Equipment

Harris MacNeill, CEO of Champ Golf, talks new Slim-Lok spike, industry

I spoke with Champ Golf’s CEO Harris MacNeill just after his visit to company factories in Hong Kong, where he also attended the Japan Golf Fair in Tokyo.

I asked him how the show differed from its equivalent in the States. He indicated that the Japanese market is much higher-end and very technically orientated. MacNeill said further that products are presented differently. Overall, he said the show was upbeat, positive, and well attended: a good sign for the second-largest golf market in the world.

Check out our conversation about the industry and the company’s new Slim-Lok spike below.

(Topics in bold with MacNeill’s words beneath)

How trends in golf shoes work

The reality of the shoe business is that there’s probably 35 or so brands that make golf shoes around the world. Ninety percent of the golf shoes are sold by four brands. You’ve really got four people—because every company has somebody at the top—that are driving technology or what is going to be saleable in the industry.

The spikeless craze over the last few years…it’s the chicken or the egg. Ecco does it, so other people follow, and the sales people say people are coming in looking for it. “We’ve gotta have spikeless” … on and on. It goes from 10 percent of the market to probably 30 percent or more very quickly…

What manufacturers are looking for

Manufacturers have challenged us: “What can you do to make a [better] lower profile spike?”

What we did develop…was called the One-Lok…as a technical system it was a snap-in and then twist-out. It works great from an execution and a technical standpoint. The problem is the tolerances were too tight for your average manufacturer. So as a development story, those things happen. We spent hundreds of thousands of dollars going down that path and building production tooling…and realizing that’s not what the industry wants.

