Equipment

Review: Adams XTD Forged Irons

Pros: A forged blade-type iron with a little bit of a size advantage for extra forgiveness. Tungsten weighting offers excellent feel, and the presence of KBS C-Taper shafts and Iomic grips as standard options reinforces the XTD Forged’s status as a “player’s iron.”

Cons: All the highfalutin standard features do make a set pretty pricy ($1100 MSRP). Also, the irons are in a middle ground between “player’s blade” and “player’s cavity back,” which might be awkward to some.

Bottom Line: The XTD Forged irons hit the forged iron “sweet spot” splendidly, combining the workability and feel of blades with the enhanced forgiveness of cavity backs, thanks to the Cut-Thru Slot.

Overview

Adams Golf has long been regarded as principally a maker of good hybrids and fairway woods, from the original Tight Lies on down to 2014’s brand-new PRO hybrid, but they are coming up in the world in terms of drivers (more on that here) and, yes, irons.

Enter the XTD Forged irons, which blend the traditional size, shape and feel of blade and “player’s cavity back” irons with the more technology-forward trend that has emerged in the last couple years of golf equipment development. Adams took the basic head shape and thickness of a blade, enlarged it somewhat and added the two recognizable technological features: tungsten weighting and what Adams calls a “Cut-Thru Slot.”

The general idea of the Cut-Thru Slot is that that space just behind the clubface — be it for a driver, fairway wood, hybrid or iron — creates a “floating face,” which enlarges the sweet spot, even on a traditionally less-forgiving sort of club such as a forged iron. The feature also helps lower the center of gravity, which produces higher-launching shots that generally do not suffer from runaway spin numbers.

The aforementioned tungsten weights also sit on the sole of the XTD Forged irons and work together with the Cut-Thru Slot to optimize each iron’s center of gravity which, once again, helps produce desirable launch and ball speed.

Adams XTD 4 iron pictured above

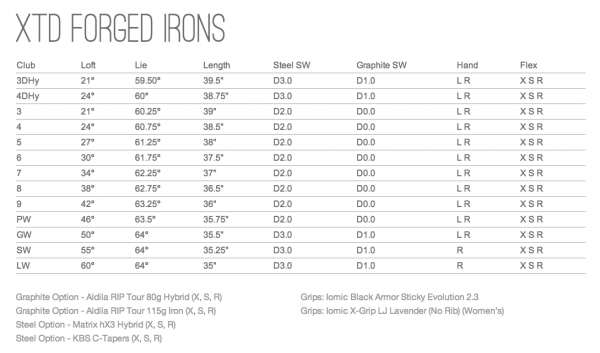

It should also be noted that the XTD Irons ($1099) come standard with the popular KBS C-Taper shafts and high-end Iomic grips. The irons are also available with Aldila’s RIP Tour 115-gram graphite shafts in R, S and X flexes for $1199.

For no upcharge, golfers can add Adams’ popular Dhy 3 or 4 hybrids, which can be substituted in the place of an XTD Forged 3 or 4 iron.

See the discussion and gallery of the full Adams XTD line in the forums.

Performance

There is palpable synergy among all facets of the XTD Forged irons. As a result, they constitute a set ideally suited to a player who may have reservations about playing “true blades” but still wants as much of the two best features of blades as possible: clear feel on different qualities of contact and wide shotmaking potential. High draws, low fades and all shots in between can be coaxed out of these irons by the skilled player.

Click the images above to enlarge

Shots produced by the irons pass the eye test handily: I noticed somewhat higher launch and good, stable ball flight when hitting shots with them both on the range and on the course. Even the long irons, when struck solidly, held firm greens. If I needed to hit a punch shot, the irons were equal to the task.

The good aesthetics of shots I hit with these irons was, happily, confirmed by the numbers they produced when I tested them on a launch monitor at Myrtle Beach’s PGA Tour Superstore location:

Ball speed / launch angle / spin rate / distance

8 iron: 111 mph / 19.4 deg / 7,055 rpm / 159 yds

5 iron: 126 mph / 12.2 deg / 4851 rpm / 200 yds

The Cut-Thru Slot and tungsten weighting in these irons were especially noticeable on shots with the longer irons. Slight misses on the heel and toe yielded little in the way of lost distance, as did shots where I made slightly thin contact.

