Equipment

Adams Speedline FAST12 Fairway Wood: Featured Review

By TCMP

Reviewed: Adams Speedline FAST 12 15º 3 wood, Pro Launch Blue Stiff Shaft

A little bit about myself and my game: I’ve been playing for about 9 years now with the first five years playing just 15-20 times per year. I didn’t take lessonsfor the first five years, just beat balls and asked my friends to help. For the last 4 years I have been working pretty hard on my game. I’ve taken lessonsfrom my local PGA professional, and played over 100 rounds per year. Four years ago, I was a 12-13 handicap. As I sit here today writing this review, my handicap index is 3. Just about all of last year I hovered around a 3-4 handicap. Fairway woods have always been hard for me to hit off the deck – so this is a great test. If I was to compare my swing to a tour pro, it would be most like Zach Johnson. I don’t have a lot of lag and I keep the shaft and my right arm in a straight line all the way above my head on the follow through (like he does). This makes for consistent ball striking, but not too much distance. I’m an average length driver of the ball with a swing speed in the 103-105mph range and a carry distance of around 240 yards or so. My 7 iron goes 160 (in the summer months).

Click here to see more pics and read discussion in the forums

First impressions:

Wow, this silver headed sleek-but-meaty club really looks nice. The silver crown with the black face really frames the ball nicely. The velocity slot on the crown serves as a nice alignment device for me. It doesn’t look bad in the least. The head shape is very traditional and looks to be dead square. Looking at the Pro Launch Blue shaft (in stiff) it has a rough texture and is supposed to be more aerodynamic. I have my doubts about this actually helping the golfer in some way.

Performance:

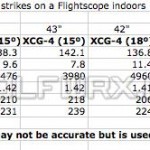

After grabbing a large bucket of balls, I hit the range (which is natural grass) to see how this thing performed. The wind was blowing right to left at a steady 10-15mph as I lined up my first shot. I fluffed up the ball on a good lie and let it rip. First shot, dead straight on a medium trajectory. Wow….now that surprised me. It usually takes me a while to warm up to 3 woods as they are pretty darn difficult to hit off the deck. Next shot, nice high fade. Hmmmm, this shaft feels a little whippy, maybe I’ll choke down on the next one to make it feel a little stiffer. Next shot, dead frozen rope straight and medium to high trajectory. Wow, ok, I can live with this. I have been playing Tour Edge Exotics XCG-4 Fairway woods since the start of last season. A 15º and 18º with Aldila NV-85 stiff shafts. They have been extraordinarily long and fun to hit.

After hitting this Fast 12, I can say that distances were a bit shorter than the titanium headed Exotics. About 7-8 yards for me. The launch was higher with the Fast 12 and it certainly stopped better coming into par 5’s with more spin and higher trajectory. The Exotics have a more boring flight with less spin, but the likely contributor is the shaft difference. The NV is a tip stiff heavy shaft. The Pro Launch blue is a tip soft 65g shaft. These two shafts couldn’t be more different.

Saturday and Sunday I had a golf outing with my old college buddies. We played two courses that were pretty challenging for us and have a little money on the matches. I took the exotics out of the bag and played the Fast 12 exclusively all weekend. On Saturday it became my go-to club as my driver was very sketchy to say the least. My playing partners definitely noticed the consistency and distance of the Fast 12. I consistently was last to play my second shot using this club.

Click here to see more pics and read discussion in the forums

Sound/Feel:

Feel is very subjective. I for one like the feel of the Fast 12. It has a different sound than I am used to. Kind of a hollowed out and slightly deeper and more powerful “ping” than the Old Big Bertha fairways of yester-year. The Pro Launch Blue shaft in this fairway has a soft tip and an overall soft profile. I think if I was to get the most out of this fairway, I would require an “X” flex Pro Launch, if it is available. Of course, it is most definitely softer than the NV-85 I play in the Exotics fairways. On several swings I felt like the shaft wasn’t keeping up and caused a high right shot.