Developing Slim-Lok

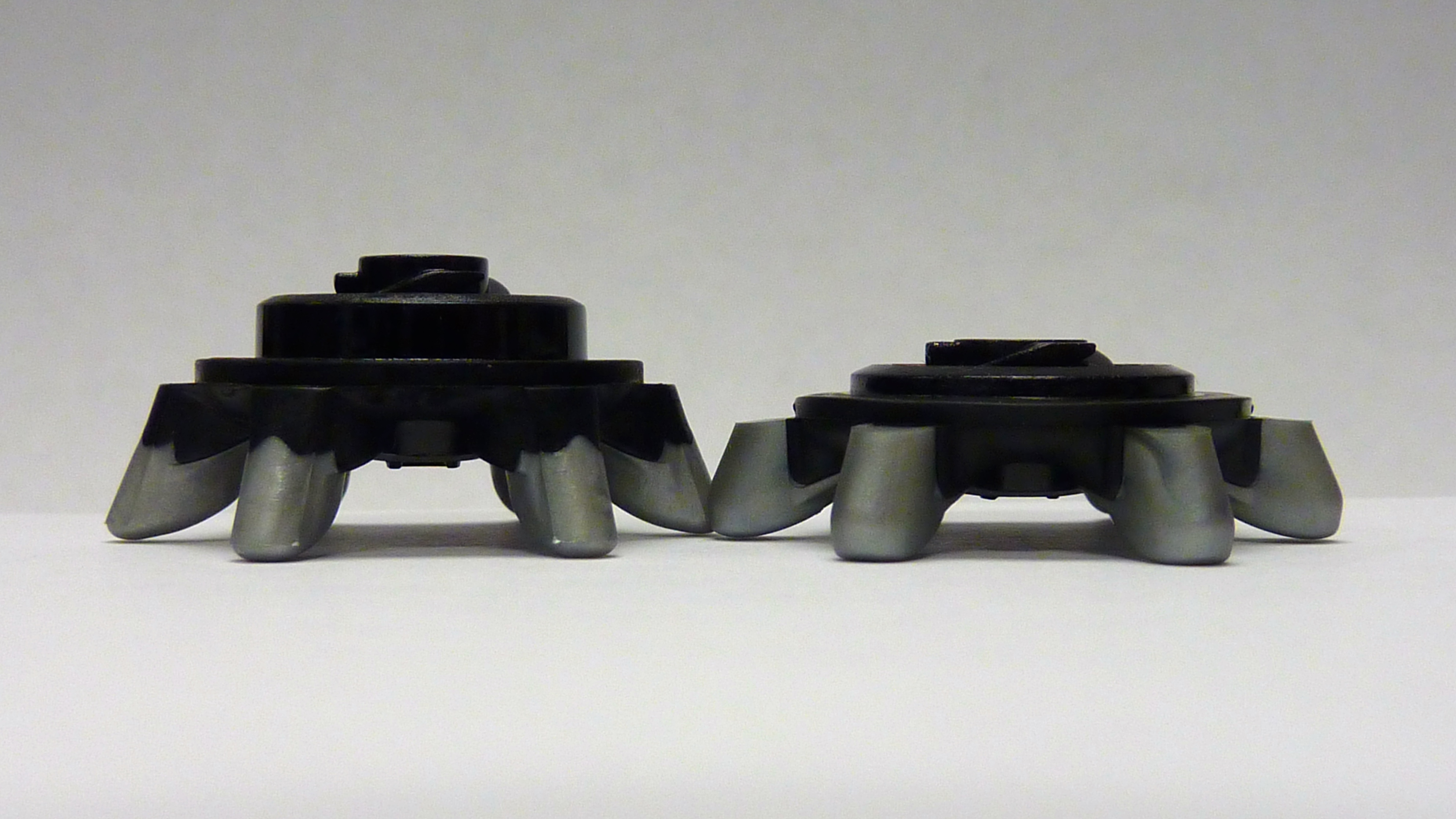

The Slim-Lok spike (right)

It was probably November of ’13. [We asked] What are all the issues with spikes in the marketplace? If we started completely from scratch, how would we do this? What do people want? They want low-profile: thin spike, thin outsole, lightweight. Also, it has to be user friendly and consumer friendly.

They’re used to using a threaded system…there are probably 25 million pairs of shoes out there like that…but from an industry perspective, there’s so many different fasteners that are there. In reality, there’s six or seven fastening systems that have been out there over the last 20 years.

We wanted to develop a spike where we could satisfy the shoe brands, where we’d make sure there were no returns and there were no issues with it…the reality is, they [brands] want spikes, but they don’t want to have to deal with it, because they’re in the business of selling shoes. The spike has to work, but they don’t want to think about it.

From a consumer standpoint…it’s the same thing.

The project

Let’s go back and re-engineer the standard in the industry, which is our Tri-Lock system. People know that, they recognize it. It works. We took that premise and we did a lot of redesign in terms of the thread configuration, the locking configuration, materials…we probably had 15 people in our company, both here in the U.S. and our Hong Kong office and our China office…between that November time frame and, say, March, we were able to fully develop the system, test the system, and then get commitments from the shoe brands to put them into their shoes starting with production in the summer and release through September first.

We were working in connection with the shoe companies, who were doing the testing and the molding.

We got equal or better torque or retention in the shoe, so the spikes don’t unscrew or pop out, which is critical, as that was the big knock on the lightweight system. We modified the thread, modified the locking mechanism, so you have a physical and audible click as you install it. You hear a click and know it’s seated and you put your wrench in and go “click, click” and it’s installed.

We made the thread so it’s backward compatible with all Tri-Lok and Fast Twist…so it’ll fit every shoe of those systems ever made. Fortunately, a lot of the work we had done previously in One-Lok with materials we were able to transfer into the Slim-Lok. That’s why we were able to get the retention that had been lacking.

From the consumer standpoint, it should be simple: they just want a spike to go in the shoe and then they can go play golf.

How the company tests and develops its products

A lot goes into the modeling, designing, tooling, testing. We have a lot of internal testing programs for mechanical testing and for bonding, pull out, torque, impact, and all those things that you’d experience in real life. Plus we put it on a large group of golfers who actually go out and try to beat the hell out of it.

The Slim-Lok was a good combination of both sides of the world. A lot of the design and concepts came from here, we did a lot of physical testing here, but the sampling, development and toolwork was done in Asia.

We’re developing on a 24-hour cycle. We work on it here. We can send the files over at the end of the day. They work on it over there, send it back. We do a lot of that, so we can really move things along.

Why OEMs don’t make spikes

The reality is for [the OEMs] to go in and design and tool up for themselves, they’d probably actually pay more for the product than if they just buy from us because of the sheer volume that we do.

