Equipment

Why Bruce Sizemore chose SuperStroke

Bruce Sizemore had the same dream as a lot of talented, young golfers as a child. He wanted to play on the PGA Tour. It wasn’t the strangest dream a boy could have, but odd for a boy from Farmington Hills, Mich., a suburb of Detroit that is much more Hockey Town than it is Harbour Town.

Maybe it was the hum of the nearby Motor City machine shops, or that his brother-in-law had a Masters in fine arts and metalworking and exposed him to many of his sculptor and blacksmith friends; or maybe it was a back injury Sizemore suffered in a car crash during his freshman year in the Professional Golf Management program at Ferris St. University that caused his mini-tour practice sessions to become almost unbearable. But somewhere between playing the Florida mini tours and building clubs at a country club to pay his bills, Sizemore decided to start making putters.

Sizemore had a knack for designing golf clubs from a young age. Before he bought his first set of clubs, he customized his own set, shaping clubs he found at a local course’s lost-and-found bucket with his grandfather’s tools from the garage. The bench grinder made the chrome-finished clubs look ugly, so he bought a can of silver spray paint to touch them up. He quickly discovered that the spray paint only lasted one round, but his passion for golf equipment endured.

In 1995, Sizemore was seven years into his professional golf career. He was making a better living in money games than he was mini-tour events, and was struggling to see how his childhood dream of becoming a PGA Tour player could become a reality.

“I always wanted to be the very best at something,” Sizemore said. “And after a few years on the mini tours, I was pretty sure I was never going to be the best at playing golf. I started looking into putter design and golf club design, and experimented with different manufacturing techniques. I thought maybe I could be the best at that.”

Less than a year later, Sizemore and partner Anthony Franco, a titan of Detroit-area public relations, founded Copper Stix, a company that aimed to produce the world’s finest putters. But like most start-ups, things didn’t go smoothly at first. The machine shop the company hired to mill the putters was a small operation. He didn’t know it at the time of his first production line, but the shop was unable to recreate the quality of his initial designs.

“It was nobody’s fault,” Sizemore said. “I was naïve enough not to know what a good quality machine shop was. [The machine shop] didn’t have the capacity to produce what I wanted.”

Sizemore faced a dilemma that threatened to destroy his newly formed company. He always admired Ben Hogan, for his work ethic, attention to detail and the injuries they shared from a car crash. There’s a story that Ben Hogan threw out his entire first production of Ben Hogan irons because one of the irons in the set didn’t have the look Hogan desired. Sizemore did the same thing with his first Copper Stix production run, essentially throwing $25,000 worth of putters in the dumpster. Sizemore switched machine shops and a year later got he putters he envisioned.

The biggest moment for a putter maker is when his or her designs find the hands of one of the best players in the world. It was fitting that Copper Stix’s breakthrough came when one of Sizemore’s putters, a CU-Rail, landed in the hands of a Canadian professional, Mike Weir, who grew up a little more than an hour north of Farmington Hills, in Sarnia, Ontario, Canada.

In 2000, Weir’s caddy Brennan Little approached Sizemore on the putting green at Firestone Country Club in Akron, Ohio, during a tournament that is now the World Golf Championships-Bridgestone Invitational. Little was impressed with the alignment features on the CU-Rail, and said that the putter could help Weir, who often struggled with the alignment of his putter face at address.

“[Little] took him a right-handed model, and he made 10 putts in a row with it right handed,” Sizemore said. “[Weir] is pretty good from the right side. Then [Weir] asked where the left-handed model was … I said I didn’t have one. That was the end of it.”

Sizemore went back to his shop in Florida, and wondered what he could do to produce Weir a lefty model. The CU-Rail was a symmetrical putter, so he drilled a hole in the right side of the putter. He plugged the hole on the left side, and bead blasted it to cover his tracks. Then he put a lefty shaft in it and worked to get the offset the way Weir wanted.

At the Canadian Open, Sizemore put the crude creation in Weir’s locker. Two months later, Weir used the putter to win the 2000 WGC-American Express Championship at Valderrama Golf Club in Sotogrande, San Roque, Spain. He birdied five of his first 11 holes on Sunday, stealing the tournament from Lee Westwood, who finished second, and Vijay Singh, Sergio Garcia, Padraig Harrington, Nick Price and Tiger Woods, who all finished in the top five.

