Equipment

Cleveland Fitting Studio

.jpg) Located in Huntington Beach, California, the Cleveland Fitting Studio has state-of-the art equipment and advice on getting the right sticks for your game. I had the pleasure of spending an afternoon with Justin Barnett, Technical Representative; John Rae, Performance Research Manager; and Nate Radcliffe, Metalwoods Development Manager. It was truly the pro experience. Guess what? You don’t have to be a tour pro or even a writer for Golf WRX to get this treatment. The Cleveland Fitting Studio experience is of no charge. That’s right, free to all golfers. Of course, you need to call and reserve a time, but it is still free. How is that for a bargain?

Located in Huntington Beach, California, the Cleveland Fitting Studio has state-of-the art equipment and advice on getting the right sticks for your game. I had the pleasure of spending an afternoon with Justin Barnett, Technical Representative; John Rae, Performance Research Manager; and Nate Radcliffe, Metalwoods Development Manager. It was truly the pro experience. Guess what? You don’t have to be a tour pro or even a writer for Golf WRX to get this treatment. The Cleveland Fitting Studio experience is of no charge. That’s right, free to all golfers. Of course, you need to call and reserve a time, but it is still free. How is that for a bargain?

One of the best parts of the visit was their putting analysis equipment. They take your putter, set up the specs, hook you up to the machine, and you get some very useful information. Firstly, you see what the face of the putter is doing at address. Justin Barnett explains that this is not as important as where the face is with respect to the ball at impact. In addition, you see putter path, impact spot, and rise & shaft at impact. You even get this information in a printout that also tells you what your clubhead rotation and rate are as well as your timing. Obsessive about your putting? This service is for you.

.jpg)

I was also able to get in some questions about the company and its vision answered from the team:

1. What was the idea behind the design of the Hi-Bore club design?

Nate Radcliffe: After designing the original Launcher 460 and Launcher 460 COMP, we knew that we had maximized the design potential of a large, traditional shape. Despite thin titanium or composite crowns, these larger traditional clubs still had a sweet spot that was positioned above the center of the face. This forced the golfer to hit the ball off of the top of the face to achieve efficient launch conditions. Impacting the ball consistently on the top of the face was not only unrealistic for the average golfer, but proved itself to be an ineffective way to utilize the “trampoline effect” that was centered on the face. We knew that the “traditional” shape was limiting performance and it was time to shift our thinking.

Traditional clubs had several key features that were holding back performance. Remember that the fundamental shape that we were using to design thin, 460cc titanium drivers was derived over 300 years ago for solid, wooden clubs. This is analogous to race car designers being forced to design the race cars of today on a Ford Model T chassis. The basic problems were:

Traditional Design Flaw #1 —- High, bulbous crown (top surface of club head)

-The HiBORE’s inverted crown surface dramatically lowers the weight of the crown section of the clubhead which lowers the overall center of gravity (CG)

Traditional Design Flaw #2 —- Tall skirt (connecting surface between the crown and sole)

-By lowering and/or eliminating the transition line between the crown and the skirt we are able to lower the CG and remove unwanted material and weight that could be placed more effectively in other CG and moment of inertia (MOI) enhancing regions of the clubhead

Traditional Design Flaw #3 —- Toe biased or “pear” shaped profile (top down profile of clubhead is biased toward the toe. Originally this was done to counter-balance the heavy weight of the solid wooden hosel on wooden drivers, but in a hollow design this can lead to a toe-biased CG requiring inefficient heel weighting

-The HiBORE design utilizes a more symmetric chassis from the top down which allows for the deepest and highest MOI weighting without causing the club to become toe weighted or fade-biased.

Traditional Design Flaw #4 —- Shallow sole depth (distance from the face to the deepest point on the sole)

-Traditional drivers extend to their deepest point on the crown and then transition forward to a smaller sole plate. This limits the ability to place weighting in the lowest and deepest possible location within the clubhead. The HiBORE design incorporates an extremely low and deep section within the chassis to allow our engineers to place all discretionary weight in the lowest and deepest possible location. This weighting provides several advantages over a traditional sole design:

* Lower CG (increases launch angle and reduces spin rate

* Deeper CG (increases launch angle and provides stability and ball speed consistency)

* Increased horizontal MOI (improves impact and ball flight consistency from the heel to the toe)

* Increased vertical MOI (improves impact and ball flight consistency up and down the face)

Most simply, the HiBORE is a deep face driver with a low profile chassis that consistently produces more efficient launch conditions than drivers of traditional shape. The HiBORE design is a geometric revision to the driver shape that was a pioneer in the modern era of geometric clubhead design.