Photo above is a raw XTD head showing the multi piece construction with floating face and tungsten inserts to lower the center of gravity.

See the discussion and gallery of the full Adams XTD line in the forums

Looks and Feel

Many club manufacturers stay very traditional when it comes to forged cavity back and blade irons. But seeing as Adams put a bit more technology into XTD Forged series, they are decidedly more modern looking. This is not to say they are gaudy or ugly, but they will certainly never be confused with your dad’s old Hogan Apexes or Wilson Button Backs.

For starters, the clubhead has a somewhat matte finish, where most players’ irons — blades and cavity backs — tend to have chrome or satin finishes. The C-Taper shafts echo the look of the heads: matte steel rather than chrome or satin, which is modern and stylish without being ostentatious.

The XTD Forged clubheads are a little larger than those of many other irons in its peer group, but not so much so that they look boxy. Their amount of offset is closer to that of forged cavity back irons than true blades. The topline is thicker than one would expect from a true blade, but again, certainly not more so than most forged cavity back irons.

The top lines of the XTD Forged irons strikes a balance between thin and thick.

Feel-wise, there are no negative surprises with the XTD Forged irons. If you hit a shot solid, you will know it and you will love it. If not, well, that’s forged irons for you. Good players would not have it any other way; feedback in irons is important, after all. These irons will not unduly muffle contact on any part of the face. If you love the sensation and slightly higher-pitched “click” of contact with forged irons, you will enjoy the XTD Forged.

The Takeaway

With the XTD Forged irons, Adams continues to establish itself as a major player in the irons category for lower handicappers. If you want to reap the agreed-upon benefits of forged irons — trim clubheads, easily discernible feel, shot workability — but are not ready to take the plunge into full-on blades, these irons deserve your serious consideration.

The XTD Forged irons come standard with one of the most popular steel shafts in golf, as well as high-end Iomic grips, which contribute to a higher price tag. However, the harmony of those big-ticket features produces a product that is worth a higher tariff for the ambitious golfer.

[wrx_buy_now oemlink=”http://adamsgolf.com/XTD-Forged-irons/DW-AL287.html” oemtext=”Learn more from Adams Golf” amazonlink=”http://www.amazon.com/gp/product/B00FXLF84E/ref=as_li_qf_sp_asin_il_tl?ie=UTF8&camp=1789&creative=9325&creativeASIN=B00FXLF84E&linkCode=as2&tag=golfwrxcom-20&linkId=XWOVYECUFUPPBDZA”]

See the discussion and gallery of the full Adams XTD line in the forums.

- LIKE145

- LEGIT30

- WOW20

- LOL10

- IDHT6

- FLOP5

- OB12

- SHANK8

Equipment

A shocking Backstryke putter appearance + 7 interesting gear photos from the Zurich Classic

Welcome to New Orleans, where TPC Louisiana plays host to the 2024 Zurich Classic. In between breakfast beignets and nightly Creole feasts, PGA Tour players are also competing in the unique two-man format at the Zurich this week.

Although the vibes in Nawlins are a bit lighter-fare than the recent back-to-back competitions the Masters and the RBC Heritage signature event), the gear news was no less serious this week.

We spotted some recent changes from Rory McIlroy, a very rare Odyssey Backstryke putter, dove into the bag of legendary New Orleans Saints quarterback Drew Brees, and spotted Patrick Cantlay continuing to test new equipment.

Get your beads out and crack your crawfish, because it’s time for an equipment rundown from The Big Easy (meaning New Orleans, of course, not Ernie Els).

See all of our photos from the Zurich Classic here

Rory’s on-and-off lob wedge

Since the end of 2023, Rory McIlroy has had an on-again, off-again relationship with a Titleist Vokey K-Grind lob wedge. In his last start, it was on, and the wedge is back in the bag again this week. We got a great look at the complicated grind that McIlroy uses.