In 2003, Sizemore came to a crossroad in his career. He’d enjoyed success with Copper Stix in the Asian Market – Korea, China and Japan, but the death of Franco caused him to reconsider his company’s future. He was working on a line of multi-material, multi-piece putters with interchangeable parts – many of the designs looked much different than the putters he was producing for Copper Stix. He decided that it was better to rebrand these putters under a new name, “Sizemore Collection,” and brought on new business partners for Sizemore Golf, a company he established in late 2004.

“The putters I developed for the Sizemore Collection were the first totally interchangeable putters,” Sizemore said. “You could slide out the alignment insert and change out the weights, based on your preferences. But it was too much for a lot of people. I had to show it to them … demonstrate how it worked for them to fully understand.”

The reason Sizemore said he had so much success in Asian markets is because of the nature of its golfers. According to Sizemore, golfers in the Asian market are much more interested in the manufacturing processes and materials used in their golf clubs, and willing to pay a premium for a superior product.

“You could not put a $100 putter in their hands and expect to sell it for $300,” Sizemore said.

The Asian market appeared to be tailor-made for Sizemore’s creations, putters that never sacrificed quality for a lower price point. For this reason, Sizemore was disappointed when his partners began manufacturing his designs at lower price points, a decision that he said he was not discussed with him. Amid conflict, he decided to resign from the company that carried his name in 2009, citing disagreements with his business partners about the direction of the company.

But like a bad round doesn’t derail a golf career, Sizemore didn’t let a bad business partnership impede his passion for club making. He returned to his home in Florida, and got to work on new putter designs, which he was prepared to sell putters on a limited basis to his biggest market, Japan. But a call from former high school classmate Darin Dingman, Vice President of Tiger Shark Golf, a Michigan-based golf equipment company, led him on a different path. Darin invited him to Tiger Shark’s headquarters in Warren, Mich., in 2010, located about a half hour from his childhood home, and showed him what the company was working on. Tiger Shark acquired SuperStroke, a company that made oversized non-tapered putter grips, in 2009. Darin and younger brother Dean Dingman, President of Tiger Shark, thought Sizemore could help them develop SuperStroke into a niche short game brand.

At first, Sizemore was not interested in partnering with the Dingmans. But when he went home to Florida with a few of the company’s revamped SuperStroke putter grips, he became impressed with the company’s product.

When Tiger Shark purchased SuperStroke, the SuperStroke grip was offered in one size and one weight. Tour pros such as K.J. Choi liked the grip’s ability to smooth out their putting stroke and lighten grip pressure, but proper installation was tricky. The grip had a metal under lifting that made it very heavy, nearly 225 grams. To install one, a player had to fasten set screws to the putter shaft, which could damage a shaft and took time to fit squarely on a putter. After Tiger Shark acquired SuperStroke, the company completely changed the grip’s under lifting, constructing it out of a 4M material that made the grips substantially lighter and improved sound and feel. Installation of these grips was much more traditional as well, requiring only standard two-sided tape and grip solvent. The company also began offering the SuperStroke grips in different sizes and colors, which grew the amount of players that would be willing to try them.

Sizemore was given the SuperStroke Slim Lite grip, which is 18 percent smaller than the original SuperStroke and weighs only 55 grams. He put the Slim Lite grip on his backup putter, and used it for testing. He was skeptical of the grip during testing until he grabbed his gamer, whose grip now felt awkward in his hands.

“My first question was, why does it feel awkward,” Sizemore said. “I was feeling more forearm rotation, tension in my left arm and my fast twitch muscles were more involved. Now I don’t even like conventional grips. It would be hard for me to go back to them.”

Sizemore got back in touch with the Dingmans, and the three began discussions of how they could work together. They kicked around the idea of Sizemore building a putter around the SuperStroke grip, but it was eventually trashed. Sizemore had never built theme putters in the past, and didn’t want to start. In 2010, they decided that Sizemore would join the company for a long-term deal, and work to finalize the designs he was considering selling in Japan. The putters would carry his and the SuperStroke name, and be available with or without the SuperStroke grip, depending on customer preference.