2. What type of player is easier to fit, a tour pro or an average golfer?

Nate Radcliffe: Both tour players and high handicappers can present challenges to a fitting process, but both stand to make substantial improvements to their game by utilizing the best technology available to help them select the proper equipment.

Most tour players experiment with their equipment on a weekly basis. They have tried lots of combinations and generally know what they like relative to aesthetics and ball flight. A tour player may have inefficient launch conditions off their driver, but the ball flight is one that they may be accustomed to and trust on the course.

Tour players are very precise and repeatable in their swings and launch conditions, but can require a very specific result in any fitting. The challenge in any tour fitting process is to make improvements within a tight window of acceptable options. At the end of the day, the club must please the player before it pleases the launch monitor.

Higher HDCP, average golfers are obviously much less repeatable in their swing and results (which is why they are not tour players) but in most cases have much more to gain and are open to suggestions. Though it can be a challenge to find enough consistent swings to separate similar shafts and clubs, glaring problems in equipment selection are easy to spot. There are typically big improvements available for average players in any reputable fitting process.

Justin Barnett: They can both be easy as well as be difficult, I would have to say that all in all the tour pro would be an easier fit. They know what specs they play usually and as well know what they want to see in ball flight.

3. What do you hope the fitting center will achieve for the average golfer?

Justin Barnett: The average golfer should achieve a more enjoyable game with his equipment being fit to his specific swing. It makes all the difference in the world

4. Why should an average golfer visit the fitting center?

Justin Barnett: The average golfer should visit the studio before his purchase so that he can get everything fit to his swing. Length, lie angle, shaft and grip size. Most of the time when you line 10 people up you will find that maybe 2 swing the same specs. Another way to look at it would be – if you’re going to buy a nice suit you’re going to want it tailored to fit your body right? So why spend all that money on new clubs and not have them tailored to your swing?

5. What are the technologies in club design that are unique to Cleveland ? To Srixon?

Nate Radcliffe: Cleveland Golf has many patented technologies that we utilize to gain performance advantages in our equipment. We were the first to explore many areas of clubhead design. Here are a few of our many firsts:

* True geometric design in the modern era of drivers (Original HiBORE driver)

* Full transition hybrid iron design (HiBORE Irons)

* Milled grooves in wedges ( Cleveland 900 series)

* Vibration absorption systems in irons (VAS)

* Multiple bounce options in wedges ( Cleveland 900 series)

Our parent company SRI Sports has vast knowledge and expertise in golf club and golf ball design. We have only begun to explore the vast horizons of collaboration between our 2 RND and Intellectual Property teams. We expect exciting innovation to occur through our collaboration with SRI going forward.

6. Will Srixon eventually manufacture clubs for the lefty golfer?

John Rae: Currently, SRI has a very strong presence in the Japanese market with both the Srixon and XXIO brands. SRI is actually the #1 driver manufacturer in Japan. The Japanese market currently does not have a significant demand for lefty clubs so Srixon does not produce any for Japan. The Srixon brand is not as widely known in the US, so the need for lefty clubs in the US is small as well.

Moving forward, Srixon hopes to capitalize on the partnership with Cleveland . With Cleveland ’s extensive market presence in the US and wider distribution network, Srixon hopes to grow in the US market over the next several years. As the brand grows and flourishes, the demand for lefty clubs will clearly increase. At that point, I expect that Srixon will produce clubs for the lefty golfer.

7. What are the types of considerations made when designing new clubs? Does everything start with PGA specs or do ideas come and then conform?

John Rae: When designing a new club, one of the main considerations is the target audience. This audience is the driving factor in where we start the design process. If we are designing a product that is geared exclusively toward the better player and elite golfer, we will start with PGA specs and design around the look and feel requirements that the better player demands. On the other hand, if we are designing an all-ability club or a game improvement club our approach is a little different. In those cases, we will often ignore the USGA rules and traditional aesthetic requirements in the initial phases of conception. By doing this, we can free our minds up to envision the designs that will truly lead to better performance and help the target golfer. Once we have completed our ‘blue sky’ research phase, we will take some of those concepts and pull them back within the USGA rules, and modify the designs to pleasing aesthetics. By taking both approaches, we can provide tour proven products that have the look and feel the better player demands, while still producing some of the most technologically advanced and innovative products in the market.

8. How difficult is it to design a new club for each season? What do you try to accomplish with each new generation?

John Rae: The design process is very difficult. Without the new Computer Aided Design (CAD) and Finite Element Analysis (FEA) software it would be impossible to produce golf clubs as high performance as current clubs. Using this new technology, it is possible to simulate a wide variety of designs and truly optimize the design before making the first prototype parts.