They’re getting our total focus on traction technology at a great price and they don’t have to think about it. The other thing is we work very closely with the designers. They will send us a concept. They’ll just say, “Here’s what the outsole looks like. Here’s the design idea of the shoe. Where it’s going to be sold. What conditions it’s going to be used in. What are the expectations? What are the price points? Here’s…what we’re looking for. Can you design something?”

We take that from there and we’ll give them a range of designs. Sometimes they’re off-the-shelf designs we already have. Other times, they’re 100 percent custom. Typically the large brands can afford specific tooling, so they’ll do custom.

Collaborative process of shoe design

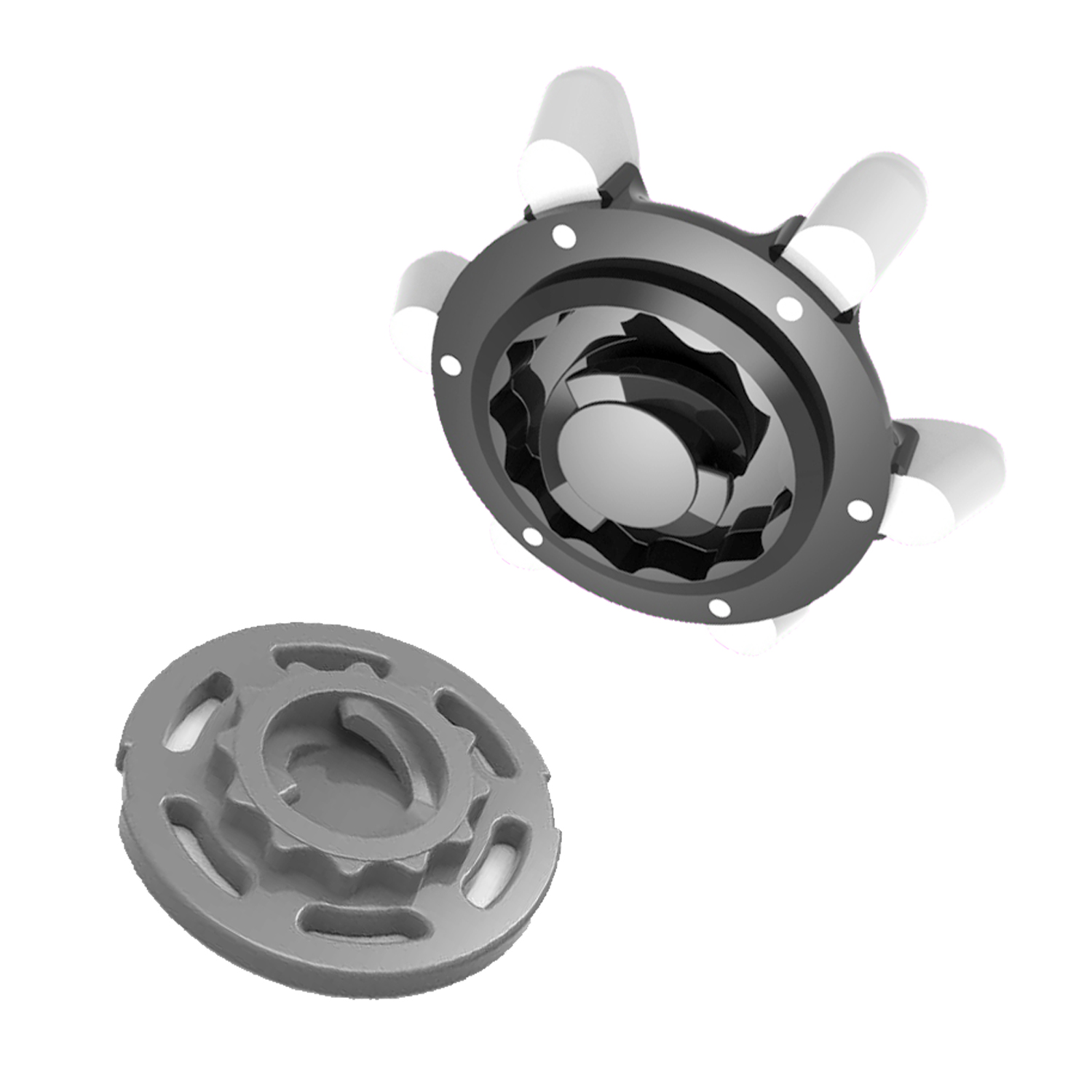

It’s very collaborative. We’re involved right at the beginning. When a shoe is manufactured, most people don’t think about, in the shoe there’s what we call the receptacle…that’s the…attachment mechanism that’s in the shoe. So they can’t start making shoes without the receptacle…that’s the first thing that happens.