View this post on Instagram

A full look into McIlroy’s bag above also shows that he switched out of the TaylorMade BRNR Mini Copper that he used at the RBC Heritage, and he’s back into the Qi10 core 3-wood. As we discussed last week, McIlroy will likely keep the BRNR around as a course-specific club, trading it in and out for the 3-wood.

See Rory McIlroy’s full 2024 WITB from the Zurich here

Turning Back the clock

Unless Tommy Gainey is in the field, it’s unlikely you’ll ever see Odyssey’s Backstryke technology make an appearance on the PGA Tour.

But then, when you least expect it, Russ Cochran shows up.

For more than a decade – since the 2013 Sony Open in Hawai’i – Cochran has been stuck on 599 PGA Tour starts. This week will be his 600th.

Cochran is in the field at the Zurich this week playing alongside Eric Cole, whose regular caddie is Reed Cochran, Russ’s son.

The Backstryke putter was first released back in 2010, and its unique design helps shift the axis point of the putter closer to the CG of the head. And, the putter is getting a nod this week at the Zurich Classic, thanks to Cochran’s 600th career PGA Tour start.

The putter is certainly awesome, but don’t forget to check out Cochran’s full WITB from this week.

Drew Brees with a Super Bowl winning Scotty Cameron putter

Drew Brees, a legendary retired quarterback for the hometown New Orleans Saints, made an appearance at the Zurich’s Wednesday Pro-Am, playing alongside Zach Johnson, Ryan Palmer, and current Saints QB Derek Carr.

Brees’ bag included a TaylorMade Stealth2 Plus driver, a BRNR Mini 13.5-degree, a Stealth 5-wood, a mixed set of P-790 and P-760 irons, Milled Grind Hi-Toe wedges, and a custom Scotty Cameron “New Orleans Saints” putter, which Scotty made for Brees following his Super Bowl MVP-winning performance in 2010.

View this post on Instagram

It should also be noted that Brees has his Venmo QR code as a bag tag.

If you’re gambling with Brees on the course, just know that not having cash won’t work as an excuse.

Brilliant.

See Drew Brees’ full WITB from the Zurich here

Stricker’s unrecognizable putter

Steve Stricker has made numerous upgrades to his bag recently, including a new TSR3 driver and T100 irons, but his longtime Odyssey White Hot No. 2 putter is still going strong. It’s the most recognizable unrecognizable putter ever.

Here’s a better look at Stricker’s flatstick, which he started using back in 2007.

View this post on Instagram

Patrick Cantlay has opened the equipment-switching floodgates

Over on the PGA Tour’s Equipment Report this week, we covered Cantlay’s recent switch into Ping Blueprint S irons, and a Titleist TSR2 driver.

Cantlay hadn’t switched irons for about seven years, so the iron switch he made at The 2024 Masters came as a shock to the norm. He simply isn’t one to change gear very often, so anytime Cantlay makes a switch, it’s news.

It seems the floodgates of equipment testing have opened up a bit for Cantlay, who was also spotted testing a custom Scotty Cameron blade putter on Tuesday this week. By Wednesday, Cantlay was back practicing with his familiar Scotty Cameron T5 Proto mallet, but it’s certainly something to keep an eye on going forward.

Daniel Berger’s custom Jailbird site lines

Berger, who’s currently using Odyssey’s Ai-One Mini Jailbird mallet putter, has a unique 3-dot, 2-line alignment on the crown of his navy-white-navy-white mallet putter. Looking down at the putter, it’s easy to see why this alignment system would help; it just seems impossible to set up to the ball off-center, or misaligned to the target.

Also, for anyone worried, you can rest easy. Yes, he’s still playing the 2013 TaylorMade TP MC irons, which we highlighted in our recent “Modern Classics: Old vs. New” video testing series.

FitzMagic teams back up

Brothers Matthew and Alex Fitzpatrick are teaming up once again at the Zurich this year, and Bettinardi Golf hooked them up with some festive “FitzMagic” headcovers to match this week.