The putters, which are now SuperStroke’s DCF-1, DCF-2, DCF-3 and DCF-4, are available in different lofts, lengths, lies and finishes. The DCF-2 and DCF-4 models have interchangeable necks that are available in both aluminum and stainless steel, which changes the weighting of the putter. The DCF-2 and DCF-3 models have interchangeable flanges and flange inserts, which can be constructed from different materials as well, and are available in different colors and styles to match the visual preferences of a player.

Click here for pictures of the DCF putters, and to see pictures of the SuperStroke Studio.

For DCF line of putters, Sizemore wanted each putter head to have its own individual look. It wasn’t an easy task for Sizemore, but one he undertook with a great amount of care.

“When I’m designing putters, I purposely don’t look at other company’s designs,” Sizemore said. “I don’t want any external influence. I don’t even show my designs to other people until they’re finished, because I don’t want them to say anything that might effect me.”

Many times, Sizemore has been worried that he could spent months perfecting a design, only to find out that he created a putter that looked like what another company had already released. But luckily that has never happened. It’s the only way Sizemore has found to keep his designs fresh, and different looking from the original PING Anser-style putter developed in 1966 by Karsten Solheim that still dominates putter design in the industry.

Another staple of Sizemore’s design process is that he creates each shape by hand from jeweler’s wax. Some companies have moved away from the traditional process of handcrafting, but Sizemore believes it’s best way to make putter. He likens his process to the way that many automobile engineers continue to hand-form cars in the early stages of design from enormous hunks of clay, despite the variety of computer programs available that are designed to do the same thing.

“Kids I teach now are totally reliant on CAD programs and machining,” Sizemore said. “In my opinion, there’s no other way [other than hand-forming] to design a putter. After you finish designing it by hand, then you go and reverse engineer it.”

But hand-formed designs have their drawbacks as well, such as the inability for standard tooling to recreate some designs for production. Often, computer programs will call some of the shapes Sizemore produces impossible to reverse engineer, which means he has to create customized tooling for the process.

“The question always is, can this club be mass produced?” Sizemore said. “Often, the answer is no, but after a few months you figure it out.”

One of the most specialized aspects of the SuperStroke line of putters is the putter face surface, from which the DCF-27 line of putters derives its name. In the period between Sizemore’s departure from the Sizemore Collection and his decision to join SuperStroke, he developed a new milled face surface that made the energy transfer from putter to ball more efficient than his previous designs.

Sizemore said that he stumbled on the idea by accident, when his Bridgeport milling machine broke down. He was forced to hand mill the face, which created a surface that was much more vertical in nature than the IND-X finish he developed for the Sizemore Collection putters.

Golf Digest’s 2008 club test identified Sizemore Golf’s XM-2 putter as the best rolling mid-sized mallet putter in their test, rolling out the farthest of any putter on center strikes. According to Sizemore, the DCF-27’s diamond-shaped milling pattern is an improvement from the IND-X pattern, because it “grips, lifts and rolls” the ball better than any putter he’s ever produced. The putter faces are milled in 27 different directions two times by a specialized tool that requires such precision that it can only be used 10 times during the manufacturing process before is has to be changed. It doesn’t matter if a player makes an ascending, descending or horizontal blow with a DCF 27 putter – the ball always contacts the high-friction vertical pattern the same way, regardless of where contact is made on the face.

But the most interesting part of SuperStroke’s new line of putters, which officially launched at the 2012 PGA Merchandise Show, is that they are manufactured in Michigan, giving Sizemore an unbelievable amount of control over the finished product. The putters are milled in a factory just a few miles from the company’s new headquarters, located in Wixom, Mich., mere minutes from where the Dingmans and Sizemore grew up.

All customization is done in house as well, which is one of the most important parts of the putter building process to Sizemore. It is true that a putter design has to get the ball rolling on the correct line with the correct speed, but according to Sizemore, putter aesthetics are just as vital as performance. His background as a professional golfer, as well as a PGA Teaching Professional and as a putter maker has made it clear to him that putting is just as much about confidence as anything else.