I think we take a rather unique approach to designing golf clubs at Cleveland Golf. We do not create a new product just to have a new product. Every product is created off of the simple question: ‘What is wrong with our current product?’ We get our answer to the question from a variety of sources. We talk to our sales representatives who are in constant communication with shop salesmen and customers. We talk to our customer services representatives who speak to the consumer on a daily basis. We perform extensive player and robotic testing. The Fitting Studio also performs a valuable function as our trained technical staff can work directly with players and determine what works well and why.

Using the knowledge we obtain from all these sources we design the next generation golf club to address these weaknesses of its predecessor without sacrificing the strengths. We do not believe that any product is perfect, so we won’t design a new product without the specific direction of how we want to improve upon the previous product.

9. Do you use the information from tour pros that you collect as well as from the average golfer in the fitting center in your designs?

John Rae: In our designs, we use data from a wide variety of sources. We have several avenues for testing new products before we release them, but after a product is in the market the Fitting Studio is one of our best resources. The Fitting Studio provides us with information on a wide variety of golfers. We can collect data on golfers in every segment of the market. For each of these golfers we then can use their data to understand why certain clubs worked or did not work for them.

This becomes very useful when starting the design of the next product. The information from the Fitting Studio helps us determine: if a shaft is too stiff or too soft for the market, if a head flies too low or too high, if the tour version is too open, or if the draw version is too closed. All of this information is crucial in improving our designs from one generation to the next.

10. What can we expect in the near future from Cleveland/Srixon?

Nate Radcliffe: Come on now . . . we can’t tell you that! What we can say is that we never release a golf club that is not measurably better than its predecessor relative to the targeted design elements. We will continue to push design against the limits set forth within the rules of golf. The future is in clubheads that push the limits without sacrificing on any design variable. There is still a significant amount to be explored within clubhead design and we all feel very lucky to be a part of the exploration.

Check out the Fitting Center for yourself. You can find all of the information on their website.

- LIKE0

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Sam Burns WITB 2024 (April)

- Sam Burns’ what’s in the bag accurate as of the RBC Heritage.

Driver: Callaway Paradym Triple Diamond S (9 degrees @10)

Shaft: Fujikura Ventus Blue 7 TX

3-wood: Callaway Paradym Ai Smoke Triple Diamond T (15 degrees @16)

Shaft: Fujikura Ventus Blue 8 X

Hybrid: Callaway Apex UW (21 degrees)

Shaft: Fujikura Ventus Blue 8 X

Irons: Callaway Apex TCB ’24 (4-AW)

Shafts: Project X 6.5 (4-PW), True Temper Dynamic Gold X100 Tour Issue (AW)

Wedges: Titleist Vokey Design SM10 (56-14F @55), WedgeWorks Proto (60-T)

Shafts: True Temper Dynamic Gold S400 Tour Issue (56, 60)

Putter: Odyssey Ai-One #7S

Grips: Golf Pride Tour Velvet Align

Ball: Callaway Chrome Tour X

Check out more in-hand photos of Sam Burns’ WITB in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Whats in the Bag

Will Zalatoris WITB 2024 (April)

- Will Zalatoris’ what’s in the bag accurate as of the RBC Heritage.

Driver: Titleist TSR2 (9 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Black 7 X (44.5 inches)

3-wood: Titleist TSi2 (15 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 8 X

Irons: Titleist T350 (3), Titleist T150 (4-PW)

Shafts: Nippon N.S. Pro Prototype G.O.S.T. 10 ST X (3), True Temper Dynamic Gold Tour Issue X100 (4-PW)

Wedges: Titleist Vokey Design SM10 (50-08F, 54-10S @55, 60-04T)

Shafts: True Temper Dynamic Gold Tour Issue X100

Putter: L.A.B. Golf Mezz.1 Max

Grips: Golf Pride Z-Grip Cord

See more photos of Will Zalatoris’ WITB in the forums.