See what else is in Alex Fitzpatrick’s WITB here

And, with that, we say goodbye to the Zurich Classic in New Orleans. Don’t forget to check out all of our photos from this week, including 30 unique photo galleries full of equipment photos.

We’ll see you next week in Texas for the 2024 CJ Cup Byron Nelson!

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Alejandro Tosti WITB 2024 (April)

- Alejandro Tosti what’s in the bag accurate as of the Zurich Classic.

Driver: Srixon ZX5 Mk II LS (9.5 degrees @10.5)

Shaft: Project X HZRDUS T1100 75 6.5

3-wood: TaylorMade Qi10 Tour

Shaft: Project X HZRDUS Black 80 TX

Hybrid: TaylorMade Qi10 Tour Rescue (22 degrees)

Shaft: Project X HZRDUS Smoke Black RDX 6.5 100

Irons: Srixon ZX7 Mk II (4-PW)

Shafts: True Temper Dynamic Gold Mid Tour Issue X100

Wedges: Cleveland RTX6 ZipCore Tour Rack (50-10 MID, 54-10 MID, 58-10 MID, 60-06 LOW)

Shafts: True Temper Dynamic Gold Mid Tour Issue X100, S400

Putter: Scotty Cameron

Grips: Golf Pride MCC Plus4

Check out more in-hand photos of Alejandro Tosti’s WITB in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Drew Brees WITB 2024 (April)

View this post on Instagram

Driver: TaylorMade Stealth 2 Plus (10.5 degrees)

Mini driver: TaylorMade BRNR Mini Copper (13.5 degrees)

5-wood: TaylorMade Stealth Plus (19 degrees)

Irons: TaylorMade P790 (4-8, PW), TaylorMade P760 (9)

Wedges: TaylorMade MG Hi-Toe (52-09, 56-10, 60)

Putter: Scotty Cameron Select Newport 2 Prototype

Check out more in-hand photos of Drew Brees’ clubs here.

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole3 days ago

19th Hole3 days agoJustin Thomas on the equipment choice of Scottie Scheffler that he thinks is ‘weird’

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole3 days ago

19th Hole3 days ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole2 weeks ago

19th Hole2 weeks agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole1 week ago

19th Hole1 week agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole1 week ago

19th Hole1 week agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why

Nathan

Oct 16, 2015 at 3:44 pm

Well my 8 iron is 155m that is 170 yards for all you lady swingers.

Pingback: Adams Golf Xtd Forged Iron Set - Seguin Valley Golf Club

paul

Nov 15, 2014 at 1:20 pm

Had thse for about 2 weeks, all i can say is awesome. They are sneaky long and have pushed my PW from 125 to 136 ! In fact Ive struggled clubbing due to the extra distance …Wow… Pricey I know but with Tour C-Taper shafts as standard you cant go wrong. Adams are onto a winner here but they are hard to get in he UK, if they had more PR the better players would love these> Ive had them all, Ping, TM, Titleist and Vega but these are the best….Highly recommended

John

Nov 13, 2014 at 3:35 pm

I have been gaming these for approx.4 months and must saw that they really do live up to my expectations. They are a little forgiving but let you know when you get it wrong. That said they are accurate and consistent shot after shot and pretty easy to shape into pins. I can hit high and low, left and right with little difficulty. I do not understand why TM have BURIED this other than to focus on their own models – that must be it. Cant help but think that the new RSi’s have more in common with Adams than TM

Travis

Sep 28, 2014 at 9:03 pm

I bought a set and changed out the shafts with a higher trajectory XP95. I took these to Dicks today and had a go on the simulator. The farthest I could get the 5i straight was 220, 6i 193, 7i 189. I turned around and said to the employee, really how much do you plus up the numbers so you sell clubs? I’ve never hit irons this long. I’ll hit the course later this week. I can say this…the actual iron head is heavy. I mean heavier than any other forged iron I have. I got a decent deal on ebay for 700 bucks or so.

brian

Sep 30, 2014 at 2:39 pm

I’ve been eyeing these for quite some time. Get back to us with the results once you have a chance to take them to the course. it would be much appreciated.