We ship the receptacles to the outsole factory so they can start making outsoles. And those end up going to the assembly line so they can start making the shoe. The very last thing that happens at the assembly plant is they put the spikes on. We’re kind of the bookends.

The recent foray into grips

I looked at grips over 10 years ago. Grips at the time, Golf Pride was still dominant. There were a lot of other players, but they were all low-tech and they were all low price. I could go into the grip business, but I couldn’t make any money at it. And if you can’t offer anything different, why bother?

Fast-forward seven, eight years later: The price points change. There’s room for engineered product and price points we can make money at. The other thing that tied in at the same time was our…global distribution network: 100-plus really fine distributors around the world servicing 120 different countries and they were asking for more products and so this was just a perfect fit.

It took about three years to develop it. I wasn’t going to develop a line of grips that weren’t unique. Something that has technology but has the tradition in it as well. So we came up with four swing models to cover all the price points and technologies and a line of putter grips.

- LIKE26

- LEGIT3

- WOW1

- LOL1

- IDHT1

- FLOP5

- OB0

- SHANK4

Equipment

Rory McIlroy spotted testing a new TaylorMade “PROTO” 4-iron at the 2024 Valero Texas Open

Update, 5:30 p.m.: Regarding his prototype iron, McIlroy offered this in his pre-tournament press conference:

“Yeah, I went out, spent a couple of days with the TaylorMade guys at the Kingdom. Yeah, they just produced these couple of proto, I guess like are they the MC replacements maybe…

“They performed really well. It’s just as fast as the 760 that I was using. Launch is a little higher actually, which was surprising, and it’s just sometimes I felt like when I hit my 5-iron in the blade and then the 4-iron in the 760 it was such a different feel. To go from a 5-iron now to that 4-iron, it feels a little closer to what I feel in the 5-iron. So just a little bit more responsive, but didn’t lose any performance from it, which is great. Yeah, it will be in the bag this week.”

————————————————————————-

Now just what do we have here?

On Wednesday at the 2024 Valero Texas Open, GolfWRX.com spotted Rory McIlroy testing a new, mysterious TaylorMade “PROTO” 4-iron.

Clearly, the 4-iron is a prototype, but since it doesn’t say “Rors Proto” or “RM” on it, then maybe it’s a prototype for an upcoming iron release from TaylorMade. Or, maybe it’s an upgrade for a previous or existing iron model from the company.

For reference, the photo below shows what McIlroy’s previous P760 4-iron looks like…

If the new prototype was an upgrade on the former P760 design, that would certainly be a large design departure, aesthetically speaking. It’s not impossible, but the new proto definitely looks significantly different.

McIlroy’s new proto – aesthetically, at least – looks more similar to TaylorMade’s P7MC irons, a model that Collin Morikawa uses for his 5 and 6-irons, as pictured below.

The new proto is also reminiscent of TaylorMade’s old P750 and P770 irons:

So what could McIlroy’s new TaylorMade “Proto” be? Is it a one-off prototype for McIlroy? Is it a re-design of an older model? Is it a harbinger of a bigger release in the future?

What is it?!

Unfortunately, TaylorMade hasn’t yet commented publicly on the prototype iron, so for now, we wait. And enjoy the photos of McIlroy testing it on Wednesday in San Antonio.

Here’s what it looks like from address…

And here’s what McIlroy’s numbers looked like while testing it on the range…

Uhh, yeah. Those are pretty good 4-iron numbers.

Will McIlroy make the switch into the new prototype 4-iron this week? That remains to be seen, but it should be noted that it was the only 4-iron in his bag on Wednesday.

*We’ll update this post as further information becomes available

See what GolfWRX members are saying about the TaylorMade “Proto” 4-iron here, plus more photos!

- LIKE18

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Raul Pereda WITB 2024 (April)

- Raul Pereda what’s in the bag accurate as of the Texas Children’s Houston Open. More photos from the event here.

