve gone through the pilot and have done all the tweaking and adjusting specs, it’s now a quality function … On our supplier’s end, it’s gone from product development to factory floor production … What they’re doing is developing these very detailed work instructions, which we help with … But it’s now a factory procedure … it’s the same thing if you’re Intel making chips.”

Likewise, Beach said that at this point in production, “It’s probably not that much different than other technical products.”

So that, in a nutshell, is how a team of designers in Carlsbad or Phoenix created the M1 or G30 that’s in your bag.

- LIKE54

- LEGIT19

- WOW5

- LOL1

- IDHT0

- FLOP0

- OB1

- SHANK10

19th Hole

Vincenzi’s 2024 Zurich Classic of New Orleans betting preview

The PGA TOUR heads to New Orleans to play the 2023 Zurich Classic of New Orleans. In a welcome change from the usual stroke play, the Zurich Classic is a team event. On Thursday and Saturday, the teams play best ball, and on Friday and Sunday the teams play alternate shot.

TPC Louisiana is a par 72 that measures 7,425 yards. The course features some short par 4s and plenty of water and bunkers, which makes for a lot of exciting risk/reward scenarios for competitors. Pete Dye designed the course in 2004 specifically for the Zurich Classic, although the event didn’t make its debut until 2007 because of Hurricane Katrina.

Coming off of the Masters and a signature event in consecutive weeks, the field this week is a step down, and understandably so. Many of the world’s top players will be using this time to rest after a busy stretch.

However, there are some interesting teams this season with some stars making surprise appearances in the team event. Some notable teams include Patrick Cantlay and Xander Schauffele, Rory McIlroy and Shane Lowry, Collin Morikawa and Kurt Kitayama, Will Zalatoris and Sahith Theegala as well as a few Canadian teams, Nick Taylor and Adam Hadwin and Taylor Pendrith and Corey Conners.

Past Winners at TPC Louisiana

- 2023: Riley/Hardy (-30)

- 2022: Cantlay/Schauffele (-29)

- 2021: Leishman/Smith (-20)

- 2019: Palmer/Rahm (-26)

- 2018: Horschel/Piercy (-22)

- 2017: Blixt/Smith (-27)

2024 Zurich Classic of New Orleans Picks

Tom Hoge/Maverick McNealy +2500 (DraftKings)

Tom Hoge is coming off of a solid T18 finish at the RBC Heritage and finished T13 at last year’s Zurich Classic alongside Harris English.

This season, Hoge is having one of his best years on Tour in terms of Strokes Gained: Approach. In his last 24 rounds, the only player to top him on the category is Scottie Scheffler. Hoge has been solid on Pete Dye designs, ranking 28th in the field over his past 36 rounds.

McNealy is also having a solid season. He’s finished T6 at the Waste Management Phoenix Open and T9 at the PLAYERS Championship. He recently started working with world renowned swing coach, Butch Harmon, and its seemingly paid dividends in 2024.

Keith Mitchell/Joel Dahmen +4000 (DraftKings)

Keith Mitchell is having a fantastic season, finishing in the top-20 of five of his past seven starts on Tour. Most recently, Mitchell finished T14 at the Valero Texas Open and gained a whopping 6.0 strokes off the tee. He finished 6th at last year’s Zurich Classic.

Joel Dahmen is having a resurgent year and has been dialed in with his irons. He also has a T11 finish at the PLAYERS Championship at TPC Sawgrass which is another Pete Dye track. With Mitchell’s length and Dahmen’s ability to put it close with his short irons, the Mitchell/Dahmen combination will be dangerous this week.

Taylor Moore/Matt NeSmith +6500 (DraftKings)

Taylor Moore has quickly developed into one of the more consistent players on Tour. He’s finished in the top-20 in three of his past four starts, including a very impressive showing at The Masters, finishing T20. He’s also finished T4 at this event in consecutive seasons alongside Matt NeSmith.

NeSmith isn’t having a great 2024, but has seemed to elevate his game in this format. He finished T26 at Pete Dye’s TPC Sawgrass, which gives the 30-year-old something to build off of. NeSmith is also a great putter on Bermudagrass, which could help elevate Moore’s ball striking prowess.

- LIKE3

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP1

- OB0

- SHANK0

19th Hole

Vincenzi’s 2024 LIV Adelaide betting preview: Cam Smith ready for big week down under

After having four of the top twelve players on the leaderboard at The Masters, LIV Golf is set for their fifth event of the season: LIV Adelaide.

For both LIV fans and golf fans in Australia, LIV Adelaide is one of the most anticipated events of the year. With 35,000 people expected to attend each day of the tournament, the Grange Golf Club will be crawling with fans who are passionate about the sport of golf. The 12th hole, better known as “the watering hole”, is sure to have the rowdiest of the fans cheering after a long day of drinking some Leishman Lager.