- LIKE1

- LEGIT0

- WOW0

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

Equipment

New Level launches new 480-DB irons, blending performance and forgiveness

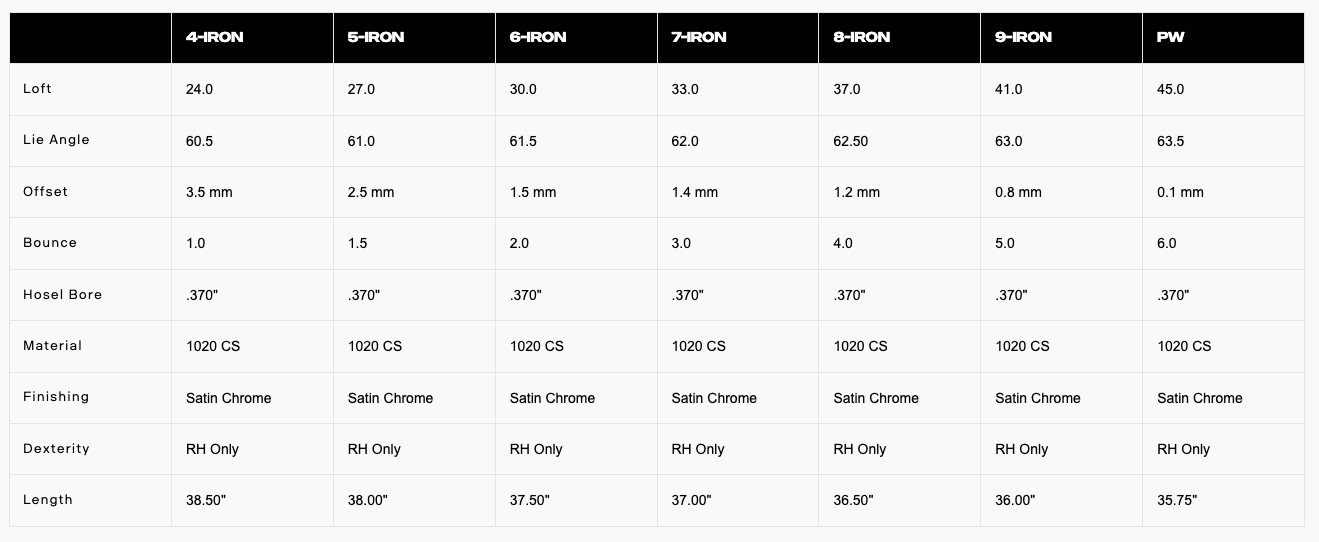

New Level has been making some really good golf equipment since the company started up in 2018. Offering irons that are more geared towards the better player, precision has been a fundamental philosophy for New Level in creating irons and wedges.

The 480 line of irons has been the flagship of the brand, and the newest member of that team is the 480-DB iron that is now open to pre-orders. A new cavity design is what the whole 480 line is about, and the 480-DB takes advantage of that with added ball speed and a larger sweet spot.

For players who require their irons to offer the best feel, rest assured the DB is a fully forged (from 1020 carbon steel) one-piece golf club. No multi-piece, hollow design with this iron.

While the 480-DB is the next generation of the popular 902-OS, New Level didn’t follow the current trend in golf by chasing distance with the new iron. They actually weakened the lofts on the 480-DB with the spec sheet showing a 33-degree 7-iron and 45-degree pitching wedge. These lofts allow the DB to have less offset while still offering consistent distance off the face.

A traditional design was also at the forefront of the new irons to make sure that golfers with an eye for detail can look down at them with confidence that they will perform under any condition.

A weight low in the back cavity will allow their master club builders to dial in the perfect weight for the golfer, no matter the length or shaft being used. New Level believes that the new 480-DB is one of the most forgiving one-piece forged irons on the market today. A pre-worn leading edge on the sole should get through the turf quickly and with reduced digging for better turf interaction.

You can pre-order the New Level 480-DB right now on the New Level website.

Pricing specs availability

- Irons: 4-PW

- Price: $149/oron

- Availability: Pre-order

- LIKE12

- LEGIT3

- WOW1

- LOL0

- IDHT0

- FLOP0

- OB0

- SHANK0

-

19th Hole2 weeks ago

19th Hole2 weeks agoDave Portnoy places monstrous outright bet for the 2024 Masters

-

19th Hole2 weeks ago

19th Hole2 weeks agoTiger Woods arrives at 2024 Masters equipped with a putter that may surprise you

-

19th Hole3 weeks ago

19th Hole3 weeks agoReport: Tiger Woods has ‘eliminated sex’ in preparation for the 2024 Masters

-

19th Hole7 hours ago

19th Hole7 hours ago‘Absolutely crazy’ – Major champ lays into Patrick Cantlay over his decision on final hole of RBC Heritage

-

19th Hole1 week ago

19th Hole1 week agoTwo star names reportedly blanked Jon Rahm all week at the Masters

-

19th Hole6 days ago

19th Hole6 days agoReport: LIV Golf identifies latest star name they hope to sign to breakaway tour

-

19th Hole1 week ago

19th Hole1 week agoNeal Shipley presser ends in awkward fashion after reporter claims Tiger handed him note on 8th fairway

-

19th Hole5 days ago

19th Hole5 days agoBrandel Chamblee has ‘no doubt’ who started the McIlroy/LIV rumor and why