Driver: Titleist TSR2 (10 degrees, B2 SureFit setting)

Shaft: Graphite Design Tour AD VF 5 X

3-wood: Titleist TSR3 (15 degrees, B1 SureFit setting)

Shaft: Graphite Design Tour AD IZ 7 X

7-wood: Ping G430 Max (21 degrees)

Shaft: Graphite Design Tour AD IZ 8 X

Irons: Titleist T150 (4), Titleist T100 (5-9)

Shafts: True Temper AMT Tour White X100

Wedges: Titleist Vokey Design SM10 (46-10F, 50-08F, 54-08M, 60-08M)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: Odyssey 2-Ball Ten Tour Lined

Grip: SuperStroke Zenergy

Grips: Golf Pride ZGrip Cord

Ball: Titleist Pro V1x+

Check out more in-hand photos of Raul Pereda’s clubs here.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Rickie Fowler WITB 2024 (April)

- Rickie Fowler what’s in the bag accurate as of the Valero Texas Open. More photos from the event here.

Driver: Cobra Darkspeed X (9 degrees @7)

Shaft: Project X Denali Black 70 TX

3-wood: Cobra Aerojet LS (14.5 degrees @13.5 degrees)

Shaft: Aldila Tour Green 75 TX

5-wood: Cobra LTDx LS (17.5 degrees @18.5)

Shaft: UST Mamiya LIN-Q White M40X 8F5

Irons: Cobra King Tour (4-PW)

Shafts: KBS Tour C-Taper 125 S+

Wedges: Cobra Snakebite (54, 56, 58 degrees)

Shafts: KBS Tour 610

Putter: Odyssey Versa Jailbird

Grip: SuperStroke Tour 3.0 17-inch

Grips: Golf Pride Tour Velvet Tack

Ball: TaylorMade TP5

Check out more in-hand photos of Rickie Fowler’s clubs here.

- LIKE5

- LEGIT1

- WOW1

- LOL1

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole1 week ago

19th Hole1 week agoJohn Daly stuns fans into silence with brutal opening tee shot on PGA Tour Champions

-

19th Hole2 days ago

19th Hole2 days agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

-

19th Hole2 weeks ago

19th Hole2 weeks ago2-time major champ announces shock retirement from the sport at age of 33

-

19th Hole1 week ago

19th Hole1 week agoCharlie Woods finds it tough going on American Junior Golf Association debut

-

19th Hole2 weeks ago

19th Hole2 weeks agoEdoardo Molinari reveals the latest PGA Tour golfer to turn down ‘good offer’ from LIV Golf

-

19th Hole2 weeks ago

19th Hole2 weeks agoScottie Scheffler had an interesting response when asked how he ‘quiets the noise’ following Players victory

-

19th Hole2 weeks ago

19th Hole2 weeks agoJon Rahm dealt fresh blow to hopes of qualifying for 2025 Ryder Cup

-

19th Hole1 day ago

19th Hole1 day agoAddiction, spinal fusion, and scam artists – Everything Anthony Kim revealed in candid interview with David Feherty

Golden

Jan 11, 2020 at 9:50 am

The slim lok spikes don’t fit the old tri-lok shoes whatsoever. They are loose and fall out over the round. Where can we still get tri-lok spikes?

SANG

Aug 21, 2017 at 8:18 pm

I have 3 sets of old tri-lock spikes. Are they suitable for those shoes with a new slim-lock system?

So, I want to make sure if shoes using this new slim-lock spikes can accept the old tri-lock spikes or not.

Richard

May 19, 2015 at 10:27 am

First pair of shoes I bought with TRI-LOK I was happy.

I had spikes that were easy to change. ANd a system that appeared to be statndarized across several shoe brands.

Of course there is NO PROFIT MARGIN MONEY in standardization, there is more money in customer lock-in via a continuous stream of new proprietary fastening systems.

In the role of customer aka sheeple:

I only bought shoe brands that used the TRI-LOK system; if you were not using TRI-LOK I was not interested. WHy would I want to shop for and stock multiple cleat types.

Some shoe vendors decided they no longer wanted to sell me product. They were free to choose this road.

Now the games have really started – design Obsolescence in full force.