Jase

Aug 19, 2014 at 3:33 am

TM messed up a good thing. Adams peaked with the CMBs, now they are in a oversize, offset, wasteland of players clubs. No one that buys in this market is looking for a clunker with more offset. Thanks industry for fixing something that wasn’t broke.

ryan

Apr 10, 2014 at 7:57 pm

I tested these last week. I really liked the feel. 6i avg. 164 carry w/4692 spin rate. 114 ball speed at 15.7 launch angle. Also tested Mizuno JPX 825 pro, Taylor TP, Ping I25, Ping Anser, and XTD CC. These were the most consistent for me. 10-12 handicap.

Kev

Mar 26, 2014 at 3:32 am

really 8 iron 159yds ! I’d be on tour if I hit irons that far

paul

Mar 31, 2014 at 2:10 am

160 for an 8 iron is not unusual. I have only a 100mph driver swing speed and My distance is 145-150 (not a strong loft on my 8i either). If someone swings at 110 they will be around 160 with an 8.

milo

Jun 22, 2014 at 5:47 am

If someone swings at 110 with an 8 iron then i would expect nearer to 200 yards! 110 would be the ball speed not swing speed.

Logical

May 20, 2016 at 9:22 pm

He’s obviously talking about the driver swing speed

Brian Delorme

Jul 18, 2014 at 7:25 pm

I’m around 96-98 MPH with an 8 iron. Hitting my 8 160 on a smooth swing. And to rip it 165 (but may suffer the hook on a full tilt rip) it’s all compression. I notice yardage difference even from ProV1 to ProV1X……

Brandon

Apr 1, 2014 at 1:34 am

My standard 8 iron at sea level is 163yds with misunderstood mp 57. Tour players don’t hit it that long.

MT

Mar 22, 2014 at 10:11 pm

The obsession by TM to add a slot to everything ruined the feel of these heads.

Martin

Mar 24, 2014 at 9:48 am

I absolutely agree. I hate the feel of the Taylormade irons with the slots in the heads. They go farther, but the feel is horrible. I was afraid this would happen.

Dave

Mar 24, 2014 at 1:52 pm

Glad I bought CMBs when I could.

Kev

Mar 26, 2014 at 3:31 am

Yep me too waited 2 years and got a brand new set at silly money, makes you woneder how they start off such a high price tag

Dan

May 3, 2014 at 3:51 pm

It was actually Adams technology from the getgo…Taylormade bought the company prior to a lawsuit over this slot technology. They said with their purchase that adams had to wait a year to put these irons out while Taylor put out the RBZ irons.

Tom Duckworth

Mar 22, 2014 at 9:40 pm

I wonder if these launch much like the Speedblades? Kind of reminds me of a CMB with a cut-thu slot. I hope TM lets Adams keep on being themselves.

The dude

Mar 22, 2014 at 7:35 am

Are those distances off TM on carry?…..with your driver CHS…hitting an 8 iron 159 seems high

Chris

Apr 23, 2014 at 5:45 pm

I hit my 7 iron 150, and I’m 56 yrs old and a 25 handicap, so I don’t agree with all the doubters regarding the distance of that 8 iron.

LorenRobertsFan

Mar 21, 2014 at 12:37 pm

Another 4.5? Guess everything is good!

Wish they weren’t so expensive, even through PUD. Seen slightly used sets on the BST for <$600

Evan

Mar 21, 2014 at 12:03 pm

I really wanted to love these considering the stock shafts/grips and the club is beautiful. Of the 2014 players offerings I hit these the shortest and the least consistent. I think the shaft is too much for me to handle, would love to try with the graphite offering but they did not have that option to test neat me.

paul

Mar 21, 2014 at 2:48 pm

I swing driver between 100-105 mph, and I found the regular flex ctaper was a better fit then stiff. I play titleist 710 CBs, and these felt better and went a few more yards I found. Loved em. I would sell my irons right now and buy these but I just bought aerotech shafts and my equipment budget is done for the year.