The Grange Golf Club is a par-72 that measures 6,946 yards. The course features minimal resistance, as golfers went extremely low last season. In 2023, Talor Gooch shot consecutive rounds of 62 on Thursday and Friday, giving himself a gigantic cushion heading into championship Sunday. Things got tight for a while, but in the end, the Oklahoma State product was able to hold off The Crushers’ Anirban Lahiri for a three-shot victory.

The Four Aces won the team competition with the Range Goats finishing second.

*All Images Courtesy of LIV Golf*

Past Winners at LIV Adelaide

- 2023: Talor Gooch (-19)

Stat Leaders Through LIV Miami

Green in Regulation

- Richard Bland

- Jon Rahm

- Paul Casey

Fairways Hit

- Abraham Ancer

- Graeme McDowell

- Henrik Stenson

Driving Distance

- Bryson DeChambeau

- Joaquin Niemann

- Dean Burmester

Putting

- Cameron Smith

- Louis Oosthuizen

- Matt Jones

2024 LIV Adelaide Picks

Cameron Smith +1400 (DraftKings)

When I pulled up the odds for LIV Adelaide, I was more than a little surprised to see multiple golfers listed ahead of Cameron Smith on the betting board. A few starts ago, Cam finished runner-up at LIV Hong Kong, which is a golf course that absolutely suits his eye. Augusta National in another course that Smith could roll out of bed and finish in the top-ten at, and he did so two weeks ago at The Masters, finishing T6.

At Augusta, he gained strokes on the field on approach, off the tee (slightly), and of course, around the green and putting. Smith able to get in the mix at a major championship despite coming into the week feeling under the weather tells me that his game is once again rounding into form.

The Grange Golf Club is another course that undoubtedly suits the Australian. Smith is obviously incredibly comfortable playing in front of the Aussie faithful and has won three Australian PGA Championship’s. The course is very short and will allow Smith to play conservative off the tee, mitigating his most glaring weakness. With birdies available all over the golf course, there’s a chance the event turns into a putting contest, and there’s no one on the planet I’d rather have in one of those than Cam Smith.

Louis Oosthuizen +2200 (DraftKings)

Louis Oosthuizen has simply been one of the best players on LIV in the 2024 seas0n. The South African has finished in the top-10 on the LIV leaderboard in three of his five starts, with his best coming in Jeddah, where he finished T2. Perhaps more impressively, Oosthuizen finished T7 at LIV Miami, which took place at Doral’s “Blue Monster”, an absolutely massive golf course. Given that Louis is on the shorter side in terms of distance off the tee, his ability to play well in Miami shows how dialed he is with the irons this season.

In addition to the LIV finishes, Oosthuizen won back-to-back starts on the DP World Tour in December at the Alfred Dunhill Championship and the Mauritus Open. He also finished runner-up at the end of February in the International Series Oman. The 41-year-old has been one of the most consistent performers of 2024, regardless of tour.

For the season, Louis ranks 4th on LIV in birdies made, T9 in fairways hit and first in putting. He ranks 32nd in driving distance, but that won’t be an issue at this short course. Last season, he finished T11 at the event, but was in decent position going into the final round but fell back after shooting 70 while the rest of the field went low. This season, Oosthuizen comes into the event in peak form, and the course should be a perfect fit for his smooth swing and hot putter this week.

- LIKE4

- LEGIT1

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Opinion & Analysis

The Wedge Guy: What really makes a wedge work? Part 1

Of all the clubs in our bags, wedges are almost always the simplest in construction and, therefore, the easiest to analyze what might make one work differently from another if you know what to look for.

Wedges are a lot less mysterious than drivers, of course, as the major brands are working with a lot of “pixie dust” inside these modern marvels. That’s carrying over more to irons now, with so many new models featuring internal multi-material technologies, and almost all of them having a “badge” or insert in the back to allow more complex graphics while hiding the actual distribution of mass.

But when it comes to wedges, most on the market today are still single pieces of molded steel, either cast or forged into that shape. So, if you look closely at where the mass is distributed, it’s pretty clear how that wedge is going to perform.

To start, because of their wider soles, the majority of the mass of almost any wedge is along the bottom third of the clubhead. So, the best wedge shots are always those hit between the 2nd and 5th grooves so that more mass is directly behind that impact. Elite tour professionals practice incessantly to learn to do that consistently, wearing out a spot about the size of a penny right there. If impact moves higher than that, the face is dramatically thinner, so smash factor is compromised significantly, which reduces the overall distance the ball will fly.

Every one of us, tour players included, knows that maddening shot that we feel a bit high on the face and it doesn’t go anywhere, it’s not your fault.

If your wedges show a wear pattern the size of a silver dollar, and centered above the 3rd or 4th groove, you are not getting anywhere near the same performance from shot to shot. Robot testing proves impact even two to three grooves higher in the face can cause distance loss of up to 35 to 55 feet with modern ‘tour design’ wedges.