Now we have PINS, If any one had bothered to ask us loyal users of Tri-LOk we would have recommended the F-PINS system instead. Three of the guys I play with loose cleats every round out of their FootJoy DNA’s. Others loose cleats out of their Addidads shoes with PINS Cleats. This makes me wonder if this is not a scheme to force us doen the road of cleatless shoes. When these wear out yo buy whole new shoes. Hmmh

I loved the Original Champ Scorpion Stinger Spikes, the newer variants of Scorpion Stingers all suck.

Strangely enough you can still buy new e.g. Nike Shoes with Scorpion Stingers in them but as soon as they wear put you are SOL. So champ will make them for Nike but no longer for US – must be part of their customer loyalty rewards program.

christian

Mar 18, 2015 at 4:00 am

Haven’t Adidas offered low profile spikes and thin soles for at least 5 years already?

Also Starring

Mar 18, 2015 at 6:23 am

True. My Adidas Samba are low profile. And, by the way, the original spikes were ok for half a year. The replacement ones are shit. I have to change them every other month. 15$ x 6 times a year = 90$

For this price, my next shoes will be spikeless. In the article they write about the “spikeless craze” that has become a 30% of the market. Probably here is the answer. it is not crazy or a trend, it is money.

Double Mocha Man

Mar 20, 2015 at 7:38 pm

So you are cheap and don’t want a good grip on wet surfaces. When can we get together for a money round of golf in a light rain?

Also

Mar 18, 2015 at 6:29 am

True. My Adidas Samba (3 yrs old) are low profile. And, by the way, the original spikes were ok for half a year. The replacement ones are not of the same quality. I have to change them every other month. 15$ x 6 times a year = 90$

For this price, my next shoes will be spikeless. In the article they write about the “spikeless craze” that has become a 30% of the market. Probably here is the answer. it is not crazy or a trend, it is money.

Double Mocha Man

Mar 20, 2015 at 7:42 pm

I wear Footjoys with Champ spikes, play 4 to 5 times a week and need to change spikes 2-3 times a year. I buy bulk spikes from eBay and average $13 a year.

Gorden

Mar 17, 2015 at 8:12 pm

SO great you make special spikes for the OEMs that go in thier shoes and you can never buy the same spike again… are spikes going to get like the grip market you buy a new set of OEM irons and a year later you cannot replace with the same grip (maybe Ping) your stuck going after one of the grip companies way over priced models…this is the customer service thing others are talking about..the OEMs are the customers all these manufatures are worried about the end users are just left to fend for themselfes…Golf grips at 10 to 14 bucks each give us a break

Albert

Mar 17, 2015 at 5:12 pm

Sorry Mark, that one was for Eej.

Albert

Mar 17, 2015 at 12:55 pm

It is clear that you are focused in your product and your profit. But it won’t last if you don’t focus on your customers.

We, the end users of spikes, are only concerned in one thing: make them LAST MORE. Durability my friend. We couldn’t care less for your Slim project.

Listen to your customers, please. Either you make them more durable or another company will do. And you will be out of business.

If no one does, then ecco-like soles will be the only one, and you will be out of business anyway.

Eej

Mar 17, 2015 at 2:57 pm

Idiot.

If they make them more durable, they will sell less, therefore the price will go up and nobody will buy them.

Mark

Mar 17, 2015 at 3:31 pm

Be careful when you speak on behalf of customers you don’t know. When you speak it is just your opinion.

I am not that concerned with how long they last. I care that they provide traction and they are easy to change.

Albert

Mar 17, 2015 at 4:53 pm

I also want traction and easy to change. Someone will like them in yellow. But I don’t see the correlation with durability. It is just a matter of using a different plastic composition with the same shape.

Albert

Mar 17, 2015 at 4:56 pm

No need to insult. Don’t get nervous. It’s only spikes, not the malaria vaccine.

“Therefore price will go up…” Therefore what? Therefore they will make less money. That’s all. A chinese company will arrive and will make them even cheaper. There is competition out there man.

Kodak insisted in film, and kodak is out of business.

Do you remember when a Cd price was 35$ and you really only wanted one song?

Eej

Mar 17, 2015 at 5:41 pm

“A chinese company will arrive and will make them even cheaper.”

You asked for durability and this is the statement you make. What an Eejit

Albert

Mar 17, 2015 at 7:54 pm

Champs are made in China.

WAE

Mar 20, 2015 at 9:20 pm

What an eejit

Albert

Mar 22, 2015 at 4:17 pm

Oh..how smart!