The factory swingweight is spec’d at D2, which is about what I prefer in my woods. I love to tinker, so a while ago I bought a swingweight scale to setup all my clubs with the right weight for me. So, I threw this stick up on the swingweight scale and it read “D2”. Ok, perfect. Good job Adams!

Off the face, the ball really rockets. Toe, heel, it doesn’t matter. If you hit the face it will go – and go far! This thing is crazy forgiving. I hit it all over the face with great results. Even shots my playing partners thought I would lose to the right, held their line quite nicely and ended up on the fringe of the green. Surprised the heck out of me! This stick is more forgiving on off center strikes than the XCG-4’s I game. No doubt about it. Shots just stay on line better.

Overall:

I am definitely a fan of the new Fast 12 fairways. The weight, balance, feel and distance are all excellent. The silver crown is actually quite nice and frames the ball beautifully at address. The velocity slot looks cool and acts as a nicealignment device for me. The Pro Launch Blue shaft didn’t quite fit my swing, but it worked fine and I was able to shoot some great scores over the weekend with it. If I was to do it over, I would have gone with the X flex shaft.

Price/Value:

2 Thumbs up! The Exotics Fairways are $299 which is pretty steep, so it is refreshing to see this much performance for $199. Without a doubt, this is a contender with the Titanium big dogs!

Click here to see more pics and read discussion in the forums

I would give Adams 2 thumbs upon this new Fairway!

- LIKE7

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Why Rory McIlroy will likely use the new TaylorMade BRNR Mini Driver Copper at the RBC Heritage

Although we spotted Rory McIlroy testing the new TaylorMade BRNR Mini Driver Copper last week during practice rounds at the Masters, he ultimately didn’t decide to use the club in competition.

It seems that will change this week at the 2024 RBC Heritage, played at the short-and-tight Harbour Town Golf Links in Hilton Head.

When asked on Wednesday following his morning Pro-Am if he’d be using the new, nostalgic BRNR Copper this week, McIlroy said, “I think so.”

“I like it,” McIlroy told GolfWRX.com on Tuesday regarding the BRNR. “This would be a good week for it.”

View this post on Instagram

According to Adrian Rietveld, the Senior Manager of Tour at TaylorMade, the BRNR Mini Driver can help McIlroy position himself properly off the tee at the tight layout.

Here’s what Rietveld told GolfWRX.com on Wednesday:

“For someone like Rory, who’s that long at the top end of the bag, and then you put him on a course like Harbour Town, it’s tough off the tee. It’s tight into the greens, and you have to put yourself in position off the tee to have a shot into the green. It kind of reminds me of Valderrama in Spain, where you can be in the fairway and have no shot into the green.

“I’m caddying for Tommy [Fleetwood] this week, so I was walking the course last night and looking at a few things. There’s just such a small margin for error. You can be standing in the fairway at 300 yards and have a shot, but at 320 you don’t. So if you don’t hit a perfect shot, you could be stuck behind a tree. And then if you’re back at 280, it might be a really tough shot into the small greens.

“So for Rory [with the BRNR], it’s a nice course-specific golf club for him. He’s got both shots with it; he can move it right-to-left or left-to-right. And the main thing about this club has been the accuracy and the dispersion with it. I mean, it’s been amazing for Tommy.

“This was the first event Tommy used a BRNR last year, and I remember talking to him about it, and he said he couldn’t wait to play it at Augusta next year. And he just never took it out of the bag because he’s so comfortable with it, and hitting it off the deck.

“So you look at Rory, and you want to have the tools working to your advantage out here, and the driver could hand-cuff him a bit with all of the shots you’d have to manufacture.”

So, although McIlroy might not be making a permanent switch into the new TaylorMade BRNR Mini Driver Copper, he’s likely to switch into it this week.

His version is lofted at 13.5 degrees, and equipped with a Fujikura Ventus Black 7X shaft.