In addition, as impact moves above the center of mass, the golf club principle of gear effect causes the ball to fly higher with less spin. Think of modern drivers for a minute. The “holy grail” of driving is high launch and low spin, and the driver engineers are pulling out all stops to get the mass as low in the clubhead as possible to optimize this combination.

Where is all the mass in your wedges? Low. So, disregarding the higher lofts, wedges “want” to launch the ball high with low spin – exactly the opposite of what good wedge play requires penetrating ball flight with high spin.

While almost all major brand wedges have begun putting a tiny bit more thickness in the top portion of the clubhead, conventional and modern ‘tour design’ wedges perform pretty much like they always have. Elite players learn to hit those crisp, spinny penetrating wedge shots by spending lots of practice time learning to consistently make contact low in the face.

So, what about grooves and face texture?

Grooves on any club can only do so much, and no one has any material advantage here. The USGA tightly defines what we manufacturers can do with grooves and face texture, and modern manufacturing techniques allow all of us to push those limits ever closer. And we all do. End of story.

Then there’s the topic of bounce and grinds, the most complex and confusing part of the wedge formula. Many top brands offer a complex array of sole configurations, all of them admittedly specialized to a particular kind of lie or turf conditions, and/or a particular divot pattern.

But if you don’t play the same turf all the time, and make the same size divot on every swing, how would you ever figure this out?

The only way is to take any wedge you are considering and play it a few rounds, hitting all the shots you face and observing the results. There’s simply no other way.

So, hopefully this will inspire a lively conversation in our comments section, and I’ll chime in to answer any questions you might have.

And next week, I’ll dive into the rest of the wedge formula. Yes, shafts, grips and specifications are essential, too.

- LIKE29

- LEGIT7

- WOW1

- LOL1

- IDHT2

- FLOP3

- OB1

- SHANK2

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole6 days ago

19th Hole6 days agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole5 days ago

19th Hole5 days agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

-

19th Hole3 weeks ago

19th Hole3 weeks agoAddiction, spinal fusion, and scam artists – Everything Anthony Kim revealed in candid interview with David Feherty

Sean

Oct 26, 2015 at 8:25 pm

Enjoyed the article. Constantly tweaking current model for the next model. That makes sense, however, I would think they need some kind of “out of the box” ideas as well. 🙂

TR1PTIK

Oct 26, 2015 at 3:45 pm

Though I have no experience with it (or even a real desire to learn it), I’ve always been fascinated with CAD. It’s amazing how much can be done with a computer these days. Tom, aside from the time spent on the design and production of new clubs you have to also consider all of the costs associated with CAD software, tooling, and R&D among many other things. I’m not thrilled with the current prices for a new set of clubs, but I fully understand the reasoning for those prices as someone who works in manufacturing and technology.

Really good read Ben.

Tom

Oct 26, 2015 at 3:30 pm

“Interestingly, Beach added, R&D may continue to work on a concept for a long time, even in excess of 10 years if the marketing team feels a technology is truly groundbreaking.” Well that blows my criticism of this technology saving time and money for companies and yet cost to consumers remains at an all time high.

Tom Wishon

Oct 29, 2015 at 1:52 pm

LOL!!! How well you pointed that out. I guess in a sense it is a different type of oxymoron to say that they use CAD to instantly create different iterations for analysis yet they take pride in saying that they spend several years before it goes to market.

Having started in clubhead design in 1986 when it was only done by machining master models from which the dies and molds were cut by EDM off the master, it’s really been interesting for me to evolve my own head design methods from all “dinosaur” to a combination of dinosaur and modern so I can still be comfortable with it. I still love to hand make my own master models of new designs and couple that with 2D old school drawings – call it a sense of pride in the hand skills and the fact that I have always designed a lot with my eyes for the look of a head in various ways.

But then of course these days I then have a CAD operator take my models and drawings and create 3d models for me to approve plus the CAD file so the die/mold production can be done more easily. And depending the model, FEA is very nice as a means to predict performance. But in the end nothing passes for me until people hit it and a robot offers what it can offer to help verify performance.

At the same time, not saying this to blow any horn whatsoever, but in any of the many technology firsts I was privileged to contribute to head design in my career, not one of them took longer than 8 months from start to finish to do and to get right. So when I read this 2-3 yrs in development, I see that as a big company with too many people having some part of the say so over what the company brings to market such that it just slows things down.

other paul

Oct 26, 2015 at 1:56 pm

I thought that was interesting.

redneckrooster

Oct 26, 2015 at 10:13 am

SOOO THERE IS NOTHING BETTER TO DO WITH OUR TIME ?

Michael

Oct 26, 2015 at 12:29 pm

Well you clearly have better things to do.

Easy on the caps lock, bro.

MARCUS

Oct 26, 2015 at 1:43 pm

Helped pass my time here at work. 10 hr work days seem to draq without something good to read.

Trab

Oct 27, 2015 at 2:39 am

How about actually doing work? You Eejit, Marcus