“The putter is the most personalized club in the bag,” Sizemore said. “You have 12 putters in your garage that are different, but I think a you are going to putt best with one that is customized specifically for you. If you’re proud of your putter, whether it is because your name is on it, or it is your favorite colors or whatever … you’re going to exude more confidence and putt better.”

With SuperStroke, Sizemore has taken personalization exceptionally far. Take the shaft band on a putter, for example. Sizemore tested more than 20 renditions of a metal shaft medallion for the new line of putters, which are offered in gold and silver, as well as a custom lettering option. Of course, with customization comes a higher cost as well. A DCF-27 starts at $349, but can cost as much as $464 with all of the available upgrades ($25 for a headcover upgrade, $25 for a silver medallion, $50 for a gold medallion, $40 for a leather grip).

Sizemore admits that a $350 putter doesn’t sell itself, that there has to be an educational aspect behind the sales of his putters. But the marketing and selling aspect of his putters is something he stays away from with SuperStroke. Dean Dingman said that one of the reasons his company chose Sizemore was because of his proven record of creating exceptionally high quality putters.

“[Sizemore] had proven he could design great putters,” Dean said. “My brother and I had proven we could sell golf clubs. It was a natural partnership.”

Sizemore has enjoyed “staying in his own lane,” as he called it, focusing on putter designs such as the company’s Fatso and Slim mallet putters, which are made from high tensile strength 7075 aluminum and offer interchangeable head weights and a variety of sight line options. With SuperStroke, the design part has gotten easier, as he’s free to take time off, turn his stereo on full blast, and work on putter designs as much as 20 hours a day when he wants.

Right now, sales of SuperStroke putters are focused mainly in Asia, which accounts for 80 percent of putters sold, but the Dingmans and Sizemore are confident that number will start to grow in the U.S. In the first Champions Tour event this year, there were four SuperStroke putters in play. In the second Champions Tour event, six of the company’s putters were in play.

Bernhard Lander was one of the Champions Tour players that requested a SuperStroke putter after working with a SuperStroke rep at one of the first Champions Tour events. Langer liked the DCF-3 model, and put in an order for 48-inch long putter with three degrees of loft, a 78.5 degree lie angle, a SuperStroke split grip, a slightly more tip stiff shaft and a head weight of 432 grams.

One of the ways the rep caught Langer’s attention was by telling him, “Bernhard, these putters are handmade in Detroit, Mich.”

Bernhard said, “Really, Detroit? That’s cool. Something that’s not made in China.”

- LIKE2

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

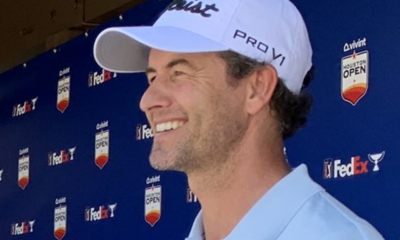

Taylor Montgomery WITB 2024 (March)

- Taylor Montgomery what’s in the bag accurate as of the Cognizant Classic. Check out more photos from the event here.

Driver: TaylorMade Qi10 (9 degrees)

Shaft: Graphite Design Tour AD VF 7 TX

3-wood: TaylorMade Qi10 Tour (15 degrees)

Shaft: Graphite Design Tour AD VF 8 TX

Hybrid: TaylorMade Qi10 Tour (19.5 degrees)

Shaft: Mitsubishi MMT HY 100 TX

Irons: TaylorMade P7TW (4-PW)

Shafts: True Temper Dynamic Gold Tour Issue X100

Wedges: TaylorMade MG4 (52-09SB, 56-12SB), Vokey Design WedgeWorks Proto (60-T)

Shafts: True Temper Dynamic Gold Tour Issue X100

Putter: TaylorMade Spider Ghost S

Grip: Elite

Grips: Golf Pride MCC

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

WITB Time Machine: Paul Casey’s winning WITB, 2019 Valspar Championship

At the 2019 Valspar Championship, Englishman Paul Casey took the trophy at the Copperhead Course for the second year in a row. On a difficult Sunday, Casey’s 1-over 72 was good enough for a one-stroke victory over Louis Oosthuizen and Jason Kokrak as Dustin Johnson faltered.