See more photos of Rory testing the BRNR Mini here

- LIKE19

- LEGIT1

- WOW0

- LOL1

- IDHT0

- FLOP0

- OB1

- SHANK3

Equipment

Spotted: TaylorMade P-UDI driving iron

It seems like the RBC Heritage is full of new gear to be spotted, and you can add TaylorMade’s P-UDI utility irons to that list.

We spotted a 17-degree P-UDI 2-iron in Nick Dunlap’s bag yesterday, and now have some photos of both the 3- and 4-irons. Nick has his P-UDI 2-iron setup with a Project X HZRDUS Black 4th Gen 105g TX shaft.

From what we can tell, this new P-UDI utility iron looks to have some of the usual TaylorMade technology as we can see the Speed Slot on the sole of the club for additional face flexibility. A toe screw is usually used to close off the hollow body design that will probably be filled with a version of TaylorMade’s Speed Foam that is present in the current iron lineup. This hollow body, foam-filled design should offer additional ball speed, soft feel, and sound, as well as an optimized CG for ball flight.

“Forged” is etched into the hosel, so we can assume that either the face, body, or both are forged for a soft and responsive feel. The club looks good from behind and at address, where we can see just a little offset and a topline that I would consider medium thickness. We don’t have the full details on what is under the hood or how many loft options will be available yet.

TaylorMade P-UDI 3-iron – 20°

TaylorMade P-UDI 4-iron – 22°

- Check out the rest of our photos from the 2024 RBC Heritage

- LIKE12

- LEGIT1

- WOW3

- LOL0

- IDHT0

- FLOP1

- OB0

- SHANK1

Whats in the Bag

Collin Morikawa WITB 2024 (April)

- Collin Morikawa what’s in the bag accurate as of the RBC Heritage. More photos from the event here.

Driver: TaylorMade Qi10 LS (9 degrees)

Shaft: Mitsubishi Diamana D+ Limited 60 TX (45 inches)

3-wood: TaylorMade Qi10 (13.5 degrees)

Shaft: Mitsubishi Diamana D+ Limited 80 TX

5-wood: TaylorMade Qi10 (18 degrees)

Shaft: Mitsubishi Diamana D+ Limited 80 TX

Irons: TaylorMade P770 (4), P7MC (5-6), P730 (7-PW)

Shafts: True Temper Dynamic Gold Tour Issue Mid 115 X100 (4-6), True Temper Dynamic Gold Tour Issue X100 (7-PW)

Wedges: TaylorMade MG4 (50-SB09, 56-LB08), TaylorMade MG4 TW (60-TW11)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: TaylorMade TP Soto

Grip: SuperStroke Zenergy Tour 2.0

Grips: Golf Pride Z-Grip Cord

Ball: TaylorMade TP5x

- LIKE4

- LEGIT0

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK1

-

19th Hole1 week ago

19th Hole1 week agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoThings got heated at the Houston Open between Tony Finau and Alejandro Tosti. Here’s why

-

19th Hole1 week ago

19th Hole1 week agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole2 weeks ago

19th Hole2 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole3 days ago

19th Hole3 days agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole3 days ago

19th Hole3 days agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole2 weeks ago

19th Hole2 weeks agoAddiction, spinal fusion, and scam artists – Everything Anthony Kim revealed in candid interview with David Feherty

-

19th Hole2 weeks ago

19th Hole2 weeks agoAnthony Kim says doctors told him that he ‘may not have much time left’ ahead of LIV return

Provisional

Apr 24, 2012 at 6:40 am

I read this review with much interest as I struggle with hitting my old TM 200 Steel 3 wood with any consistancy and was v. curious about the new Adams club. It was what I’d like to see with all club reviews. Everyone else should follow this approach to give meaningful reviews.

Pingback: Adams Speedline FAST12 Fairway Wood: Featured Review | Augusta Blog