Check out Casey’s clubs from five years ago below.

Driver: TaylorMade M4 (10.5 degrees)

Shaft: Mitsubishi Diamana D+ Limited 70 TX (tipped 1 inch)

3-wood: TaylorMade M1 (15 degrees)

Shaft: Mitsubishi Diamana D+ 80 TX Limited (tipped 1.75 inches)

Irons: Mizuno MP-25 (3), Mizuno JPX 919 Hot Metal Pro (4), Mizuno MP-5 (5-PW)

Shafts: Nippon N.S. Pro Modus3 Tour 120 TX

Wedges: Titleist Vokey Design SM7 (52-08F, 56-10S), Vokey Proto (60)

Shaft: Nippon N.S. Pro Modus3 Tour 120 X

Putter: Scotty Cameron Circle T 350-SSS

Grip: Scotty Cameron Matador

Grips: Golf Pride ZGrip Cord Midsize

Golf Ball: Titleist Pro V1

Mizuno’s Senior Club Engineer, Chris Voshall told us Casey’s somewhat surprising setup in his long irons is simply the product of Casey hitting the windows he wants to with the particular clubs in question.

“It’s all based on the height of the ball flight,” Voshall said. The MP-25 3-iron was more penetrating and better for him off the tee, so he kept it in there.”

- LIKE2

- LEGIT1

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

Coolest thing for sale in the GolfWRX Classifieds (3/22/24): Nike Vapor Pro Combo 4-A iron heads

At GolfWRX, we are a community of like-minded individuals that all experience and express our enjoyment of the game in many ways.

It’s that sense of community that drives day-to-day interactions in the forums on topics that range from best driver to what marker you use to mark your ball. It even allows us to share another thing we all love – buying and selling equipment.

Currently, in our GolfWRX buy/sell/trade (BST) forum, there is a listing for a set of Nike Vapor Pro Combo 4-A iron heads.

From the seller: (@DrCoFo): “Nike Vapor Pro Combo 4-A heads in really nice shape. Just bought these recently- thought I would be the cool kid on the block with the Nikes. Was going to do a custom look, but I was way too ambitious and would rather just have a new set of irons. So here we are. Heads are already pulled from the shafts. Ready for your project needs. $550 shipped.”

To check out the full listing in our BST forum, head through the link: Nike Vapor Pro Combo 4-A iron heads

This is the most impressive current listing from the GolfWRX BST, and if you are curious about the rules to participate in the BST Forum you can check them out here: GolfWRX BST Rules

- LIKE3

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

Whats in the Bag3 weeks ago

Whats in the Bag3 weeks agoScottie Scheffler WITB 2024 (March)

-

Tour Photo Galleries3 weeks ago

Tour Photo Galleries3 weeks agoPhotos from the 2024 Arnold Palmer Invitational

-

19th Hole3 weeks ago

19th Hole3 weeks agoJoaquin Niemann names 3 PGA Tour events he’d love to play each year ‘in a perfect world’

-

19th Hole3 weeks ago

19th Hole3 weeks ago‘Seems suspect’ – PGA Tour pro hits out at decision to hand Adam Scott and Webb Simpson Bay Hill sponsor exemptions

-

Equipment3 weeks ago

Equipment3 weeks agoSpotted: Bettinardi irons at the Arnold Palmer Invitational

-

19th Hole2 weeks ago

19th Hole2 weeks agoPaulina Gretzky opens up on receiving death threats following DJ’s move to LIV Golf

-

19th Hole3 weeks ago

19th Hole3 weeks agoVincenzi’s 2024 Arnold Palmer Invitational betting preview: Big names ready to pounce at Bay Hill

-

19th Hole3 weeks ago

19th Hole3 weeks agoVincenzi’s LIV Golf Hong Kong betting preview: Trio of major champs primed for big week

makaveli

Mar 9, 2012 at 7:43 pm

Detroit! thats whats up, good stuff Zak.